Conductive gelatin methacrylate-poly(aniline) hydrogel for ... · on pre-fabricated PANi films, as...

Transcript of Conductive gelatin methacrylate-poly(aniline) hydrogel for ... · on pre-fabricated PANi films, as...

Biomedical Physics & EngineeringExpress

PAPER

Conductive gelatin methacrylate-poly(aniline)hydrogel for cell encapsulationTo cite this article: Stephen W Sawyer et al 2018 Biomed. Phys. Eng. Express 4 015005

View the article online for updates and enhancements.

Related contentA fast-degrading thiol-acrylate basedhydrogel for cranial regenerationA M Emmakah, H E Arman, J C Bragg etal.

-

3D bioprinting of GelMA scaffolds triggersmineral deposition by primary humanosteoblastsChristine McBeth, Jasmin Lauer, MichaelOttersbach et al.

-

A bioprintable form of chitosan hydrogelfor bone tissue engineeringTurul Tolga Demirta, Gülseren Irmak andMeneme Gümüdereliolu

-

This content was downloaded from IP address 128.153.48.208 on 05/12/2017 at 15:25

Biomed. Phys. Eng. Express 4 (2018) 015005 https://doi.org/10.1088/2057-1976/aa91f9

PAPER

Conductive gelatin methacrylate-poly(aniline) hydrogel for cellencapsulation

StephenWSawyer1,3, PingDong1,3, SarahVenn1, AndrewRamos1, DavidQuinn1, JasonAHorton2 andPranav Soman1

1 Department of Biomedical andChemical Engineering, SyracuseUniversity, Syracuse, NY,United States of America2 Department ofOrthopedic Surgery, SUNYUpstateMedical University, Syracuse, NY,United States of America3 co-first authors.

E-mail: [email protected]

Keywords: polyaniline, gelatinmethacrylate, cell encapsulation, stereolithography

AbstractNew conductive hydrogels with superior biocompatibility continue to be developed in order to serveas bioactive scaffolds capable ofmodulating cellular functionality for tissue engineering applications.We developed an electrically conductive gelatinmethacrylate-poly(aniline) (GelMA-PANi) hydrogelthat is permissive ofmatrixmineralization by encapsulated osteoblast-like cells. Incorporation ofPANi clusters within theGelMAmatrix increases the electro-conductivity of the composite gel, whilemaintaining the osteoid-like softmechanical properties that allows three-dimensional encapsulationof living cells. Viability of human osteogenic cells encapsulatedwithinGelMA-PANi hydrogels wassimilar to that of GelMA.Cells withinGelMA-PANi also demonstrated the capability of depositingmineral within the hydrogelmatrix after being chemically induced for twoweeks, although the totalmineral content was lower as compared toGelMA. Additionally, we demonstrated that theGelMA-PANi-composite hydrogel could be printed in complex, user-defined geometries using digitalprojection stereolithography.

Introduction

The past few decades have seen the development ofnew biomaterials capable of mimicking the in vivo 3Dmicroenvironment in an effort to modulate cellularresponses for a variety of tissue engineering applica-tions. To this end, hydrogels have emerged as idealbiomaterials in the development of biomimetic 3Dtissue scaffolds due to their hydrated extra-cellularmatrix like properties [1–3]. Within the past few years,hydrogel biomaterials laden with living cells have alsobeen used to simulate the 3D in vivo microenviron-ment as an alternative to conventional 2D configura-tions [4, 5]. However, the electrically non-conductivenature of hydrogels impedes its use for excitable cellssuch as neural, skeletal and cardiac muscle, and bonecells [6, 7]. To extend the utility of hydrogels, conduct-ing elements like metallic nanoparticles [8–14] andinherently conductive polymers (IHPs) [6, 15–19]have been incorporated within hydrogel matrices inorder to add conductive properties to the 3Dmicroenvironments.

Most recently hydrogels have been combined withpolyaniline (PANi), a commonly used IHP [17, 20],since it is capable of conducting electricity due to thepresence of conjugated double bonds in its chemicalstructure [6]. Additionally, PANi has favorable prop-erties to researchers such as low cost, ease of synthesis,and the ability to electrically switch between resistiveand conductive states. Studies involving PANi havebeen extensively centered around the seeding of cellson pre-fabricated PANi films, as synthesis of 2D thinfilms can be processed quite easily with current manu-facturingmethods such as inkjet printing, casting, self-assembly, and electrospinning [21–25]. The use ofPANi in engineering cell-laden three-dimensionalbiomimetic constructs has been limited due to its diffi-cult and non-biocompatible processing steps and itsinsolubility in common solvents [17, 26–28].

Previously, we have reported that PANi can beintegrated with synthetic PEGDA and naturallyderived gelatin methacrylate (GelMA) hydrogelsin situ in order to develop 3D conductive-hydrogelsthat are sufficiently biocompatible with seeded cells

RECEIVED

12 September 2017

REVISED

27 September 2017

ACCEPTED FOR PUBLICATION

9October 2017

PUBLISHED

27November 2017

© 2017 IOPPublishing Ltd

[29, 30]. However, like studies similar to ours, theharsh processing methods were incompatible with cellencapsulation approaches. In this study, we developeda conductive PANi-GelMA composite by incorporat-ing PANi clusters within a photo-polymerizableGelMA hydrogel and investigate the ability of encap-sulated osteoblast-like cells to mineralize within thehydrogel matrix. Additionally, we provide a proof-of-concept that our conductive hydrogel can be printedusing digital stereolithography in order to createdefined areas ofmineralization.

Materials andmethods

Gelatinmethacrylate/poly(aniline) solutionpreparationPoly(aniline) clusters (PANi)were synthesized accord-ing to published studies [31–33]. Briefly, aniline (AcrosOrganics) and ammonium persulfate (APS, SigmaAldrich)were dissolved separately in 1Mhydrochloricacid (HCl) to specified concentrations of 0.32 M and0.16 M, respectively. Once dissolved, the two solutionswere quickly mixed and left to stand for 24 h(figure 1(A)). After polymerizing, the aniline-APSpolymer solution was dialyzed against distilled waterin 12–14 KDa dialysis tubing (SpectrumTM, ThermoFisher Scientific) for 3 d. After 72 h, the dialyzedsolution was filtered with a micro-filter paper (poresize-0.46 μm) and dried at room temperature.

Gelatinmethacrylate (GelMA)macromer was syn-thesized according to our published work [34]. Briefly,porcine skin gelatin (SigmaAldrich)wasmixed at 10%(w/v) in phosphate buffered saline (PBS, ThermoFisher Scientific), combined with methacrylic anhy-dride, dialyzed against distilled water, lyophilized, andstored at −80 °C until needed. GelMA pre-polymersolution was created by combining the freeze-driedGelMA macromer with PBS and 0.25% UV photo-initiator Irgacure 2959 (Specialty Chemicals) in spe-cific ratios depending on the desired application (%w/v).

PANi was dissolved in 0.1 MHCL in order to pro-duce solutions of 1%, 5%, 7.5%, 10%, and 15% (w/v),respectively, and sonicated for 30 min prior to incor-poration into GelMA to facilitate dispersion. Aftersonication, PANi solution was added to 15% (w/v)GelMA pre-polymer solution to create the hybridGelMA-PANi solutions used for mechanical analysis(referred to as 0.05, 0.25, 0.375, 0.5, and 0.75 PANirespectively).

Characterization of hybrid conductive hydrogelThe size and morphology of the PANi clusters wereanalyzed via transmission electron microscopy (TEM,JOEL 2000EX) under an acceleration voltage of100 kV. As previously described, a 0.1%PANi solutionwas synthesized and deposited onto a thin barformvar-carbon hexagonal 400 Cu mesh grid

(FCFTH400-Cu, Electron Microscopy Sciences) andsubsequently dried in a desiccant chamber. Afterdrying, the grids were stained with a 2% uranyl acetatesolution and placed in the desiccant chamber brieflyprior to imaging.

In order to show incorporation of PANi intoGelMA hydrogel solution, the UV–visible absorptionspectra for uncured 15% (w/v) GelMA, 0.1% PANisolution, and combined GelMA-PANi pre-polymersolution was obtained using a UV–Visible Spectro-photometer (Evolution 201, Thermo Fisher Scien-tific). To obtain the measurements, 3 ml of eachsample solution was added to a plastic cuvette stan-dard to the device. Absorbance at wavelengthsbetween 200 and 800 nm was recorded, and data wasexported to Excel (Microsoft) for analysis. Back-ground calculations were normalized to deionizedwater.

Hydrogel slabs used for mechanical, electrical, andswelling measurements were made by injecting theGelMA-PANi solutions between two glass slides sepa-rated by Teflon spacers (0.81 mm thick for electricalcharacterization; 1.62 mm thick for mechanical andswelling characterization). The pre-polymer solutionwas crosslinked via UV light (Omnicure S2000 UVLamp, Lumen Dynamics) for 10 min (UV intensity10W cm−2) to generate samples.

The electrical conductivity of GelMA-PANi slabswere measured against 15% (w/v)GelMA using a cus-tommade electrical chip. 0.81 mm slabs were made aspreviously described, placed inside the chip, and sub-sequently compressed with a 10 g weight. Resistanceswere measured incrementally from 0 to 300 s and thedata points between 100 and 200 s were averaged forthe reported resistance values.

The compressive modulus of both the GelMA andGelMA-PANi slabs were measured via dynamicmechanical analysis (DMA, Q800, TA Instruments,Inc.). A 15% (w/v) GelMA slab with a thickness of1.62 mm was compared against 15% (w/v) GelMA-PANi slabs of the same thickness containing four dif-ferent concentrations of stock PANi solution (1%, 5%,10%, and 15%). A new slab was created prior to eachtest and was placed on a compression clamp where thestrain was incrementally increased from 5% to 20%with a preloaded force of 0.01 N.

The swelling ratios of the four different types ofGelMA-PANi slabs were calculated by the followingequation:

*= -( ) ( )/W W Wswelling ratio % 100%,w d d

where Ww is wet weight and Wd is dry weight. Toobtain the measurements, fresh GelMA-PANi slabswere immersed in deionized water for 3 d, weighed,dried under ambient humidity for 7 d at roomtemperature, andweighed again.

2

Biomed. Phys. Eng. Express 4 (2018) 015005 SWSawyer et al

Saos-2 culture and encapsulationHuman osteosarcoma cells (Saos-2, ATCC) wereemployed as analogs for osteoblasts as they aregenerally representative of the early stages of osteo-genic differentiation and mineralization [35]. TheSaos-2 cells were cultured in Dulbecco’s Modificationof Eagles’s Media (DMEM, Life Technologies) supple-mented with 1% GlutaMAX (G, Life Technologies),1% penicillin-streptomycin (Life Technologies) and10% fetal bovine serum (FBS lot G12102, AtlantaBiologicals), and cultivated at 37 °C in a humidified95%air/5% CO2 atmosphere. Cells were grown toconfluence and passaged using 0.25% trypsin-EDTA(Life Technologies) prior to any new experiment.

Saos-2 cells were encapsulated in GelMA orGelMA-PANi by mixing 5 μl of a cell suspension con-taining approximately 10 000 cells μl−1 with 15 μl ofeither 20% (w/v) GelMA or 20% (w/v) GelMA sup-plemented with PANi (refer to G+0.5PANi infigure 1). The 20 μl cell/hydrogel pre-polymer solu-tion was pipetted into 5 mL of autoclaved vegetableoil, taking advantage of a surface tension techniqueused in previous studies [34] and UV cured for 1 minand 20 s using a Hamamatsu LED Controller (Hama-matsu C11924-511; Hamamatsu Photonics K.K.,Japan)with an output of 5 mW cm−2. Once cured, theGelMA and GelMA-PANi beads containing approxi-mately 50 000 cells were washed in sterile PBS and

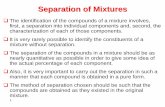

Figure 1.PANi synthesis andmaterial characterization. (A) Schematic of PANi clusters. (B)TEM image of 0.1% (w/v)PANi clustersinHCl (scale bar = 500 nm). (C)Brightfield images of representative GelMA-PANi composite slabs used formechanical and electricaltests. From left to right, increasing amounts of PANi incorporation intoGelMA (1%, 5%, 10%, and 15%) created composites withincreasing opacity (scale bar = 5 mm). (D)UV–vis absorbance spectra of GelMA-PANi composite (green), pure PANi (red), andGelMAhydrogel (blue), indicating homogenous incorporation of PANi nanowires intoGelMAhydrogels. (E)Resistancemeasurements ofGelMA-PANi composites with increasing amounts of PANi. Conductivity increased significantly with increasingPANi concentration (n = 5; * = p < 0.05). (F)DMAanalysis of GelMA andGelMA-PANi composites. Increasing amounts of PANiadded to theGelMAmatrix reduced the hydrogelmodulus significantly (n = 6; * = p < 0.05). (G) Swelling of GelMA-PANicomposites increasedwith increasing concentrations of PANi (n = 5; * = p < 0.05).

3

Biomed. Phys. Eng. Express 4 (2018) 015005 SWSawyer et al

transferred into cell culture media. Media was refre-shed every 2–3 d on each construct using standard cellculture procedures.

Cellular viability andmorphologyAfter 1 d of culture under standard conditions, GelMAand GelMA-PANi samples containing encapsulatedSaos-2 cells were analyzed for viability using a standardLive/Dead assay. This time point was chosen toaccount for process-associated apoptosis and necrosiswhich can take several hours to execute. To measureviability, GelMA and GelMA-PANi constructs weretransferred into warmed media supplemented withcalcein-AM (1:2000 dilution, Life Technologies) andethidium homodimer (1:500 dilution, Life Technolo-gies), and incubated for 1 h prior to imaging, respec-tively staining live cells green and dead cells red. Live/Dead images were taken at the top, middle, andbottom of each sample using a Leica DMI4000 Binverted research microscope (Leica) and the relativeproportion of live and dead cells were analyzed usingImageJ software (NIH).

GelMA and GelMA-PANi samples to be imagedfor nuclei and f-actin were fixed in cold 4% paraf-ormaldehyde (Sigma-Aldrich) after 3 d of culture andwere subsequently transferred into room temperaturePBS for staining. Samples were treated with 0.2% Tri-ton X-100 (Sigma) for 30 min, washed twice with PBS,and stained for actin with Alexa Fluor 488 Phalloidin(1:100 dilution, Life Technologies). Sample nucleiwere counterstained with 2.5 μg ml−1 4,6-diamidino-2-phenylindole (DAPI, 1:50 dilution, Life Technolo-gies) and imaged with a LSM 780 laser scanning con-focalmicroscope (Zeiss).

MineralizationAfter 1 dof culture,GelMAandGelMA-PANihydrogelscontaining approximately 50 000 encapsulated Saos-2cells were chemically stimulated to induce mineraldeposition. Specifically, the hydrogel samples weretransferred 24 h after encapsulation into an osteogenicmedium consisting of DMEM, 10% FBS, 1% PSG,10 nM dexamethasone (DEX, Sigma-Aldrich), 100 μML-ascorbic acid-2-phosphate (AA2P, Sigma-Aldrich),and 10mM β-glycerophosphate (BGP, Sigma-Aldrich).Osteogenic media was refreshed every 2–3 d on eachconstruct using standard cell culture procedures.

After 14 d of culture in osteogenic media, GelMAand GelMA-PANi samples were fixed in cold 4% for-maldehyde for 24 h, after which they were washed andstored in PBS. Samples were imaged for mineral con-tent at a 16 μm3 voxel resolution using a μCT-40instrument operating at 55kVp with a 200 ms integra-tion time (Scanco Medical AG, Brüttisellen, Switzer-land ) [36]. Samples were lightly packed in PBSsaturated cotton gauze inside standard μCT sampletubes. After imaging, samples were transferred intoPBS and prepared for histological analysis.

RT-qPCRRT-qPCR was performed on RNA extracts fromGelMA and GelMA-PANi samples to evaluate expres-sion of a panel of osteogenic genes. For RNA extrac-tion, GelMA and GelMA-PANi samples were createdin triplicate, grown in culture medium for either 1 or14 d, washed in PBS, and transferred to stock cell lysisbuffer that is supplied by Qiagen RNeasy Mini Kits(Qiagen). Sample triplicates were homogenized in thebuffer three times via a Precellys homogenizer (BertinInstruments), transferred to a Qiagen Qiashreddercolumn, and subsequently processed via publishedQiagenRNeasy protocols. Extracted RNAwas checkedfor quantity and purity by UV absorbance spectro-metry using a Tecan Infinite 200 Nanoquant platereader (Tecan Trading AG), and stored at−80 °Cuntilneeded.

After RNA extraction, cDNA was created accord-ing to published protocol with an iScript ReverseTranscription kit (Bio-Rad Laboratories, Inc.) in anEppendorf Mastercycler pro (Eppendorf AG) forqPCR reactions. iTaq universal SYBRGreen Supermix(Bio-Rad Laboratories, Inc.)was used for the real timeqPCR reaction according to manufacturer recom-mended protocol in an Eppendorf RealPlex 2 Mas-tercycler (Eppendorf AG). Relative expression of fivedifferent transcripts associated with osteogenesis werecompared by real time RT-qPCR and normalized tohuman beta actin (ACTB) expression: osteonectin(SPARC), osteopontin (SPP1/OPN), osteocalcin(BGLAP), human collagen 1 alpha 1 (hCOL1A1), andhuman alkaline phosphatase (hALPL). Oligonucleo-tide primers were synthesized by RealTimePrimers(ACTB, SPARC, SPP1/OPN, BGLAP) or Eurofins Sci-entific (hCOL1A1 and hALPL). Amplicons were eval-uated for primer specificity by melt-curve analysis andagarose gel electrophoresis. Amplification efficiencyfor each primer pair was determined by interpolationto an 8-point standard curve of two-fold dilutionsof cDNA.

Histological analysisGelMA and GelMA-PANi samples were prepared forhistological analysis via standard paraffin embeddingprotocols. Briefly, samples containing encapsulatedcells were grown in culture medium for either 1 d (nochemical induction) or 14 d (with chemical induction)andfixed in cold 4%paraformaldehyde for 24 h beforedehydration through ascending ethanol series, clear-ing in xylene, and infiltration and embedment in Type9 paraffin at 58 °C. Sections (5 μm thick)were cut on arotary microtome (RM2155, Leica) and mounted onSuperFrost Plus slides.

Hematoxylin and eosin (H&E) stainingSections were deparaffinized in xylene and rehydratedthrough descending ethanol series to deionized waterand stained by standardH&Eprocedure usingMayer’s

4

Biomed. Phys. Eng. Express 4 (2018) 015005 SWSawyer et al

Hematoxylin and Eosin/Phloxine solutions (ElectronMicroscopy Sciences). Sections were then dehydratedthrough an ethanol series, cleared in xylene, andcover-slippedwith Permount (Fisher Scientific).

Collagen 1-α-1 immunohistochemistryFor immunohistochemical demonstration of de novocollagen synthesis, sections ofGelMAorGelMA-PANisamples were de-parafinized and rehydrated asdescribed above. Prior to immunohistochemical stain-ing, heat-induced epitope retrieval was performed in10 mM citrate buffer (pH 6.0) for 4 min using apressure cooker. Sections were subsequently blockedwith 2.5% horse serum for 1 h (ImmPRESSTM VRReagent Kit, Vector Laboratories) and afterwardsincubated with 2 μg ml−1 of mouse anti-collagen type1 aminopropeptide IgG (SP1.D8, Developmental Stu-dies Hybridoma Bank) diluted in blocking buffer for16 h at 4 °C. Slides were then washed several times inPBS, and endogenous peroxidase activity was inacti-vated by incubation in blocking solution (Bloxall,Vector Laboratories) for 10 min at room temperature.Next, sample slides were rinsed with PBS and probedfor primary immunoreactivity using a peroxidase-conjugated horse anti-mouse secondary antibody(Anti-Mouse IgG Peroxidase, ImmPRESSTM VRReagent Kit, Vector). After 20 min, the slides wererinsed with PBS and sections were probed for 10 minusing a polymeric peroxidase substrate (ImmPACTChromogen, ImmPACTTMDAB Peroxidase SubstrateKit, Vector), washed in deionized water, and counter-stained with Hematoxylin. Sections were then dehy-drated through ethanol, cleared in xylene, and cover-slippedwith Permount.

Alizarin Red S and toluidine blue staining (mineral andcounterstain)Alizarin Red S was used to visualize calcium mineraldeposition in the GelMA and GelMA-PANi samples.Briefly, sections were deparaffinized in xylene andrehydrated through ethanol to deionized water, thenincubated in 40 mM Alizarin Red S solution (4.1 pH,Sigma) for approximately 5 min. Slides were thenwashed in deionized water and counterstained withToluidine blue O (Sigma) for 2 min Sections were thendehydrated through ethanol, cleared in xylene, andcover-slippedwith Permount.

Histological imagingCover-slipped and stained sections were imaged using aNikonEclipse E-400microscope (NikonCorporation).

PrintingGelMA-PANi-cells using digitalstereolithographyAUV-stereolithography platformwith a digitalmicro-mirror device (DMD) was used to print GelMA-PANilines containing encapsulated Saos-2 cells. A 20 μlsolution of 15% GelMA-PANi containing 50 000 cells

was created as previously described and pipetted dropwise onto a standard glass slide. Two glass spacers withthicknesses of 1 mm were fixed onto the glass slide,thereby creating a ‘well’ in which theGelMA-PANi cellsolution was contained. Amethacrylated 12 mm coverslip (Platinum Line) was placed on top of the spacers.Ultraviolet light from anOmnicure S2000was focusedonto the samples via a digital mirror array prepro-grammed with a ‘cross-shaped’ digital mask for 4.7 s(UV intensity 10W cm−2). The coverslip was thenwashed with 37 °C PBS to remove uncured GelMA-PANi, and immediately transferred into culturemedia. Live/dead staining was performed on the 3Dprinted structure as previously described at 24 h postencapsulation. 3D printed samples were also subjectedto osteogenic media as previously described for twoweeks prior toμCT analysis.

Statistical analysisNumerical data was entered into Microsoft Excel tocalculate mean and standard deviation and performStudent’s T-test to assess statistical significance ofdifferences; p-values less than 0.05 were accepted asstatistically significant.

Results

Poly(aniline) synthesis andmaterialcharacterizationPast work on conductive hydrogels has focused onadding conductive properties to the hydrogel matricesduring the initial synthesis process. Unfortunately, theharsh nature of the synthesis creates environmentsunsuitable for cellular encapsulation in situ and, as aresult, inhibits these composites from being used forsubsequent tissue engineering applications. In order towork around this issue, PANi clusters were synthesizedindependently of the GelMA macromer and added invarious concentrations directly prior to hydrogel curingand cellular encapsulation (figure 1(A)). Upon polymer-ization, the poly(aniline) solution was dialyzed againstdistilled water and lyophilized to create PANi clusters(referred to as simply PANi in this work). Transmissionelectronmicroscopy images of 0.1% (w/v) PANi inHClare representative of the PANi synthesized by ourmethod (figure 1(B)). For electrical and mechanicalstudies, 1%, 5%, 10%, and 15% (w/v) stock PANisolutions in HCl were added to GelMA pre-polymersolutions to create hybrid GelMA-PANi hydrogelsexhibiting an increasing opacity (figure 1(C)). In orderto show that low concentrations of PANi could beincorporated homogenously within the GelMA matrix,0.1% (w/v) PANi was combined with GelMA pre-polymer solution and subjected to UV–vis spectroscopy(figure 1(D)). As indicated by the absorbance spectra,GelMA-PANi hybrid solutions exhibited the character-istic spectra associated with pure PANi in HCl. WhilePANi incorporation into the GelMA matrix was

5

Biomed. Phys. Eng. Express 4 (2018) 015005 SWSawyer et al

homogenous, it was necessary to determine how theadded PANi affected the electrical conductivity, mod-ulus, and swelling ratio as compared to a GelMA onlyhydrogel. As expected, adding increasing concentrationsof PANi toGelMA significantly increased the conductiv-ity of the composite hydrogel (figure 1(E)), however thesmall dilutionofGelMAmacromer causedby increasingconcentrations of PANi resulted in a drop in thehydrogel compressivemoduli (figure 1(F)). Accordingly,a reduction inmoduliwas accompaniedby an increasingswelling ratio as more GelMA was displaced by PANi(figure 1(G)), a correlation supported in previouswork [34, 37].

Cellular encapsulationTo determine the biocompatibility of GelMA-PANicomposites, human osteosarcoma cells (Saos-2) werechosen to serve as a model line for the cellularencapsulation studies. GelMA and GelMA-PANi solu-tions pre-diluted with cells were crosslinked intospherical constructs approximately 2mm in diameter(figure 2(A)). Twenty-four hours after encapsulation,brightfield images showed a homogenous distributionof cells throughout both types of hydrogels (figure 2(B)).Live/Dead analysis also showed a similar distribution ofcells in both GelMA and GelMA-PANi hydrogels withviabilities between 40% and 50% respectively, a resultconsistent with other cellular encapsulation studies

(figures 2(C) and (E)) [34]. However, while both GelMAand GelMA-PANi hydrogels showed similar cellulardistribution and viability, differences in cellular morph-ology couldbe observed (figure 2(D)). Confocal imagingof both the nuclei (blue) and cytoskeleton (green) ofencapsulated cells after 3 d of culture showed that cellswithin a GelMA matrix displayed a spread morphologywhile those in GelMA-PANi samples had noticeablymore spherical structures.

Mineral depositionTo demonstrate potential for bone tissue engineeringapplications, it was necessary to determine how theaddition of conductive PANi would affect mineraldeposition in vitro (figure 3(A)). Cells were encapsu-lated as previously described in either GelMA orGelMA-PANi hydrogels and chemically stimulated fortwo weeks with osteogenic media, after-which theywere fixed and scanned for mineral accumulation. Inboth samples cell mineralization appeared to occurrobustly at the periphery of the gels adjacent to themedia interface and waned toward the center of theconstructs (figures 3(B) and (C)). Despite this organi-zation, mineral within the GelMA samples appearedmore uniform and contiguous while mineral withinthe GelMA-PANi samples appeared disorganized.Quantification ofμCT imaging data further illustratedthat GelMA-PANi samples were significantly less

Figure 2.Viability andmorphology of encapsulated cells. (A) Schematic of cellular encapsulation and representative GelMA andGelMA-PANi spheres containing approximately 50 000 encapsulated cells (scale bar = mm). (B)Brightfield images of GelMA andGelMA-PANi spheres containing encapsulated cells showing uniform cellular distribution. Reported images were taken at the top ofeach sphere (B,C scale bar = 0.5 mm). (C) Live(green)/Dead(red)fluorescent images of GelMA andGelMA-PANi spheres. Reportedimages were taken at the top of each sphere. (B,C scale bar = 0.5 mm). (D)Nuclei(blue) and actin(green) confocal images ofencapsulated cells after 3 d of culture. Cells encapsulated inGelMA-PANi sampleswere significantlymore rotund than thosewithinGelMA (scale bar = 50 μm). (E)Cellular viability of encapsulated cells withinGelMA andGelMA-PANi hydrogels. Cells showedviabilities approaching 50% in both gels, respectively (n = 3).

6

Biomed. Phys. Eng. Express 4 (2018) 015005 SWSawyer et al

dense and mineralized matrix occupied a significantlysmaller volume fraction than that produced by sam-ples composed of only GelMA (figure 3(D)). Non-cellular induced controls and non-induced cell-ladencontrols showed nomineralization, respectively, whenanalyzed viaμCT (data not shown).

Histological staining was performed on paraffinembedded GelMA and GelMA-PANi samples aftertwo weeks of induction to evaluate differences inmatrix deposition (figure 3(E)). Aside from PANigranules being visible in GelMA-PANi sections, nodifference in morphology or collagen deposition wasevident by H&E and collagen 1-α-1 stains, with celllacunae being equally visible in both samples. Sectionsstained for mineral, however, did show differenceswith deposition in GelMA samples appearing orga-nized and directional (figure 3(E), right panel top)

while deposition in GelMA-PANi samples appearingrandom and disordered (figure 3(E), right panel bot-tom). Furthermore, mineral deposition in GelMAsamples occurred in a gradient pattern, with moremineral being deposited towards the hydrogel periph-ery and decreasing towards the center of the construct.

In order to determine the potential osteoconductiveproperties of GelMA-PANi hydrogels, we used RT-qPCR to assay expression of genes associatedwith osteo-blastic matrix synthesis and mineralization in samplescollected both 1 d after encapsulation and 14 d after cul-ture (figure 3(F)). In samples collected 24 h after encap-sulation, osteopontin expression was significantlydown-regulated (1.02 to 0.30, p=0.01) and collagen1-α-1 expression was significantly up-regulated (1.17 to3.78, p=0.04) in GelMA-PANi samples relative toGelMA samples. However, after two weeks of culture,

Figure 3.Mineral deposition analysis. (A) Schematic ofmineral depositionwithinGelMA andGelMA-PANi spheres. After cellularencapsulation, samples were stimulated chemically for twoweeks to producemineral. (B) and (C)RepresentativeμCT images of bothGelMA andGelMA-PANi spheres after twoweeks of chemical stimulation.Mineral formation inGelMA appearedmore uniform (B,left) thanGelMA-PANi (C, left).Middle cross sections of side and top views ofGelMA showedmore continuous and directedmineralformation (B, right) thanGelMA-PANi (C, right). (D)Quantification ofμCT showsmineral deposited inGelMA samples havesignificantly higher density and occupy a greater volume thanmineral deposited inGelMA-PANi composites (n = 4; * = p < 0.05).(E)Histological staining of 5 μmsections taken frombothGelMA andGelMA-PANi samples. No significant differences were shownviaH&E and collagen 1-α-1 staining, however Alizarin Red staining indicated thatmineral depositionwithinGelMA sampleswasorganized as compared toGelMA-PANi (scale bar = 0.1 mm;white arrow represents sample edge). (F)RT-qPCR gene expression forcells withinGelMA versusGelMA-PANi 1 d post encapsulation (F, left) and 14 d after chemical stimulation (F, right). One day postencapsulation, cells withinGelMA-PANi composites showed an up-regulation in collagen 1-α-1 expression and a down-regulation inosteopontin expression as compared to cells withinGelMA samples, however gene expression normalized after 14 d of chemicalstimulation (n = 3; *= p < 0.05).

7

Biomed. Phys. Eng. Express 4 (2018) 015005 SWSawyer et al

gene expression in GelMA-PANi samples showed nosignificant differences relative toGelMA.

Printing of conductive hydrogels using digitalstereolithographyAlthough a variety of conductive hydrogels have beendeveloped, the poor mechanical properties of thesematerials do not allow for the fabrication of functionalcircuits. In this work, we used projection-basedstereolithography to print GelMA-PANi lines at amicrometer resolution in order to establish a proof-of-concept that user-defined features could be printedusing this material. A DMD (figure 4(A)) was used toprint a 500 μm thick cell-laden GelMA-PANi cross,with arms approximately 200 μm wide. Live/Deadstaining performed 24 h after printing showed highcellular viability in addition to an even cell distribution(figure 4(B)). Chemical induction for two weeksshowed mineralization along the arms of the crosswith no mineral formation in the center, presumablydue to inherent diffusion limitations (figure 4(C)).

Discussion

The application of electrical signals in tissue engineer-ing substitutes is under-explored as compared tomoretraditional biophysical and biochemical cues such asmechanical forces and growth factors. The limited

work in this field is most likely due to the challengesinvolved in developing new conductive biomaterialsthat provide a biomimetic 3D environment while stillallowing for reliable charge transfer between livingcells [38, 39]. This work develops a GelMA-PANi-cellcomposite that enables the encapsulated Saos-2 cells tobe viable within a conductive 3D environment anddeposit mineral within the matrix. Additionally, wedemonstrate that this material can be printed intouser-defined micro-geometries using a digital stereo-lithography method, a necessary first step in thesuccessful integration of conductive hydrogels intofunctional tissue regenerating devices [40, 41].

We chose GelMA as our base hydrogel, as it hasseveral advantages for use in bone tissue engineering.Not only is GelMA comprised of denatured collagen,the main organic component found in bone tissue[42], but it also retains bioactive cell-attachment siteswithin a hydrated mesh-like structure that allows foreasy cell attachment and metabolic waste exchangewith the surrounding media [43]. Additionally,GelMA can be processed into useful structures usingUV-crosslinking, an easy-to-use processing methodwhich has been shown to not cause lasting damage toencapsulated cells in short exposures [29]. Further-more, due to the relative ease with which the hydrogelcan be synthesized and cured, the addition of PANiand cells post processing make GelMA an optimal

Figure 4.Printing of conductive hydrogels. (A) Schematic of aDMDdevice used to print conductive hydrogels in specific patternsusingUV-photo-crosslinking process. (B) Live(green)/Dead(red)fluorescent image ofGelMA-PANi printed in the shape of a crossoverlaid on the corresponding brightfield image (scale bar = 0.2 mm). (C)RepresentativeμCT images of a 3DprintedGelMA-PANicross after 2weeks of chemical stimulation.

8

Biomed. Phys. Eng. Express 4 (2018) 015005 SWSawyer et al

medium for the creation of GelMA-PANi-Saos-2composites.

For cell encapsulation experiments, GelMA wasmixed with PANi and irradiated with UV light. Theamount of PANi and exposure time was chosen tomaximize the electrical conductivity within the com-posite hydrogel while at the same timemaintaining thestructural properties of GelMA. Based on the results(figures 1(E)–(G)), GelMA with 0.50 PANi providedmaximal conductive properties and maintained acompressive modulus and swelling ratio suitable forcellular encapsulation. Furthermore, no significantdifference in the viability of encapsulated Saos-2 cellsin GelMA and GelMA containing 0.50 PANi wasdemonstrated (figure 2(E)), indicating that the PANinanowires were not cytotoxic. The overall generallylow viability of encapsulated Saos-2 cells within bothtypes of hydrogels, however, could be attributed to dif-fusion limitations inherent in our comparably largerstructures, an observation that was emphasized by thelack ofmineralization in the diffusion limited center ofthe constructs (figures 3(B) and (C)). Accordingly, ithas been shown that cells are required to be within200–300 μm of a nutrient supply to function appro-priately, indicating that future studies would need toaddress this obvious limitation.

The addition of PANi appeared to decrease the abil-ity of encapsulated Saos-2 cells to spread (figure 2(D)),suggesting a possible interruption of cell attachmentdynamics. Additionally, mineral deposition was sig-nificantly affected by the presence of PANi as both thedensity and volume of mineral deposited within thecomposite matrix was significantly lower than thatdeposited in GelMA (figure 3(D)). It has been shownrecently that bone cells seeded onto softer matrices tendto deposit less mineral [44], a phenomena that lends anexplanation to the reduced deposition in our softerGelMA-PANi composites. Furthermore, after 1 d ofencapsulation, cells within GelMA-PANi hydrogels hadan up-regulation of collagen 1-α-1 expression and adown-regulation of osteopontin relative to those withinGelMA, indicating that the newly encapsulated cells inthe composites were attempting to synthesizematrix forsupport rather than producemineral. Alternatively, cellswithinGelMAhydrogels showed amore spreadmorph-ology (figure 2(D)) and produced mineral in a moreordered fashion (figures 3(C) and (E)), indicating thattheywere capablemigrating readily through the gel.

Conductive GelMA-PANi composites were alsoamenable to stereolithographic printing. Specifically,by using a DMDprinter it was possible to print lines ofGelMA-PANi containing encapsulated cells in user-defined geometries, allowing for the potential fabrica-tion of electro-active biological circuits. In future stu-dies, cell-laden conductive hydrogels could be activelystimulated with external electrical cues, potentiallyserving as a novel way for the study of how active elec-trical signals affect cellular function.

Conclusion

In this work, we successfully demonstrated a novelmethod for incorporating a conductive polymer into acell-laden, biomimetic hydrogel without compromis-ing cell viability. Furthermore, we demonstrated thatthis conductive, cell-laden hydrogel is compatible withdigital stereolithography, thereby allowing for thecreation of spatially precise, user-defined structures.While there is much work that remains to be done tomodulate cellular function, this research has devel-oped an improved electro-conductive cell ladenhydrogel for further investigation.

Acknowledgments

Thisworkwaspartially supportedby theNational ScienceFoundation (NSF) (CMMI 1634997 and 1547095). Thiswork was supported by the Soft Interfaces IntegrativeGraduate Education and Research Traineeship (IGERT)DMR-DGE- 1068780 at Syracuse University and fundedby theNational ScienceFoundation (NSF).

Author contribution

SS and PS wrote the manuscript; SS, PD, JH, and PSconceived and designed the experiments; SS and JHperformed cell studies; PD and SV synthesized poly(aniline); DQ developed the resistance test-chip forconductive analysis; AR performed data analysis andsynthesizedGelMAmacromer.

Statement of significance

Cell-laden GelMA-PANi hydrogel composites have athree-fold advantage over traditional platforms usedfor tissue engineering in that they are electricallyconductive, support cellular viability and osteogenicmineralization, and are capable of being printed inuser-definedmicroscale geometries.

ORCID iDs

Pranav Soman https://orcid.org/0000-0001-9456-0030

References

[1] KloxinAM,TibbittMWandAnsethK S 2010 Synthesis ofphotodegradable hydrogels as dynamically tunable cell cultureplatformsNat. Protocols 5 1867–87

[2] Lewis K J R andAnsethK S 2013Hydrogel scaffolds to studycell biology in four dimensionsMRSBull. 38 260–8

[3] TibbittMWandAnsethK S 2009Hydrogels as extracellularmatrixmimics for 3D cell cultureBiotechnol. Bioeng. 103655–63

[4] Hwang S J et al 2011The implications of the response ofhumanmesenchymal stromal cells in three-dimensional

9

Biomed. Phys. Eng. Express 4 (2018) 015005 SWSawyer et al

culture to electrical stimulation for tissue regenerationTissueEng.A 18 432–45

[5] Shen FH et al 2013 Implications of adipose-derived stromalcells in a 3D culture system for osteogenic differentiation: anin vitro and in vivo investigation Spine J. 13 32–43

[6] Balint R, CassidyN J andCartmell SH2014Conductivepolymers: towards a smart biomaterial for tissue engineeringActa Biomater. 10 2341–53

[7] Cao J,ManY and Li L 2013 Electrical stimuli improveosteogenic differentiationmediated by aniline pentamer andPLGAnanocompositesBiomed. Rep. 1 428–32

[8] Dvir T et al 2011Nanowired three-dimensional cardiacpatchesNat. Nanotechnol. 6 720–5

[9] Ferris C J 2009Conducting bio-materials based on gellan gumhydrogels SoftMatter 5 3430–7

[10] Gaharwar AK, PeppasNAandKhademhosseini A 2014Nanocomposite hydrogels for biomedical applicationsBiotechnol. Bioeng. 111 441–53

[11] MacDonald RA,VogeCM,KariolisM and Stegemann J P2008Carbonnanotubes increase the electrical conductivity offibroblast-seeded collagen hydrogelsActa Biomater. 4 1583–92

[12] Ahadian S et al 2014Hybrid hydrogels containing verticallyaligned carbon nanotubes with anisotropic electricalconductivity formusclemyofiber fabrication Sci. Rep. 4 4271

[13] Lamberti F, Giulitti S, GiomoMandElvassoreN2013Biosensingwith electroconductive biomimetic softmaterialsJ.Mater. Chem.B 1 5083–91

[14] Shin SR et al 2013Carbon-nanotube-embedded hydrogelsheets for engineering cardiac constructs and bioactuatorsACSNano 7 2369–80

[15] Guiseppi-Elie A 2010 Electroconductive hydrogels: synthesis,characterization and biomedical applicationsBiomaterials 312701–16

[16] GreenRA et al 2012Conductive hydrogels:mechanicallyrobust hybrids for use as biomaterialsMacromol. Biosci. 12494–501

[17] MawadD et al 2012A single component conducting polymerhydrogel as a scaffold for tissue engineeringAdv. Funct.Mater.22 2692–9

[18] HarmanDG et al 2015 Poly(3,4-ethylenedioxythiophene):dextran sulfate (PEDOT:DS)–a highly processable conductiveorganic biopolymerActa Biomater. 14 33–42

[19] DingH et al 2014 Biologically derived soft conductinghydrogels using heparin-doped polymer networksACSNano 84348–57

[20] Rivers T J, HudsonTWand Schmidt C E 2002 Synthesis of anovel, biodegradable electrically conducting polymer forbiomedical applicationsAdv. Funct.Mater. 12 33–7

[21] CaoY, SmithPandHeegerA1989Spectroscopic studiesofpolyaniline in solutionand in spin-castfilmsSynth.Met.32263–81

[22] Zhang L andWanM2003 Self‐assembly of polyaniline—fromnanotubes to hollowmicrospheresAdv. Funct.Mater. 13815–20

[23] LiM,GuoY,Wei Y,MacDiarmidAG and Lelkes P I 2006Electrospinning polyaniline-contained gelatin nanofibers fortissue engineering applicationsBiomaterials 27 2705–15

[24] Jang J,Ha J andCho J 2007 Fabrication ofwater‐dispersiblepolyaniline‐poly (4‐styrenesulfonate)nanoparticles for inkjet‐printed chemical‐sensor applicationsAdv.Mater. 19 1772–5

[25] NgamnaO,Morrin A, KillardA J,Moulton S E,SmythMR andWallaceGG2007 Inkjet printable polyanilinenanoformulations Langmuir 23 8569–74

[26] Kang E,NeohK andTanK 1998 Polyaniline: a polymerwithmany interesting intrinsic redox statesProg. Polym. Sci. 23277–324

[27] Bidez PR, Li S,MacDiarmidAG,Venancio EC,Wei Y andLelkes P I 2006 Polyaniline, an electroactive polymer, supportsadhesion and proliferation of cardiacmyoblasts J. Biomater.Sci., Polym. Ed. 17 199–212

[28] Humpolicek P, KasparkovaV, Saha P and Stejskal J 2012Biocompatibility of polyaniline Synth.Met. 162 722–7

[29] WuY et al 2016 Fabrication of conductive gelatinmethacrylate–polyaniline hydrogelsActa Biomater. 33122–30

[30] WuY,Chen YX, Yan J, Yang S, Dong P and SomanP 2015Fabrication of conductive polyaniline hydrogel using porogenleaching and projectionmicrostereolithography J.Mater.Chem.B 3 5352–60

[31] LiD andKaner RB 2006 Shape and aggregation control ofnanoparticles: not shaken, not stirred J. Am.Chem. Soc. 128968–75

[32] Huang J andKaner RB 2004Nanofiber formation in thechemical polymerization of aniline: amechanistic studyAngew. Chem. 116 5941–5

[33] ChiouN-R and Epstein A J 2005A simple approach to controlthe growth of polyaniline nanofibers Synth.Met. 153 69–72

[34] Sawyer S,OestM,Margulies B and SomanP 2016 Behavior ofencapsulated saos-2 cells within gelatinmethacrylate hydrogelsJ. Tissue Sci. Eng. 7 2

[35] Murray E, Provvedini D, CurranD,Catherwood B,SussmanH andManolagas S 1987Characterization of ahumanosteoblastic osteosarcoma cell line (SAOS‐2)withhigh bone alkaline phosphatase activity J. BoneMineral Res. 2231–8

[36] BouxseinML, Boyd SK, Christiansen BA,Guldberg R E,JepsenK J andMüller R 2010Guidelines for assessment ofbonemicrostructure in rodents usingmicro–computedtomography J. BoneMineral Res. 25 1468–86

[37] ChenYX et al 2015Anovel suspended hydrogelmembraneplatform for cell culture J. Nanotechnol. Eng.Med. 6 021002

[38] Weaver J andAstumian R1990The response of living cells tovery weak electricfields—the thermal noise limit Science 247459–62

[39] GuarinoV, Alvarez‐PerezMA, Borriello A,Napolitano T andAmbrosio L 2013Conductive PANi/PEGDAmacroporoushydrogels for nerve regenerationAdv.HealthcareMater. 2218–27

[40] Jeong J-W, ShinG, Park S I, YuK J, Xu L andRogers J A 2015Softmaterials in neuroengineering for hard problems inneuroscienceNeuron 86 175–86

[41] GreenRA et al 2013 Living electrodes: tissue engineering theneural interface Engineering inMedicine and Biology Society(EMBC), 2013 35thAnnual Int. Conf. of the IEEE (Osaka, July2013) (Piscataway, NJ: IEEE) pp 6957–60

[42] RobinsonRA1952An electron-microscopic study of thecrystalline inorganic component of bone and its relationship tothe organicmatrix J. Bone Joint Surg. Am. 34 389–476

[43] YueK, Trujillo-de SantiagoG, AlvarezMM,Tamayol A,AnnabiN andKhademhosseini A 2015 Synthesis, properties,and biomedical applications of gelatinmethacryloyl (GelMA)hydrogelsBiomaterials 73 254–71

[44] Chatterjee K et al 2010The effect of 3Dhydrogel scaffoldmodulus on osteoblast differentiation andmineralizationrevealed by combinatorial screeningBiomaterials 31 5051–62

10

Biomed. Phys. Eng. Express 4 (2018) 015005 SWSawyer et al