Clark cmp 20_25_30

Click here to load reader

description

Transcript of Clark cmp 20_25_30

Pneumatic Tire Lift TrucksLPG/Dual Fuel/Diesel

CMP20 4,000 lbs 2000 kg

CMP25 5,000 lbs 2500 kg

CMP30 6,000 lbs 3000 kg

IC-P

NEU

MAT

IC

w w w . c l a r k m h c . c o m

CMP20/25/30M Series

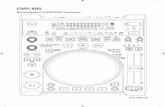

Frame41.6 in.

(1060 mm)

14 Standard Forks

42

Track16

OverallWidth

19 Turning Radius

22 Right Angle Stack Aisle

MaximumFork Spread

40 in.(1016 mm)

Add Load Length & Clearance

42

Track

Over Drive Axle

18

OverheadGuard

Overall Height ExtendedWith 48" Standard

Table

B°

Max. Fork HeightSee Upright

Table

17

OverallHeight

Lowered

48 in.(1220 mm)

40

Drive Tires

20 Load Center Distance

B%

Standard Tilt

41 Wheelbase

15 Length to Fork Face

Seat39.5 in.

(945 mm)

SeatAdjustment11.9-17.8 in.

(302-452 mm)

C.G of

Load

Free Lift

F°

40

Steer Tires

A%

see Upright Table

84.0(2133)

44

12

SeeUpright

Table

10

BackrestSee Upright

For corresponding data see Specification Chart.

CMP20/25/30

DI

ME

NS

IO

NS

1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

18

19

20

22

23

24

25

26

28

29

30

31

32

34

35

36

37

38

39

40

41

42

44

46

47

49

51

52

53

54

57

58

Gen

era

l In

form

ati

on

Basi

c D

imen

sio

ns

Perf

orm

an

ce1

Weig

hts

1C

hass

isD

rive L

ine

Manufacturer

Model

Load Capacity

Load Center

Drive Unit

Operator Type

Tire Type

Wheels (x=driven)

Upright

Upright Tilt

Fork

Overall Dimensions

Turning Radius

Load Center Distance

Right Angle Stack Aisle

Stability

Speeds

Speed on Grade, Loaded

Lift Speeds, Loaded/Empty

Lower Speeds, Loaded/Empty

Drawbar Pull, Maximum

Gradeability

Service weight

Axle loading

Tires

Wheelbase

Track

Ground Clearance

Service Brake

Parking Brake

Steering

Engine

Transmission

Hydraulic Pressure

Sound Level

Manufacturer’s Designation

lbs(kg)

Fork Face Load CG in(mm)

Type

Front/Rear

Maximum Fork Height, Full Capacity in(mm)

Lift Height (preferred standard upright) in(mm)

Free Lift in(mm)

Back/Forward (see tilt specifications) degrees

Std. Fork Size (T x W x L) in(mm)

Length to Fork Face in(mm)

Width in(mm)

Height, Upright Lowered in(mm)

Height, Upright Extended w/load back rest in(mm)

Height, overhead guard in(mm)

in(mm)

Center of Drive Axle to Fork Face in(mm)

Add Load Length and Clearance in(mm)

According to ANSI B56.1

Travel Speed, Max w/ Load mph(kph)

Travel Speed, Max w/o Load mph(kph)

5% mph(kph)

10% mph(kph)

15% mph(kph)

Standard Upright fpm(ms)

Triple Stage Upright fpm(ms)

Standard Upright fpm(ms)

Triple Stage Upright fpm(ms)

With Load lbs(N)

Without Load lbs(N)

At 1 mph (1.6 kph) with Load %

Maximum with/without Load %

lbs(kg)

With Load, Front lbs(kg)

With Load, Rear lbs(kg)

W/O Load, Front lbs(kg)

W/O Load, Rear lbs(kg)

Number, Front/Rear

Size, Front in

Size, Rear in

in(mm)

Front/Rear in(mm)

Minimum/at Center of Wheelbase in(mm)

Type

Actuation

Type

Manufacturer/Model

Rated Output HP/kW @ rpm

Torque lb-ft/Nm @ rpm

Speed, max Governed rpm

Cylinders/Displacement cu. in.-Liters

Manufacturer/Type, Speeds F/R

For Attachments psi/bar

Avg. at Operator’s Ear per ASME B56.11.5 dB(A)

Clark

CMP20

4000 (2000)

24 (500)

LPG

Rider Counterbalanced

Pneumatic

2x / 2

137 (3500)

130 (3300)

4.1 (105)

10 / 8

1.8 x 4 x 42 (40 x 100 x 1070)

100.2 (2545)

47.6 (1210)

88.4 (2245)

178 (4520)

84 (2133)

92.5 (2350)

17.7 (450)

110.2 (2800)

Yes

12.6 (20.3)

12.8 (20.6)

11.2 (18.1)

5.8 (9.3)

3.7 (5.9)

102/110 (.52/.56)

102/110 (.52/.56)

100/100 (.51/.51)

100/100 (.51/.51)

3,238 (14406)

2,187 (9731)

25.0

27.7 / 22.2

7,747 (3514)

10,256 (4824)

1,491 (691)

3,642 (1652)

4,105 (1862)

2 / 2

7.00 x 12 - 14 ply rating

6.50 x 10 - 10 ply rating

63.8 (1620)

39.6/36.9 (1006/938)

4.7/6.9 (120/175)

Hydraulic Drum and Shoe

Hand

Hydrostatic

Mitsubishi 4G64

47.5/35.4 @ 2250

120/163 @ 1600

2600

4 / 143-2.4

Clark/Powershift, 1/1

Adjustable

79

Clark

CMP25

5000 (2500)

24 (500)

LPG

Rider Counterbalanced

Pneumatic

2x / 2

137 (3500)

130 (3300)

4.1 (105)

10 / 8

1.8 x 4 x 42 (40 x 100 x 1070)

101.6 (2580)

47.6 (1210)

88.4 (2245)

178 (4520)

84 (2133)

94.1 (2390)

17.7 (450)

111.8 (2840)

Yes

12.6 (20.3)

12.8 (20.6)

10.5 (16.9)

5.0 (8.0)

3.0 (4.8)

98/110 (.50/.56)

98/110 (.50/.56)

100/100 (.51/.51)

100/100 (.51/.51)

3,251 (14465)

2,121 (9437)

21.9

24.3 / 20.3

8,254 (3744)

11,802 (5568)

1,452 (677)

3,534 (1603)

4,720 (2141)

2 / 2

7.00 x 12 - 14 ply rating

6.50 x 10 - 10 ply rating

63.8 (1620)

39.6/36.9 (1006/938)

4.7/6.9 (120/175)

Hydraulic Drum and Shoe

Hand

Hydrostatic

Mitsubishi 4G64

47.5/35.4 @ 2250

120/163 @ 1600

2600

4 / 143-2.4

Clark/Powershift, 1/1

Adjustable

79

No

tes:

1W

eights an

d p

erform

ance in

form

ation are g

iven fo

r trucks

equip

ped

with

130 in

(3302 m

m) M

FH stan

dard

uprig

hts.

SP

EC

IF

IC

AT

IO

NS

No

tes:

1W

eights

and p

erfo

rman

ce info

rmat

ion a

re g

iven

for

truck

seq

uip

ped

with 1

30 in (

3302 m

m)

MFH

sta

ndar

d u

pri

ghts

.

SP

EC

IF

IC

AT

IO

NS 1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

18

19

20

22

23

24

25

26

28

29

30

31

32

34

35

36

37

38

39

40

41

42

44

46

47

49

51

52

53

54

57

58

Gen

era

l In

form

ati

on

Basi

c D

imen

sio

ns1

Perf

orm

an

ce1

Weig

hts

1C

hass

isD

rive L

ine

Manufacturer

Model

Load Capacity

Load Center

Drive Unit

Operator Type

Tire Type

Wheels (x=driven)

Upright

Upright Tilt

Fork

Overall Dimensions

Turning Radius

Load Center Distance

Right Angle Stack Aisle

Stability

Speeds

Speed on Grade, Loaded

Lift Speeds, Loaded/Empty

Lower Speeds, Loaded/Empty

Drawbar Pull, Maximum

Gradeability

Service weight

Axle loading

Tires

Wheelbase

Track

Ground Clearance

Service Brake

Parking Brake

Steering

Engine

Transmission

Hydraulic Pressure

Sound Level

Manufacturer’s Designation

lbs(kg)

Fork Face Load CG in(mm)

Type

Front/Rear

Maximum Fork Height, Full Capacity in(mm)

Lift Height (preferred standard upright) in(mm)

Free Lift in(mm)

Back/Forward (above 157 in/3990 mm MFH) degrees

Std. Fork Size (T x W x L) in(mm)

Length to Fork Face in(mm)

Width in(mm)

Height, Upright Lowered in(mm)

Height, Upright Extended w/load back rest in(mm)

Height, overhead guard in(mm)

in(mm)

Center of Drive Axle to Fork Face in(mm)

Add Load Length and Clearance in(mm)

According to ANSI B56.1

Travel Speed, Max w/ Load mph(kph)

Travel Speed, Max w/o Load mph(kph)

5% mph(kph)

10% mph(kph)

15% mph(kph)

Standard Upright fpm(ms)

Triple Stage Upright fpm(ms)

Standard Upright fpm(ms)

Triple Stage Upright fpm(ms)

With Load lbs(N)

Without Load lbs(N)

At 1 mph (1.6 kph) with Load %

Maximum with/without Load %

lbs(kg)

With Load, Front lbs(kg)

With Load, Rear lbs(kg)

W/O Load, Front lbs(kg)

W/O Load, Rear lbs(kg)

Number, Front/Rear

Size, Front in

Size, Rear in

in(mm)

Front/Rear in(mm)

Minimum/at Center of Wheelbase in(mm)

Type

Actuation

Type

Manufacturer/Model

Rated Output HP/kW @ rpm

Torque lb-ft/Nm @ rpm

Speed, max Governed rpm

Cylinders/Displacement cu. in.-Liters

Manufacturer/Type, Speeds F/R

For Attachments psi/bar

Avg. at Operator’s Ear per ASME B56.11.5 dB(A)

Clark

CMP30

6000 (3000)

24 (500)

LPG

Rider Counterbalanced

Pneumatic

2x / 2

137 (3500)

130 (3300)

4.1 (105)

10 / 8

1.8 x 5 x 42 (40 x 125 x 1070)

105.7 (2685)

48.8 (1240)

88.4 (2245)

178 (4520)

84 (2133)

98.4 (2500)

17.7 (450)

116.1 (2950)

Yes

13.0 (20.9)

13.2 (21.3)

7.9 (12.7)

4.0 (6.5)

1.8 (2.9)

94/110 (.48/.56)

94/110 (.48/.56)

100/100 (.51/.51)

100/100 (.51/.51)

3,073 (13671)

2,161 (9614)

17.2

19.8 / 18.8

9,224 (4184)

13,530 (6395)

1,693 (790)

3,608 (1637)

5,615 (2547)

2 / 2

28 x 9 x 15 - 14 ply rating

6.50 x 10 - 10 ply rating

66.9 (1700)

40.6/36.9 (1030/938)

4.7/6.9 (120/175)

Hydraulic Drum and Shoe

Hand

Hydrostatic

Mitsubishi 4G64

47.5/35.4 @ 2250

120/163 @ 1600

2600

4 / 143-2.4

Clark/Powershift, 1/1

Adjustable

79

1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

18

19

20

22

23

24

25

26

28

29

30

31

32

34

35

36

37

38

39

40

41

42

44

46

47

49

51

52

53

54

57

58

Gen

era

l In

form

ati

on

Basi

c D

imen

sio

ns

Perf

orm

an

ce1

Weig

hts

1C

hass

isD

rive L

ine

Manufacturer

Model

Load Capacity

Load Center

Drive Unit

Operator Type

Tire Type

Wheels (x=driven)

Upright

Upright Tilt

Fork

Overall Dimensions

Turning Radius

Load Center Distance

Right Angle Stack Aisle

Stability

Speeds

Speed on Grade, Loaded

Lift Speeds, Loaded/Empty

Lower Speeds, Loaded/Empty

Drawbar Pull, Maximum

Gradeability

Service weight

Axle loading

Tires

Wheelbase

Track

Ground Clearance

Service Brake

Parking Brake

Steering

Engine

Transmission

Hydraulic Pressure

Sound Level

Manufacturer’s Designation

lbs(kg)

Fork Face Load CG in(mm)

Type

Front/Rear

Maximum Fork Height, Full Capacity in(mm)

Lift Height (preferred standard upright) in(mm)

Free Lift in(mm)

Back/Forward (see tilt specifications) degrees

Std. Fork Size (T x W x L) in(mm)

Length to Fork Face in(mm)

Width in(mm)

Height, Upright Lowered in(mm)

Height, Upright Extended w/load back rest in(mm)

Height, overhead guard in(mm)

in(mm)

Center of Drive Axle to Fork Face in(mm)

Add Load Length and Clearance in(mm)

According to ANSI B56.1

Travel Speed, Max w/ Load mph(kph)

Travel Speed, Max w/o Load mph(kph)

5% mph(kph)

10% mph(kph)

15% mph(kph)

Standard Upright fpm(ms)

Triple Stage Upright fpm(ms)

Standard Upright fpm(ms)

Triple Stage Upright fpm(ms)

With Load lbs(N)

Without Load lbs(N)

At 1 mph (1.6 kph) with Load %

Maximum with/without Load %

lbs(kg)

With Load, Front lbs(kg)

With Load, Rear lbs(kg)

W/O Load, Front lbs(kg)

W/O Load, Rear lbs(kg)

Number, Front/Rear

Size, Front in

Size, Rear in

in(mm)

Front/Rear in(mm)

Minimum/at Center of Wheelbase in(mm)

Type

Actuation

Type

Manufacturer/Model

Rated Output HP/kW @ rpm

Torque lb-ft/Nm @ rpm

Speed, max Governed rpm

Cylinders/Displacement cu. in.-Liters

Manufacturer/Type, Speeds F/R

For Attachments psi/bar

Avg. at Operator’s Ear per ASME B56.11.5 dB(A)

Clark

CMP20

4000 (2000)

24 (500)

Diesel

Rider Counterbalanced

Pneumatic

2x / 2

137 (3500)

130 (3300)

4.1 (105)

10 / 8

1.8 x 4 x 42 (40 x 100 x 1070)

100.2 (2545)

47.6 (1210)

88.4 (2245)

178 (4520)

84 (2133)

92.5 (2350)

17.7 (450)

110.2 (2800)

Yes

12.6 (20.3)

12.8 (20.6)

11.2 (18.1)

5.8 (9.3)

3.7 (5.9)

102/110 (.52/.56)

102/110 (.52/.56)

100/100 (.51/.51)

100/100 (.51/.51)

3,238 (14406)

2,187 (9731)

25.0

27.7 / 22.2

7,747 (3514)

10,256 (4824)

1,491 (691)

3,642 (1652)

4,105 (1862)

2 / 2

7.00 x 12 - 14 ply rating

6.50 x 10 - 10 ply rating

63.8 (1620)

39.6/36.9 (1006/938)

4.7/6.9 (120/175)

Hydraulic Drum and Shoe

Hand

Hydrostatic

Yanmar 4TNV94

59/42.9 @ 2500

130/176 @ 1600

2650

4 / 171-2.8

Clark/Powershift, 1/1

Adjustable

79

Clark

CMP25

5000 (2500)

24 (500)

Diesel

Rider Counterbalanced

Pneumatic

2x / 2

137 (3500)

130 (3300)

4.1 (105)

10 / 8

1.8 x 4 x 42 (40 x 100 x 1070)

101.6 (2580)

47.6 (1210)

88.4 (2245)

178 (4520)

84 (2133)

94.1 (2390)

17.7 (450)

111.8 (2840)

Yes

12.6 (20.2)

12.8 (20.6)

10.5 (16.9)

5.0 (8.0)

3.0 (4.8)

98/110 (.50/.56)

98/110 (.50/.56)

100/100 (.51/.51)

100/100 (.51/.51)

3,251 (14465)

2,121 (9437)

21.9

24.3 / 20.3

8,254 (3744)

11,802 (5568)

1,452 (677)

3,534 (1603)

4,720 (2141)

2 / 2

7.00 x 12 - 14 ply rating

6.50 x 10 - 10 ply rating

63.8 (1620)

39.6/36.9 (1006/938)

4.7/6.9 (120/175)

Hydraulic Drum and Shoe

Hand

Hydrostatic

Yanmar 4TNV94

59/42.9 @ 2500

130/176 @ 1600

2650

4 / 171-2.8

Clark/Powershift, 1/1

Adjustable

79

No

tes:

1W

eights an

d p

erform

ance in

form

ation are g

iven fo

r trucks

equip

ped

with

130 in

(3302 m

m) M

FH stan

dard

uprig

hts.

SP

EC

IF

IC

AT

IO

NS

No

tes:

1W

eights

and p

erfo

rman

ce info

rmat

ion a

re g

iven

for

truck

seq

uip

ped

with 1

30 in (

3302 m

m)

MFH

sta

ndar

d u

pri

ghts

.

SP

EC

IF

IC

AT

IO

NS 1

2

3

4

5

6

7

8

9

10

11

12

14

15

16

18

19

20

22

23

24

25

26

28

29

30

31

32

34

35

36

37

38

39

40

41

42

44

46

47

49

51

52

53

54

57

58

Gen

era

l In

form

ati

on

Basi

c D

imen

sio

ns1

Perf

orm

an

ce1

Weig

hts

1C

hass

isD

rive L

ine

Manufacturer

Model

Load Capacity

Load Center

Drive Unit

Operator Type

Tire Type

Wheels (x=driven)

Upright

Upright Tilt

Fork

Overall Dimensions

Turning Radius

Load Center Distance

Right Angle Stack Aisle

Stability

Speeds

Speed on Grade, Loaded

Lift Speeds, Loaded/Empty

Lower Speeds, Loaded/Empty

Drawbar Pull, Maximum

Gradeability

Service weight

Axle loading

Tires

Wheelbase

Track

Ground Clearance

Service Brake

Parking Brake

Steering

Engine

Transmission

Hydraulic Pressure

Sound Level

Manufacturer’s Designation

lbs(kg)

Fork Face Load CG in(mm)

Type

Front/Rear

Maximum Fork Height, Full Capacity in(mm)

Lift Height (preferred standard upright) in(mm)

Free Lift in(mm)

Back/Forward (above 157 in/3990 mm MFH) degrees

Std. Fork Size (T x W x L) in(mm)

Length to Fork Face in(mm)

Width in(mm)

Height, Upright Lowered in(mm)

Height, Upright Extended w/load back rest in(mm)

Height, overhead guard in(mm)

in(mm)

Center of Drive Axle to Fork Face in(mm)

Add Load Length and Clearance in(mm)

According to ANSI B56.1

Travel Speed, Max w/ Load mph(kph)

Travel Speed, Max w/o Load mph(kph)

5% mph(kph)

10% mph(kph)

15% mph(kph)

Standard Upright fpm(ms)

Triple Stage Upright fpm(ms)

Standard Upright fpm(ms)

Triple Stage Upright fpm(ms)

With Load lbs(N)

Without Load lbs(N)

At 1 mph (1.6 kph) with Load %

Maximum with/without Load %

lbs(kg)

With Load, Front lbs(kg)

With Load, Rear lbs(kg)

W/O Load, Front lbs(kg)

W/O Load, Rear lbs(kg)

Number, Front/Rear

Size, Front in

Size, Rear in

in(mm)

Front/Rear in(mm)

Minimum/at Center of Wheelbase in(mm)

Type

Actuation

Type

Manufacturer/Model

Rated Output HP/kW @ rpm

Torque lb-ft/Nm @ rpm

Speed, max Governed rpm

Cylinders/Displacement cu. in.-Liters

Manufacturer/Type, Speeds F/R

For Attachments psi/bar

Avg. at Operator’s Ear per ASME B56.11.5 dB(A)

Clark

CMP30

6000 (3000)

24 (500)

Diesel

Rider Counterbalanced

Pneumatic

2x / 2

137 (3500)

130 (3300)

4.1 (105)

10 / 8

1.8 x 5 x 42 (40 x 125 x 1070)

105.7 (2685)

48.8 (1240)

88.4 (2245)

178 (4520)

84 (2133)

98.4 (2500)

17.7 (450)

116.1 (2950)

Yes

13.0 (20.9)

13.2 (21.3)

7.9 (12.7)

4.0 (6.5)

1.8 (2.9)

94/110 (.48/.56)

94/110 (.48/.56)

100/100 (.51/.51)

100/100 (.51/.51)

3,073 (13671)

2,161 (9614)

17.2

19.8 / 18.8

9,224 (4184)

13,530 (6395)

1,693 (790)

3,608 (1637)

5,615 (2547)

2 / 2

8.15 x 15 - 14 ply rating

6.50 x 10 - 10 ply rating

66.9 (1700)

40.6/36.9 (1030/938)

4.7/6.9 (120/175)

Hydraulic Drum and Shoe

Hand

Hydrostatic

Yanmar 4TNV94

59/42.9 @ 2500

130/176 @ 1600

2650

4 / 143-2.4

Clark/Powershift, 1/1

Adjustable

79

CLARK CMP 20 SERIES pneumatic tire trucks aredesigned for durability and ease of operation. They are idealfor both indoor and outdoor applications in manufacturing,warehousing and distribution operations. Equipped withsingle-speed powershift transaxles and LPG, dual fuel ordiesel engines to suit the most rugged demands.

Operator Control & ComfortThe CMP20 Series provides high levels of operator comfortand control while meeting expectations productivity anddurability.

An isolated operator cell supported on rubber mountsreduces vibration and sound transmission to the operatorseat and controls. Low in-frame steps on both sides, 17.1 in.(435 mm) high, enable easy access to the operatorcompartment. A rubber floor mat makes footing secure.Cowl-mounted hydraulic control levers provide short reachand low effort enabling precise load control. Electricdirectional control lever allows “fingertip” operation of thepowershift transaxle. The tilt steering wheel can be securedat any position within its range of travel. A two-pedal inch-brake system provides excellent control and comfort; leftpedal is for inch and brake operation, right pedal for brakesonly.

Equipped with a legendary Clark safety seat with shoulderrestraints, adjustable and fold-down back rest, moldedbolsters for comfort and support, six inches (150 mm)fore/aft adjustment, a retractable seat belt and an operatormanual in the seat pocket. Rear-hinged clamshell hood withlocking gas cylinder strut makes access for daily inspectionconvenient.

The high visibility upright, overhead guard and load backrestdesigns improve operator vision during travel and stackingoperations.

Instrument PanelAn operator display monitor includes indicator lights forengine oil pressure, check engine light, battery charge,transmission temperature, park brake “on,” low LPG, Glowplugs (diesel) turn signal indicators and panel test light. Fivedigit hour meter, analog engine temperature gauge and fuelgauge (dual fuel and diesel models) are provided on thedisplay.

EngineFeaturing a Mitsubishi model 4G64, 2.4 liter (143 c.i.) 4-cylinder overhead cam engine with internal dynamicbalancers for reduced vibration and an EPA 2004 compliantLPG fuel system with diagnostics. Camshaft and balancersare cog belt driven. Cast iron deep skirt block wih aluminumcylinder head, 5-main bearing crankshaft, hydraulic valvelifters and electronic ignition reduce maintenancerequirements. An automatic engine shut-down systemprotects the engine from high engine coolant temperature orlow engine oil pressure. This engine is well known for lowmaintenance and long service life.

An optional Yanmar model 4TNV94, 2.8 liter (171 c.i.) 4cylinder Diesel engine with direct injection is also available.Vertical exhaust is standard on Diesel. 2004 EPA compliant,not U.L. listed.

Engine Accessories/CapacitiesElectrical systems are 12 volt, negative ground, and 50 ampalternator with integral regulator on LPG and 40 amp ondiesel engines. Low maintenance battery is rated at 550cold cranking amps at 0°F (-18 °C) on LPG and 800 CCA ondiesel engines. The heavy-duty engine air cleaner is easilyserviced. An external high-mounted air intake with rain capis provided.

Cooling system capacity is 6.7 quarts (6.3 L); engine oilcapacity with filter is 4.0 quarts (4.2 L). Fuel tanks on duelfuel or diesel models are 9.8 gals. (37 L).

TransaxleFeaturing a Clark Model TA-18 single-speed, full reversing,powershift transaxle. This rugged and proven Clarktransaxle is an integral unit with high ratio, industrial torueconverter, full-floating drive axles and drum/shoe brakes.Equipped with electrically controlled directional control, fullymodulated cluth packs and precise inching conrol system.Test ports, fluid check and full-flow oil filter are easilyaccessible. An integral oil cooler is located in the open coreradiator.

Electric shift control provides consistent shift operation;linkage wear and adjustment are eliminated. Full-floatingdrive axle design adds durability as only torsional forces, not

truck loads, are transmitted through the axle shafts.Transaxle clutch packs incorporate hydraulic modulationand cushioning systems to provide smooth engagementand protect internal components under rapid directionreversals. Highly accessible transaxle control, gear drive forhydraulic pump and spin-on full-flow lubricant filter areeasily serviced.

BrakesSelf-energizing, hydraulic-actuated drum and shoe typeservice brakes. Heavy cast iron brake shoes, backing platesand drums with openings for lining inspection andadjustment. All components are asbestos-free. The brakesare accessed by removing the wheel hub, axleshaft andbrake drum. The left hand actuated parking brake pedalactuates service brakes at both drive wheels, with electrictransmission interrupt and fingertip release. Thetransmission is disengaged when the parking brake isapplied.

SteeringSteering is full hydrostatic with tilt wheel, utilizing a compactaxle beam and integral double-acting steer cylinder. Highstrength spindle assemblies incorporate kingpins anddouble metal sealed bearings to provide rugged, easilyserviced assemblies. The steering linkage uses sphericalbearings, double shear link pins and grease fittings. Rubberisolation mounts support the axle, absorb shock and reducenoise.

HydraulicsA single gear driven pump provides fluid for hydraulicfunctions and steering. The priority-demand steering systemconserves energy by supplying hydraulic fluid on demand-only basis. The hydraulic tank is integral with the truck framewith an in-tank screen, and the in-tank return line filter iseasily serviced without spill. A quick-connect pressure portallows convenient pressure checks.

The main hydraulic valve is a modular design, allowingadditional auxiliary sections and adjustable for pressure andauxiliary flow requirements. Hydraulic tank coverincorporates return line fittings, dipstick and breather filter.Sump tank capacity is 10.0 gal. (38 L).

Upright AssemblyHigh visibility CLARK designed uprights are available in twostage, HiLo and triple stage full free lift designs and areconfigured to provide maximum forward visibility. A widerange of lift heights is available. Interlocking rail/nested rollerupright design utilizes specially rolled inner rail and channelsection outer rails. This provides high strength under allupright load conditions and greater tolerance to unbalancedloads. Uprights feature negative rail drop enabling uprightrollers to be easily accessed for adjustment.

Tilt cylinders incorporate spherical bushings at both ends toextend seal life by minimizing axial cylinder loads. Hydrauliccounterbalance valve prevents improper tilt cylinderoperation, flow limiting valves protect against rapid carriagedescent in the event of a line failure and a lowering control-valve regulates lowering speeds. ITA Class II and III hooktype carriages incorporate six main rollers and two sidethrust rollers to resist deflection due to off center loads.Forks are upset forged and have adjustable fork locks; forksare retained by the load backrest extension.

Additional FeaturesA single auxiliary valve, internal hosing, sideshifter, twoheadlights mounted on the overhead guard, tail lights, brakelights, turn signals and flashers are all standard equipment.Other standard features are open core radiator, high airintake, tow pin in the counterweight, rear tie-downs, low fuelwarning indicator. The operator manual is permantentlyattached inside the rear pocket of the comfortable safetyseat. Color is high visibility Clark Green with matte blackoperator cell and upright. Wheels are bright white. Clark’sEmployer’s Guide to Material Handling Safety and operatorsafety video are provided with truck.

DE

SC

RI

PT

IO

N

CMP 20/25/30 Speci f icat ion Sheet

59-894-0322 Printed in USA CCIrev0305

your authorized CLARK dealer is:n North America CMHCWorldwide Headquarters700 Enterprise DriveLexington, KY 40510866-252-5275www.clarkmhc.com

Upright Table

Maximum Overall Height 1 Standard2

Fork Height Lowered Free Lift3 Tilt Spec

in mm in mm in mm B°/F°

CMP20/25/30Standard

78 2000 62.8 1595 4.1 105 10/890 2300 68.7 1745 4.1 105 10/898 2500 72.6 1845 4.1 105 10/8106 2700 76.6 1945 4.1 105 10/8118 3000 82.5 2095 4.1 105 10/8

• 130 3300 88.4 2245 4.1 105 10/8137 3500 92.3 2345 4.1 105 10/8145 3700 96.3 2445 4.1 105 10/8157 4000 102.2 2595 4.1 105 6/4177 4500 120.3 3055 4.1 105 6/4196 5000 130.1 3305 4.1 105 6/4

CMP20/25/30Triple Stage

145 3700 73.6 1870 48.8 1240 6/4157 4000 77.6 1970 52.8 1340 6/4169 4300 81.5 2070 56.7 1440 6/4177 4500 84.1 2135 59.3 1505 6/4185 4700 86.6 2200 65.0 1650 6/4

• 189 4800 88.6 2250 65.0 1650 6/4196 5000 90.6 2300 65.7 1670 6/4216 5500 98.8 2510 74.0 1880 6/4236 6000 108.3 2750 83.5 2120 3/1.5256 6500 115.2 2925 90.6 2300 3/1.5275 7000 124.6 3165 100.0 2540 3/1.5

CMP20/25/30Hi-Lo

106 2700 78.0 1980 55.1 1400 8/8118 3000 83.9 2130 61.0 1550 8/8

• 130 3300 89.8 2280 66.9 1700 8/8

• Indicates preferred common specification.1 For overall height raised with load backrest, add 48 in.

(1220 mm) to maximum fork height.2 Standard Tilt shown. Contact a Clark representative

for information on optional tilt.3 Freelift dimensions shown are without load backrest.

Other uprights available, contact a Clark representative.

Grade Clearance

Model A% B%

CMP 20 71 24

CMP 25 53 24

CMP 30 57 22

Notes

Production engines and driveline components mayvary in output and/or efficiency by ±10%. Theperformance shown represents nominal valueswhich may be obtained under typical operatingconditions of a machine.

Clark products and specifications are subject tochange without notice.

© Clark Material Handling Company 2005.

ANSI and Insurance Classification

Standard truck meets all applicable mandatoryrequirements of ANSI-B56.1 Safety Standard forPowered Industrial Trucks and UnderwritersLaboratories requirements as to fire hazard only. Fortype LP and LPS classification. For furtherinformation contact a Clark representative.

For Your Safety

Before operating a lift truck, an operator must:• Be trained and authorized• Read and understand the operator’s manual• Not operate a faulty lift truck• Not repair a lift truck unless trained and

authorized• Have the overhead guard and load

backrest extension in place

During operation, a lift truck operator must:• Wear a seat belt• Keep entire body inside truck cab• Never carry passengers or lift people• Keep truck away from people and

obstructions• Travel with lift mechanism as low as

possible and tilted back

To park a lift truck, an operator must:• Completely lower forks or attachments• Shift into neutral• Turn key off• Set parking brake

Contact your Clark dealer for operator training information.

Available Equipment• Double auxiliary valve• Hose adaptations• Hydraulic control options• Side shifters• Strobe lights• Rear work light• Reverse alarm• Mirrors• Suspension seat, vinyl and cloth• Operator cab with heater and radio• U.L. Type LPS construction• Dual Fuel• Diesel• Travel speed limit - LPG / Dual Fuel• Various tire options