COMPUTER INTEGRATED MANUFACTURING - … · 1.3.4 Computer-Aided Manufacturing ... 8.1 Introduction...

Transcript of COMPUTER INTEGRATED MANUFACTURING - … · 1.3.4 Computer-Aided Manufacturing ... 8.1 Introduction...

A. ALAVUDEEN • N. VENKATESHWARAN

COMPUTERINTEGRATED

MANUFACTURING

COMPUTER INTEGRATED MANUFACTURING

����������� ���������������

��������������������� ���

� ���� ������� �������������� �������������������� �����������������

���������

��� ����������������������� ���

� ���� ������� �������������� ���!�"�������������� ����#��� �

#� ����

PHI Learning Private LimitedNew Delhi-110001

2010

COMPUTER INTEGRATED MANUFACTURINGA. Alavudeen and N. Venkateshwaran

© 2008 by PHI Learning Private Limited, New Delhi. All rights reserved. No part of this book may bereproduced in any form, by mimeograph or any other means, without permission in writing from thepublisher.

ISBN-978-81-203-3345-1

The export rights of this book are vested solely with the publisher.

Second Printing … … … … January, 2010

Published by Asoke K. Ghosh, PHI Learning Private Limited, M-97, Connaught Circus,New Delhi-110001 and Printed by Jay Print Pack Private Limited, New Delhi-110015.

v

CONTENTS

Preface .........................................................................................................................................xv

Acknowledgements..................................................................................................................... xix

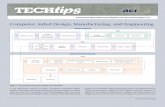

1. Introduction ................................................................................................ 1–201.1 Definitions 11.2 Basic Concepts 3

1.2.1 Nature and Role of the Elements of CIM System 51.2.2 CIM Wheel 71.2.3 Concept or Technology? 8

1.3 Evolution of CIM 81.3.1 Development of Numerical Control 91.3.2 Emergence of Computers 91.3.3 Computer-Aided Design 91.3.4 Computer-Aided Manufacturing (CAM) 101.3.5 From CAD and CAM to CAD/CAM 101.3.6 CASA/SME CIM Wheel (Background) 10

1.4 Manufacturing Automation Protocol 121.4.1 Overview 121.4.2 Problems 121.4.3 Definition 121.4.4 Physical Alternatives (Layer 1 OSI Model) 121.4.5 Data Link Layer (Layer 2 OSI Model) 131.4.6 Application Layer 13

1.5 Details for TOP 131.6 Application Layer 141.7 MAP and TOP 151.8 MAP and Other Standards 161.9 Islands of Automation 18

vi Contents

1.10 Challenges and Trends 181.10.1 Manufacturing in Transition 181.10.2 Profit and Performance 191.10.3 Productivity and Automation 19

Review Questions 20

2. Group Technology .................................................................................... 21–422.1 Introduction 212.2 Basic GT Layouts 232.3 Process (Functional) Layouts 242.4 Product Layouts (Sequential-flow; Assembly Line) 252.5 Comparison of Product and Process Layouts 262.6 Designing Process Layouts 26

2.6.1 Block Diagramming 272.7 Relationship Diagramming 292.8 Service Layouts 312.9 Designing Product Layouts 31

2.9.1 Line Balancing 312.10 Coding System 37

2.10.1 Opitz Classification System 382.10.2 The MICLASS System 38

Review Questions 41

3. Flexible Manufacturing Systems ............................................................. 43–673.1 Introduction 433.2 Dedicated Manufacturing Systems 433.3 Flexible Manufacturing Systems 43

3.3.1 Cellular Manufacturing Systems 443.4 Major Elements of FMS 47

3.4.1 Production Equipment 473.5 Materials Handling System 483.6 Problems with FMS 493.7 Enterprise Resource Planning (ERP) 493.8 Mixed-Model Assembly Lines 493.9 Cell Technology and Flexible Manufacturing Systems 51

3.9.1 Process/Production Flows and Cell Technology 513.9.2 Teams and Cells 51

3.10 Automatic Guided Vehicles (AGVs) 513.10.1 Advantages of Using AGV Systems in FMS 52

3.11 Automated Storage (AS) and Retrieval Systems (RS) 533.11.1 Buffer Storing of Parts 533.11.2 Chip Removal and Washing Stations 543.11.3 Computer Control System 55

3.12 Optimization of FMS 553.12.1 Operational Elements of a Typical Flexible Manufacturing Cell 56

Contents vii

3.12.2 Types of Data Associated with the Flexible Manufacturing Cell 573.12.3 Job Scheduling 573.12.4 Tool Requirements 583.12.5 Setting up Workplace Carrier 593.12.6 Clamping or Palletising 603.12.7 Material Flow Control 603.12.8 Machine Tool Program 613.12.9 Synchronization 613.12.10 CNC Program Supply 613.12.11 Tool Flow Control 623.12.12 Tool Changing 633.12.13 Cell Magazine Management 633.12.14 System Visualization 643.12.15 System Configuration 64

Review Questions 65

4. Shop Floor Control ................................................................................... 68–814.1 Introduction 684.2 Shop Floor Control Features 694.3 Major Displays 694.4 Major Reports 694.5 Phases of SFC 70

4.5.1 Order Release 704.5.2 Order Scheduling 714.5.3 Order Progress 72

4.6 Manufacturing Control 724.7 Methodology 744.8 Application 75

4.8.1 Simplified Manufacturing Planning and Control System 754.8.2 Inputs Manufacturing Planning and Control System 764.8.3 Manufacturing Planning Software 764.8.4 Manufacturing Control Software 764.8.5 Cost of Inadequate MPC 774.8.6 MPC System Activities 77

4.9 Shop Floor Data Collection 774.10 Types of Data Collection Systems 77

4.10.1 On-line Data Collection Systems 784.10.2 Off-line (batch) Data Collection Systems 78

4.11 Data Input Techniques 784.11.1 Centralized Terminal 784.11.2 Satellite Terminals 794.11.3 Work Centre Terminals 79

4.12 Automatic Data Collection System 794.12.1 Bar Code Technology 79

viii Contents

4.12.2 Fixed Beam Reader 804.12.3 Moving Beam Reader 80

Review Questions 80

5. Production Planning and Control ........................................................... 82–895.1 Operation Management 825.2 The Conversion Process 825.3 Where Do New Products and Services Come From? 835.4 Planning for Production 84

5.4.1 Design Planning 845.4.2 Facilities Planning and Site Selection 845.4.3 Operational Planning 85

5.5 Operations Control 865.5.1 Purchasing 865.5.2 Inventory Control 86

5.6 Scheduling 875.7 Quality Control 88Review Questions 89

6. Computer Aided Process Planning ....................................................... 90–1146.1 Automated Process Planning 906.2 Computer-Aided Process Planning 916.3 Methods of Computer-Aided Process Planning 94

6.3.1 Variant Process Planning 946.3.2 Generative Process Planning 97

6.4 Artificial Intelligence 1006.5 Implementation Considerations 1016.6 Process Planning Systems 1026.7 MRP (Material Requirements Planning) 105

6.7.1 Manufacturing Resource Planning (MRP II) 107Review Questions 114

7. JIT-Lean Production ............................................................................ 115–1427.1 History of MRP, JIT and Lean Production 115

7.1.1 Automobile Manufacturing 1167.1.2 Production Methods 116

7.2 Toyota Production System 1177.3 Just-in-Time Production 119

7.3.1 Kanban System 1197.3.2 Automation 120

7.4 Lean Manufacturing 1217.4.1 What is Lean Manufacturing? 1217.4.2 Principle of Lean 1227.4.3 Some Basic Characteristics of Lean Manufacturing 123

Contents ix

7.4.4 Value of Product 1247.4.5 Continuous Improvement 1247.4.6 Perfection 1247.4.7 Focus on Waste 1247.4.8 The Relationship of Waste to Profit 1267.4.9 Four Functions of Lean Production 1277.4.10 Production Flow 1277.4.11 Planning 1287.4.12 Performance Measures 1317.4.13 Organization 1317.4.14 The True Costs of Inventory 1317.4.15 Production Operations 1327.4.16 Operations Support 1347.4.17 The Supply Chain 1357.4.18 The Lean Enterprise 1357.4.19 Leaning Your Customers 1367.4.20 Keys to Lean Success 1377.4.21 Characteristics of Lean Manufacturing 1377.4.22 Benefits of Lean Production 1387.4.23 Applications 139

7.5 Agile Manufacturing 1397.5.1 Introduction 139

Review Questions 142

8. Open System/CIM Data Model ........................................................... 143–1608.1 Introduction 1438.2 Open Manufacturing Systems 1438.3 Modelling a Manufacturing System 145

8.3.1 Open Manufacturing Systems 1458.4 Development of Manufacturing Execution System for Machining 1468.5 Future of Open Manufacturing System Use 1468.6 Networks, Protocols and Standards 1488.7 The Intelligent Manufacturing Systems (IMS) Center 1488.8 Manufacturing Automation Protocol (MAP) Activities 1498.9 Research and Development in Manufacturing 1498.10 Computer Integrated Manufacturing/MAP 150

8.10.1 Production Engineering Capabilities 1518.10.2 Equipment Development Capabilities 151

8.11 Database in CIM 1528.11.1 Relational Databases and Object Orientation 1528.11.2 The Relatiol Data Model 1538.11.3 The Object Model 1548.11.4 Persistence Frameworks 1548.11.5 Essential Characteristics of an Object-relational Framework 155

x Contents

8.12 Common Object-Relational Services 1568.12.1 Persistence 1578.12.2 Query 1578.12.3 Transactions 1588.12.4 Concurrency 158

Review Questions 159References 159

9. NC and CNC Machines ........................................................................ 161–2089.1 Introduction 1619.2 Historical Background 1629.3 Basic Components of an NC 163

9.3.1 Program of Instruction 1639.3.2 Machine Control Unit 163

9.4 Steps in NC 1659.4.1 Process Plan 1659.4.2 Part Programming 1659.4.3 Preparation of Punched Tape 1669.4.4 Verification of Punched Tape 1669.4.5 Production 166

9.5 Verification of Numerical Control Machine Tool Programs 1169.6 Classifications of NC Machine Tools 168

9.6.1 Based on Motion Type 1699.6.2 Based on Control Loops 1699.6.3 Based on Power Supply 1709.6.4 Based on Positioning System 171

9.7 Basics of Motin Control and Feedback for NC Machines 1719.7.1 Control of NC Machines 1729.7.2 What Does ‘CNC’ Mean 173

9.8 NC Part Programming 1779.8.1 Introduction 1779.8.2 Punched Tape 178

9.9 Part Programming Methods 1859.9.1 Manual Part Programming 1859.9.2 Computer Assisted Part Programming 1889.9.3 Punched Tape Programming Format 1889.9.4 NC Part Programming 190

9.10 Modern Machining Systems: Interpolation and DNC 1979.11 Automatically Programmed Tools 1989.12 Direct Numerical Control (DNC) 201

9.12.1 Actual Arrangement of DNC 2029.12.2 Function of DNC 203

9.13 Adaptive Control 2049.13.1 Types of Adaptive Control System 204

Review Questions 207

Computer Integrated Manufacturing

Publisher : PHI Learning ISBN : 9788120333451 Author : ALAVUDEEN,A., VENKATESHWARAN, N.

Type the URL : http://www.kopykitab.com/product/7383

Get this eBook

25%OFF