[Constantina Tzia, George Liadakis] Extraction Opt(Bookos.org) 2

-

Upload

alidaqestani -

Category

Documents

-

view

149 -

download

17

Transcript of [Constantina Tzia, George Liadakis] Extraction Opt(Bookos.org) 2

-

Extraction Optimization in Food Engineering

edited by

Coustantina Tzia National Technical Universig of Athens

Athens, Greece

George Liadakis 700SE

Pireas, Greece

M A R C E L

MARCEL DEKKER, INC.

D E K K E R

NEW YORK - E ~ A S E L

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Although great care has been taken to provide accurate and current information, neitherthe author(s) nor the publisher, nor anyone else associated with this publication, shall beliable for any loss, damage, or liability directly or indirectly caused or alledged to becaused by this book. The material contained herein is not intended to provide specificadvice or recommendations for any specific situation.

Trademark notice: Product or corporate names may be trademarks or registered trade-marks and are used only for identification and explanation without intent to infringe.

Library of Congress Cataloging-in-Publication DataA catalog record for this book is available from the Library of Congress.

ISBN: 0-8247-4108-0

This book is printed on acid-free paper.

HeadquartersMarcel Dekker, Inc., 270 Madison Avenue, New York, NY 10016, U.S.A.tel: 212-696-9000; fax: 212-685-4540

Distribution and Customer ServiceMarcel Dekker, Inc., Cimarron Road, Monticello, New York 12701, U.S.A.tel: 800-228-1160; fax: 845-796-1772

Eastern Hemisphere DistributionMarcel Dekker AG, Hutgasse 4, Postfach 812, CH-4001 Basel, Switzerlandtel: 41-61-260-6300; fax: 41-61-260-6333

World Wide Webhttp://www.dekker.com

The publisher offers discounts on this book when ordered in bulk quantities. For moreinformation, write to Special Sales/Professional Marketing at the headquarters addressabove.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

Neither this book nor any part may be reproduced or transmitted in any form or by anymeans, electronic or mechanical, including photocopying, microfilming, and recording,or by any information storage and retrieval system, without permission in writing fromthe publisher.

Current printing (last digit):

10 9 8 7 6 5 4 3 2 1

PRINTED IN THE UNITED STATES OF AMERICA

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

FOOD SCIENCE AND TECHNOLOGY

A Series of Monographs, Textbooks, and Reference Books

EDITORIAL BOARD

Senior Editors Owen R. Fennema University of Wisconsin-Madison Y. H. Hui Science Technology System Marcus Karel Rutgers University (emeritus) Pieter Walstra Wageningen University John R. Whitaker University of California-Davis

Additives P. Michael Davidson University of Tennessee-Knoxville Dairy science James L. Steele University of Wisconsin-Madison Flavor chemistry and sensory analysis John H. Thorngate 111 University

Food engineering Daryl B. Lund University of Wisconsin-Madison Food lipids and flavors David B. Min Ohio State University Food proteindfood chemistry Rickey Y. Yada University of Guelph Health and disease Seppo Salminen University of Turku, Finland Nutrition and nutraceuticals Mark Dreher Mead Johnson Nutritionals Phase transifion/food microstructure Richard W. Hartel University of

Processing and preservation Gustavo V. Barbosa-Canovas Washington

Safety and toxicology Sanford Miller University of Texas-Austin

of California-Davis

Wisconsin-Madison

State University-Pullman

1. Flavor Research: Principles and Techniques, R. Teranishi, 1. Horn- stein, P. Issenberg, and . L. Wick

2. Principles of Enzymology for the Food Sciences, John R. Whitaker 3. Low-Temperature Preservation of Foods and Living Matter, Owen R.

Fennema, William D. Powrie, and Elmer H. Marth 4. Principles of Food Science

Part I: Food Chemistry, edited by Owen R. Fennema Part II: Physical Principles of Food Preservation, Marcus Karel, Owen R. Fennema, and Daryl 5. Lund

5. Food Emulsions, edited by Stig E. Friberg 6. Nutritional and Safety Aspects of Food Processing, edited by Steven

R. Tannenbaum 7. Flavor Research: Recent Advances, edited by R. Teranishi, Robert A.

Flath, and Hiroshi Sugisa wa 8. Computer-Aided Techniques in Food Technology, edited by Israel

SWUY

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

9. Handbook of Tropical Foods, edited by Harvey T. Chan 10. Antimicrobials in Foods, edited by Alfred Larry Branen and P. Michael

Davidson 11. Food Constituents and Food Residues: Their Chromatographic

Determination, edited by James F. Lawrence 12. Aspartame: Physiology and Biochemistry, edited by Lewis D. Stegink

and L. J. Filer, Jr. 13. Handbook of Vitamins: Nutritional, Biochemical, and Clinical Aspects,

edited by Lawrence J. Machlin 14. Starch Conversion Technology, edited by G. M. A. van Beynum and J.

A. Roels 15. Food Chemistry: Second Edition, Revised and Expanded, edited by

Owen R. Fennema 16. Sensory Evaluation of Food: Statistical Methods and Procedures, Mi-

chael O'Mahony 17. Alternative Sweeteners, edited by Lyn O'Brien Nabors and Robert C.

Gelardi 18. Citrus Fruits and Their Products: Analysis and Technology, S. V. Ting

and Russell L. Rouseff 19. Engineering Properties of Foods, edited by M. A. Rao and S. S. H.

RiZVi 20. Umami: A Basic Taste, edited by Yojiro Kawamura and Morley R.

Kare 21. Food Biotechnology, edited by Dietrich Knon 22. Food Texture: Instrumental and Sensory Measurement, edited by

Howard R. Moskowitz 23. Seafoods and Fish Oils in Human Health and Disease, John E.

Kinsella 24. Postharvest Physiology of Vegetables, edited by J. Weichmann 25. Handbook of Dietary Fiber: An Applied Approach, Mark L. Dreher 26. Food Toxicology, Parts A and B, Jose M. Concon 27. Modern Carbohydrate Chemistry, Roger W. Sinkley 28. Trace Minerals in Foods, edited by Kenneth T, Smith 29. Protein Quality and the Effects of Processing, edited by R. Dixon

Phillips and John W. Finley 30. Adulteration of Fruit Juice Beverages, edited by Steven Nagy, John A.

Attaway, and Martha E. Rhodes 31. Foodborne Bacterial Pathogens, edited by Michael P. Doyle 32. Legumes: Chemistry, Technology, and Human Nutrition, edited by

Ruth H. Matthews 33. Industrialization of Indigenous Fermented Foods, edited by Keith H.

Steinkra us 34. International Food Regulation Handbook: Policy 0 Science 0 Law,

edited by Roger D. Middlekauff and Philippe Shubik 35. Food Additives, edited by A. Larry Branen, P. Michael Davidson, and

Seppo Salminen 36. Safety of Irradiated Foods, J. F. Diehl

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

37. Omega3 Fatty Acids in Health and Disease, edited by Robert S. Lees and Marcus Karel

38. Food Emulsions: Second Edition, Revised and Expanded, edited by KAre Larsson and Stig E. Friberg

39. Seafood: Effects of Technology on Nutrition, George M. figott and Barbee W. Tucker

40. Handbook of Vitamins: Second Edition, Revised and Expanded, edited by Lawrence J. Machlin

41. Handbook of Cereal Science and Technology, Klaus J. Lorenz and Karel Kulp

42. Food Processing Operations and Scale-Up, Kenneth J. Valentas, Leon Levine, and J. Peter Clark

43. Fish Quality Control by Computer Vision, edited by L. F. Pau and R. Olafsson

44. Volatile Compounds in Foods and Beverages, edited by Henk Maarse 45. Instrumental Methods for Quality Assurance in Foods, edited by

Daniel Y. C. Fung and Richard F. Matthews 46. Listeria, Listeriosis, and Food Safety, Elliot T. Ryser and Elmer H.

Marth 47. Acesulfame-K, edited by D. G. Mayer and F. H. Kernper 48. Alternative Sweeteners: Second Edition, Revised and Expanded, ed-

ited by Lyn O'Brien Nabors and Robert C. Gelardi 49. Food Extrusion Science and Technology, edited by Jozef L. Kokini,

Chi-Tang Ho, and Mukund V. Karwe 50. Surimi Technology, edited by Tyre C. Lanier and Chong M. Lee 51. Handbook of Food Engineering, edited by Dennis R. Heldman and

DarylB. Lund 52. Food Analysis by HPLC, edited by Leo M. L. Nollet 53. Fatty Acids in Foods and Their Health Implications, edited by Ching

Kuang Chow 54. Clostridium botulinum: Ecology and Control in Foods, edited by

Andreas H. W. Hauschild and Karen L. Dodds 55. Cereals in Breadmaking: A Molecular Colloidal Approach,

Ann-Charlotte Eliasson and KAre Larsson 56. Low-Calorie Foods Handbook, edited by Aaron M. Altschul 57. Antimicrobials in Foods: Second Edition, Revised and Expanded,

edited by P. Michael Davidson and Alfred Larry Branen 58. Lactic Acid Bacteria, edited by Seppo Salminen and Atte von Wright 59. Rice Science and Technology, edited by Wayne E. Marshall and

James 1. Wadsworth 60. Food Biosensor Analysis, edited by Gabriele Wagner and George G.

Guilba ult 61. Principles of Enzymology for the Food Sciences: Second Edition, John

R. Whitaker 62. Carbohydrate Polyesters as Fat Substitutes, edited by Casimir C.

Akoh and Barry G. Swanson 63. Engineering Properties of Foods: Second Edition, Revised and

Expanded, edited by M. A. Rao and S. S. H. Rizvi

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

64. Handbook of Brewing, edited by William A. Hardwick 65. Analyzing Food for Nutrition Labeling and Hazardous Contaminants,

edited by Ike J. Jeon and William G. lkins 66. Ingredient Interactions: Effects on Food Quality, edited by Anilkurnar

G. Gaonkar 67. Food Polysaccharides and Their Applications, edited by Alistair M.

Stephen 68. Safety of Irradiated Foods: Second Edition, Revised and Expanded, J.

F. Diehl 69. Nutrition Labeling Handbook, edited by Ralph Shapiro 70. Handbook of Fruit Science and Technology: Production, Composition,

Storage, and Processing, edited by D. K. Salunkhe and S. S. Kadarn 71. Food Antioxidants: Technological, Toxicological, and Health Perspec-

tives, edited by D. L. Madhavi, S. S. Deshpande, and D. K. Salunkhe 72. Freezing Effects on Food Quality, edited by Lester E. Jeremiah 73. Handbook of Indigenous Fermented Foods: Second Edition, Revised

and Expanded, edited by Keith H. Steinkraus 74. Carbohydrates in Food, edited by Ann-Charlotte Eliasson 75. Baked Goods Freshness: Technology, Evaluation, and Inhibition of

Staling, edited by Ronald E. Hebeda and Henry F. Zobel 76. Food Chemistry: Third Edition, edited by Owen R. Fennema 77. Handbook of Food Analysis: Volumes 1 and 2, edited by Leo M. L.

Nollet 78. Computerized Control Systems in the Food Industry, edited by Gauri

S. Miffal 79. Techniques for Analyzing Food Aroma, edited by Ray Marsili 80. Food Proteins and Their Applications, edited by Srinivasan Damo-

daran and Alain Paraf 81. Food Emulsions: Third Edition, Revised and Expanded, edited by Stig

E. Friberg and K5re Larsson 82. Nonthermal Preservation of Foods, Gustavo V. Barbosa-Canovas,

Usha R. Pofhakamury, Enrique Palou, and Bany G. Swanson 83. Milk and Dairy Product Technology, Edgar Spreer 84. Applied Dairy Microbiology, edited by Elmer H. Marth and James L.

Sfeele 85. Lactic Acid Bacteria: Microbiology and Functional Aspects: Second

Edition, Revised and Expanded, edited by Seppo Salrninen and Affe von Wright

86. Handbook of Vegetable Science and Technology: Production, Composition, Storage, and Processing, edited by D. K. Salunkhe and S. S. Kadam

87. Polysaccharide Association Structures in Food, edited by Reginald H. Walter

88. Food Lipids: Chemistry, Nutrition, and Biotechnology, edited by Casimir C. Akoh and David 6. Min

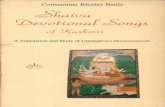

89. Spice Science and Technology, Kenji Hirasa and Mitsuo Takemasa

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

90. Dairy Technology: Principles of Milk Properties and Processes, P. Walstra, T, J. Geurts, A. Noomen, A. Jellema, and M. A. J. S. van Boekel

91. Coloring of Food, Drugs, and Cosmetics, Gisbert Offerstijffer 92. Listeria, Listeriosis, and Food Safety: Second Edition, Revised and

Expanded, edited by Elliot T. Ryser and Elmer H. Marth 93. Complex Carbohydrates in Foods, edited by Susan Sungsoo Cho,

Leon Prosky, and Mark Dreher 94. Handbook of Food Preservation, edited by M. S h a h Rahman 95. International Food Safety Handbook: Science, International Regula-

tion, and Control, edited by Kees van der Heijden, Maged Younes, Lawrence Fishbein, and Sanford Miller

96. Fatty Acids in Foods and Their Health Implications: Second Edition, Revised and Expanded, edited by Ching Kuang Chow

97. Seafood Enzymes: Utilization and Influence on Postharvest Seafood Quality, edited by Norman F. Haard and Benjamin K. Simpson

98. Safe Handling of Foods, edited by Jeffrey M. Farber and Ewen C. D. Todd

99. Handbook of Cereal Science and Technology: Second Edition, Re- vised and Expanded, edited by Karel Kulp and Joseph G. Ponte, Jr.

100. Food Analysis by HPLC: Second Edition, Revised and Expanded, edifed by Leo M. L. Nollet

101. Surimi and Surimi Seafood, edited by Jae W. Park 102. Drug Residues in Foods: Pharmacology, Food Safety, and Analysis,

Nickos A. Botsoglou and Dimitrios J. Fletouris 103. Seafood and Freshwater Toxins: Pharmacology, Physiology, and

Detection, edited by Luis M. Botana 104. Handbook of Nutrition and Diet, Babasaheb 6. Desai 105. Nondestructive Food Evaluation: Techniques to Analyze Properties

and Quality, edited by Sundaram Gunasekaran 106. Green Tea: Health Benefits and Applications, Yukihiko Hara 107. Food Processing Operations Modeling: Design and Analysis, edited

by Joseph lrudayaraj 108. Wine Microbiology: Science and Technology, Claudio Delfini and

Joseph V. Formica 109. Handbook of Microwave Technology for Food Applications, edited by

Ashim K. Daffa and Ramaswamy C. Anantheswaran 110. Applied Dairy Microbiology: Second Edition, Revised and Expanded,

edited by Elmer ti. Marth and James L. Steele 11 1. Transport Properties of Foods, George D. Saravacos and Zacharias

B. Maroulis 1 12. Alternative Sweeteners: Third Edition, Revised and Expanded, edited

by Lyn OBrien Nabors 113. Handbook of Dietary Fiber, edited by Susan Sungsoo Cho and Mark

L. Dreher 114. Control of Foodborne Microorganisms, edited by Voay K. Juneja and

John N. Sofos 11 5. Flavor, Fragrance, and Odor Analysis, edited by Ray Marsili

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

11 6. Food Additives: Second Edition, Revised and Expanded, edited by A. Larry Branen, P. Michael Davidson, Seppo Salminen, and John H. Thorngate, 111

117. Food Lipids: Chemistry, Nutrition, and Biotechnology: Second Edition, Revised and Expanded, edited by Casimir C. Akoh and David B. Min

118. Food Protein Analysis: Quantitative Effects on Processing, R. K. Owusu-Apenten

119. Handbook of Food Toxicology, S. S. Deshpande 120. Food Plant Sanitation, edited by Y. H. Hui, Bernard L. Bruinsma, J.

Richard Gorham, Wai-Kit Nip, Phillip S. Tong, and Phil Ventresca 121. Physical Chemistry of Foods, Pieter Walstra 122. Handbook of Food Enzymology, edited by John R. Whitaker, Alphons

G. J. Voragen, and Dominic W. S. Wong 123. Postharvest Physiology and Pathology of Vegetables: Second Edition,

Revised and Expanded, edited by Jerry A. Bartz and Jeffrey K. Brecht 124. Characterization of Cereals and Flours: Properties, Analysis, and Ap-

plications, edited by Goniil Kalefung and Kenneth J. Breslauer 125. International Handbook of Foodborne Pathogens, edited by Marianne

D. Miliotis and Jeffrey W. Bier 126. Food Process Design, Zacharias B. Maroulis and George D. Sara-

vacos 127. Handbook of Dough Fermentations, edited by Karel Kulp and Klaus

Lorenz 128. Extraction Optimization in Food Engineering, edited by Constantina

Tzia and George Liadakis 129. Physical Principles of Food Preservation: Second Edition, Revised

and Expanded, Marcus Karel and Daryl B. Lund

Additional Volumes in Preparation

Handbook of Vegetable Preservation and Processing, edited by Y. H. Hui, Sue Ghazala, Dee M. Graham, K. D. Murrell, and Wai-Kit Nip

Food Emulsions: Fourth Edition, Revised and Expanded, edited by Stig E. Friberg, Kire Larsson, and Johan Sjoblom

Handbook of Frozen Foods, edited by Y. H. Hui, Paul Cornillon, Isabel Guerrero Legarreta, Miang Lim, K. D. Murrell, and Wai-Kit Nip

Handbook of Food and Beverage Fermentation Technology, edited by Y. H. Hui, Lisbeth M. Goddik, Aase Solvejg Hansen, Jytte Josephsen, Wai-Kit Nip, Peggy S. Stanfield, and Fidel Toldra

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Industrialization of Indigenous Fermented Foods: Second Edition, Revised and Expanded, edited by Keith H. Sfeinkraus

Genetic Variation in Taste Sensitivity, edited by John Prescott and Beverly J. Tepper

Handbook of Food Analysis: Second Edition, Revised and Expanded: Volumes 1, 2, and 3, edited by Leo M. L. Nollet

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Preface

Extraction is an important separation process that is extensively used in variousapplications in food engineering. Extraction is used either to recover importantfood components, being a main processing stage for the production of certainfood products (sugar, oils, proteins), or to isolate desired components (antioxi-dants, flavors). It also removes contaminants and other undesirable components(alkaloids, cholesterol) from food sources.

Extraction, as a major operation of the manufacturing process in manyfood industries, requires a food engineer to have knowledge of the thermody-namics, theory, methods, and systems of extraction, while the feasible designand efficient operation of an extraction process requires knowledge of the tech-nological parameters of the process and of optimization methods respectively.

Solvent or water extraction, liquidliquid extraction, and leaching havealready been incorporated in basic food processing, while supercritical fluidextraction (SFE) is a promising alternative method for new or improved applica-tions in food engineering; SFE is recommended for the production of high-valuefood components as natural food products.

Despite the great variety of extraction applications already in use, it isdifficult to interpret and transfer theory to application at the industrial scale.Even in recent applications of extraction, optimal extraction or separation condi-tions are obtained empirically. One primary goal of food process engineering isfinding out how an extraction process works bestachieving the optimum inrespect of yield, quality, or costand consequently finding the adjustable pro-cessing factor values that produce the optimum.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

iv Preface

Optimization of extraction processes is needed either for extraction pro-cesses that are already in use or for future process designs for certain applica-tions in food engineering. Consequently, it is important for the food industryto optimize food extraction processes; that is, to attain the optimum operatingconditions (yield, quality, operation time, and cost) using appropriate methodsand techniques.

In this book, we review the extraction methods used in food processingfrom fundamental theory to optimum practical application using the relevantequipment and the appropriate methods of optimization. All of the contributorsare experts in the field of extraction, in research as well as in applications inindustrial food processes. This book will be useful for food process engineerswho employ extraction processes.

In order to introduce and apply an extraction process in the food industry,the knowledge of thermodynamic principles and the existing extractive systemsis necessary. Irrespective of the extraction method used, the feasibility of theprocess or the system is affected by the operation parameters of the process orsystem. Consequently, the best result in respect of yield or quality characteristicsof the final product should be achieved. That is the objective of the optimizationof a process or a system.

An elementary review of thermodynamics is presented in Chapter 1, con-taining the basic laws, glossary, concepts, and relations of thermodynamics,particularly of chemical thermodynamics covering mixtures, solutions, phaseequalibria, chemical reactions, etc. Chapter 1 presents fundamental knowledgeuseful for the understanding of extraction theory, operation, and applications infood processing.

Solidliquid extraction or the leaching proces is described in Chapter 2.The characteristics and steps, as well as the basic variables affecting the extrac-tion operation in relation to the solvent and the microstructure of the solid beingextracted, are described. The relationship between the solid microstructure andthe extraction rate based on the mass transfer mechanism due to liquid diffusioninside the solid is also explained.

Supercritical fluid extraction (SFE) using supercritical fluids (SCFs), anovel method providing the possibility for green processing of foods, is re-viewed in Chapter 3. The basic (physical and chemical) properties of SCFs,particularly of the commonly used SC-CO2, and the key factors that play signifi-cant roles in the success of the SFE operation (as solubility of solutes in SCFs,phase equilibria, mass transfer) are discussed; the effective use of SCFs in ex-traction and fractionation of food-related materials is also discussed.

The methods and equipment used in conventional solvent extraction andthe relative extraction systems that have been applied in food industrial pro-cesses are presented in Chapter 4 with the equipment required for solid pretreat-

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Preface v

ment and solvent recovery. Similarly, for the alternative SFE method the selec-tion and design of the required equipment are discussed.

Optimization theory and appropriate methods involved in design and pro-cess operation having economical and technological interest for food engineersare discussed in Chapter 5. An extraction process should operate efficiently bydetermining the operation time in order to achieve the best yield. The applica-tions of optimization in food engineering and especially in food extraction (con-ventional or SFE) processing are reviewed.

In the following chapters, the most important applications of extractionprocesses in food production industry are presented under the aspect of optimi-zation of the already operating extraction systems; novel and alternative opera-tions and case studies are also presented.

Vegetable oil extraction of oil-bearing materials is covered in Chapter 6.The most efficient method of solvent extraction and the factors affecting theoperation such as the solvent characteristics, extraction temperature, solid pre-treatment, modes of operation, and equipment are discussed. Commercial unitsused for oil extraction and extraction technology for oilseeds with the pre- andpost-treatment are presented; extraction of essential oils is also discussed.

Extraction processes for protein isolation from various edible proteinsources (oilseeds, cereals, etc.) and production of protein products with manyapplications in food systems are covered in Chapter 7. Commercial processingand advanced methods of vegetable protein isolates are discussed from the view-point of yield and quality (nutritional, organoleptic, functional properties) ofprotein products.

Sugar extraction from sugar beet and sugar cane is presented in Chapter8, as extraction is one of the major stages in the sugar manufacturing industry.Characteristics of sugar beet and cane, parameters affecting the extraction pro-cesses, and the optimization of the industrial process of beet sugar are discussed.Techniques of extraction, extractors, and other equipment required for industrialsugar production are presented. Extraction of starch and carbohydrates fromcorn is also discussed.

The extraction processes for isolation of desired components such as fla-vor and aroma substances or compounds with antioxidant activity (natural anti-oxidants) from plant sources are reported in Chapters 9 and 10, respectively.The main sources of natural antioxidants and synergists, the relative extractionprocesses, and the effect of processing parameters, as well as the conventionalor SFE extraction procedures and purification of extracts, are discussed. Solventextraction is one of the most important methods for producing natural extractsof aroma and flavor compounds; extraction solvents used, SFE processes, andapplications of solvent extraction of flavor and aroma compounds are discussed.

The extraction processes for removal of undesirable or toxic constituents,

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

vi Preface

such as alkaloids from natural products, or compounds with adverse effect onhuman health (e.g., cholesterol) from various food products with emphasis onSFE processes are covered in Chapters 11 and 12, respectively. The physiologi-cal effects and applications of alkaloids, the commercial-scale operations forextraction and isolation of the most valuable alkaloids, especially the decaffeina-tion of coffee and black tea using conventional extraction or SFE, are described.Similarly, the physiological effects of cholesterol on health and the extractionand fractionation processes of cholesterol from milk, fat, eggs, and meats aredescribed. Both for alkaloids and cholesterol removal, future prospects usingSFE are offered.

The safety, health, and environmental issues of solvent extraction, con-cerning mainly the edible oil and fat extraction industry, are described in Chap-ter 13, along with regulatory concerns and toxicity of solvents (hexane or alter-native solvents) in commercial processes.

Constantina TziaGeorge Liadakis

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Contents

PrefaceContributors

1. Introduction: Fundamental Notes on Chemical ThermodynamicsPetros Tzias

2. SolidLiquid ExtractionJose Miguel Aguilera

3. Supercritical Fluid Extraction in Food EngineeringNurhan Turgut Dunford, Jerry W. King, and Gary R. List

4. Extraction SystemsRudolf Eggers and Philip T. Jaeger

5. OptimizationConstantina Tzia

6. Fats and Oils from Plant MaterialsLei Xu and Levente L. Diosady

7. Proteins from Plant MaterialsLei Xu and Levente L. Diosady

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

viii Contents

8. Sugars and CarbohydratesPascal Christodoulou

9. Flavor and Aroma SubstancesYoun-Woo Lee and Youn Yong Lee

10. Extraction of Natural AntioxidantsVassiliki Oreopoulou

11. Extraction of Alkaloids from Natural Plants UsingSupercritical FluidsMarleny D. A. Saldana and Rahoma S. Mohamed

12. Removal of Cholesterol from Food Products UsingSupercritical FluidsRahoma S. Mohamed, Marleny D. A. Saldana,Alvaro B. A. de Azevedo, and Uiram Kopcak

13. Solvent Extraction: Safety, Health, and Environmental IssuesPhillip J. Wakelyn and Peter J. Wan

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Contributors

Jose Miguel Aguilera Universidad Catolica de Chile, Santiago, Chile

Pascal Christodoulou Hellenic Sugar Industry S.A., Thessaloniki, Greece

Alvaro B. A. de Azevedo The State University of CampinasUnicamp, Cam-pinas, Sao Paulo, Brazil

Levente L. Diosady Department of Chemical Engineering and AppliedChemistry, University of Toronto, Toronto, Ontario, Canada

Nurhan Turgut Dunford Food and Agriculture Products Research and Tech-nology Center, and Department of Plant and Soil Sciences, Oklahoma StateUniversity, Stillwater, Oklahoma, U.S.A.

Rudolf Eggers Technische Universitat Hamburg-Harburg, Hamburg,Germany

Philip T. Jaeger Technische Universitat Hamburg-Harburg, Hamburg, Ger-many

Jerry W. King National Center for Agricultural Utilization Research, Ag-ricultural Research Service, U.S. Department of Agriculture, Peoria, Illinois,U.S.A.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

x Contributors

Uiram Kopcak The State University of CampinasUnicamp, Campinas, SaoPaulo, Brazil

Youn-Woo Lee Supercritical Fluid Research Lab, Korea Institute of Scienceand Technology, Seoul, Korea

Youn Yong Lee Korea Institute of Science and Technology, Seoul, Korea

Gary R. List U.S. Department of Agriculture, Peoria, Illinois, U.S.A.

Rahoma S. Mohamed School of Chemical Engineering, The State Universityof CampinasUnicamp, Campinas, Sao Paulo, Brazil

Vassiliki Oreopoulou National Technical University of Athens, Athens,Greece

Marleny D. A. Saldana The State University of CampinasUnicamp, Cam-pinas, Sao Paulo, Brazil

Constantina Tzia National Technical University of Athens, Athens, Greece

Petros Tzias Athena S.A., Athens, Greece

Phillip J. Wakelyn National Cotton Council, Washington, D.C., U.S.A.

Peter J. Wan U.S. Department of Agriculture, New Orleans, Louisiana,U.S.A.

Lei Xu University of Toronto, Toronto, Ontario, Canada

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

1IntroductionFundamental Notes onChemical Thermodynamics

Petros TziasAthena S.A.Athens, Greece

I. INTRODUCTION

Thermodynamics is a very useful tool for many scientists and engineers, includ-ing geologists, geophysicists, and mechanical engineers, and is considered the sci-entific cornerstone for chemical engineers.

When we study a handbook containing papers from a certain field ofchemical engineering, it is very useful to have some notes on thermodynamicson hand to help us understand what were reading. This is the purpose of thischapter; to give a brief, elementary review of thermodynamics, reminding to thereader the basic laws, glossary, concepts, and relations of this important branch ofscience so as to make the study of the present volume much easier and pleasant.

This chapter is intended for chemical engineers and chemists, and for thisreason we devote most of this chapter to dealing with chemical thermodynamics,covering mixtures, solutions, phase equilibria, chemical reactions, etc.

We are going to cite simple definitions of the different thermodynamicfunctions and quantities, and we will not enter to any analytical description orphilosophical discussion about them; similarly we will not prove the mentionedthermodynamic relations, as these are beyond the scope of this chapter.

We will deal mainly with reversible processes, so far as an interest is inchemical thermodynamics, and we will not refer to statistical or nuclear andrelativistic phenomena.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

2 Tzias

II. SCOPE

Thermodynamics is a branch of physical sciences concerned with the study ofthe transformation of heat, work, and other kinds of energy (electrical, lightenergy, etc.) from one form to another, in the different physicochemical phe-nomena and determines the laws and relations governing and describing theseenergy transformations.

Historically (1), many scientists studied the interconversion of heat andwork, from N.L.S. Carnot with his famous ideal gas cycle, to Clausius, wholaid the foundations of the classical thermodynamics with the expression of thefirst and second laws of thermodynamics.

Later, J. Willard Gibbs extended the application of the thermodynamicpostulates and relations to chemical reaction and phase equilibria putting thefoundations for the development of the field, which we call today chemicalthermodynamics.

Thermodynamics consists of a collection of equalities and inequalitieswhich interrelate physical and chemical properties of substances as well as somephysical or chemical phenomena. These relations are deduced in a mathematicalway from some laws, the thermodynamic laws, which are derived directly fromexperience. The physical quantities used are taken either from physics, or theyare introduced in thermodynamics. Using these relations, we can predict thepossible direction of chemical reactions or the final result of a physical process,as well as the quantities of the different kinds of energy involved in these trans-formations.

Thermodynamics is an experimental science (2). All the physical or chem-ical quantities used in its relations are independently measurable, but some ofthem are easier to be measured than others. Another feature of thermodynamicsthat makes it very important and useful is the capability of calculation, throughits relations, quantities measured with difficulty or low accuracy by others mea-sured easier and more accurately.

Another advantage is that very often from existed data of some physicalquantities we can calculate through thermodynamic relations the values of thephysical quantities we are interested in, in this way avoiding long and difficultexperiments and also saving time and money.

Therefore, it becomes obvious that thermodynamics can be a very usefultool to a chemist or a chemical engineer.

III. GLOSSARY OF BASIC THERMODYNAMIC TERMS (26)

There are a variety of thermodynamic terms, the most common of which aredefined below, together with their SI units (3).

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 3

The amount of substance (2) nb of an entity b is a physical quantity propor-tional to the number nb of entities b in the system. The SI unit of the amount ofsubstance is the mol.

A. Pressure, Volume, TemperaturePressure and volume are concepts taken from physics.

Pressure is defined as the ratio of a perpendicular force to a surface bythe area of this surface. The SI unit of pressure is the Pa.

Volume (m3) is the three-dimensional space occupied by a substance. Spe-cific volume (m3/kg) is the volume per unit mass. Molar volume is the volumedivided by the amount of substance. Density is the reciprocal of the specificvolume.

Temperature is a fundamental concept used in thermodynamics, and itsdefinition is a very difficult matter. However we could simply describe it as thedegree of hotness of a substance or as the property of matter which has equalmagnitude in systems, connected by diathermic walls and where thermal flowdoes not exist (3).

B. Temperature Scales (4)The Celcius scale (C) is established by assigning the value 0.01C to the triplepoint of water and the value 100C to the boiling point of water at an atmo-spheric pressure of 1 standard atm (760 torr).

The absolute temperature scale (T) is a scale which is related to the Cel-cius scale by the relation:

T = t (C) + 273.15T is given in degrees Kelvin. In this scale it is enough to define just one pointand this is the triple of water equal to 273.16 K. The freezing point of water at1 atm is 273.15 K.

The ideal gas temperature scale defined as:

T = 273.16K limP273.160

PTP273.16where PT and P273,16 are the pressures of a gas trapped in a gas thermometer atthe temperatures T and 273.16 K. The ideal gas temperature scale is the samewith the absolute scale. Constant volume gas thermometers are used to deter-mine the thermodynamic absolute temperatures.

The International Practical Temperature Scale (IPTS-68). This scale givesthe temperatures at some reproducible fixed points together with some interpo-

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

4 Tzias

lating instruments and functions, by which we find the temperatures betweenthese points. The fixed points as well as the functions have been determined byconstant volume gas thermometers. The IPTS-68 gives the possibility by theabove mentioned instruments and functions to measure in an easy and accurateway the absolute temperature. In the literature (4), we can find temperatures atdifferent fixed points as well as the instruments used to measure the absolutetemperature between these points. In the SI system for the absolute temperaturewe use the degree K.

C. SystemIn thermodynamics, we call any part of the real world we are choosing to studya system. All the rest of the parts of the world are the surroundings of thesystem. Practically by surroundings we consider the part of the world aroundthe system which can interact with it.

A system is closed if no matter enters or leaves it during any process westudy. Otherwise it is open. A system is called isolated if neither matter norenergy enters or leaves it.

The state of a system is defined by the values of its properties. Propertiesare physical quantities like temperature, volume, pressure, etc., which are relatedwith a system and they have fixed values at any given state of the system. Inorder to define the state of a system, it is not necessary to know the values ofall its properties, but only a certain number of them, which are called indepen-dent and all the rest (dependent) can be calculated by the values of the indepen-dent ones. Since a property is fixed by the state of a system it is also called astate function. A mathematical relationship between thermodynamic state func-tions is called an equation of state.

D. Extensive and Intensive PropertiesConsidering that we divide a system in different parts, if for one property itsvalue for the whole system is equal to the sum of its values for the differentparts, then this property is called extensive. Extensive properties are the volume,the mass, the internal energy, etc.

If the value of a property for the whole system is equal to the values forits different parts, then the property is called intensive. Intensive properties arethe temperature, the pressure, the molar volume, the density, etc.

E. Phase

If for a system, throughout all its parts, all its intensive properties have the samevalue, then the system is a homogeneous one and is called a phase. One system

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 5

can consist of more than one phases. In that case it is heterogeneous and someof its intensive properties have not the same value at all its parts.

One phase can be open when it exchanges matter either with its surround-ings or with another phase within the system. In the opposite case it is calledclosed.

F. Process

Process is the pathway through which one system passes from one state toanother.

If during a process the temperature of the system remains constant, theprocess is called isothermic, if the volume of the system remains constant, theprocess is called isometric or isochoric, and if the pressure remains constant,the process is called isobaric. If no heat enters or leaves a system undergoingone process the system and the process are called adiabatic.

A process is called reversible if it takes place slowly and in such a waythat at any stage of the process the properties of the system differ from equilib-rium by infinitesimal amounts. Otherwise the process is called irreversible. Allnatural processes are irreversible.

G. Molar QuantitiesFrom any extensive quantity X of a phase, it is defined an intensive quantityXm by the relation:

Xm =X

i

ni(1)

where i

ni is the sum of the amounts of the different substances contained in

this phase.

H. Mole FractionThe mole fraction Xa of a substance a in a phase is defined by the ratio:

Xa =na

i

ni(2)

where na the amount of substance of a and i

ni the sum of the amounts of all

substances in this phase.It follows immediately from the above definition that

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

6 Tzias

i

Xi = 1 (3)

I. MolalityMolality m is the number of moles of a substance in 1 kg of solvent.

J. MolarityMolarity c is the number of moles of a substance in 1 L of solvent.

K. Partial Molar QuantitiesFrom any extensive quantity X of a phase we define an intensive quantity calledthe partial molar quantity Xa of the substance a in the phase by the relation:

Xa = XnaT,P,nina

(4)

where ni na means all ns except na in this phase.

IV. THE CONCEPTS OF W, PE, KE, U, Q AND S (68)

W (work), PE (potential energy), and KE (kinetic energy) are concepts bor-rowed from physics.

Work (W) is produced by a force (F) acting on a system and replacing itby a distance (ds) in the direction of the force and equals to:

dW = F dsIn the case of a uniform pressure P acting on a systems wall of surface

S and replacing it by a distance xdW = P s dx or dW = P dV (5)By energy we mean the ability of a system to produce work.Potential energy (PE) is the energy possessed by a system because of its

position.PE = m g h (6)

where m is the mass of the system, g the gravity acceleration and h the heightof the system from zero level.

Kinetic energy (KE) is the energy possessed by a system of mass m, be-cause of its velocity () and is equal to:

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 7

KE = mE2

2(7)

Internal energy (U) is the total energy, except potential and kinetic, con-tained within a system at a certain state. It is a magnitude determined by thestate of a system. We cant measure the absolute value of U, but only differencesU = U2 U1 between two states (1) and (2). U depends only on the states (1)and (2) and not on the path followed to pass from one to the other.

Heat (Q) is the amount of energy, transferred from one system to anotherbecause of the difference in the temperature of the two systems. The amount ofheat depends on the followed path and not on the original and final states of aprocedure.

For a system receiving heat Q,Q = C (T2 T1) (8)

where C is the heat capacity of the system and T2, T1 its final and originaltemperatures.

The entropy (S) (6) is an extensive property, depending on the state of asystem. It can be defined as:

dS = dQT

(9)

where dS is the heat received by it in a reversible way at a temperature T.In natural processes S always increases and

dQ T dS (10)The SI unit for W, PE, KE, and Q is the Joule.The SI unit for S is Joule

K.

V. THERMODYNAMIC LAWS (2, 5, 6, 7)

Thermodynamic laws are laws formed from experience, and there is no excep-tion to them. There are several expressions for them all equivalent with eachother. Below are given the most common ones.

A. First Law of ThermodynamicsIn any process the total energy is conserved. In other words, there is no devicewhich can create or eliminate energy. Considering the transformation of heat towork or vice-versa in a system, the first law can be expressed as:

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

8 Tzias

dU = dW + dQ (11)where dU is the variation of the internal energy of the system, dW is the workproduced, and dQ is the heat transferred.

dU is an exact differential depending only upon the original and final stateof the system, but dQ and dW are not exact differentials and depend upon thepathway of the process. By substituting Eqs. (5) and (9) to (11), the first lawcan be expressed as:

dU = P dV + T dS (12)

B. Second Law of ThermodynamicsIt is not possible to transfer heat from a lower temperature to a higher tempera-ture without the expenditure of work. In other words, in any process the totalentropy of an isolated system increases.

C. Third Law of ThermodynamicsThe expression of the third law is not possible without reference to statisticalmechanics (2). As expression for the third law we could give Planks postulate(7): At 0K the entropy of a pure crystalline is zero.

D. Law of Thermal EquilibriumIf two systems are in thermal equilibrium with a third one, then they are also inthermal equilibrium between them.

This law is not an independent one but it is derived from the first andsecond thermodynamic laws (2).

VI. THERMODYNAMIC FUNCTIONS AND SOMERELATIONS FOR ONE-PHASE CLOSED SYSTEM (6, 7)

We have already met the properties P, V, T and the thermodynamic functionsU, Q, W, and S and for the last two functions:

W = P dV and dS = dQT

Furthermore, there are the following very important thermodynamic func-tions:

the enthalpy H = U + P V (13)the Helmholtz free energy A = U T S (14)

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 9

and the Gibbs energy or Gibbs functionG = H T S = A + P V = U T S + P V (15)All the three above functions are state functions and they have the dimen-

sions of energy.Since they are state functions their differentials are exact differentials and

for reversible processes we have:

dH = T dS + V dP (16)dA = S dT P dV (17)dG = S dT + V dP (18)By applying the properties of exact differentials we can obtain the follow-

ing very useful relations:

UVS

= P, USV

= T (19)

ATV

= S, AVT

= P (20)

GPT

= V, GTP

= S (21)

HSP

= T, HPS

= V (22)

and also the following:

TVS

= PSV

(23)

TPS

= VSP

(24)

SVT

= PTV

(25)

SPT

= VTP

(26)

PTV

TVP

VPT

= 1 (27)

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

10 Tzias

a =1V VT

P

is the coefficient of thermal expansion (28)

K = 1V VP

T

is the isothermal compressibility (29)

KS = 1V VP

S

is the adiabatic compressibility (30)

CV = UTV

is the heat capacity at constant volume (31)

CP = HTP

is the heat capacity at constant pressure (32)

VII. FUNDAMENTAL INEQUALITIES

We have already seen (Sec. IV.) that although for a reversible process dQ = T dS and for natural processes dQ T dS. Similarly for natural processes fromEqs. (12), (16), (17), and (18) we derive:

dU T dS P dV (33)dH T dS + V dP (34)dA S dT P dV (35)dG S dT + V dP (36)

This means that for a natural process at equilibrium the above functions get thelowest value, except the entropy which gets the maximum.

In other words for any closed isolated system (2):

St U,V,ni

> 0 (37)

which means, that if anything happens in that system then S is increasing, andif

St U,V,ni

= 0 (38)

then the system is in equilibrium.Similarly, from:

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 11

Ut S,V,ni

< 0 (39)

that if anything happens in a system at constant V, S and content then U isdecreasing, from:

Ht S,P,ni

< 0 (40)

that if anything happens in a system at constant S, P and content then H isdecreasing, from:

At T,V,ni

< 0 (41)

that is anything happens in a system at constant T, V, and content then A isdecreasing, and from:

Gt T,P,ni

< 0 (42)

that if anything happens in a system at constant T, P, and content then G isdecreasing.

The above (42) inequality is very important for chemists since most chem-ical reactions take place at constant T and P.

If in the place of the above inequalities we consider the respective equali-ties, this will mean that the system to which they are referred is in equilibrium.

VIII. RELATIONS OF THERMODYNAMIC FUNCTIONS INONE-PHASE OPEN SYSTEM (2, 6, 7)

We have already seen the Eq. (12) dU = P dV + T dS, which is the expres-sion of the first law of thermodynamics for a change involving only the transfor-mation of energy. If we suppose that in the system under consideration there isalso addition or removal of matter, then the above equation should be writtenunder the following form:

dU = T dS P dV + i

idni (43)

where dni is the amount of substance of species i transferred and i its molarenergy.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

12 Tzias

In a similar way, from Eqs. (16), (17), and (18) we derive:dH = T dS + V dP +

iidni (44)

dA = S dT P dV + i

idni (45)dG = S dT + V dP +

iidni (46)

Eqs. (43) through (46) are called Gibbs equations.Considering U, H, A and G as the functions U(S, V, ni), H(S, P, ni), A(T,

V, ni) and G(T, P, ni) we can prove in a very easy way that the is in theprevious four relations are equal and that:

i = UniS,V,nki

= HniS,P,nki

= AniT,V,nki

= GniT,P,nki

(47)

where n ki indicates all the other species nk except ni.The above defined quantity i is called the chemical potential of the sub-

stance i; it is an intensive thermodynamic function, it has the dimensions ofenergy per amount of substance and its unit in the SI system is the Joule permole.

By definition:

i = R T lni (48)where i is called the absolute activity of the species i in the multicomponentsystem.

Integration of the Eq. (43) by keeping P, T, and ni constant (2) leads to:U = S T P V +

inii (49)

or

G = i

nii (50)

Differentiation of (50) gives:dG =

inidi +

iidni (51)

Equating the expressions for dG in Eqs. (46) and (51) yields:S dT V dP +

inidi = 0 (52)

which is known as the Gibbs-Duhem equation.Replacing in (52) i by its form in function of activity (48) the Gibbs-

Duhem equation takes the form:

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 13

S dT V dP + i

niRTdlni = 0 (53)

From Eqs. (46) by simple mathematical manipulations we can derive thefollowing useful relations:

iTP,ni

= SniT,P,nki

(54)

iPT,ni

= VniT,P,nki

(55)

inkT,P,nki

= kni T,P,nki

(56)

iTV,ni

= SniT,V,nki

(57)

iVT,ni

= PniT,V,nki

(58)

inkT,V,nji

= kni T,V,nji

(59)

IX. MIXTURES (2, 6, 7)

A system consisting of more than one substance is called mixture. A mixturemay exist in gaseous, liquid, or solid phase. We shall confine ourselves to binarymixtures, from which the extension to multicomponent ones is straightforward.

By definition a mixture is said to be ideal if for any component i (6):i = 0i + R T lnXi (60)

where i, 0i are the chemical potentials of component i with a mole fraction Xiin the mixture and of pure i respectively, both at the same P and T.

In other words if for any component i in the mixture (2):i = Xi 0i (61)

where i, 0i are the absolute activities of the component i with a mole fractionXi in the mixture and of pure i respectively, again at the same P and T.

A mixture for which (60) or (61) are not valid is called a real mixture.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

14 Tzias

In an ideal mixture the interactions between like and unlike species are thesame and the components in the mixture they behave as in the pure components.

A. Mixing FunctionsFor a binary mixture of components A and B with mole fractions (1-x) and xrespectively and for any extensive thermodynamic quantity X, such as G, A, H,S, or V the mixing function is defined as:

mix Xm = Xm (T, P, x) (1-x) Xm (T, P, 0) x Xm (T, P, 1) (62)or

mix Xm = (1-x) [XA (T, P, 1-x) Xm (T, P, 0)] + (63)x [XB (T, P, x) Xm (T, P, 1)]

where Xm (T, P, x) is the molar function of the mixture at (T, P, x), XA (T, P,1-x), XB (T, P, x) the molar functions of A and B in this mixture at molefractions 1-x and x and Xm (T, P, 0), Xm (T, P, 1) the molar functions of thepure components A and B respectively.

From (62) and (63) using Eqs. (50) and (61) and for Xm = Gm we obtainfor an ideal mixture:

mix Gidm = R T[(1-x) ln (1 x) + x lnx] > 0 (64)From (21) and (64) at constant P, n we obtain:mix Sidm = R [(1-x) ln (1 x) + x lnx] < 0 (65)From (64), (65), and (15):mix Hidm = 0 (66)

and from (21) and (64):mix Vidm = 0 (67)

B. Excess Functions

By definition Excess function XEm is the difference between the real mixXm andthe ideal one. That is:

XEm = mixXm mixXidm (68)

C. Thermodynamic Functions of DilutionIf in one binary or multicomponent one-phase homogeneous mixture of nonre-acting species, one component is in excess related to the others, and more of thisis added to the mixture, this process is called dilution.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 15

The thermodynamic functions of the dilution process are given as thedifference of thermodynamic functions of mixing between the final diluted stateand the original one, that is

Xm,dil = (Xm,mix)2 (Xm,mix)1 (69)

D. Standard and Reference States of ThermodynamicFunctions (8, 9)

We define as standard thermodynamic function of a component i in a system atany temperature and at a fixed pressure the thermodynamic function of i at agiven composition. The state thus defined is called standard state.

Historically the standard states are defined at the fixed pressure of 1 atm(= 101.325 Pa) and in that case the standard Thermodynamic functions dependonly on the temperature.

Usually, for gases as standard state is accepted the pure ideal gas at 1 atmand for liquids and solids the pure liquids or solids at certain P, T where P canbe defined as 1 bar.

As reference state is called one state that is used as reference for thecalculation of the different thermodynamic functions.

Any thermodynamic function can be expressed in function of its standardor reference state.

X. GASES AND GASEOUS MIXTURES (5, 6, 8)

The PVT behavior of a pure fluid, e.g., a gas, can be expressed by the equation:P Vm = R T (1 + B P + C P2 + . . . ) (70)

or

P Vm = R T (1 + bVm+

c

V2m+ . . . ) (71)

where Vm is the molar volume of the gas, Vm =Vn

, V the volume and n the mol

of the gas, and R is the gas constant, which in SI units is equal to 8.3144 J mol1 K1.

Eqs. (70) and (71) are called virial equations of state of a gas and thecoefficients b, c, . . . of (71) virial coefficients and they depend on the tempera-ture and on the type of chemical species of the gas. The coefficients B, C, . . .can be calculated from b, c, . . . .

when P 0 then P Vm = R T (72)

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

16 Tzias

This is the equation of state of an ideal gas. The virial coefficients show thedeviation of a real gas from ideality.

The PVT behavior of the gases is also expressed by the aid of the com-pressibility factor:

z =PVmRT

(73)

For an ideal gas z = 1 and P Vm = R TOne other attempt to express the PVT behavior of the real gases is the

van der Waals equation:

P + aV2m (Vm b) = R T (74)which tries to take in account the volume (coefficient b) of the molecules andthe interactions between them (coefficient a).

For an ideal gas we can derive the following relations:

HPT

= V TnRT

P T

P

= V nRTP

= 0 (75)

CP = CV + n R (76)The Gibbs-Duhem equation at constant T and for a pure gas becomes:n d = V dP (77)If the gas is ideal, substituting in (77) the volume from (72) we obtain:

n d = nRTdPP

(78)

or

d = R T d lnP (79)and for a change at constant T from P1 to P2

2 1 = R T lnP2P1 (80)A. Fugacity (7, 10, 11)To express the properties of a real gas in the same way with an ideal gas, Lewisand Randall (10) originated the term fugacity (f), which has the dimensions ofpressure.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 17

So, for a real gas or vapor instead of (79) or (80) we write (10):d = R T dlnf (81)

or

2 1 = R T lnf2f1

(82)

where f is the fugacity of the gas or vapor.

The ratio = fP

(83)

is called fugacity coefficient. Since ideal gas behavior is approached as P 0then

limP0

= limP0

fP

= 1 (84)

As we will see in the phase equilibrium the fugacity of a liquid or a solidwhich is in equilibrium with its vapor is equal to the fugacity of its vapor.

The fugacity of a real pure gas at a given P, T can be evaluated (7) throughthe relation:

ln fP = P0VmRT 1PdPT

(85)

if we know the equation of state of that gas.For multicomponent real gases, the partial fugacity fi of a component i is

defined in terms of the chemical potential i as follows:

di = R T d(lnfi) (86)In this case:

limP0

fixiP

= 1 (87)

where xi is the mole fraction of component i and P is the total pressure (not thepartial pressure Pi).

For multicomponent gases, the fugacity fi can be also evaluated (7)through the following relation, if we know the equation of state of that gasmixture:

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

18 Tzias

lnfi = ln(xi P) + P0(Vm)iRT 1PdP

T

(88)

where (Vm)i is the partial molar volume of species i.

B. The Standard State of a Gas Component (2)The standard state of a gas component in a mixture of gases is given by:

B (g, T, P, xc) = 0B (g, T) + R T lnxB PP0 + P

0VB(g, T, P, xC) RTP dP (89)

where T, P, xC are the temperature, pressure and composition of the gas mixture,xB the mole fraction of B in the mixture and 0B (g, T) is the chemical potentialof the pure ideal gas, at temperature T and pressure P0. Historically P0 = 1 atm.

XI. LIQUID MIXTURES (2, 8)

All that was mentioned in Sec. IX and what it will follow are applicable toliquid and to solid mixtures as well.

For a liquid mixture using Eq. (48) we obtain:

i = 0i + R T lni0i

(90)

or

i = 0i + R T lnai (91)where i, 0i are the chemical potentials of component i with mole fraction xiand of the pure liquid i at certain P, T, i, 0i the absolute activities of i and0i respectively and

ai =i0i

(92)

is what we call relative activity of component i in the mixture. Some authorscall ai simply activity.

For the absolute activity, the activity coefficient fi is defined by the rela-tion:

i = fi xi (93)

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 19

and for the relative activity the corresponding activity coefficient i is definedby the relation:

ai = i xi (94)When ai = 1 from (91) we obtain i = 0i , that is the term R T lnai gives

the difference between i and its reference state 0i at certain P, T and if P = 1bar then the difference of i from its standard state.

From (91) and (94) we get i = 0i + R T lnxi + R T lni (95)Since for the case of an ideal mixture i = 0i + R T lnxi (Eq. [60]), the

term R T ln i expresses the deviation of i from ideality.After defining the standard state for i the standard states for the other

thermodynamic functions can be derived in an easy way. In particular

S0i = d0idT

(96)

H0i = 0i Td0idT

(97)G0i = 0i (98)

where S0i , H0i , and G0i are the standard molar functions of S, H, and G respectively.

XII. EQUILIBRIUM OF PHASES (2, 6, 8, 11, 12)

In many industrial processes there is coexistence of two or more phases. Whenthere is mass transfer from one phase to the other the phases are not in equilib-rium. The study of the mass transfer in these processes requires exact knowledgeof the phases at equilibrium. In this section, we will treat liquid-vapor equilib-rium states. Similar results can be derived from the treatment of liquidsolidand solidvapor equilibrium.

We say that two or more phases are in equilibrium regarding several inten-sive properties if these properties have the same value in both phases. For exam-ple we have:

Thermal equilibrium, when the temperatures T of the different phases areequal

Hydrostatic equilibrium, when the pressures P of the different phases areequal

Chemical equilibrium, when there is no reaction between the constituentsof all the phases

Osmotic equilibrium, when P, T, and several i are the sameDiffusive equilibrium, when P, T, and all i are the same

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

20 Tzias

We will deal here with equilibrium states between phases where P, T, i areequal in all phases.

A. The Phase Rule (4, 6, 8, 11)For a closed, isolated system consisting of several phases a, b, c, . . . in thermal,hydrostatic and chemical equilibrium (fixed composition) and where there is notransfer of mass, at macroscopic observation, from one phase to the other, writ-ing the Gibbs-Duhem equations for each phase, since dP, dT and dni are zero itis derived that, for every component i, ai = bi = ci = . . .

The minimum number of intensive properties (pressure, temperature, molefractions, etc.) needed so that the state of a closed, isolated nonreacting systemis completely defined is called the degrees of freedom F.

Gibbs derived a very important rule involving phase equilibria which con-nects the degrees of freedom F with the number of phases P and the number ofdifferent substances C in the system. This rule is given by the following relation:

F = C + 2 P (99)For example in the P, T diagram of Fig. 1 for a pure substance we observe

that for the regions of only one phase (P = 1), the relation (99) yields F = 2,which means that both P, T are needed for the definition of the state. For pointson the curves we have two phases P = 2 and F = 1 which means that only oneof P, T is needed for the definition of the state and finally at the triple point T,

Figure 1 P-T diagram for a pure substance.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 21

P = 3 and F = 0, which means that there is no degree of freedom and only onepair of P, T corresponds to the state of coexistence of three phases.

If a reaction is taking place in the system or we want to take in account apeculiarity of the equilibrium phases, for instance an azeotrope, then the phaserule must be modified.

For a single-component two phase system, following the vaporizationcurve (Fig. 1) up to the end point C, we observe that by increasing graduallythe temperature of the system we pass to vapor and liquid phases which theybecome more and more similar in density and molar volume and the meniscusseparating the two phases becomes more indistinct. Finally at the point C thetwo phases become identical and the meniscus between the two phases disap-pears. Beyond C there is no liquid or vapor phase, but only one single-fluidphase.

At the critical point

PVTC

= 0, 2PV2TC

= 0 (100)

Point C is called the critical point and the corresponding P, T the critical Pres-sure PC and the critical Temperature TC of the studying substance.

B. The Chemical Potential in Phase Equilibria (7, 11)In the previous section we saw that between two phases a, b in equilibrium forevery substance i

ai = bi (101)or

0,ai + R T ln aai = 0,bi + R T ln abi (102)Since the 0,ai and 0,bi are the chemical potentials of the pure i at the same P, Tthen

0,ai = 0,bi (103)and consequently from (103)

aai = a

bi (104)

but this does not mean that necessarily the activity coefficients ai , bi will beequal since usually xai xbi

For the case of liquidvapor equilibrium we have seen for the vapor phasethat

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

22 Tzias

vi = 0,vi + R T lnfvif 0,vi

(105)

while for the liquid phase

Ri = 0,Ri + R T lnRi0,Ri

= 0,Ri + R T ln aRi (106)

From the previous relations it is obtained the following relation, connect-ing the absolute activity, the relative activity and the fugacity of a component iin a system at equilibrium

fif 0i

=

i0i

= ai (107)

The equations relating the thermodynamic functions of phases at equilib-rium are very important since from data of one phase we can calculate theproperties of the other phase.

C. Binary Vapor-Liquid Systems (7, 9, 11)There are important differences between the behavior of a single componentvaporliquid system and a multicomponent one. For instance, in a single com-ponent the vapor and liquid phases have the same composition, but not in amulticomponent system.

During the evaporation at constant pressure for a single-component systemthe temperature remains constant, but in a multicomponent system at constantP the temperature changes during the evaporation. It is obvious that the behaviorof a multicomponent system is more complicated than that of a single compo-nent. As an example of multicomponent system we study here a two-phasebinary system.

Fig. 2 shows a vapor-pressure, composition (X = mole fraction) diagramfor an ideal mixture of two liquids. At any mole fraction X between 0 and 1 thevapor pressure Pmix of the mixture is

Pmix = PA (1 X) + PBX (108)where PA, PB the vapor pressures of the pure components A, B.

Fig. 3 shows the P, X diagram of a real mixture of two component liquidsA and B, completely miscible through the whole range of X. At any pressure acomposition of the liquid phase Xliq corresponds to a different composition Xvapof the vapor phase, which is in equilibrium with the liquid. The compositionsof the liquid phase form a curve called bubble point line and the correspondingcompositions of the vapor phase form another curve called dew point line. Asimilar to Fig. 3 diagram can be drawn relating T with X.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 23

Figure 2 Vapor-pressure composition diagram for an ideal mixture of two liquids, Aand B.

Figure 3 Vapor-pressure composition diagram for a real mixture of two liquids.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

24 Tzias

Each liquid component, when its mole fraction tends to 1, behaves like inan ideal solution.

Some binary liquid mixtures, at a fixed composition, have identical com-position in both the liquid and vapor phase. This composition is called azeo-tropic and the mixture azeotrope. In these cases, although the compositions ofthe two phases are equal, it does not mean that the mixture is an ideal one.

There are positive azeotropes with azeotropic pressure Paz higher than thevapor pressure of the two pure components and negative azeopropes with Pazlower than the vapor pressure of the two pure components of the mixture.

Fig. 4 shows the P, T diagram of a binary liquid mixture at a constantcomposition. Since in this case there is one more degree of freedom from thesingle component system, in order to define the state of the system for the vapor+ liquid region we need both P, T (for the single component system it is neededeither only P or only T).

In Fig. 4, the region included inside the ABCDE curve is in the place ofthe vaporization line of Fig. 1. To pass from the pure liquid to the vapor underconstant pressure the temperature is changing. This passage becomes shorter aswe approach the critical point C. The end temperatures, at the start and the endof this process, are called bubble point and dew point temperatures respectivelyat the pressure of vaporization. At each composition there is one curve ABCDEand one critical point.

Similar behavior is observed for the processes of fusion and sublimationand it is not necessary to study them separately.

Figure 4 P-T diagram at constant composition for a mixture of two liquids.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 25

D. Principle of Corresponding States (7, 12)For different real gases at the same pressure and temperature the molar volumes

Vm are different. The compressibility factor z =PVmR T

defined in Sect. X expresses

the deviations of the real gases from ideality and it is different for the differentgases at the same P and T.

However, it has been observed, by defining the reduced pressure Pr, thereduced temperature Tr and the reduced molar volume Vm,r by the relations:

Pr =PPC

, Tr =TTC

, Vm,r =Vm

Vm,C(109)

where PC , TC, Vm,C are the critical P, T and Vm that for equal Pr, Tr the Vm,r ofall gases are approximately equal.

This is known as the van der Waals principle of corresponding states.The critical compressibility factor

zC =PC Vm,CR TC

(110)

is also found experimentally to be in the narrow range 0.20.3 and it can beconsidered as a universal constant.

So we finally havez = F (Pr, Tr) (111)

where F is the same function for all the gases.

E. Enthalpy and Entropy Change in a Two-PhaseTransition (2, 7, 12)

When there is transition from one phase to another we define a property calledchange of transition of state by the relation

Mabi = Mbi Mai (112)Thus for the case of vaporization we have:

VRvi = Vvi VRi (113) HRvi = Hvi HRi (114) SRvi = Svi SRi (115)

where by R and v we mean liquid and vapor respectively.Knowing that at equilibrium

Ri = vi or GRi = Gvi (116)for a two-phase one-component system at each phase:

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

26 Tzias

Gi = Hi T Si (117)and dGi = Si dT Vi dP (118)From (117) and (118), it is finally deriveddPsatidT

=

SRviVRvi

(119)dPsatidT

=

HRviTVRvi

(120)

where Psati is the vapor pressure at the equilibrium of the two phases.From Eqs. (119) and (120) we can calculate the entropy and enthalpy

change of vaporization.

XIII. SOLUTIONS (2, 5, 11, 13)

For several mixtures it is convenient to distinguish some components from theothers, for instance when one solid, liquid, or gas has a limited solubility in aliquid and its mole fraction in the mixture does not cover the whole range from0 to 1.

In this case, by convention we call the liquid which has the higher molefraction the solvent, the component with the limited solubility solute, and themixture the solution. When the solvent is in excess and the solute in low concen-tration, the solution is called a dilute solution.

For a binary solution the chemical potential of the solvent is given as inmixtures of liquids by the relation:

i = 0i + R T lnai = 0i + R T lni xi (121)where 0i is the reference chemical potential of pure solvent at certain P, T. ai,iare, respectively, its relative activity and activity coefficient.

When xi 1 then also i 1, and the solvent behaves as in an idealmixture. At these compositions near the pure solvent the partial pressure andthe fugacity of the solvent are proportional to its mole fraction.

Pi = P0i xi or fi = f0i xi (122)where Pi, fi, xi are the partial pressure, fugacity, and mole fraction of the solventand P0i , f 0i are the vapor pressure and the fugacity of the pure solvent respectivelyat the temperature of the solution.

In this region, the solvent behaves in an ideal way and the relations, Eq.(122), express what we call as Raoults law (Fig. 5).

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 27

Figure 5 Fugacity of a solvent and a solute as function of their mole fraction.

The standard chemical potential of the solvent is that of the pure liquid at1 atm and the temperature of the solution. For the solute, however, it is notpossible to define a similar standard state since there cannot be solutions aftera certain composition, with higher solute concentrations. In this case, it isadopted as standard state for the solute the hypothetical, ideal unit concentrationof solute solution, at certain pressure and temperature (reference state) or at thefixed pressure of 1 atm (standard state).

This solute standard state is derived by the extrapolation of the fugacityof the solute at conditions of infinite dilution (the mole fraction of all the solutesin the solution tend to zero), where the fugacity of the solute fi is proportionalto its mole fraction xi,

fi = K xi (123)to the hypothetical state of solution with solute mole fraction 1.

The relation (123) is called Henrys law and K is a constant called Henrysconstant.

In the region of very dilute solutions where the relation (123) is valid thesolute behaves in an, by convention, ideal way which is different from the idealconditions near the pure solvent.

From the above mentioned the chemical potential of the solute in a solu-tion is given by:

i = 0i + R T lnixi = 0i + R T lnfif 0i

(124)

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

28 Tzias

where i, fi are the activity coefficient and the fugacity of i at a mole fraction xiand f0i , 0i are the fugacity and the chemical potential of pure i at the referencestate of infinite dilution conditions and at the temperature and pressure of thesolution.

The standard chemical potential of a solvent is given by the relation (2):

02(T, P0) = *2 (T, P) + P0

P

V*2 (T, P)dP (125)

where P0, P are the standard pressure and the pressure of the solution respec-tively, * means is pure solvent, and V*2 the volume of pure solvent.

The standard chemical potential of a solute is given by the relation (2):

0i (T) = 1(T,P,m1) RTlnm1m

01 + P

0

P

V1 (T,P)dP (126)

where means conditions at infinite dilution, 1(T,P,m1) the chemical potentialat T, P, m1, m01 the standard molality, P0 the standard pressure and V1 the volumeof solute at conditions of infinite dilution.

All the other thermodynamic functions and relations for the solution canbe derived in a straight mathematical way from the above relations.

XIV. ELECTROLYTE SOLUTION (2, 8, 14)

Electrolytes are a special class of solute substances, which involve several com-plications in their thermodynamic study, not found in solutions of nonelectro-lytes.

The difficulties arise from the fact that the electrolytes in solution arefound under complete or partial dissociation in the ions of which they are con-sisted. Because of the restriction of electrical neutrality in an electrolyte solutionit is not possible to define thermodynamic functions of one ion, for example itschemical potential, since this would imply the change of the amount of sub-stance of this ion by keeping constant the amount of substance of all the restions, which has no physical meaning.

To overcome this difficulty, we consider all the thermodynamic functionswith both the anions and the cations of one electrolyte.

For example, for the case of a strong, completely dissociated electrolyteof the type M+A, where + and are the number of positive and negativeions, respectively, in the molecule of the electrolyte, we can write:

MA = + + + (127)

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 29

and using molalities

+ (T, P, m) = R T lnm+ + R T ln+ (T, P, m) + 0+ (T, P) (128)

(T, P, m) = R T lnm

+ R T ln

(T, P, m) + 0

(T, P) (129)Substituting (128) and (129) to (127) we obtain:MA = R T lnm++ m + R T ln++ (T, P, m) ++0+ (T, P) + 0 (T, P) (130)The mean activity coefficient is defined as:

= ++ (131)and the mean molality:

m = m

++ m

(132)where = + +

From (131), (132) and (130) and by defining:0MA (T, P) = + 0+ (T, P) + 0 (T, P) (133)MA (P, T) = R T lnm + R T ln (T, P, m) + 0MA (T, P) (134)The m, and 0MA (T, P) have a similar meaning as for the nonelectrolyte

solutions when m 0 then 1 and MA (T, P) is equal to 0MA (T, P) at thereference state. To obtain the standard state for an electrolyte solute it is fol-lowed a similar procedure to that of a nonelectrolyte solute providing that theappropriate quantities are plotted (13, 14).

For the case of weak electrolytes the method to obtain expressions for thechemical potentials are the same as for strong electrolytes.

A. The DebyeHuckel Limiting Law (2, 6)In 1923 Debye and Huckel developed a theory about the behavior of strongelectrolytes in dilute solutions. This theory was a mathematical treatment ofsome ideas previously assumed by Arrhenius regarding the dissociation of elec-trolytes in solution.

By this theory after a series of mathematical calculations we arrive to aformula giving the mean ionic activity coefficient, which for very dilute solu-tions by approximation takes the form:

ln = C I1/2 z+ z (135)where C = (2 N0s)1/2 (e2 / 4 K T)3/2

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

30 Tzias

N0 = Avogadros numbers = density of the pure solvente = the charge on a proton = 0 r, where r is the dielectric constant of the solvent and 0 is thedielectric constant of a vacuum

T = temperature of the solution

K = RN0

, R = gas constant

I is called ionic strength and is given for a 1-1 type electrolyte by:

I = 12

(m+ z2+ + m z2) (136)

m+, m, the molalities of the ionsz

2+, z

2

, the electrical charges of the ions.

The Debye-Huckel law is very accurate for very dilute solutions of strongelectrolytes.

For mixed electrolytes the theory is still valid with

I = 12 i miz

2i (137)

XV. THERMOCHEMISTRYCHEMICAL REACTIONEQUILIBRIUM (11, 15)

The application of thermodynamics to chemically reacting systems is very im-portant. Together with mass balance the first thermodynamic law under certainconditions gives exactly the energy absorbed (endothermic) or released (exother-mic) by a chemical reaction. For instance we can calculate the energy neededto produce from some substances other useful substances or the energy releasedfrom the combustion of a fuel.

The second thermodynamic law can predict if one chemical reaction willproceed to one direction or to the opposite and at which extend it will stop(equilibrium state).

However, in several cases, although from the second thermodynamic lawit results that one reaction should proceed to one direction, this reaction doesnot start and to overcome this hindrance, catalysts or other means are used.

But still, in these cases thermodynamics is useful, since through the pre-diction by the second thermodynamic law of the possibility of realization of areaction, it can allow us or release us from the trouble, to seek finding theappropriate catalyst for this reaction.

Copyright 2003 by Marcel Dekker, Inc. All Rights Reserved.

-

Introduction 31