COMPARATIVE MATERIAL STUDY BETWEEN PZT CERAMIC … · Comparative material study between PZT...

Transcript of COMPARATIVE MATERIAL STUDY BETWEEN PZT CERAMIC … · Comparative material study between PZT...

1Comparative material study between PZT ceramic and newer crystalline PMN-PT and PZN-PT...

© 2010 Adva_ced Study Ce_ter Co. Ltd.

Rev.Adv.Mater.Sci. 24(2010) 1-9

Corresponding author: Ioan Alexandru Ivan, e-mail: [email protected]

COMPARATIVE MATERIAL STUDY BETWEEN PZTCERAMIC AND NEWER CRYSTALLINE PMN-PT AND

PZN-PT MATERIALS FOR COMPOSITE BIMORPHACTUATORS

Ioan Alexandru Ivan1, Micky Rakotondrabe1, Joël Agnus1, Roger Bourquin2,Nicolas Chaillet1, Philippe Lutz1, Jean-Claude Poncot3, Roland Duffait3 and

Olivier Bauer3

1Automatic Control and Micro-Mechatronic Systems (AS2M) Department, FEMTO-ST Institute, CNRS UMR 6174,UFC, ENSMM, UTBM, 24, rue Alain Savary, 25000 Besancon, France

2Time Freque_cy (TF Departme_t, FEMTO-ST I_stitute, 26, Chemi_ de ]’Epitaphe, 25000 Besa_co_, Fra_ce3Technology Development Department (DDT) of Pierre-Vernier Institute (IPV), 24 rue Alain Savary, 25000,

France

Received: July 17, 2009

Abstract. The advent of commercially available giant piezoelectric coefficient monocrystallinematerials such as PMN-PT (lead magnesium niobate - lead titanate) or PZN-PT (lead zinc niobate- lead titanate) broadens the gate for silicon-integrated applications (PiezoMEMS). Becomingmore compatible with microtechnology batch processes, further advances are expected in termsof miniaturization, optimization, functionality or integration with electronics, all while reducingmanufacturing costs. Subsequently, operating voltage will be lower and devices response timewill improve dramatically. The paper compiles a base knowledge for composite bimorph actua-tors in line with a bottom-up approach for further more complex piezoelectric device designssuch as “microrobots-o_-chip”. Materia] properties a_d co_stitutive equatio_s of piezoe]ectricbimorph cantilevers are initially overviewed. Analytical and finite elements modeling (FEM) areafterwards performed on two designs: classical PZT on copper cantilevers and innovative PMN-PT and PZN-PT on silicon. Comparative results clearly report quantitative improvement of PMN-PT on Si design in terms of tip displacement and blocking force.

1. INTRODUCTION

Piezoelectric actuators started being commerciallydesigned and manufactured about four decades ago,spreading our days into an ever increasing spec-trum of applications related to positioning and mo-tion control. An exhaustive list would be very long;he_ce we ca_ o_]y me_tio_ the actua] “tre_ds” i_the above areas:· Precision Mechanics:

Stimulation or active cancellation of vibrations;Precision tool adjustment;

Micro and nanopositioning stages;Rotary and linear piezo drives (Inch-Worm, Stick-Slip, Ultrasonic Motors);Microgrippers;Microvalves.

· Robotics:Micro/nanomanipulators;Mobile microrobots.

· Microtechnology:Microlithography;Wafer and mask alignment;

2 I.A. Ivan, M. Rakotondrabe, J. Agnus, R. Bourquin, N. Chaillet, P. Lutz, J.-C. Poncot et al.

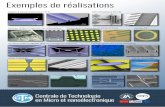

Fig. 1. Miniaturised PZT piezo cantilever (a) of6.0x0.04x0.2 mm developed at IPV/DDT. Compari-son with regular-size actuators (b).

Fig. 2. Bending piezo-cantilever and its correspond-ing axis system.

Inspection system, e.g. profilometers.· Optics, Nanometrology:

Image stabilization;Auto focus systems;Scanning mirrors;Adaptive optics;Interferometry;Scanning microscopy (AFM, STM etc.);Optic fiber alignment.

· Bio-Medical:Living cell and gene manipulation;Microdispensers;Micro- to pico-liter pumps.Piezoelectric devices can perform actuation and

micropositioning tasks with resolutions from mi-crometers down to sub-nanometer scale. Blockingforce can range from several thousand Newtons(stacked actuators) to less than microNewtons(AFM, piezocantilever, etc.). In static operation thepower consumption is extremely small while in dy-namic operation, settling time can be far under amillisecond.

PiezoMEMS actuators started to emerge forseveral years, usually made of deposited films ofAlN, BaTiO3 or PZT (Pb[Zr,Ti]O3). New single-cristalmaterials such as PMN-PT and PZN-PT providehigher piezoelectric properties, energy density andelectromechanical coupling factors. Several appli-cations were reported such as in [1,2] but they arenot yet silicon-integrated.

In this trend for functional miniaturization, IPV/DDT department recently developed a new techniquefor molecular-level bonding and lapping of piezoelec-tric layers on silicon wafer. Adhesives are eliminated

and interface mechanical strength increased. Firstattempts on composite bimorph cantilevers (Fig. 1)are promising. Dimensions were reduced from 15.0x 2.0 x 0.4 mm (central-bottom in image) to only6.0 x 0.04 x 0.2 mm. IPV is currently developing anew series of miniaturized PMN-PT micro-actuatorson silicon.

This paper presents a comparative performanceanalysis of piezocantilevers based on PMNPT, PZN-PT and PZT materials. The analysis deals with theblocking-force and the displacement at the tip ofthe cantilever according to its sizes and to the ap-plied voltage. Simulation of theoretical formulationsis compared with Finite Elements Method (FEM)results in order to obtain and discuss their perfor-mances.

The paper is organized as follows. Section 2 re-minds PMN-PT and PZT materials for possible bend-ing actuators. Then, the constituent equations of abending piezoactuator (piezocantilever) are given inSection 3. Section 4 describes the comparative re-sults of PMN-PT and PZT based piezocantilevers.Finally, section-V is dedicated to some remarks.

2. PIEZOELECTRIC MATERIALS FORBENDING CANTILEVERS

Uniaxial PZT sintered ceramics are well known instatic or resonant sensors and actuator applications.PMN-PT crystals started also being employed butespecially into ultrasonic transducers. Their poten-tial for actuator designs is yet to be fully revealed.

A comparative overview between classical PZTand newer PMN-PT piezoelectric materials is to bepresented for composite bimorph actuators (some-times referred as unimorphs in literature). We willconsider the classical rectangular blocked-freebender design where the piezoelectric plate (layer)is bonded or deposited on a passive substrate. Theaxis directions are given in Fig. 2.

These types of devices work in transverse mode,for this purpose transverse d31 piezoelectric coeffi-cient is of most importance.

3Comparative material study between PZT ceramic and newer crystalline PMN-PT and PZN-PT...

Fig. 3. FEM of PZT-5H plate stretching: original(20x20x0.2 mm) and deformed (104 times) shape.Coefficients given by Morgan Electroceramics.

Fig. 4. FEM of PMN-30PT plate poled along [001]:original and deformed shape (104 times). Coefficientstaken from [5].

Material sE111/TPa sE

331/TPa d31pm/V d33pm/V T331/ 0 k31

Soft PZTs 15-17 19-22 -140 to -280 300 to 600 1350 to 4200 0.28 to 0.48Hard PZTs 8-13 8-14 -42 to -140 130 to 475 950 to 1650 0.16 to 0.35

Table 1. Overview of typical PZT ceramic properties from several manufacturers (PI Ceramic, Morgan, APCetc.).

2.1. PZT material

About five decades ago it was discovered that thePb[ZrXTi1-X]O3 system, abbreviated PZT, possessesexploitable ferroelectric properties for compositionsaround x =0.52 where the symmetry is rather com-plex, i.e. a mixt of tetragonal, rhomboedral andmonoclinic [3]. Application of external field in PZTisotropic ceramics (temperature above 100 °C) leadsto domain alignment and important piezoelectricproperties. Symmetry of poled PZT is uniaxial, thematrix of coefficients being similar to that of a 6mmclass, represented by a number of 13 independentconstants.

Depending on doping, PZT materials are classi-fied as soft or hard. Soft PZT is mostly used foractuators and sensors while hard PZT is employedfor ultrasonic applications, exhibiting less mechani-cal losses but smaller piezoelectric coefficients.There are many types of commercially available PZTceramics, and usually manufacturers classify theirown products. Ranges of several elastic, piezoelec-tric and dielectric coefficients as well as the trans-verse coupling factor k31 (square root of ratio be-tween converted mechanical energy and input elec-trical energy for XZ directions) are depicted in theTable 1.

We will employ in simulations the soft PZT-5Hmaterial that is well known for its highest piezo-electric properties.

More recently, technological advances alloweddeposition of thin films of PZT. Several methodsbecame possible: chemical vapor deposition, sol-gel [4], screen-printing, RF magnetron sputtering orhydrothermal deposition. Very recently, epitaxialdirectly growth on silicon was also achieved. How-ever, as a rule PZT single or multilayer thin filmssignificantly possess reduced piezoelectric proper-ties relative to that of regular ceramics.

2.2. PMN-PT and PZN-PT materialsand manufacturers

In the recent years there has been an increas-ing interest in growing and characterizing of xPb(Mg1/3Nb2/3)O3–(1-x)PbTiO3 (PMN–PT [5-9] a_d ofxPb(Zn1/3Nb2/3)O3–(1-x)PbTiO3 (PZN–PT [10-12]solid solutions. Initially used as ceramic, they canbe actually grown into single crystals by modifiedBridgman or solid-state single crystal growth meth-ods [13].

These materials exhibit ultra-high piezoelectricproperties for compositions near morphotropic phase

4 I.A. Ivan, M. Rakotondrabe, J. Agnus, R. Bourquin, N. Chaillet, P. Lutz, J.-C. Poncot et al.

Material, sE111/TPa sE

331/TPa d31pm/V d32pm/V d33pm/V d15pm/V poling dir.

PMN-PT [001] 50-70 40-120 -800 to -1500 =d31 1500 to 3000 < 160PMN-PT [011] ~18 50-90 -1/3d32 -1200 to -1900 400 to 1000 1100 to 2500PMN-PT [111] N/A N/A >-250 >-250 <450 3000 to 7000

PZN-PT [001] 80-90 110-145 -950 to -1600 =d31 2000 to 2900 140-180PZN-PT [011] ~68 ~60 -1/3d32 ~-1460 ~1150 ~1800

Table 2. Overview of PMN-PT and PZN-PT properties for concentrations around morphotropic phaseboundary.

Fig. 5. FEM of PMN-29PT plate poled along [011]:original and deformed shape (104 times). Coefficientstaken from [7].

boundary which is located at x = 65% for PMN-PTand x = 91.5% for PZNPT. Finally, electrostrictiveproperties are also high [14].

Initial spontaneous polarization directions aresymmetric, external poling is therefore required to“privi]ege” certai_ directio_s i_to e_gi_eered domai_sappropriate for maximum longitudinal, transverse orshear strains. Various sets of piezoelectric elasticand dielectric matrices are provided in literature fordifferent concentrations, cuts and poling directions.

Near morphotropic phase boundary these ma-terials are in a rhomboedral symmetry of 3 mm class.Crystalline axes are referred in a pseudo-cubic sys-tem. Spontaneous polarization directions of eachdomain unit cell are along one of the eight cubicdirections <111>. External polarization along [001]axis produces a tetragonal 4 mm symmetry struc-ture, privileging longitudinal (d33) and transverse(d31=d32) extension.

Cutting and poling along [011] will lead to mac-roscopic orthorhombic 2 mm symmetry where crys-tal is highest sensitive in a single transverse direc-tion, showing a huge d32 constant (negative value).This type of symmetry is particularly interestingbecause, unlike PZT ceramics, d31 presents a posi-tive sign (see Table 2), which theoretically allowsan increased strain along axis-2 (Y-direction).

Very high longitudinal or transverse shear (d15,d24) may be obtained if poling in [111] directions (3m symmetry) but this aspect is more important forresonator designs than actuators.

Table 2 gives an order of magnitude for mostimportant elastic and piezoelectric constants sum-marized from literature [5-7,10,11] and from severalmanufacturer datasheets. Values recorded from onlyo_e refere_ce are marked with a “~” sig_.

Figs. 3-5 picture a series of FEM simulationsunder COMSOL Multiphysicsäperformed for differ-ent materials with identical geometry and orienta-tion, i.e. 20x20x0.2 mm3 in XY plane. Three PZTand PMN-PT plates are analyzed. Applied voltage

in polarization Z-direction is 10 V (EZ= –0.5kV%cm .Total displacements are depicted. Deformed shapeis magnified 10,000 times for optimal visualization.Largest transverse strain is obtained in Y-directionfor the PMN-PT plate poled along [011] plate, as inFig. 5.

As seen, PMN-PT and PZN-PT (same charac-teristics as PMN-PT) are around 3 to 5 times morepiezoelectric than PZT ceramics. However their com-pliance is higher, privileging strain to stress. Electro-mechanical coupling coefficients are very high, usu-ally ranging from 0.8 up to 0.97. Reported densityis higher than that of PZT ceramics, of around 8060-8200 kg/m3. Dielectric constants are also higher thanthat of PZT, for instance T

33 can exceed a value of7500 for certain concentrations.

Manufacturers such as TRS Technologies, JFEMineral, Morgan Electroceramics, HC Materials,

5Comparative material study between PZT ceramic and newer crystalline PMN-PT and PZN-PT...

Fig. 6. Composite bimorph cantilever.

APC International have started selling custom platesof PMN-PT especially, which is recorded to be moremechanically stable than PZN-PT. We notice thatthere is a large dispersion in material constants pro-vided by different manufacturers, explainable not onlyby various material compositions but also by pro-prietary growing processes. Manufacturers providelimited information about their materials; it is veryrare to easily find all necessary material constants.This is a reason why in Section 4 we use the com-plete sets of matrices investigated by [5,7,10,11]rather than incomplete manufacturer datasheets.

3. CONSTITUTIVE EQUATIONS FORBENDING CANTILEVERS.

In [15] J.G. Smits and W.S. Choi provided anenakemesomorph matrix E between the followingquantities for a blocked-free beam: beam rotationangle , tip displacement , displaced volume andelectrical charge Q on one side and on the otherside, a mechanical moment M, an external trans-verse force F (along z-direction, at the end of thebeam), a uniform load p and an electrical voltage Vz

as in Fig. 6.The constituent equation set applies for hetero-

geneous bimorphs, (sometimes referred asunimorphs) at thermodynamic equilibrium. Startingfrom well-known strain-charge coupled equations,the energy density is integrated and summed forthe piezoelectric and the passive element. Then thecanonical conjugates with the external quantities(voltage, momentum, etc.) are determined by par-tial derivatives, providing elements for the E matrix.

M. Weinberg [16] presented a rather differentapproach, more related to structural mechanics anddedicated for multilayer beams. Constitutive equa-tion set was extended to include axial tension/com-pression. Neutral axis is determined, then piezo-electric axial force and torque per unit voltage. Cur-vature related to different parameters is derived andconstitutive coefficients are provided. Even though

the deriving method is different than [15], simula-tions prove identical results.

[17] proposed a modeling analog to that of Smitsbut for a specific type of duo-bimorph actuators (thatallowed both in plane and out of plane displacement).In this paper we eventually adapted the generalequations from [17] to derive the transverse freetip displacement z_free for a beam of length L andwidth w:

p p

Z free zp p

d dLH H V

B s s

1 22

31 31

_ 1 21 2

1 11 11

3,

(1)

where p1 and p2 superscripts refer by convention tothe two layers: passive and piezoelectric respec-tively. ps 1

11and ps 2

11are the compliance coefficientss

at constant electric field and pd 2

31is the piezoelec-

tric coefficient ( pd 1

31= 0 in our case). Other terms

are:

p gH h h z

1 12 , (2)

p gH h h z

2 22 , (3)

p p

p p g p p g

p g p

p g p

h h h s h h h sz

h s h s h s

1 2

1 1 11 2 2 11

1 2

1 11 11 2 11

/ /1,

2 / / /

(4)

p

g g pp

p

p p p

g g p p p

g

gg

hB h h h z

s

hh zh z

s

h h h z h zh z

hh z

s

1 2

1 11

11

22 2

1 1 2

11

2 2 2

2 2 2

2 2

11

3 6 2

4 3 3

3 6 2 4 3 3

12 ,

(5)

where hp1 and hp2 are the thickness of passive andpiezoelectric layers respectively while hg is the thick-ness of the interface layer (adhesive). The latter wasneglected here for a first approximation.

If an external transverse force Fz is applied atthe end of the beam, displacement becomes:

p p

z z zp p

d dL LF H H V

B w B s s

1 23 2

31 31

1 21 2

1 1 11 11

4 3.

(6)

Blocking force Fz_blocking for zero tip displacementis used to provide information related to beam stiff-ness. For the same Vz voltage and using small dis-placements approximation we have:

z blocking z freeF B w L3

_ 1 _/ 4 . (7)

6 I.A. Ivan, M. Rakotondrabe, J. Agnus, R. Bourquin, N. Chaillet, P. Lutz, J.-C. Poncot et al.

Fig. 7. FEM evaluation of: (a) blocking force modeand (b) free tip displacement mode of a 5.0x0.3x0.14mm3 PZT on Cu actuator submitted to 80 V in thepolrization direction (-8.0 kV/cm). Deformed shapesare magnified around 50 times.

Fig. 8. Analytical comparative diagram of free tipdisplacement with respect to passive layer thick-ness for different materials. Piezoelectric layer is0.1 mm thick, length is 5 mm, width is 0.3 mm andapplied voltage 80 V.

In depicted formulae the free displacement z_free

varies with the square of the length L while blockingforce Fz_blocking varies linearly with the width w andinversely proportional with L3.

4. COMPARATIVE RESULTSBETWEEN PZT ON COPPER ANDPMN-PT ON SILICON

In this section, analytical expressions (1) and (7)are employed for free end displacement and relatedblocking force. Alternately, finite elements model-ing (FEM) results are provided (Fig. 7).

We consider the stiffness coefficients for cop-per ps 1

11=1/110x10-9 m2/N (1/110 GPa) and for sili-

con ps 1

11=1/170x10-9 m2/N. Silicon modulus of 170

GPa corresponds to [110] direction from a {100}wafer. The following five material combinations willbe modeled:· PZT-5H on Copper:

pd 2

31= -274x10-12 m/V; ps 2

11= 16.5x10-12 m2/N;

· PMN-30PT poled along [001] on Silicon [110] X-direction:

pd 2

31= -921×10-12 m/V; ps 2

11= 52x10-12 m2/N; data from

[5].· PMN-29PT poled along [011] on Silicon [110]:

pd 2

32= -1883×10-12 m/V; ps 2

22= 112×10-12 m2/N; dataa

from [7].· PZN-7PT poled along [001] on Silicon [110]:

pd 2

31= -1204×10-12 m/V; ps 2

11= 85.9x10-12 m2/N; data

from [10].· PZN-7PT poled along [011] on Silicon [110]:

pd 2

32= -1460×10-12 m/V; ps 2

22= 102x10-12 m2/N ; data

from [11].

Note: PMN-29PT [011] and PZN-7PT [011] actua-tors are oriented along Y-axis in order to fully ben-efit from d32 coefficient.

We consider an applied voltage of 80 V in thepolarization direction, knowing that maximum al-lowed electric field for PZT varies from 7 to 10 kV/cm. Geometry is L = 5.0 mm by w = 0.3 mm with afixed piezoelectric layer thickness of hp2 =100 m.Passive layer thickness hp1 is considered as vari-able and its optimum value for the given materialpairs is investigated.

As seen from Fig. 8 obtained from calculation ofEq. (1), optimal passive layer thickness for best dis-placement is 37 m for PZT-5H on Copper, 19 mfor PMN-30PT [001] on Silicon and 13 m for PMN-29PT [011] on Silicon. In the case of the PZN-7PT[001] and [011] optimal silicon thickness are 15 mand 14 m respectively. Smaller stiffness coefficientsof PMN-PT and PZT-PT than PZT favour displace-ment to blocking force (smaller blocking force gain,Fig. 9), which is an advantage for microactuatorsand micromanipulators. Maximum ratio of displace-ment gain is 3.8 for PMN-30PT [001] (actuator alongX-direction) and 8.9 in the case of PMN-29PT [011](actuator along Y-direction).

Figs. 10 and 11 respectively illustrate the ana-lytical calculation of the free displacement and ofthe blocking force according to the cantilever length.Accordi_g to o_e’s specific app]icatio_, the desig_ershould choose the appropriate length that privilegesforce or displacement. A more general illustration ofthe trade-off is shown in Fig. 12.

7Comparative material study between PZT ceramic and newer crystalline PMN-PT and PZN-PT...

Fig. 9. Comparative diagram of blocking force withrespect to passive layer thickness for different ma-terials (analytical).

Fig. 10. Free tip displacement as a function of length(analytical).

Fig. 11. Blocking force dependence on beam length(analytical).

Fig. 12. (a) Free tip displacement and (b) blockingforce dependence on silicon thickness hp1 and beamlength L. Material is PMN-30PT poled along [001]axis of 0.1 mm thick and 0.3 mm wide.

A_isotropy of si]ico_ You_g’s modu]us makesdisplacement and blocking force slightly dependingon wafer orientation. Fig. 13 shows PMN-30PTcurves for different silicon cuts. We considered ac-tuator geometry along [100], [110], and [111] direc-tions, for which related tensile modulus is 130 GPa,170 GPa, and 189 GPa respectively. A very smallimprovement is obtained for the orientation [111] forwhich correspo_di_g You_g’s modu]us is the high-est. Figs. 12a and 12b summarize actuating de-pendence on length L and passive layer thicknesshp1 for PMN-30PT.

Figs. 14 and 15 depict simulation results per-formed by FEM analysis considering the samebimorphs than previously. Results show that block-ing force obtained with FEM is similar to the ana-lytical ones. However, significant differences in termsof maximum free tip displacement which is lowerespecially for PMN-PT and PZN-PT occur. The rela-

tive difference between FEM and analytical resultsreach -37%, -69%, -50%, and -58% for PMN-30PT[001], PMN-29PT[011], PZN-7PT[001], andPZN-7PT[011] respectively. For PZT-5H the differ-ence is more acceptable, of around -18%.

Several arguments may explain these differ-ences. First, Smits and Choi [15] as well as Weinberg[16] methods treat in-plane problems where elec-tric field distribution is like that from a plane capaci-tor. The effect of mechanical strain and stress onelectric field is not taken into account. Also, ana-]ytica] methods do_’t take i_to accou_t the e]ectro-

mechanical coupling factor ( E Tk d s31 31 11 33

/ ) that

influences on electrical displacement. For PZT-5Hk31 equals 0.38 and for [001]-poled single crystals it

8 I.A. Ivan, M. Rakotondrabe, J. Agnus, R. Bourquin, N. Chaillet, P. Lutz, J.-C. Poncot et al.

Fig. 13. (a) Free tip displacement and (b) blockingforce dependence of silicon layer thickness. Tracesfor PMN-30PT poled along [001] and three silicondirections: [100], [110], and [111].

Fig. 14. Free tip displacement w.r.t passive sub-strate thickness (FEM analysis). Length is 5 mm,width is 0.3 mm and piezoelectric layer thicknessis 0.1 mm.

Fig. 15. Blocking force w.r.t passive substrate thick-ness (FEM analysis). Same dimensions as in fig-ure 14.

larger: 0.49 and 0.58 for PMN-30PT and PZN-7PTrespectively. For materials poled along [011], ho-mologue k32 factors are 0.94 and 0.86 for PMN-29PTand PZN-7PT. There is a correlation between thesecoupling factor values and differences noticed anddepicted the paragraph above. Obviously, workingexpressions (1) and (7) miss out those couplingcoefficients that over-estimate the electrical field andincrease the actual mechanical stiffness. Finally,for the analytical methods, the neutral fiber positionis fixed. However, in fact, for composite bimorphdesign and especially for high coupling factor mate-rials, the neutral fiber position is varying accordingto the applied voltage. Hence, the immediate con-sequence is the reduction of the free tip displace-ment.

Notice that in our case, the utilized width (0.3mm) is quite comparable to total thickness(0.11…0.25 mm . The a_a]ysis of such a case shou]dbe done with 3D rather than actual 2D boundaryconditions. This is why the differences betweenanalytical and FEM methods are primarily explainedby inherent simplifications of analytical model. WhileFEM method treats the coup]i_g prob]em more “rig-orous]y”, i_ 3D, the ]atera] deformatio_s are _ot take_into account by analytical methods. Hence, thereexists a curvature in the YZ cross-section of thecantilever, due to interfacial stress between piezo-electric of the silicon layers, that analytical meth-ods do not take into account.

5. FINAL REMARKS

Compared to PZT ceramics, PMN-PT and PZN-PTsingle crystal materials are around three to five timesmore piezoelectric, making actuation range increas-ing substantially, as seen in Section IV. Compara-tive results were related to a similar geometry, di-mensions and same applied voltage. Maximum ap-plicable voltage however differs. As an average,manufacturers usually restrict maximum bipolarworking fields for soft PZTs to ±8 kV/cm while PMN-PT may be drive_ betwee_ arou_d –2 kV%cm a_d+25 kV/cm (TRS Technologies). This means thatPMN-PT may be driven up to 68% more voltage thanPZT, allowing a theoretical increase of the actuat-ing range. However these values must be consid-ered informative, as we did not take into accountmaterial nonlinearities (e.g. hysteresis) or the qua-dratic electrostrictive effect that comes into place

9Comparative material study between PZT ceramic and newer crystalline PMN-PT and PZN-PT...

at high voltages. Also, significant differences werenoticed between finite element results and analyti-cal ones. As discussed in section-IV, the lattermodel should be ameliorated by taking into accountthe very high coupling factor of these materials.

As drawbacks for single crystal high piezoelec-tric coefficient PMN-PT and PZN-PT, their compli-ance coefficients are higher, implying some limita-tions in blocking force (smaller increase than thatof free displacement). For manufacturing, tensilestresses should be avoided and compressive loadslimited to a couple MPa. However these aspectsare impediments more likely for piezoelectric stackactuators rather than described composite bimorphsintended for fragile micro-objects manipulation. Othercautions to be taken into account with single crys-tals refer to a more mechanically fragile structurethan PZT and to a lower coercitive field of around2.5 to 4.5 kV/cm that limits full bipolar driving capa-bilities. Some temperature dependence is discussedin [12]. Curie temperature is lower for these singlecrystals than PZT ceramics, ranging around 150 °C.Finally, their working temperature is limited by somemanufacturers below 80-85 °C.

6. CONCLUSION

This paper has presented a comparative study ofperformances of PMN-PT and PZN-PT single crys-tals and PZT materials based piezocantilever ac-tuators. The analyzed performances concern theblocking force and the tip displacement, and for thispurpose both analytical constitutive expressions andFEM simulations were employed. A significant dif-ference between the two types of simulation wasnoticed and explained, FEM method is more reli-able for high coupling factor materials. PMN-PT andPZN-PT are three to five times more piezoelectricthan PZT. On the other hand, blocking forces forthese single crystal materials are comparable tothat of PZT. As seen, relating on specific applica-tion and geometry restrictions, there are differenttrade-offs privileging displacement range or block-ing force. The results and discussions show thatPMN-PT and PZN-PT materials are very attractivefor designing silicon integrated microactuators, pro-viding high range of displacement and high resolu-tion.

REFERENCES

[1] M. Sitti, D. Campolo, J. Yan, R.S. Fearing,T. Su, D. Taylor and T. Sands, In: Developmentof PZT and PZN-PT Based Unimorph

Actuators for Micromechanical FlappingMechanisms (IEEE Int. Conf. Robotics andAutomation, Seoul Korea, 2001), p. 3839.

[2] B. Ko and B. H. Tongue // Smart Mater.Struct. 15 (2006) 1912.

[3] A.J. Moulson and J.M. Herbert,Electroceramics: Materials, Properties,Applications 2nd Edition (John Wiley and Sons,2003).

[4] S. Muensit, P. Sukwisut, P. Khanemkeaw andS.B. Lang // Appl .Phys. A. 92 (2008) 659.

[5] R. Zhang, W. Jiang, B. Jiang and W. Cao //AIP Conf. Proc. 626 (2002) 188.

[6] H. Cao, V. H. Schmidt, R. Zhang and W. Cao// J. of Appl. Phys. 96 (2004) 549.

[7] F. Wang, L. Luo, D. Zhou, X. Zhao and H. Luo// Appl. Phys. Lett. 90 (2007) 212903.

[8] A. M. Moisin, A. I. Dumitru, I. Pasuk andG. Stoian // J. of Optoel. and. Adv. Mat. 8(2006) 555.

[9] P. Kumar, S. Sharma, O.P. Thakur, C. Prakashand T.C. Goel // Ceramics International 30(2004) 585.

[10] R. Zhang, B. Jiang and W. Cao // J. of Mat.Sci. Lett. 21 (2002) 1877.

[11] R. Zhang, B. Jiang and W. Cao // AppliedPhys. Lett. 89 (2006) 242908.

[12] L. Lebrun, G. Sebald, B. Guiffard, C. Richard,D. Guyomar and E. Pleska // Ultrasonics 42(2004) 501.

[13] Y. M. Kim, S. H. Lee, H. Y. Lee, and Y. R.Roh, In: Measurement of all the materialproperties of PMN-PT syngle crystals grownby the Solid-State-Crystal-Growth (SSCG)method (2003 IEEE Ultrasonics Symp.,2003) p. 1987.

[14] A. Hall, M. Allahverdi, E.K. Akdogan andA. Safari // Journal of Electroceramics 15(2005) 143.

[15] J.G. Smits and W.S. Choi, In: Theconstituent equations of piezoelectricheterogeneous bimorphs (IEEE UltrasonicSymposium, 1990), p. 1275.

[16] M.S. Weinberg // ASME/IEEE Journal ofMEMS 8 (1999) 71.

[17] P. De Lit, J. Agnus and N. Chaillet, In: Proc.of Int. Symp. on Assembly and TaskPlanning (France-Comte Univ., ISAPT, 2003)p. 1.