Impact of organic pig production systems on CO2 emission ...

CO2 SOLUTIONS - LENNOX...greenhouse effect. It incorporates the direct impact of refrigerant...

Transcript of CO2 SOLUTIONS - LENNOX...greenhouse effect. It incorporates the direct impact of refrigerant...

www.lennoxemea.com

CO2 SOLUTIONSTranscritical CO2 solutions

eCO2Boost Transcritical CO2 booster unit for production of low and chill temperatures for supermarkets applications

Sub-critical CO2 solutions

MULTIWAVE Sub-critical CO2 condensation unit with cascade for production of low (R134a) and chill (CO2) temperatures for supermarkets applications

eCO2Gen Sub-critical CO2 rack with cascade in medium-temperature circuit for supermarkets applications

eCO / eMR Sub-critical CO2 rack with cascade in glycol water circuit for industrial applications

TRANSCRITICAL CO2 SUB-CRITICAL CO2

ECO2BOOST - MULTIWAVE - ECO2GEN - ECO / EMR

2

Our label E SolutionsOur commitment toward green solutions

Natural fluidsReducing the impact of systems on the climateTEWI is a measurement defining the impact of a refrigeration system on the greenhouse effect. It incorporates the direct impact of refrigerant emission and the indirect impact of electricity use (CO2 emitted when power is generated).Refrigeration solutions that use natural fluids have come into their own since the European Union committed to reducing greenhouse emissions by 20% in the coming years.Large-scale food distributors have decided to reduce their carbon footprints. Nowadays, refrigeration accounts for up to 50% of energy use in stores.

Environment"Life Cycle Cost Performance"• Designing refrigeration systems whose performance in terms of climate

change is optimised throughout their life cycle > less CO2 (R744) refrigerant is required and it is less expensive.

• Preparing for end-of-life recycling: CO2 (R744) is not subject to any legislation in terms of elimination or recovery > by choosing natural CO2 fluid (R744) it is possible to pre-empt tax issues relating to refrigerants (abolition of HFCs in 2015).

Energy efficiencyOptimising energy consumption • Energy consumption can be reduced by up to 20% with a CO2 (R744)

system with cascade in a medium-temperature circuit.

CO2 - GREEN COOLING SOLUTIONS

CO2 (R744) A natural refrigerant for the production of coldNew regulations aimed at reducing greenhouse gases and protecting the environment are prompting manufacturers to develop new technologies and use new refrigerants with low global warming potential. CO2, whose global warming potential is on average 3,800 times lower than R404A, is therefore increasingly being used for refrigeration.

Services and ExpertiseAn entire team at your disposal!We provide you with our expertise to help you set up your CO2 (R744) systems

Training on commissioning CO2 (R744) equipment• Description of how the CO2 (R744) unit and its various components

operate.• Training on the principle of regulation.• Performing the system load and start-up procedure.• Performing an assessment of the system.

On-site audit and advice • General operating principle of a CO2 rack.• Inspecting the regulation system in place and addressing the various

specific features of this type of installation.

CO2 increases the efficiency of systems• High theoretical coefficient of performance

(COP) for lower condensation temperatures than the critical temperature for CO2.

• High heat transfer coefficients during evaporation and condensation (up to 60% higher than with HFCs).

• Highly compatible with standard materials and refrigerator oils.

A range tailored to your new or remodelling projects • Production of low temperatures • Production of chill temperatures • An electrical and control cabinet• A support package: training, on-site

audits and technical advice

Refrigeration equipment selection softwareThis software is used to size the entire system (chill temperature CO2 rack, low temperature unit and options) and access technical data.

Pressure Equipment Directive

Our compressorized products are compliant with EU Directive 97/23/EC

A summary of benefits:• Non-toxic and non-flammable • Not subject to legislation on fluorinated fluids• No decline in food quality • No load limit• Inexpensive • 1,300 to 4,000 times less impact on the climate than HFC-type

refrigerants (CO2 (R744) Global Warning Potential =1) • Compact systems: due to the physical properties of CO2, all components

(compressor, piping, valve, etc.) are more compact than in conventional refrigerant-based systems.

3

'Transcritical' technologyThe defining feature of transcritical CO2 technology is that it is impossible to condense CO2 on the high-pressure side of the refrigerating circuit if its temperature exceeds 31°C (approximately 72 bar). Our technology adapts particularly well to this constraint and optimises the performance of systems including in regions where ambient temperatures are relatively high.

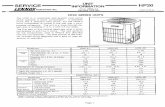

eCO2BoostCO2 booster unit incorporating production of: - Chill temperatures : 70 > 250 kW - Low temperatures : 15 > 100 kW

ECO2BOOST - THE TRANSCRITICAL CO2 SOLUTION FOR SUPERMARKETS

3C-ACubic unit cooler

1 > 35 KW

eCO2Boost Transcritical CO2 booster rack

The eCO2Boost transcritical system is a booster rack enabling all low and chill temperature requirements to be covered with CO2. The booster configuration allows to optimise the way the system runs by stepping compression which improves operating conditions of the compressors.eCO2Boost is designed based on a single frame that includes all low and chill temperature compression assemblies, the liquid receiverand all refrigerating and control components that enable this type of system to operate (high-pressure control, heat exchanger control, oil management, etc.). eCO2Boost can also accommodate heat exchangers to recover heat for sanitary hot water and heating.In slightly warmer climates, the efficiency of the eCO2Boost transcritical system can be optimised using parallel compression or external subcooler solutions.Our service also includes a gas cooler which cools CO2 under high pressure.

GAS COOLER

4

MULTIWAVE Encased condensation unit• An innovatively designed range for installations where space may be a problem.• Environmentally-friendly, natural refrigerant (CO2) for refrigeration in supermarkets.• "Ready-to-use" range with refrigeration and electrical equipment grouped and connected on a single frame.• Low energy consumption thanks to EC motors, compressor speed variation and heat recovery (optional extras).• Microchannel technology allowing a significant reduction of refrigerant charge.• State of the art design with hidden fans for a perfect architectural integration.

'Sub-critical' technologyCO2 condenses below 31°C (critical point). Sub-critical applications or cascade refrigerating systems are projects in which a cascade system is created where CO2 is condensed either by a heat transfer liquid (e.g. glycol water) or a refrigerant whose characteristics enable condensation to occur in line with external temperature conditions: NH3, hydrocarbon (propane), HFC (R404A or R 134a).

MULTIWAVE - THE SUB-CRITICAL CO2 SOLUTION FOR SUPERMARKETS

MULTIWAVEPackaged encased CO2 unit for production of low and chill temperatures23 > 200 kW

3C-ACubic unit cooler

1 > 35 KW

5

eCO2Gen Installation in a machine roomeCO2Gen operates in cascade with chilled water production enabling HFCs to be increasingly confined to a machine room. A cascaded configuration in a glycol water loop is beneficial as it offers flexible control and thermal inertia.The eCO2Gen range is designed based on a shared frame where the various CO2 compression and condensation assemblies and liquid receiver are grouped and interconnected. These different sub-assemblies include all the special equipment for this type of technology that enables a system to function properly.Our service also includes the supply of all components needed to fit a store including:• A low temperature rack.• A Eurovent-certified air-cooled condenser.• All safety and control elements.

A range of compressor racks operating with CO2

• Chill temperature• Sub-critical operation• Cooling capacity of 18 to 80 kW• CO2 (R744) system with cascade in a medium-temperature circuit: - Glycol water as heat transfer liquid - or direct expansion R404A/R134a

10 models as standard, 3 or 4 compressors

Cooling capacity in kW (-35°C / -5°C)

Feuille1

Page 1

17 22,7 23,3 29,7 31,1 37,3 39,6 49,7

eCO2gen 18/3 eCO2gen 24/4 eCO2gen 25/3 ECO2gen 32/3 ECO2gen 33/4 ECO2gen 40/3 ECO2gen 42/4 ECO2gen 53/4

eCO2Gen 18/3

eCO2Gen 24/4

eCO2Gen 25/3

eCO2Gen 32/3

eCO2Gen 33/4

eCO2Gen 40/3

eCO2Gen 42/4

eCO2Gen 53/4

eCO2Gen 60/3

eCO2Gen 80/4

0 10 20 30 40 50 60 70 80

ECO2GEN - THE SUB-CRITICAL CO2 SOLUTION FOR SUPERMARKETS

Low temperature production• Production of chill temperatureseCO2Gen CO2 (R744) low temperature rack

18 > 80 kW

MXWAxial fan condenser with microchannel coil technology50 > 1660 kW

MOPSHLow temperature rack with glycol water

heat exchanger or in direct expansionsemi-hermetic piston compressors

150 > 400 kW

PEGLow temperature rack with glycol water heat exchanger semi-hermetic screw compressors300 > 700 kW

3C-ACubic unit cooler

1 > 35 KW

6

MXWAxial fan condenser with microchannel coil technology50 > 1660 kW

eCO / eMR A complete CO2 solution for industrial applications

ECO/EMR - THE SUB-CRITICAL CO2 SOLUTION FOR INDUSTRIAL COOLING

PEGChilled water production300 > 760 kW• Cooling capacity: - 290 to 780 kW (glycol water -4°C/-8°C / +45°C condensation temperature)

- 280 to 690 kW (glycol water -5°C/-9ºC / +45°C condensation temperature) • Refrigerant charge confined.• 1, 2 or 3 separate refrigerating circuits. • Up to three levels of capacity steps : 100%/75%/50%.• Electronic expansion valves with controller, probes, sensors and solenoid valve.

eCO / eMRSub-critical CO2 chill temperature rack108 > 341 kW

• CO2 racks with condensation in a glycol water circuit that are both reliable and compact

• Cooling capacity: 108 to 341 kW (-35/-3°C; glycol water at -8/-4°C)

• Two versions available: eCO = encased outdoor eMR = machine room

• Heat recovery for producing hot glycol water at a temperature of 40/50°C

eCO/eMR options

DES Braze plate desuperheaterGMP Safety group (MINI unit delivered mounted and connected)2CD 2 x 50/50% condensers PC1 Rack pre-wired with 5 m cable availablePEI Painted frameMPI Injected polyurethane foam insulationVAR Head compressor speed variator

A comprehensive range designed to meet the demands of current markets:• Natural fluids and reduced refrigerant charge• Energy efficient• Compact • Quiet equipment

0

1000

2000

3000

4000

5000

6000

0 1 2 3 4 5

Produit standard Produit avec accessoires de dégivrage

Produit avec manchette souple uniquement

Tem

ps d

e dé

givr

age

Configurations :

Performance des solutions de dégivrage

Dégivrage électriqueDégivrage imbriqué glycol chaud T 20°C

Référenciel

Tempsdivisé

par 2,5

Conditions d'ambiance : ‐25°C / HR 90% QVEG = 2,5 m3/h

0

1000

2000

3000

4000

5000

6000

0 1 2 3 4 5

Coût

total

de pr

oprié

té (€

)

Années

Dégivrage eau glycol chaud Dégivrage électrique Dég. életrique avec accessoires de dégivrage

Données : Nombre d'appareil = 1 - Puissance de dégivrage électrique = 13200W - Nb cycle dégivrage quotidien = 4Temps de dégivrage électrique = 30 mn - Temps de dégivrage électrique avec accessoires = 12 mnPuissance absorbée pompe = 480 W - Prix kWh = 0,12€ - Coût total de propriété = coût d'acquisition + coût d'opération

Comparatif économique des solutions de dégivrage

0

500

1000

1500

2000

2500

3000

3500

4000

4500

5000

40 60 80 100 120 140 160

0-10V

7

MXWAxial fan condenser with microchannel coil technology50 > 1660 kW

NKIndustrial cubic unit cooler7 > 130 kW

EC motor regulation principle

• Range available in tow versions : NKT: large heat exchange surface suitable for humidity-sensitive products. NKH: High efficiency suitable for storage of packaged products.

• High-performance defrosting systems for chill temperature applications.

ECO/EMR - THE SUB-CRITICAL CO2 SOLUTION FOR INDUSTRIAL COOLING

GTAIndustrial dual discharge evaporator20 > 82 kW

• High level of acoustic comfort.• Low air speed• Easy access for commissioning and maintenance• EC motors (option).

• High power density and reduced refrigerant charge by using microchannels.• Up to 75% reduction in refrigerant charge.• Coils arranged in a "W" shape to optimise floor space.• The architecture enables independent control of several compression racks on the

same device.

Performance of defrosting solutions

Defro

stin

g tim

e

Tota

l cos

t of o

wner

ship

(€)

Hot glycol water defrosting

Years

Electrical defrosting Electrical defrosting with defrosting accessories

Data :Number of devices 1 - Electrical defrosting capacity 13200 W No. of defrosting cycles per day 4 Electrical defrosting time 30 mins – Electrical defrosting time with accessories 12 mins Pump absorbed power 480 W - Price kW/h 0.12€ Total cost of ownership – cost of acquisition + operating cost

Standard product Product with defrosting accessories

Time divided by 2.5

Hot glycol defrost T 20°CElectrical defrosting

Ambient conditions : -25°C / HR 90% / QVeg = 2,5 m3/h

Product with flexible sleeve only

Economic comparison of defrosting solutions

Energy comparison of heat exchanger technologies

Capacity (KW)

Actu

al a

bsor

bed

powe

r (W

)

Copper tube/aluminium fin coil Microchannel coil

Pressure drop on air reduced by 30% to 40%

www.lennoxemea.com

FRANCE42, rue Roger Salengro - BP 205 - 69741 Genas Cedex - FranceTel.: +33 (0) 472 471 444 - Fax: +33 (0) 472 471 [email protected]__________

GERMANYGothaer Straße 15 - 40880 Ratingen - DeutschlandTel.: +49 (0) 211 950 79 600 - Fax: +49 (0) 211 950 79 [email protected]__________

SPAINAvenida Meridiana, n°354, planta 12 - 08027 Barcelona - EspañaTel.: +34 93 573 76 20 - Fax: +34 93 573 76 [email protected]__________

PORTUGALCentro Empresarial da Lionesa - Rua da Lionesa, 446 Ed. G21 4465-671 Leça do Balio - PortugalTel.: +351 229 066 050 - Fax: +351 229 066 [email protected]__________

POLANDUl. Wybrzeże Gdyńskie 6A - 01-563 Warszawa - PolskaTel.: +48 22 58 48 610 - Fax: +48 22 58 48 [email protected]__________

RUSSIAUl. Staroalexeevskaja Dom 5, Office 262 - 129 626 Moscow - RussiaTel +7 495 504 08 [email protected]__________

OTHER COUNTRIES42, rue Roger Salengro - BP 205 - 69741 Genas Cedex - FranceTel.: +33 (0) 472 471 444 - Fax: +33 (0) 472 471 [email protected]

Lenn

ox E

MEA

rese

rves

the

right

to m

ake

any

chan

ges

with

out p

rovi

ding

not

ice

- Non

con

trac

tual

pic

ture

s - 0

7/16