CMA Complex Metallic Alloys · industrial applications VIU-IT Karl Hoehener 4 Complex Metallic...

Transcript of CMA Complex Metallic Alloys · industrial applications VIU-IT Karl Hoehener 4 Complex Metallic...

The potential of CMA for industrial applications

1VIU-IT Karl Hoehener

CMA Complex Metallic Alloys

The route to industrial applications

The potential of CMA for industrial applications

2VIU-IT Karl Hoehener

Agenda

1. The network of excellence (NoE)Complex Metallic Alloys (CMA)

2. Potential for industrial applications

3. The combined expertise of the CMA Laboratories (VIL)

4. Maturity of the CMA technologies

5. Collaboration with industry

6. Euroschool, continuous education and specific training for industry

7. Next steps

The potential of CMA for industrial applications

3VIU-IT Karl Hoehener

The NoE Complex Metallic Alloys (CMA)

The CMA Network of Excellence

Università degli Studi di Torinowww.unito.it

Universitad Autonoma de Madrid

www.uam.es

The University of Liverpoolwww.liverpool.ac.uk

Katholieke Universiteit Leuven

www.kuleuven.be

Centre de Recherche Public Henri Tudor

www.tudor.lu

Eidgenössische Technische Hochschule Zürich

www.ethz.ch

EMPA, Swiss Federal Lab for Materials Testing

and Researchwww.empa.ch

Jozef Stefan Institute, Ljubljana

www.ijs.si

Technische Universität Wienwww.tuwien.at

AGH University of Science and Technology

www.agh.edu.pl

Koszalin University of Technical

www.tu.koszalin.pl

Royal Institute of Technologywww.kth.se

Forschungs-zentrum Jülich

www.fz-juelich.de

Johann Wolfgang Goethe-Universität

www.uni-frankfurt.de

Universität Stuttgartwww.uni-stuttgart.de

Technische Universität Darmstadt

www.tu-darmstadt.de

Max Planck Gesellschaftwww.mpg.de

DresdenBerlin

Ludwig-Maximilians-Universität München

www.uni-muenchen.de

Grenoble Vitry-Thiais

Nancy

Marseille

Toulouse

Centre National de la Recherche Scientifique

www.cnrs.fr

Paris

The potential of CMA for industrial applications

4VIU-IT Karl Hoehener

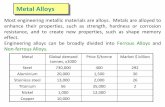

Complex Metallic Alloys (CMA)

Complex Metallic Alloys: New metallic materials!Today: Metals-based industries today rely

largely on materials based on elementary metals and binary metallic alloys to which a number of additional elements are added in smaller quantities to tailor them for particular properties.

CMAs: Complex metallic alloys are formed with crystal structures based on giant unit cells containing many tens, up to more than a thousand atoms per cell. As a result, these materials can offer unique combinations of properties, which are excluded in conventional materials.

Dr. J.-M. [email protected]

The potential of CMA for industrial applications

5VIU-IT Karl Hoehener

Agenda

1. The network of excellence (NoE)Complex Metallic Alloys (CMA)

2. Potential for industrial applications

3. The combined expertise of the CMA Laboratories (VIL)

4. Maturity of the CMA technologies

5. Collaboration with industry

6. Euroschool, continuous education and specific training for industry

7. Next steps

The potential of CMA for industrial applications

6VIU-IT Karl Hoehener

Potential for industrial applications

Other applications

Applications where high temperature stability is requiredMetallic and polymer-based materials reinforced by precipitates or dispersions of nanoparticles of the CMA familyCatalysisMagnetic applicationsOptical applications

Other applications

Applications where high temperature stability is requiredMetallic and polymer-based materials reinforced by precipitates or dispersions of nanoparticles of the CMA familyCatalysisMagnetic applicationsOptical applications

CMA Applications in IndustryCMA Applications in Industry

Energy applications

Heat insulationsThermoelectric applicationsHydrogen storage

Energy applications

Heat insulationsThermoelectric applicationsHydrogen storage

Coating applications

Tribological applicationsCold welding reductionAbrasion reductionWetting adaptationCorrosion protectionNanostructuredmaterials

Coating applications

Tribological applicationsCold welding reductionAbrasion reductionWetting adaptationCorrosion protectionNanostructuredmaterials

The potential of CMA for industrial applications

7VIU-IT Karl Hoehener

Potential for industrial applications

CMA Applications in IndustryCMA Applications in Industry

Energy applications

Heat insulationsThermoelectric applicationsHydrogen storage

Energy applications

Heat insulationsThermoelectric applicationsHydrogen storage

Coating applications

Tribological applicationsCold welding reductionAbrasion reductionWetting adaptationCorrosion protectionNanostructuredmaterials

Coating applications

Tribological applicationsCold welding reductionAbrasion reductionWetting adaptationCorrosion protectionNanostructuredmaterials

Other applications

Applications where high temperature stability is requiredMetallic and polymer-based materials reinforced by precipitates or dispersions of nanoparticles of the CMA familyCatalysisMagnetic applicationsOptical applications

Other applications

Applications where high temperature stability is requiredMetallic and polymer-based materials reinforced by precipitates or dispersions of nanoparticles of the CMA familyCatalysisMagnetic applicationsOptical applications

Thermoelectric application:• Temperature range: 600 – 800 K• Materials: clathrate compounds

Ba8NixGe46-x as well as for the filled skutterudites Pr(Fe,Ni)4Sb12 and MM(Fe,Ni)4Sb12 where MM stands for mischmetall.

• ZT (figure of merit) > 1.4

The potential of CMA for industrial applications

8VIU-IT Karl Hoehener

Potential for industrial applications

Other applications

Applications where high temperature stability is requiredMetallic and polymer-based materials reinforced by precipitates or dispersions of nanoparticles of the CMA familyCatalysisMagnetic applicationsOptical applications

Other applications

Applications where high temperature stability is requiredMetallic and polymer-based materials reinforced by precipitates or dispersions of nanoparticles of the CMA familyCatalysisMagnetic applicationsOptical applications

CMA Applications in IndustryCMA Applications in Industry

Energy applications

Heat insulationsThermoelectric applicationsHydrogen storage

Energy applications

Heat insulationsThermoelectric applicationsHydrogen storage

Coating applications

Tribological applicationsCold welding reductionAbrasion reductionWetting adaptationCorrosion protectionNanostructuredmaterials

Coating applications

Tribological applicationsCold welding reductionAbrasion reductionWetting adaptationCorrosion protectionNanostructuredmaterials

Nanostructured metal matrix-CMA composites exhibiting low friction on sliding against hardened steel in ambient air

The potential of CMA for industrial applications

9VIU-IT Karl Hoehener

Potential for industrial applications

CMA Applications in IndustryCMA Applications in Industry

Energy applications

Heat insulationsThermoelectric applicationsHydrogen storage

Energy applications

Heat insulationsThermoelectric applicationsHydrogen storage

Coating applications

Tribological applicationsCold welding reductionAbrasion reductionWetting adaptationCorrosion protectionNanostructuredmaterials

Coating applications

Tribological applicationsCold welding reductionAbrasion reductionWetting adaptationCorrosion protectionNanostructuredmaterials

Other applications

Applications where high temperature stability is requiredMetallic and polymer-based materials reinforced by precipitates or dispersions of nanoparticles of the CMA familyCatalysisMagnetic applicationsOptical applications

Other applications

Applications where high temperature stability is requiredMetallic and polymer-based materials reinforced by precipitates or dispersions of nanoparticles of the CMA familyCatalysisMagnetic applicationsOptical applications

Hydrogen storage in CMAs based on the intergrowth of CaCu5 and Laves phase structure types to combine high storage capacity with improved corrosion resistivity.

The potential of CMA for industrial applications

10VIU-IT Karl Hoehener

Agenda

1. The network of excellence (NoE)Complex Metallic Alloys (CMA)

2. Potential for industrial applications

3. The combined expertise of the CMA Laboratories (VIL)

4. Maturity of the CMA technologies

5. Collaboration with industry

6. Euroschool, continuous education and specific training for industry

7. Next steps

The potential of CMA for industrial applications

11VIU-IT Karl Hoehener

The combined expertise of the CMA Laboratories (VIL)

Offers to Industry

Materials Designand Synthesis

Structuresand Defects

PhysicalProperties

Surface, Physics,Chemistry,

NanosciencesVIL-D

TechnologicalApplication

Advanced CoatingsTechnology

- Provision of wellcharacterized, specific high-quality samples• Equilibrium

Thermo-dynamics

• Melt Spinning

- Development of novel CMA materials

- Process technology on a pilot scale

Characterization of materials (composition, structure, micro-structure, phase diagrams) for:

- incoming materials control

- process optimisation

- behaviour during use

- Measurements of mechanical, electrical, dynamical properties of existing and newmaterials

- Numerical atomisticsimulation

- Improvement of industrial measurementmethods

- Surface propertiesanalysis: corrosion,friction, oxidation,cohesion

- Understanding ofmechanisms leading to specific knowledge forindustrial problemsolution

- Implementation of coating processes on machines

- Know-how, techniquesand tools for processing of metallic coatings and thin films (wetting, oxidation, corrosion, friction)

- Handling of engineeringaspects

- Analysis of extrinsicproperties and systemsrequirements

- Expertise in bulk materials and coatings

The potential of CMA for industrial applications

12VIU-IT Karl Hoehener

Agenda

1. The network of excellence (NoE)Complex Metallic Alloys (CMA)

2. Potential for industrial applications

3. The combined expertise of the CMA Laboratories (VIL)

4. Maturity of the CMA technologies

5. Collaboration with industry

6. Euroschool, continuous education and specific training for industry

7. Next steps

The potential of CMA for industrial applications

13VIU-IT Karl Hoehener

Maturity of the CMA technologies

CMA applications are in an early stage

Industry has the opportunity to collaborate at an early stage with outstanding experts on mid and long term requirement

Invention leader

Innovation leader

Basicresearch

Early followerLate follower

Mat

urity

Time

Dominant design

Invention leader

Innovation leader

Basicresearch

Early followerLate follower

Mat

urity

Time

Dominant design

CMAs today

The potential of CMA for industrial applications

14VIU-IT Karl Hoehener

Productdevelopment

Productdevelopment

1 2 3 4 6 7

Technologydevelopment

AppliedR&D

Applicationand

productdevelopment

New products (radical innovations)

New functionalities and requirements of the market (incremental innovations)

Utilization of existing knowledge

Basicresearch

New knowledge

Project durationin years

Knowledge

Proof of PrinciplesFeasibility

studies

Proof of PrinciplesFeasibility

studies

Confidence, the Success Factor 1

Maturity of the CMA technologies

The potential of CMA for industrial applications

15VIU-IT Karl Hoehener

Agenda

1. The network of excellence (NoE)Complex Metallic Alloys (CMA)

2. Potential for industrial applications

3. The combined expertise of the CMA Laboratories (VIL)

4. Maturity of the CMA technologies

5. Collaboration with industry

6. Euroschool, continuous education and specific training for industry

7. Next steps

The potential of CMA for industrial applications

16VIU-IT Karl Hoehener

Collaboration with industry

How to collaborate

Common projects Science-Industry:Analytics of complex problems whereCMA-knowledge and applicationsmay have a high potentialSpecification of mid and long termrequirements, definition of strategies to reach common objectivesProof of principlesFeasibility studiesStrategic Projects

new

new

new

Applications

Sci

entif

ic F

indi

ngs

CMAProject with

Industry

Techn

ologie

s

new

new

new

Applications

Sci

entif

ic F

indi

ngs

CMAProject with

Industry

CMAProject with

Industry

Techn

ologie

s

The potential of CMA for industrial applications

17VIU-IT Karl Hoehener

Collaboration with industry

The Method

Customer Value

Functions

Technologies

Competence-Centers

Science, Research

PUSHKTT

Knowledgeand

TechnologyTransfer

and Offersfrom the Science

community

PULLKTD

Knowledge andTechnology

Demand fromEnterprises

KTT/Dof the future?

Private-Public-Partnership!

IDEA

Marketenterprises

KTT Knowledge and Technology TransferKTD Knowledge and Technology Demand

The potential of CMA for industrial applications

18VIU-IT Karl Hoehener

Collaboration with industry

CMA the Road to Collaborations

Demands ofIndustry

Offersfrom Science

Matching, Clustering of Topics

ThematicRoad Map

Proposals for Collaborations

Partnering ofInstitutions

Proof ofPrinciples

FeasibilityStudies

IndividualProjects

AllianceProjects

CMA PUSH Application PULL

The potential of CMA for industrial applications

19VIU-IT Karl Hoehener

Collaboration with industry

Outline of CMA Thematic Road Maps

BasicFindings Needed

Findings

FutureApplication

Functionality

NeededProcesses

FutureApplication

Functionality

NeededTechnology

BasicFindings

BasicFindings

BasicFindings

Basic Research(Intrinsic properties)

Technology- & process-development

(Extrinsic and systemproperties)

Applications (System requirements)

CMA PUSH ApplicationPULL

Time Axis

The potential of CMA for industrial applications

20VIU-IT Karl Hoehener

Roadmap Bulk Intermetallic Phases On Demand Working Draft

Industrial Application

MaterialProduction

Facilities / instruments / measurement methods:

• X-ray powder diffraction (10 K – 3000 K)• X-ray Laue technique• Differential Thermo-Analysis DTA• Thermo-Gravimetric-Analysis TG• Optical microscopy• Ultrasound microscopy• Scanning Electr. Microscopy SEM

equipped with EDX, WDX

Material area of expertise:• Metals• Intermetallic compounds• Quasicrystals, CMA• Binary and Ternary Oxides, Halogenides

Properties to be analysed:• Phase composition• Homogeneity• Crystal Orientation (if single crystal)• Thermodynamic Properties (Phase

diagrammes)

Deliverables:• Phase diagrammes• Material analysis• Optimized preparation techniques for

selected phases

Facilities:• See Mat. Production

Services for industry:• Melting techniques for

selected materials, e.g. NiTi, Al-Ti-Mg-compounds

Scope of cooperation:• Common interest: Basic

research up to production optimization, e.g. large size crystal growth techniques

Deliverables:• Optimized process

technology, e.g. for production of sputter targets

Process DevelopmentMaterial Analysis

Application fields foreseen:• A• B• ...

Complementary information about demands to be provided by industry:• X• Y• ...

Deliverables:• Transfer of process

know-how• ...

Facilities:• Preparation of metals without air contact in large

glove boxes• Electrical furnaces (max. 1800°C)• High frequency heated furnaces (max. 2800°C)• Laser-Zone-Melting (1400°C)• Electron-Beam Melting (1800°C)• Melt Spinning• Argon-Arc-Melting• Crucible or quasi crucible free melt techniques• Growth methods for single crystals by different

techniques: Czochralski, Bridgman, Zone-melting, Flux-growth

Material area of expertise:• Pure metals• Intermetallic compounds and alloys• Complex metallic alloys• Quasicrystals• Oxides and others

Produceable amounts of alloys:• Limitation of max 30-50g/batch

Resolution of weight or volume percentage of metals in alloys:• Homogenization by melting and stirring• Change of physical properties by adding of

small amounts of other elements (below 1%)

Deliverables:• Material in single and polycrystalline form

The potential of CMA for industrial applications

21VIU-IT Karl Hoehener

Roadmap Bulk Intermetallic Phases On Demand Working Draft

Facilities:• Preparation of metals without air contact in large

glove boxes• Electrical furnaces (max. 1800°C)• High frequency heated furnaces (max. 2800°C)• Laser-Zone-Melting (1400°C)• Electron-Beam Melting (1800°C)• Melt Spinning• Argon-Arc-Melting• Crucible or quasi crucible free melt techniques• Growth methods for single crystals by different

techniques: Czochralski, Bridgman, Zone-melting, Flux-growth

Material area of expertise:• Pure metals• Intermetallic compounds and alloys• Complex metallic alloys• Quasicrystals• Oxides and others

Produceable amounts of alloys:• Limitation of max 30-50g/batch

Resolution of weight or volume percentage of metals in alloys:• Homogenization by melting and stirring• Change of physical properties by adding of

small amounts of other elements (below 1%)

Deliverables:• Material in single and polycrystalline form

Facilities:• See Mat. Production

Services for industry:• Melting techniques for

selected materials, e.g. NiTi, Al-Ti-Mg-compounds

Scope of cooperation:• Common interest: Basic

research up to production optimization, e.g. large size crystal growth techniques

Deliverables:• Optimized process

technology, e.g. for production of sputter targets

Material Production

Process DevelopmentMaterial Analysis Industrial

Application

Facilities:• Preparation of metals without air contact

in large glove boxes• Electrical furnaces (max. 1800°C)• High frequency heated furnaces (max.

2800°C)• Laser-Zone-Melting (1400°C)• Electron-Beam Melting (1800°C)• Melt Spinning• Argon-Arc-Melting• Crucible or quasi crucible free melt

techniques• Growth methods for single crystals by

different techniques: Czochralski, Bridgman, Zone-melting, Flux-growth

The potential of CMA for industrial applications

22VIU-IT Karl Hoehener

Roadmap Bulk Intermetallic Phases On Demand Working Draft

Facilities:• Preparation of metals without air contact in large

glove boxes• Electrical furnaces (max. 1800°C)• High frequency heated furnaces (max. 2800°C)• Laser-Zone-Melting (1400°C)• Electron-Beam Melting (1800°C)• Melt Spinning• Argon-Arc-Melting• Crucible or quasi crucible free melt techniques• Growth methods for single crystals by different

techniques: Czochralski, Bridgman, Zone-melting, Flux-growth

Material area of expertise:• Pure metals• Intermetallic compounds and alloys• Complex metallic alloys• Quasicrystals• Oxides and others

Produceable amounts of alloys:• Limitation of max 30-50g/batch

Resolution of weight or volume percentage of metals in alloys:• Homogenization by melting and stirring• Change of physical properties by adding of

small amounts of other elements (below 1%)

Deliverables:• Material in single and polycrystalline form

Process Development

Material Production

Industrial ApplicationMaterial Analysis

Material area of expertise:• Pure metals• Intermetallic compounds and alloys• Complex metallic alloys• Quasicrystals• Oxides and others

The potential of CMA for industrial applications

23VIU-IT Karl Hoehener

Roadmap Bulk Intermetallic Phases On Demand Working Draft

Facilities:• Preparation of metals without air contact in large

glove boxes• Electrical furnaces (max. 1800°C)• High frequency heated furnaces (max. 2800°C)• Laser-Zone-Melting (1400°C)• Electron-Beam Melting (1800°C)• Melt Spinning• Argon-Arc-Melting• Crucible or quasi crucible free melt techniques• Growth methods for single crystals by different

techniques: Czochralski, Bridgman, Zone-melting, Flux-growth

Material area of expertise:• Pure metals• Intermetallic compounds and alloys• Complex metallic alloys• Quasicrystals• Oxides and others

Produceable amounts of alloys:• Limitation of max 30-50g/batch

Resolution of weight or volume percentage of metals in alloys:• Homogenization by melting and stirring• Change of physical properties by adding of

small amounts of other elements (below 1%)

Deliverables:• Material in single and polycrystalline form

Facilities:• See Mat. Production

Services for industry:• Melting techniques for

selected materials, e.g. NiTi, Al-Ti-Mg-compounds

Scope of cooperation:• Common interest: Basic

research up to production optimization, e.g. large size crystal growth techniques

Deliverables:• Optimized process

technology, e.g. for production of sputter targets

Process Development

Material Production Material Analysis Industrial

Application

Produceable amounts of alloys:• Limitation of max 30-50g/batch

Resolution of weight or volume percentageof metals in alloys:

• Homogenization by melting and stirring• Change of physical properties by adding

of small amounts of other elements (below 1%)

Deliverables:• Material in single and polycrystalline form

The potential of CMA for industrial applications

24VIU-IT Karl Hoehener

Roadmap Bulk Intermetallic Phases On Demand Working Draft

Facilities:• Preparation of metals without air contact in large

glove boxes• Electrical furnaces (max. 1800°C)• High frequency heated furnaces (max. 2800°C)• Laser-Zone-Melting (1400°C)• Electron-Beam Melting (1800°C)• Melt Spinning• Argon-Arc-Melting• Crucible or quasi crucible free melt techniques• Growth methods for single crystals by different

techniques: Czochralski, Bridgman, Zone-melting, Flux-growth

Material area of expertise:• Pure metals• Intermetallic compounds and alloys• Complex metallic alloys• Quasicrystals• Oxides and others

Produceable amounts of alloys:• Limitation of max 30-50g/batch

Resolution of weight or volume percentage of metals in alloys:• Homogenization by melting and stirring• Change of physical properties by adding of

small amounts of other elements (below 1%)

Deliverables:• Material in single and polycrystalline form

Facilities / instruments / measurement methods:

• X-ray powder diffraction (10 K – 3000 K)• X-ray Laue technique• Differential Thermo-Analysis DTA• Thermo-Gravimetric-Analysis TG• Optical microscopy• Ultrasound microscopy• Scanning Electr. Microscopy SEM

equipped with EDX, WDX

Material area of expertise:• Metals• Intermetallic compounds• Quasicrystals, CMA• Binary and Ternary Oxides, Halogenides

Properties to be analysed:• Phase composition• Homogeneity• Crystal Orientation (if single crystal)• Thermodynamic Properties (Phase

diagrammes)

Deliverables:• Phase diagrammes• Material analysis• Optimized preparation techniques for

selected phases

Facilities:• See Mat. Production

Services for industry:• Melting techniques for

selected materials, e.g. NiTi, Al-Ti-Mg-compounds

Scope of cooperation:• Common interest: Basic

research up to production optimization, e.g. large size crystal growth techniques

Deliverables:• Optimized process

technology, e.g. for production of sputter targets

Material Production

Process DevelopmentMaterial Analysis Industrial

Application

Application fields foreseen:• A• B• ...

Complementary information about demands to be provided by industry:• X• Y• ...

Deliverables:• Transfer of process

know-how• ...

Facilities / instruments / measurement methods:

• X-ray powder diffraction (10 K – 3000 K)

• X-ray Laue technique• Differential Thermo-Analysis

DTA• Thermo-Gravimetric-

Analysis TG• Optical microscopy• Ultrasound microscopy• Scanning Electr. Microscopy

SEM equipped with EDX, WDX

The potential of CMA for industrial applications

25VIU-IT Karl Hoehener

Roadmap Bulk Intermetallic Phases On Demand Working Draft

Facilities:• Preparation of metals without air contact in large

glove boxes• Electrical furnaces (max. 1800°C)• High frequency heated furnaces (max. 2800°C)• Laser-Zone-Melting (1400°C)• Electron-Beam Melting (1800°C)• Melt Spinning• Argon-Arc-Melting• Crucible or quasi crucible free melt techniques• Growth methods for single crystals by different

techniques: Czochralski, Bridgman, Zone-melting, Flux-growth

Material area of expertise:• Pure metals• Intermetallic compounds and alloys• Complex metallic alloys• Quasicrystals• Oxides and others

Produceable amounts of alloys:• Limitation of max 30-50g/batch

Resolution of weight or volume percentage of metals in alloys:• Homogenization by melting and stirring• Change of physical properties by adding of

small amounts of other elements (below 1%)

Deliverables:• Material in single and polycrystalline form

Facilities / instruments / measurement methods:

• X-ray powder diffraction (10 K – 3000 K)• X-ray Laue technique• Differential Thermo-Analysis DTA• Thermo-Gravimetric-Analysis TG• Optical microscopy• Ultrasound microscopy• Scanning Electr. Microscopy SEM

equipped with EDX, WDX

Material area of expertise:• Metals• Intermetallic compounds• Quasicrystals, CMA• Binary and Ternary Oxides, Halogenides

Properties to be analysed:• Phase composition• Homogeneity• Crystal Orientation (if single crystal)• Thermodynamic Properties (Phase

diagrammes)

Deliverables:• Phase diagrammes• Material analysis• Optimized preparation techniques for

selected phases

Material Production

Process DevelopmentMaterial Analysis Industrial

Application

Material area of expertise:• Metals• Intermetallic compounds• Quasicrystals, CMA• Binary and Ternary Oxides,

Halogenides

The potential of CMA for industrial applications

26VIU-IT Karl Hoehener

Roadmap Bulk Intermetallic Phases On Demand Working Draft

Facilities:• Preparation of metals without air contact in large

glove boxes• Electrical furnaces (max. 1800°C)• High frequency heated furnaces (max. 2800°C)• Laser-Zone-Melting (1400°C)• Electron-Beam Melting (1800°C)• Melt Spinning• Argon-Arc-Melting• Crucible or quasi crucible free melt techniques• Growth methods for single crystals by different

techniques: Czochralski, Bridgman, Zone-melting, Flux-growth

Material area of expertise:• Pure metals• Intermetallic compounds and alloys• Complex metallic alloys• Quasicrystals• Oxides and others

Produceable amounts of alloys:• Limitation of max 30-50g/batch

Resolution of weight or volume percentage of metals in alloys:• Homogenization by melting and stirring• Change of physical properties by adding of

small amounts of other elements (below 1%)

Deliverables:• Material in single and polycrystalline form

Facilities / instruments / measurement methods:

• X-ray powder diffraction (10 K – 3000 K)• X-ray Laue technique• Differential Thermo-Analysis DTA• Thermo-Gravimetric-Analysis TG• Optical microscopy• Ultrasound microscopy• Scanning Electr. Microscopy SEM

equipped with EDX, WDX

Material area of expertise:• Metals• Intermetallic compounds• Quasicrystals, CMA• Binary and Ternary Oxides, Halogenides

Properties to be analysed:• Phase composition• Homogeneity• Crystal Orientation (if single crystal)• Thermodynamic Properties (Phase

diagrammes)

Deliverables:• Phase diagrammes• Material analysis• Optimized preparation techniques for

selected phases

Material Production

Process DevelopmentMaterial Analysis Industrial

Application

Properties to be analysed:• Phase composition• Homogeneity• Crystal Orientation (if single

crystal)• Thermodynamic Properties

(Phase diagrammes)

The potential of CMA for industrial applications

27VIU-IT Karl Hoehener

Roadmap Bulk Intermetallic Phases On Demand Working Draft

Facilities:• Preparation of metals without air contact in large

glove boxes• Electrical furnaces (max. 1800°C)• High frequency heated furnaces (max. 2800°C)• Laser-Zone-Melting (1400°C)• Electron-Beam Melting (1800°C)• Melt Spinning• Argon-Arc-Melting• Crucible or quasi crucible free melt techniques• Growth methods for single crystals by different

techniques: Czochralski, Bridgman, Zone-melting, Flux-growth

Material area of expertise:• Pure metals• Intermetallic compounds and alloys• Complex metallic alloys• Quasicrystals• Oxides and others

Produceable amounts of alloys:• Limitation of max 30-50g/batch

Resolution of weight or volume percentage of metals in alloys:• Homogenization by melting and stirring• Change of physical properties by adding of

small amounts of other elements (below 1%)

Deliverables:• Material in single and polycrystalline form

Facilities / instruments / measurement methods:

• X-ray powder diffraction (10 K – 3000 K)• X-ray Laue technique• Differential Thermo-Analysis DTA• Thermo-Gravimetric-Analysis TG• Optical microscopy• Ultrasound microscopy• Scanning Electr. Microscopy SEM

equipped with EDX, WDX

Material area of expertise:• Metals• Intermetallic compounds• Quasicrystals, CMA• Binary and Ternary Oxides, Halogenides

Properties to be analysed:• Phase composition• Homogeneity• Crystal Orientation (if single crystal)• Thermodynamic Properties (Phase

diagrammes)

Deliverables:• Phase diagrammes• Material analysis• Optimized preparation techniques for

selected phases

Material Production

Process DevelopmentMaterial Analysis Industrial

Application

Deliverables:• Phase diagrammes• Material analysis• Optimized preparation

techniques for selected phases

The potential of CMA for industrial applications

28VIU-IT Karl Hoehener

Roadmap Bulk Intermetallic Phases On Demand Working Draft

Facilities:• Preparation of metals without air contact in large

glove boxes• Electrical furnaces (max. 1800°C)• High frequency heated furnaces (max. 2800°C)• Laser-Zone-Melting (1400°C)• Electron-Beam Melting (1800°C)• Melt Spinning• Argon-Arc-Melting• Crucible or quasi crucible free melt techniques• Growth methods for single crystals by different

techniques: Czochralski, Bridgman, Zone-melting, Flux-growth

Material area of expertise:• Pure metals• Intermetallic compounds and alloys• Complex metallic alloys• Quasicrystals• Oxides and others

Produceable amounts of alloys:• Limitation of max 30-50g/batch

Resolution of weight or volume percentage of metals in alloys:• Homogenization by melting and stirring• Change of physical properties by adding of

small amounts of other elements (below 1%)

Deliverables:• Material in single and polycrystalline form

Facilities / instruments / measurement methods:

• X-ray powder diffraction (10 K – 3000 K)• X-ray Laue technique• Differential Thermo-Analysis DTA• Thermo-Gravimetric-Analysis TG• Optical microscopy• Ultrasound microscopy• Scanning Electr. Microscopy SEM

equipped with EDX, WDX

Material area of expertise:• Metals• Intermetallic compounds• Quasicrystals, CMA• Binary and Ternary Oxides, Halogenides

Properties to be analysed:• Phase composition• Homogeneity• Crystal Orientation (if single crystal)• Thermodynamic Properties (Phase

diagrammes)

Deliverables:• Phase diagrammes• Material analysis• Optimized preparation techniques for

selected phases

Facilities:• See Mat. Production

Services for industry:• Melting techniques for

selected materials, e.g. NiTi, Al-Ti-Mg-compounds

Scope of cooperation:• Common interest: Basic

research up to production optimization, e.g. large size crystal growth techniques

Deliverables:• Optimized process

technology, e.g. for production of sputter targets

Material Production

Process DevelopmentMaterial Analysis Industrial

Application

The potential of CMA for industrial applications

29VIU-IT Karl Hoehener

Roadmap Bulk Intermetallic Phases On Demand Working Draft

Facilities:• Preparation of metals without air contact in large

glove boxes• Electrical furnaces (max. 1800°C)• High frequency heated furnaces (max. 2800°C)• Laser-Zone-Melting (1400°C)• Electron-Beam Melting (1800°C)• Melt Spinning• Argon-Arc-Melting• Crucible or quasi crucible free melt techniques• Growth methods for single crystals by different

techniques: Czochralski, Bridgman, Zone-melting, Flux-growth

Material area of expertise:• Pure metals• Intermetallic compounds and alloys• Complex metallic alloys• Quasicrystals• Oxides and others

Produceable amounts of alloys:• Limitation of max 30-50g/batch

Resolution of weight or volume percentage of metals in alloys:• Homogenization by melting and stirring• Change of physical properties by adding of

small amounts of other elements (below 1%)

Deliverables:• Material in single and polycrystalline form

Facilities / instruments / measurement methods:

• X-ray powder diffraction (10 K – 3000 K)• X-ray Laue technique• Differential Thermo-Analysis DTA• Thermo-Gravimetric-Analysis TG• Optical microscopy• Ultrasound microscopy• Scanning Electr. Microscopy SEM

equipped with EDX, WDX

Material area of expertise:• Metals• Intermetallic compounds• Quasicrystals, CMA• Binary and Ternary Oxides, Halogenides

Properties to be analysed:• Phase composition• Homogeneity• Crystal Orientation (if single crystal)• Thermodynamic Properties (Phase

diagrammes)

Deliverables:• Phase diagrammes• Material analysis• Optimized preparation techniques for

selected phases

Facilities:• See Mat. Production

Services for industry:• Melting techniques for

selected materials, e.g. NiTi, Al-Ti-Mg-compounds

Scope of cooperation:• Common interest: Basic

research up to production optimization, e.g. large size crystal growth techniques

Deliverables:• Optimized process

technology, e.g. for production of sputter targets

Material Production

Process DevelopmentMaterial Analysis Industrial

Application

Application fields foreseen:• A• B• ...

Complementary information about demands to be provided by industry:• X• Y• ...

Deliverables:• Transfer of process

know-how• ...

The potential of CMA for industrial applications

30VIU-IT Karl Hoehener

Industry Support Group ISG

The benefit for the CMA ISG member

Direct access to the combined expertise of the CMA Network of ExcellenceImmediate information on latest technological breakthroughs Influence on topics to be addressed in science and technology developmentFormation of new partnerships with science and opening of new market opportunities Access to up-to-date state-of-the-Art knowledge databasePossibility to take over R&D results produced within the CMA Network

Collaboration with industry

The potential of CMA for industrial applications

31VIU-IT Karl Hoehener

Agenda

1. The network of excellence (NoE)Complex Metallic Alloys (CMA)

2. Potential for industrial applications

3. The combined expertise of the CMA Laboratories (VIL)

4. Maturity of the CMA technologies

5. Collaboration with industry

6. Euroschool, continuous education and specific training for industry

7. Next steps

The potential of CMA for industrial applications

32VIU-IT Karl Hoehener

Euroschool

The aim of the Euroschool is to provide a lecture-style background to students, graduate students and industry in the fields of :

• materials, in particular the physics of metals • basic atomistic physics • industrial processing

Lecturers have been invited from academia, research and industry.

The Euroschool will provide tutorial and advanced lectures of the school-type and will not contain conference-style elements.

The potential of CMA for industrial applications

33VIU-IT Karl Hoehener

Euroschool Programme and Abstracts of 2nd Euroschool 2007

Basic tutorials and lecturers:1. Thermoelectric materials

2. Hydrogen-storage materials

3. Magnetism of complex metallic alloys

4. Thermal conductivity of complex metallic alloys

5. Complex metallic alloys versus quasicrystals

6. Design, discovery, growth and physical properties of novel intermetallic compounds

Silke Buehler-Paschen, Vienna

Andreas Zuettel, Fribourg

Ernst Bauer, Vienna

Ana Smontara, Zagreb

Ryuji Tamura, Tokyo

Paul C. Canfield, Ames

May 20 - 26, 2007

The potential of CMA for industrial applications

34VIU-IT Karl Hoehener

Euroschool Programme and Abstracts of 2nd Euroschool 2007

Advanced tutorials and lecturers:1. Smart materials Jean-Marie Dubois, Nancy

2. Hydrogen and it's storage, challenge for materialsscience Louis Schlapbach, Zuerich

3. Korea national program for hydrogen storage Jong Won Kim, Daejeon

4. Hydrogen storage materials, recent developments and future strategy of Japan Etsuo Akiba, Tsukuba

5. First-principles calculations and applications for materials design Ryoji Asahi, Nagakute Aichi

6. Simulating structure and physical properties of complex metallics alloys Hans-Rainer Trebin, Stuttgart

May 20 - 26, 2007

The potential of CMA for industrial applications

35VIU-IT Karl Hoehener

Agenda

1. The network of excellence (NoE)Complex Metallic Alloys (CMA)

2. Potential for industrial applications

3. The combined expertise of the CMA Laboratories (VIL)

4. Maturity of the CMA technologies

5. Collaboration with industry

6. Euroschool, continuous education and specific training for industry

7. Next steps

The potential of CMA for industrial applications

36VIU-IT Karl Hoehener

Step 1: Get informed

CMA Knowledge Data Base

www.cma-ecnoe.net

MONITORING

Theses branch oriented ConferencesScientific literature state-of-the-art SeminarsPatents bottlenecks ExhibitionsBooks solutions ....Conference proceedings potenials ....... .... ....

Selection Selection Selection

——————

In preparation

Operational

Publicationsinternal / external

Functionalitiesinternal

Eventsinternal (external)

——————

——————

CMA e-newsletter

WP 20: Karl Hoehener

The potential of CMA for industrial applications

37VIU-IT Karl Hoehener

Step 2: Get support www.cma-ecnoe.net

Innovation &Technology Transfer: Karl HoehenerCMA, VIU-ITCH-9320 ArbonPhone: +41 (71) 446 50 30Email: [email protected]

The potential of CMA for industrial applications

38VIU-IT Karl Hoehener

Step 3 : Collaboration (Pre-competitive and competitive) www.cma-ecnoe.net

First steps towards a collaboration Industry - NoE CMA

CMA, Network of ExcellenceProvide strategic consultancy and road maps for solutions

Provide analytical supportto industry

Offer training and education to industry

EnterprisesIdentify actual and future needs of future functionalities (mechanical, electrical and thermal properties of surfaces and bulk materials)Identify lack of knowledge (complex problems) where CMA-knowledge may have a high potential for solutions.Identify requirements for continuing education

The potential of CMA for industrial applications

39VIU-IT Karl Hoehener

Step 3 : Collaboration (Pre-competitive and competitive) www.cma-ecnoe.net

Second steps of a collaboration Industry - NoE CMA

CMA, Network of ExcellencePartnership with Industry to convert the Road Map into action:

• Proof of principles• Feasibility studies• Individual projects• Alliance projects

..(add services related to topic)

EnterprisesPartnership with NoE to convert the Road Map into action:

• Proof of principles• Feasibility studies• Individual projects• Alliance projects

.. (add topic)

The potential of CMA for industrial applications

40VIU-IT Karl Hoehener

Step 3 : Collaboration Specify requirement www.cma-ecnoe.netTitle of the project (Topic) Budget available from industry: Euro: … Date of request: Proposed duration of the project:

…… months Proposed project type:

not confidential confidential For more

information, confidentiality agreement required

Confidentiality:

Remarks:

Company or acronym if company's name is strictly confidential:

Name of contact person (optional)

City: email: Address of the company (optional) Street: Phone: Further contacts through:

Application field(s):

Market potential:

Description of the requirements:

Target specifications:

Today's solution

The potential of CMA for industrial applications

41VIU-IT Karl Hoehener

Step 4: Get financial support www.cma-ecnoe.net

1. Regional resources2. National resources3. Framework Programme 7

The potential of CMA for industrial applications

42VIU-IT Karl Hoehener

Innovation means seeing

what everybody sees and anticipating

what no one has anticipated

Thank you for your attention

![1 Introduction to the Science of Complex Metallic Alloys · Complex metallic alloys (or CMA for short), also called SCAPs (for structurally complex alloy phases) for some time [1]](https://static.fdocuments.net/doc/165x107/5f217b2c32e27a58f3493217/1-introduction-to-the-science-of-complex-metallic-complex-metallic-alloys-or-cma.jpg)