CONCRETE DRAWINGS - nebula.wsimg.com

Transcript of CONCRETE DRAWINGS - nebula.wsimg.com

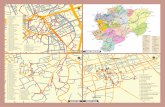

CONCRETE

DRAWINGS

G:\M

y D

rive\A

M JO

BS\1013-O

N C

avern

14 In

frastru

ctu

re\IFA

\STEEL P

KG

IFA

02-25-208\D

raw

in

g1.d

wg

, 5/2/2019 10:21:29 A

M

UP

SA

SC

S5S4

SB

S2

S3

C

B

14'-0"13'-9"

14'-0"

10'-4"

1'-10

3

4"

16

4'-0"

S 1676'-11

5

8"

E 614'-10

5

8"

6

1

8"

6"

(TYP)

2'-8"

1'-6"

±20'-3"

DET 1- - -

DET 1- - -

6"

COLD JOINT

AGAINST FACE

COLD JOINT

AGAINST FACE

±12'-0"

5"

2'-0"

6"

(TYP)

COLD JOINT AGAINST FACE

2" (CLR)

(TYP)

A- - -

A- - -

2" GAP

±3" (CLR FROM

EXISTING SHEET

METAL @ GRADE)

EAST WEST BENCH MARK LOCATION IS BACK

OF CONCRETE PEDESTAL @ COL LINE SB

6"

2'-0"

TYP

A- - -

6" O

VERLAP

1"

EDGE OF EXIST BASE PL

CO

NC

CU

RB

OR

WALL

1-#4 (L)

B=20"

O=22"

#4 CONT

DETAIL 1- - -

6"

6"

# 4 CONT

3"

FIELD TO BUSH HAMMER DOWN

1

4

" MIN,

CLEAN AND APPLY BONDING AGENT

IMMEDIATELY BEFORE POUR OF CONCRETE

2" CLR

41-#4 @ 12" & MIN 1 @ EACH END & CORNER

L=9" EA

FIELD TO DRILL

5

8

"∅ x 4

1

2

" DEEP HOLES AND

DOWEL #4 BARS USING HILTI HIT 150

SECTION(TYPICAL)

A----

#4 CONT

1-#4(W)

O=19"

B=6"

DETAIL 1- - -

(1 #4 VERTICAL

DOWEL @ EACH

CORNER)

20"

MIN

. SPLICE

N

W E

S

SPLASH PREVENTION CURB

NOTES:

1. ALL DIMENSIONS ARE CENTERED UNLESS NOTED OTHERWISE.

2. ALL CONCRETE WORK SHALL CONFORM TO THE JOB

SPECIFICATIONS, AND ACI-318 LATEST EDITION.

3. ALL CONCRETE SHALL HAVE A MINIMUM COMPRESSIVE

STRENGTH OF 4,000 PSI AT 28 DAYS.

4. ALL REINFORCING BARS SHALL BE NEW, CLEAN, GRADE 60,

BILLET-STEEL AS PER ASTM DESIGNATION A-615.

5. ALL REINFORCING BARS SHALL BE DETAILED AND PLACED AS

PER ACI MANUALS 315 AND 318 LATEST EDITION.

6. ALL EXPOSED CONCRETE AND GROUT CORNERS AND EDGES

SHALL BE CHAMFERED 3/4 " UNLESS NOTED OTHERWISE.

7. WORK THIS DWG WITH THE FOLLOWING APPLICABLE

STANDARDS & CLIENT SPECIFICATIONS:

FOR CONCRETE PACKAGE

SP-C-01 CONCRETE GENERAL NOTES & STANDARDS

SP-C-02 CONCRETE CONCRETE ABBREVIATIONS AND SYMBOLS

SP-C-03 CONCRETE ANCHOR BOLTS

SP-C-04 CONCRETE REBAR STANDARD

8. THIS DRAWING IS PART OF A SET OF

1032-KA-C-200

9. FOR BENCH MARK ELEVATION SEE THIS DRAWING.

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

A

B

C

D

E

F

G

H

I

J

K

L

M

N

AMAM Industrial Civil Structural Engineering and Design, LLC

DATE

P.O. #:

NO. REVISION DESCRIPTION BY APP.

ALIISSUED FOR APPROVALAA

REV #DRAWING NUMBERPROJECT NO.

CLIENT

CAD FILE: SCALE:

9-11-19

1032-KA-C-200 0A

1032-KA

AM

KANEKA TEXAS CORPORATION

PASADENA, TEXAS

FIRM REG # F-19357

P.O. #:

ENGINEER

DESIGNALI 2-06-14

ALI

281-570-9265 FIRM REG #F-19357

I

S

S

U

E

D

F

O

R

C

O

N

S

T

R

U

C

T

I

O

N

APICAL THINWALL PROJECT

SPILL CURB CONFINEMENT EXTENT

COLD JOINT AGAINST FACE

FIELD TO USE STYROFOAM PANEL FILLER TO

HOLD PLYWOOD FRAMEWORK IN TIGHT

SPACES AGAINST STEEL COLUMN AND EXIST

PUMP FOUNDATION TO FACILITATE EASY

REMOVAL OF FRAMEWORK WITHOUT

DAMAGE OF NEW CURB

ALIISSUED FOR CONSTRUCTIONAA

9-20-19

G:\M

y D

rive\A

M JO

BS\1032-K

A cu

rb

\IFC

\1032-K

A-C

-200 fo

r cu

rb

D

etailed

IFC

.d

wg

, 9/20/2019 1:25:09 P

M

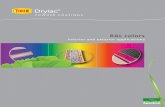

CONCRETE

STANDARDS & SPECS

G:\M

y D

rive\A

M JO

BS\1013-O

N C

avern

14 In

frastru

ctu

re\IFA

\STEEL P

KG

IFA

02-25-208\D

raw

in

g1.d

wg

, 5/2/2019 10:29:19 A

M

D.Concrete Work (continue)

5. Disposable fiber forms may be used for circular vertical form work.

6. All exposed concrete and grout corners

and edges shall be chamfered 3/4"

unless noted otherwise (See Fig. 1).

7. Construction joints between new and

hardened concrete shall be clean, free

of laitance and intentionally roughened

to a full amplitude of 1/4" inch.

8. Field probe and locate all underground

pipes, foundations, conduits and any other

obstructions before drilling or excavating

as required.

9. All underground piping, electrical grounding and duct banks shall be in

place prior to pouring foundations and paving. The method and extent

of electrical grounding shall be as shown on referenced electrical

system drawings when required.

10.Unless shown on the drawings as demolition, all existing slabs, curbs,

walls, etc. which are removed or damaged during construction, shall

be replaced. Replacement slab, etc. shall match existing grades and

construction. Re-use or match reinforcement when re-pouring and

restore concrete to existing condition and elevation.

Standard PracticeAM Industrial Civil Structural

Engineering and Design, LLC

Issued ByRelease Date Controlled Document

AM CONCRETE GENERAL NOTES AND STANDARDS

SP-C-01Page 2 of 2

Feb 2019

E. Paving

1. Before pouring paving the field shall make suitable provisions for the

installation of all underground piping and electrical grounding.

2. Careful attention shall be given to providing thickened paving as

required by the design drawings for small equipment, pipe supports,

platforms, etc.... reinforcement and anchor bolts extending into paving

shall be placed when paving is poured.

3. Concrete paving shall be protected during the early stages of

hardening from damage due to construction activities.

34"

3 4"

Exposed Concreteor Grout Corner

Fig. 1

CHAMFER DETAIL

A. Al-Mukdadi

E. Drilled Shafts

1. Each drilled pier excavation shall be inspected and approved by the

Owner's Construction Engineer before placing concrete.

2. If concrete is to be placed by tremie or pumping methods, the

concrete slump shall be 7 to 9 inches, with 3/4" maximum size

aggregate.

3. If the required straight shaft depth or bell diameter cannot be

obtained, the Owner's Construction Engineer shall be contacted for

further instructions.

4. Drilled pier construction including any casing and slurry requirements

shall be in accordance with ACI 336.1 (latest edition), and Project

Specifications.

AB Anchor BoltABT AboutALT AlternateBC Bolt CircleBCD Bolt Circle DiameterBOB Bottom Of Base PlateBOF Bottom Of FoundationBOT BottomBKT BracketBS Both SidesBTW BetweenC/C Center to CenterCHKD PL Checkered PlateCLR ClearCOL ColumnCONC ConcreteCONN ConnectionCONT ContinuationCY Cubic YardDET DetailDIA DiameterDWG DrawingEA EachEF Each FaceEJ Expansion JointEL ElevationEQ EqualEW Each WayEXIST ExistingFDN FoundationF TO F Face TO FaceFL FloorFLG FlangeFS Far SideFT FeetFTG FootingGRTG GratingHOR HorizontalHP High PointHS High StrengthID Inside DiameterIDENT IdenticalIN InchesINCL Include (Inclusive)JT JointLBS PoundsLF Long FaceLOC LocationLP Low PointMAX MaximumMIN MinimumMISC MiscellaneousMK MarkMOM MomentNO NumberNON STD Non-StandardNS Near SideNTS Not To ScaleOD Outside DiameterOPNG OpeningOPP OppositeOR Outside RadiusPCO Pile Cut OffPL PlatePLATF PlatformPOS Point Of SupportPSI Pounds per Square InchPROJ ProjectionR RadiusREF EL Reference ElevationREQ'D RequiredRNDM LG Random Length

SCH ScheduleSECT SectionSF Short Face or Square FeetSP SpaceSPEC SpecificationSQ SquareSS Stainless SteelSTD StandardSTIFF StiffenerSTL SteelSYM SymmetricalT & B Top & BottomTHK ThickTL Tangent LineTOC Top Of ConcreteTOS Top Of SteelTYP TypicalUN Unless NotedUNO Unless Noted OtherwiseVERT VerticalYD YardW/ WithWP Working PointWWF Welded Wire Fabric& And@ At℄ Centerline° DegreesØ Diameter± Plus/Minus% Percent

Symbols

Sand

Earth

Concrete

Concrete (Existing)

Grating

Grating Span

Grating (Existing)

Demo Region

Checker Plate

Checker Plate (Existing)

Welded Wire Fabric (WWF)

Welded Wire Fabric (Existing)

Hand Rail (HR)Hand Rail (Existing)

Structural Steel

Structural Rebar / Steel (Existing)

ConcreteConcrete (Existing)

Expansion Joint

Construction Joint

Control Joint

Slope Line

Center Line

Dimension Line

Cold Joint

Slope Direction

Crushed Stone

SLOPE

Standard PracticeAM Industrial Civil StructuralEngineering and Design, LLC

Issued By

Release Date Controlled DocumentAM CONCRETE ABBRIVIATIONS AND SYMBOLS

SP-C-02

Page 1 of 1

Dec 2018

Abbreviations

A. Al-Mukdadi

1. Circled numbers refer to standard hook types as

shown in the table above.

2. Dimension "0" & "B" is measured from outside to

outside of bars with fabrication tolerance of:

±1/2" for #3 to #7 bars

±1" for #8 to #11 bars

3. Bar bends, other than standard hooks shall be made

around pins of:

6 bar diameters (6d) for bar sizes #3 to #8 inclusive, and

8 bar diameters (8d) for bar sizes #9 to #11 inclusive

Rebar Symbols

Bar Types

Formulas for

total bar lengths

" K " values for bar length formulas, in. bar sizes, and theoretical weight lb/ft.

DETMK# Bar Shapes (See Note) #3

0.376

#4

0.668

#5

1.043

#6

1.502

#7

2.044

#8

2.670

#9

3.400

#10

4.303

#11

5.313

J L = O + K 5 7 9 10 12 14 16 18 20

L L = O + B - K 1 1 1 2 2 3 3 4 4

U L = O + 2B - K 2 2 3 4 4 5 7 7 8

N L = (1.66) O + K

9 11 13 - - - - - -

W L = O + 2B + K 5 6 7 - - - - - -

T L = 2(O + B) + K

4 5 6 - - - - - -

A L = 2 O² + B² + K 4 5 6 - - - - - -

C L = (3.14) O + K

12 12 15 18 21 24 27 30 33

H L = O + K 5 6 7 8 10 11 15 17 19

HH L = O + K 10 12 14 16 20 22 30 34 38

SP Detailed on Design Given on Design

- - - - - - - - -

ST By Default all straight bars cut to length have no DET MK# designation and are called

out by bar size only.

Standard Hook Details and Dimensions:

Bar

Size

#3 #4 #5 #6 #7 #8 #9 #10 #11

90

° H

oo

k

dim

en

sio

ns

lo

ng

ra

diu

s

K 5 7 9 10 12 14 16 18 20

A 6 8 10 12 14 16 19 22 24

D 2

1

4

3 3

3

4

4

1

4

5

1

4

6 9 10 11

1

4

18

0° H

oo

k

dim

en

sio

ns

K 5 6 7 8 10 11 15 17 19

A 4 4

1

2

5 6 7 8 10

1

4

11

1

4

12

3

4

D 2

1

4

3 3

3

4

4

1

4

5

1

4

6 9 10 11

1

4

90° H

ook

dimen

sions

shor

tra

dius

K 3 4 5

A 4 5 6

D 1

1

2

2 2

1

2

1O

B

O

B

O

D DD

O D+LAP2

D=0.4142

2D+LAP

3B

O

3

B

O

33

3135° MAX

O

B

OLAP

O

2

O2 2

K

AD

Dim. O

1

Approx

Dim. O

D

K

A

2

Dim. O

D

K

A3

Bar Hooks tosit on bottomrebar layer

3" C

LR

3"

Fig. 1

POUR

ED C

ONC

EL

Bar Call outBar Call out

in other direction

Number of BarsBar Size

Spacing (Eq spacedwhen omitted)

X" G

ROUT

2" CLR

2"

3"

POS

EL X

X

(PRO

J)

3 - #5 (U) @ 12"

L

Notes:

1. Details, fabrication and tagging of

reinforcement shall be in accordance

with ACI 315 Manual, latest edition,

unless shown otherwise on the

drawings.

2. Minimum lap splice of bars shall be

40 x Ø of bar unless noted otherwise on

drawing. Example:

#4 lap splice = 40 x 0.5" = 20".

W2.9xW2.9-6x6 = 12"

#3 = 15" #4 = 20" #5 = 25"

#6 = 30" #7 = 35" #8 = 40"

3. For all rectangular mats, the rebar

running in the long direction is to be

placed first for bottom steel and last for

top steel, unless a specific written

notation is made on the drawing.

4. Provide the following concrete

protective clear covering for "Main

Reinforcing", unless otherwise noted

See (Fig. 1) Below:

a. 3" for all concrete deposited directly

against the ground.

b. 2" for main vertical rebar in columns

and piers in all cases.

c. 1

1

2

" Protective clear cover for ties.

Bar Type(Default Straight Bar if omitted)

Standard PracticeAM Industrial Civil Structural

Engineering and Design, LLC

Issued ByRelease Date Controlled Document

AM CONCRETE REBAR STANDARD

SP-C-04Page 1 of 1

Sep 2019

Rebar

See Notes6 a, b, c & eEM

B

DET

MK#

Bar

Size

Drilled

Hole

Ø EMB

RD-3 #3

1

2

3

1

2

RD-4 #4

5

8

4

1

2

RD-5 #5

3

4

5

3

4

RD-6 #6

7

8

7

RD-7 #7 1 8

RD-8 #8 1

1

8

9

RD-9 #9 1

3

8

12

RD-10 #10 1

1

2

15

RD-11 #11 1

9

16

17

RD-SP

As noted on FDN dwg

(RD) Rebar Dowel

EMBED USING DET MK# (RD - 4)

EMBED USING DET MK# (RD-SP-1)# 6L = 24"DRILLED Ø = 7 8"DRILLED EMBED = 12"

List ofadditionalParametersnot in table

Callout Examples:

ADHEASIVE INSTALLATION PROCEDURE

1. Use Hilti HIT-RE 500 V3 or approved equal.

2. Care shall be taken not to cut any existing rebars while drilling. If existing

rebar is encountered, relocate hole within 2" provided that all relative

details can be modified or corrected accordingly to mach new location.

Prior approval of engineer of record is required.

3. Insure drilled hole is clean and completely dry. Insert the threaded rod or

rebar to the bottom of the hole while turning clockwise. The threaded rod

or rebar should be free of dirt, grease, oil, rust or any foreign materials. Do

not disturb or bolt-up until minimum bolt-up time has passed.

4. Follow all manufacturer recommendations.

Example of Bar Callout :

Bolt P

rojec

tedLe

nght

Adhesive Anchoring

A. Al-Mukdadi