Compression, Consolidation, Permeation & Flow of Ultrafine ... · Compression, Consolidation,...

Transcript of Compression, Consolidation, Permeation & Flow of Ultrafine ... · Compression, Consolidation,...

Compression, Consolidation, Permeation & Flow of Ultrafine Cohesive Powders Abbas Kamranian Marnani, Katja Mader-Arndt and Jürgen Tomas Mechanical Process Engineering, Faculty of Process and Systems Engineering, Otto von Guericke University Magdeburg

Problem Definition Objectives Cooperation

Experimental Methods

Analytical Description

DFG-Graduate School 1554 “Micro-Macro-Interactions in Structured Media and Particle Systems”

1. Process and handling problems of ultrafine, cohesive powders (d<10 µm)

Dosing & Packing Product design Conveying Transport

Macroscopic permeation and flow properties

Particle size d µm Permeability kf in m/s Force ratio FH0 /FG

10 – 100 10-7 – 10-5 1 – 100

1 – 10 10-9 – 10-7 100 – 104

0.01 – 1 10-13 – 10-9 104 – 108

2. Decreasing particle size d: decreasing pore size and permeability and increasing ratio of adhesion force/weight force

Goal: Understanding of physical particle properties at

Flow-around Approach Contact Detachment Sliding

Ultrafine, dry and adhesive particles

(1) Combination of Fluid Dynamics (CFD) and Discrete

Element Method (DEM) by PFC3D and fluid coupling

(2) Measurement of macroscopic powder properties

(compression, consolidation and permeation tests)

(3) Evaluation of the process (experiments – simulations)

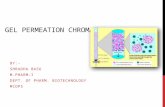

Flow & Permeation of Powders

Modeling & Simulation

L. Tobiska – U MD: Numerics of CFD-DEM

coupling

A. Kharaghani – U Magdeburg Pore network and flow

simulations

D. Thevenin – U Magdeburg (MD) Fluid Mechanics, CFD & DEM coupling

A. Bertram – U Magdeburg: Fundamentals of constitutive laws

S. Luding – U Twente: Calibration of DEM simulations

K. Mader-Arndt – U MD Model “Stiff particles with soft contacts”

1) Compression test and model-based data evaluation

New Home-built Test Rig

3) Model-based data evaluation of compression and shear work

2) Micro-macro aspects of cohesive powder consolidation and shear 5) Micro-macro aspects of

hindered powder flow

Air permeation resistance = particle flow-around drag + macroscopic powder bed

resistance (pressure drop) Macroscopic powder flow resistance in a convergent hopper = cohesive flow resistance + air permeation resistance

4) PI-flow chart and side view of compression, consolidation & permeation cell

Process Variables Hopper Discharge and Laminar Permeation through a Cohesive Powder Bridge

Differential equation of motion

Permeation resistance acc. to Molerus1

Discharge velocity-time law

Stationary discharge velocity

Characteristic discharge (relaxation) time

Velocity-displacement law

Differential equation

Displacement-time law

Discharge time Only numerically solvable

lam,76lam,76St,s

lam,76b

amin

t1

tttanh

v2)(Bg

tttanh

gdH/dp

bb1g

dt)t(dh

+

⋅

ε⋅⋅ε⋅

⋅

ρ

−−⋅

=

( ) ( )

−

⋅

+−

+

⋅

−

−

+

⋅

−

ρ

−−⋅⋅=

1t

ttanhln'bt12

11t

ttanhln'bt12

1

'bt1

tttanhln

'bt11

gdH/dp

bb1tg)t(h

lam,76lam,76lam,76lam,76

lam,76lam,7622

lam,76b

amin2lam,76

ρ

−−⋅=⋅ε⋅ε⋅

+⋅θ+

+gdH/dp

bb1gv

v)(Bgv

btan)1m(2

dtdv

b

amin

St,s

2

ε⋅⋅ε⋅

−⋅θ+

=St,slam,76

lam,st v2)(Bg

t1

tan)1m(2bv

2/1

b

amin

2

st,slam,76 g

dH/dpb

b1b

tan)1m(g2v2

)(Bgt

−

ρ

−−⋅θ+

+

ε⋅⋅ε⋅

=

lam,76lam,76St,s

lam,76b

amin

t1

tttanh

v2)(Bg

tttanh

gdH/dp

bb1g

)t(v+

⋅

ε⋅⋅ε⋅

⋅

ρ

−−⋅

=

)(BRe24

195.01

21

195.01692.01

Re24Eu

2

3

3

3

3

B ε⋅=

ε−−ε−

⋅+ε−−

ε−⋅+⋅=

1 Molerus, O., (1993). Principles of Flow in Disperse Systems. Chapman & Hall, London

Data of a very cohesive limestone powder (d50 = 1.2 µm)

[ ]

[ ]lam,76

')0(

lam,76

St,s

St,s

')0(

lam,76

St,s

b

amin

)1(

t1vlnh

btan)1m(4

)(Btgv

tanhv2

)(Bg

vlnhb

tan)1m(4)(Btg

vtanh

gdH/dp

bb1g

)h(v−

+⋅θ+⋅

ε⋅ε⋅

⋅ε⋅ε⋅

+⋅θ+

ε⋅ε⋅

⋅

ρ

−−⋅

=