Composite Materials Manufacturing Composite Materials Manufacturing 정분방.

-

Upload

brooke-dennis -

Category

Documents

-

view

318 -

download

15

Transcript of Composite Materials Manufacturing Composite Materials Manufacturing 정분방.

Composite Composite MaterialsMaterialsManufacturingManufacturing

정분방

IntroductionIntroduction Definition: a material composed of 2 or more

constituents Reinforcement (e.g., Fibers) matrix (e.g.,epoxy)

Advantages High strength and stiffness Low weight ratio Material can be designed in addition to the structure Can manufacture structures and eliminate joints

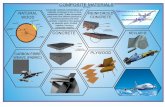

Applications

Aerospace industry Sporting goods Automotive Construction

Costs of composite manufacture

Material costs -- higher for composites Constituent materials (e.g., fibers and resin) Processing costs -- embedding fibers in matrix

Design costs -- lower for composites

Can reduce the number of parts in a complex assembly by designing the material in combination with the structure

Material Forms and Material Forms and mmanufacturinganufacturing

Objectives of material production assemble fibers impregnate resin shape product cure resin

Sheet Molding Compound (SMC)Sheet Molding Compound (SMC)

Chopped glass fiber added to polyester resin mixture

Manufacturing - Filament WindingManufacturing - Filament Winding

Highly automated low manufacturing costs if

high throughput e.g., Glass fiber pipe,

sailboard masts the only manufacturing

technique suitable for making certain specialized structures, such as pressure vessels.

Prepregs

Prepreg and prepreg layup “prepreg” - partially cured mixture of fiber and

resin Unidirectional prepreg tape with paper backing

wound on spools Cut and stacked

Curing conditions Typical temperature and pressure in autoclave is 120-

200C, 100 psi

Manufacturing - LayupsManufacturing - Layups

compressionmolding

vacuum bagging

AutoclaveAutoclave

Limitationslabor intensive, high labor cost

Advantagesgood for building prototype parts and small quantity runs

Resin transfer molding (RTM)Resin transfer molding (RTM)

Dry-fiber preform placed in a closed mold, resin injected into mold, then cured

High cost, tooling design is complex

Manufacturing - Manufacturing - PultrusionPultrusion Fiber and matrix are pulled through a die, like extrusion

of metals -- assembles fibers, impregnates the resin, shapes the product, and cures the resin in one step.

Example:Fishing rods Advantages:

simple low-cost, continuous, and automatic process.

Limitations: the axial direction, fiber angles 0°, not suit for tapered

and complex shapes

PultrusionPultrusion

Thank you