CIC-presentation of RP-577 presentation

-

Upload

ibrahim-eldesoky -

Category

Documents

-

view

344 -

download

37

description

Transcript of CIC-presentation of RP-577 presentation

Cairo Inspection Company Eng. Ibrahim Eldesoky

ASNT –NDT-- LEVEL III

ASME AUTHORIZED INSPECTOR

API AUTHORIZED INSPECTOR

API 577 welding

inspection and

metallurgy

INTRODUCTION

Much of the content of RP-577 has been gathered from

other technical and Code publications. Overall it is a fine

publication and represents a lot of hard work.

Since many of these subjects are covered in previous

lessons, such as several of the NDE processes and Welding

procedures this lesson will not address those same issues

again, unless there is added information not presented

previously.

•RP-577 Welding Inspection and

Metallurgy

2 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

INTRODUCTION

RP-577 should be taken quite seriously during study. It is a

new document on the examination, and as such you should

expect a fairly high concentration of questions from it.

You may even prefer to use this document as your primary

source for the study of welding and NDE as it is specifically

pointed at in-service inspection methods.

However the ASME Code Sections V, VIII Div.1 and, IX

must not be neglected as they are still, to a lesser degree, a

part of the examination.

•RP-577 Welding Inspection and

Metallurgy

3 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

INTRODUCTION

The parts of RP-577 covered in the lesson will not be

addressed completely. The effort will be to introduce the

topics of RP-577 and familiarize the student with its content

and study responsibilities. However a question and answer

study exercise will be provided for exam preparation.

•RP-577 Welding Inspection and

Metallurgy

4 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Objectives

• Become familiar with definitions and welding

inspection terminology

• Understand the tasks and processes required to

perform welding inspections.

- Tasks Prior to Welding.

- Tasks during Welding Operations

- Tasks Upon Completion of Welding

- Non-conformances and Defects

- NDE Examiner Certification

- Safety Precautions

•RP-577 Welding Inspection and

Metallurgy

5 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Objectives

• Introduce the welding process types and their

advantages and disadvantages based on intended

application, these include:

- Shielded Metal Arc Welding (SMAW)

- Gas Tungsten Arc Welding (GT AW)

- Gas Metal Arc Welding (GMAW)

- Flux Core Arc Welding (FCAW)

- Submerged Arc Welding (SAW)

- Stud Arc Welding (SW)

•RP-577 Welding Inspection and

Metallurgy

6 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Objectives

• Introduce Non-Destructive Examinations methods not

covered in previous class lessons and their

applications, to include;

- Types of Discontinuities

- Materials Identification methods

- Visual Examination (VT)

- Alternating Current Field Measurement (ACFM)

- Eddy Current Inspection (ET)

- Hardness Testing

- Pressure and Leak Testing (LT)

- Weld Inspection Data Recording

•RP-577 Welding Inspection and

Metallurgy

7 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Objectives

• Outline basic application of metallurgy to the welding

processes, including;

- The Structure of Metals and Alloys

- Physical Properties

- Mechanical Properties

- Preheating

- Post-weld Heat Treatment

- Hardening

- Material Test Reports

- Weldability of Steels

- Weldability of High-alloys

•RP-577 Welding Inspection and

Metallurgy

8 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Objectives

• Present the nature of and remedies for Refinery and

Petrochemical Plant Welding Issues, such as;

- General Issues in welding

- Hot Tapping and In-service Welding

- Lack of Fusion with GMAW-S Welding Process

Other Items to be discussed

• Welding Terminology and Welding Symbols

• Actions to Address Improperly made production

welds.

• Guide to common filler metals selection

• Example RT reports

•RP-577 Welding Inspection and

Metallurgy

9 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

We will begin with Section 3 - Definitions on page 2.

Once again we will not attempt to cover any of these items in their entirety during class. This is to be considered an introduction to RP-577 and to the subject material on the exam Body of Knowledge.

•RP-577 Welding Inspection and

Metallurgy

10 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Definitions

Many of the definitions listed are common and probably many of these you already know. However what you and I think of as being one thing, they may use a different term for. Example: Penetrameter is an outdated term it is now called an Image Quality Indicator (IQI). We will go through a few of the less known definitions, but subjects from RP-577 is largely a read and remember task for the exam.

•RP-577 Welding Inspection and

Metallurgy

11 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Definitions „Some of the less known‟

autogenous weld: A fusion weld made without filler metal. ( The most common of these types of welds is made on tubing and performed with Gas Tungsten Arc Welding often using an automated welding device)

•RP-577 Welding Inspection and

Metallurgy

12 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Definitions

- actual throat: The shortest distance between the weld

root and the face of a fillet weld.

•RP-577 Welding Inspection and

Metallurgy

13 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Definitions

- direct current electrode negative (DCEN): The

arrangement of direct current arc welding leads in which the

electrode is the negative pole and work piece is the positive

pole of the welding arc. (Commonly known as straight

polarity).

•RP-577 Welding Inspection and

Metallurgy

14 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Section 4

Welding Inspection page 4.

The focus of Section 4 is to detail the tasks that are

considered the responsibility of the Inspection group as

well other concerned parties who will design, examine, or

perform welding.

•RP-577 Welding Inspection and

Metallurgy

15 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Section 4

Welding Inspection page 4.

Section 4 follows this pattern;

4.1 General

4.2 Tasks Prior to Welding

4.2.1 Drawings, Codes, and Standards

4.2.1.1 Quality Control Items to assess

4.2.1.2 Potential Inspector Actions

4.2.2 Weld Requirements

4.2.2.1 Quality Control Items to assess

4.2.2.2 Potential Inspector Actions

•RP-577 Welding Inspection and

Metallurgy

16 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Tasks Prior to Welding

• Preplanning will eliminate most mistakes before they

happen. A good repair plan will always include a preplanning

stage for the welding part of the repair.

4.2.1 - Drawings, Codes, Standards requirements should

be clearly defined and understood.

4.2.1.1 Quality Control Items to Assess Include:

• Welding symbols and sizes

• Weld joint designs clearly defined

• Weld maps for major projects that specify the WPS used.

•RP-577 Welding Inspection and

Metallurgy

17 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Tasks Prior to Welding

4.2.1.1 Quality Control Items to Assess Include:

• Potential for weld distortion addressed

• Welding consumable handling addressed (rod ovens

ect.)

• Base metal requirements addressed (type, impact tests.)

• Mechanical testing required and acceptance criteria

• Protection for welding such as wind and rain barriers

•RP-577 Welding Inspection and

Metallurgy

18 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Tasks Prior to Welding

4.2.1.2 Potential Inspector actions:

The inspector‟s responsibilities prior to welding can include;

• Look for missing details and information

• Determine if the planned testing is adequate

• Look for Code and specification violations in the plan

• Identify possible welding problems ( Example: inadequate

root spacing or a bevel that will not allow full penetration)

•RP-577 Welding Inspection and

Metallurgy

19 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Tasks Prior to Welding

4.2.2 Weldment Requirements

4.2.2.1 Quality Control Items to Assess Include:

• Competency of the Welding Organization to meet

requirements of Codes and Standards to be used

• Competency of the Inspection Organization

• The roles and responsibilities of the various parties

involved

• Independence of the Inspection Organization from the

Production group.

•RP-577 Welding Inspection and

Metallurgy

20 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Tasks Prior to Welding

The other issues that the inspector must address as part of

tasks prior to welding are;

NDE Information

Welding Equipment and Instruments

Heat Treatment and Pressure Testing

Materials

Weld Preparation

Preheat

Welding Consumables

The items above are very similar in there language as to the

individual of the various group‟s responsibilities, concentrate

on the INSPECTOR’S tasks during your studies.

•RP-577 Welding Inspection and

Metallurgy

21 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

4.3 Tasks During Welding Operations

Welding inspection during welding operations include

things to be checked for conformance to the WPS.

4.3.1 Quality Assurance

• Establish a quality assurance and quality control

relationship with the welding organization, the inspector

should make it clear what is expected during the job.

•RP-577 Welding Inspection and

Metallurgy

22 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

4.3 Tasks During Welding Operations

4.3.1.1 Quality Control items to assess;

• Make sure all involved know that the welder is responsible

for the quality of the welds he makes

• Make sure the welder meets the qualification requirements

• Determine if the welder understands the welding procedure

and requirements this includes any inspection hold points.

•RP-577 Welding Inspection and

Metallurgy

23 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Tasks During Welding Operations

4.3.2 Welding Parameters and Techniques

4.3.2.1 Quality Control Items to Assess:

• Make sure essential variables are maintained during

welding. Such as;

1. The correct filler metal, fluxes and gasses are used.

2. Purge techniques, flow rate, gas analysis, etc.

3. Rod warmers are used or maximum time out of the rod

oven is followed.

•RP-577 Welding Inspection and

Metallurgy

24 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

4.3 Tasks During Welding Operations 4.3.2.1 Quality Control Items to Assess:

4. Make sure they use the specified preheat during tack

welding as well as during the actual welding.

5. Verify equipment setting are in compliance with the

WPS. Such as voltage, amperage, wire speed, etc.

6. Verify that interpass temperatures are be observed.

7. Where it applies confirm weld travel speed. This is a

key element in control of heat input.

•RP-577 Welding Inspection and

Metallurgy

25 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

4.3 Tasks During Welding Operations 4.3.3 Weldment Examination

Perform visual examination and possibly in-process NDE

Quality Control Items to Assess:

1. Confirm tack welds are acceptable.

2. Weld root pass has adequate penetration and quality.

3. That cleaning between passes and back gouged

surfaces are adequate.

4. Witness or perform NDE between passes as required.

5. Verify in-process repairs and defect removal

6. Ferrite measurements when required are recorded

7. Verify final butt-weld reinforcement or fillet weld size

•RP-577 Welding Inspection and

Metallurgy

26 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

4.3 Tasks During Welding Operations 4.3.3.2 Potential Inspector Action;

• Reject unacceptable workmanship.

•RP-577 Welding Inspection and

Metallurgy

27 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

4.4 Tasks Upon Completion of Welding

Read and become familiar with all of the following;

4.4.1 Appearance and Finish;

4.4.1.1 Quality Control Items to assess

4.4.1.2 Potential Inspector action.

Other topics include;

NDE Review

PWHT

Pressure Testing

Documentation Audit

Non-Conformances and Defects

NDE Examiner Certifications

Safety Precautions

•RP-577 Welding Inspection and

Metallurgy

28 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

While Section 4 of RP-577 is rather lengthy, it follows a

definite outlined pattern. The emphasis should be on items

that you do not have actual work experience with.

For example if you have not followed a PWHT procedure

spend you time studying these items as opposed to

something you have experience with.

Do not overlook items such as Safety Precautions or

Documentation during your studies.

•RP-577 Welding Inspection and

Metallurgy

29 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

1. An autogenous weld is a fusion weld made ____filler

metal.

a. with

b. without

c. with or without

Fill in the blanks:

2. The inspector‟s responsibilities prior to welding can

include a. ________________b.____________________

c._______________________ d.__________________

•Class Quiz

30 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

1. An autogenous weld is a fusion weld made ____filler

metal.

b. without

2. The inspector‟s responsibilities prior to welding can

include a. ________________ b.____________________

c._______________________ d.__________________

a. Look for missing details and information

b. Determine if the planned testing is adequate

c. Look for Code and specification violations in the plan

d. Identify possible welding problems

•Solutions

31 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Welding Processes

• These 6 welding process types and their advantages and

disadvantages based on intended application should be

thoroughly understood prior to examination day. The

following is a brief overview of;

- Shielded Metal Arc Welding (SMAW)

- Gas Tungsten Arc Welding (GT AW)

- Gas Metal Arc Welding (GMAW)

- Flux Core Arc Welding (FCAW)

- Submerged Arc Welding (SAW)

- Stud Arc Welding (SW)

•RP-577 Welding Inspection and

Metallurgy

32 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.2 Shielded Metal Arc Welding (SMAW)

SMAW is the most widely used of the various arc welding

processes. SMAW uses an arc between a covered

electrode

and the weld pool. It employs the heat of the arc, coming

from the tip of a consumable covered electrode, to melt

the

base metal. Shielding is provided from the decomposition

of

the electrode covering, without the application of pressure

and with filler metal from the electrode.

•RP-577 Welding Inspection and

Metallurgy

33 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.2 Shielded Metal Arc Welding (SMAW)

• Either alternating current (ac) or direct current (dc) may be

employed, depending on the welding power supply and the

electrode selected.

• A constant-current (CC) power supply is preferred. SMAW

is a manual welding process. See Figures 1 and 2 for

schematics of the SMAW circuit and welding process.

•RP-577 Welding Inspection and

Metallurgy

34 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.2 Shielded Metal Arc Welding (SMAW)

•RP-577 Welding Inspection and

Metallurgy

35 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.2 Shielded Metal Arc Welding (SMAW)

• Advantages

- Simple, inexpensive and portable

- Useable in tight places

- Less sensitive to wind and drafts than other processes

- Useable with most common metals and alloys

• Limitations

- Slow welding compared to GMAW or SAW

- Cleaning problems due to slag left from electrode

covering

•RP-577 Welding Inspection and

Metallurgy

36 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.3 Gas Tungsten Arc Welding (GTAW)

• GTAW is an arc welding process that uses an arc between

a non-consumable tungsten electrode and the weld pool.

The process is used with shielding gas and without the

application of pressure. GTAW can be used with or without

the addition of filler metal (Autogenous).

• The Constant Current (CC) type power supply can be used

with either dc or ac, the choice depends largely on the metal

to be welded.

•RP-577 Welding Inspection and

Metallurgy

37 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.3 Gas Tungsten Arc Welding (GTAW)

• Direct current welding is typically performed with the

electrode negative (DCEN) polarity. (Called Straight Polarity)

• DCEN welding offers the advantages of deeper penetration

and faster welding speeds. Alternating current provides a

cathodic cleaning (sputtering) that removes refractory oxides

from the surfaces of the weld joint, which is necessary for

welding aluminum and magnesium.

•RP-577 Welding Inspection and

Metallurgy

5.3 Gas Tungsten Arc Welding (GTAW)

• The cleaning action occurs during the portion of the ac

wave, when the electrode is positive with respect to the

work piece. See Figures 3 and 4 for schematics of the

GTAW equipment and welding process.

•RP-577 Welding Inspection and

Metallurgy

39 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.3 Gas Tungsten Arc Welding (GTAW)

•RP-577 Welding Inspection and

Metallurgy

40 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.3 Gas Tungsten Arc Welding (GTAW)

• Advantages

- High quality welds

- Little cleaning required after welding

- Superior root pass weld penetration

- May be used for Autogenous welds (no filler metal)

• Limitations

- Slow welding compared to SMAW, GMAW or SAW

- Base and filler metals must be clean and shielding

gasses must be contaminant free.

- Not easy to use in drafty environments due to loss of

gas shielding.

•RP-577 Welding Inspection and

Metallurgy

41 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.4 Gas Metal Arc Welding (GMAW)

GMAW is an arc welding process that uses an arc between

continuous filler metal electrode and the weld pool. The

process is used with shielding from an externally supplied

gas and without the application of pressure. GMAW may be

operated in semiautomatic, machine, or automatic modes. It

employs a constant voltage (CV) power supply, and uses

either the short circuiting, globular, or spray methods to

transfer metal from the electrode to the work:

•RP-577 Welding Inspection and

Metallurgy

42 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.4 Gas Metal Arc Welding (GMAW)

The type of transfer is determined by a number of factors.

The most influential are:

a. Magnitude and type of welding current.

b. Electrode diameter.

c. Electrode composition.

d. Electrode extension.

e. Shielding gas.

•RP-577 Welding Inspection and

Metallurgy

43 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.4 Gas Metal Arc Welding (GMAW)

5.4.1 Short Circuiting Transfer (GMAW-S)

GMAW-S encompasses the lowest range of welding

currents and electrode diameters associated with GMAW

process.

• This process produces a fast freezing weld pool that is

generally suited for joining thin section, out-of position, or

root pass. Due to the fast-freezing nature of this process,

there is potential for lack of sidewall fusion when welding

thick wall equipment or a nozzle attachment.

•RP-577 Welding Inspection and

Metallurgy

44 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.4 Gas Metal Arc Welding (GMAW)

5.4.2 Globular Transfer

This process encompasses relatively low current (below

250 A). The globular transfer mode is characterized by a

drop size with a diameter greater than that of the

electrode. In general, this process is limited to the flat

position and can produce spatter.

•RP-577 Welding Inspection and

Metallurgy

45 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.4 Gas Metal Arc Welding (GMAW)

5.4.3 Spray Transfer

The spray transfer mode results in a highly directed stream

of discrete drops that are accelerated by arc forces. Spatter

is negligible. Due to its high arc forces with high current,

applying this process to thin sheets may be difficult.

• The thickness limitation of the spray arc transfer has been

overcome by the use of pulsed GMAW. Pulsed GMAW is a

variation of the GMAW in which the current is pulsed to

obtain the advantage of spray transfer at the less average

currents than that of spray transfer mode.

•RP-577 Welding Inspection and

Metallurgy

46 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.3 Gas Metal Arc Welding (GMAW)

• Advantages

- The only consumable electrode process that can used

with commercial metals and alloys

- Weld deposition rates are much higher than SMAW

- Minimal cleaning (no slag)

• Limitations

- Welding is costly and complex more so than SMAW

- Sensitive to air drafts and loss of shielding.

- GMAW-S is subject to lack of fusion

•RP-577 Welding Inspection and

Metallurgy

47 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.5 Flux Cored Arc Welding (FCAW)

FCAW is an arc welding process that uses an arc between

continuous tubular filler metal electrode and the weld pool.

The process is used with shielding gas evolved from a flux

contained within the tubular electrode ( a trade name is

inner-shield), with or without additional shielding from an

externally supplied gas.

Normally a semiautomatic process, the use of FCAW

depends on the type of electrodes available, the mechanical

property requirements of the welded joints, and the joint

designs and fit-up. The recommended power source is the

dc constant-voltage type, similar to sources used for GMAW.

•RP-577 Welding Inspection and

Metallurgy

48 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.5 Flux Cored Arc Welding (FCAW)

• Advantages

- Metallurgical benefits from the flux

- Slag supports and forms the weld bead

- High Deposition of weld metal

- Shielding is produced at the surface giving better

protection against drafts

• Limitations

- Welding is costly and complex more so than SMAW

- Heavy fumes requiring exhaust equipment.

- Slag removal between passes

- Backing material is required for root pass welds

•RP-577 Welding Inspection and

Metallurgy

49 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.6 Submerged Arc Welding (SAW)

Submerged arc welding is an arc welding process that uses

an arc or arcs between a flux covered bare metal

electrode(s) and the weld pool. The arc and molten metal

are shielded by a blanket of granular flux, supplied

through the welding nozzle from a hopper. The process is

used without pressure and filler metal from the electrode and

sometimes from a supplemental source (welding rod, flux, or

metal granules). SAW can be applied in three different

modes: semiautomatic, automatic, and machine. It can

utilize either a CV or CC power supply. SAW is used

extensively in shop pressure vessel fabrication and pipe

manufacturing.

•RP-577 Welding Inspection and

Metallurgy

50 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.6 Submerged Arc Welding (SAW)

• Advantages

- Very High Deposition rates

- High and consistent quality

• Limitations

- High current and 100% duty cycle

- The weld is hidden by flux making it harder to control

- Equipment is costly and not very portable

- Limited to shop work in the flat position

•RP-577 Welding Inspection and

Metallurgy

51 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.7 Stud Arc Welding (SW)

• SW is an arc welding process that uses an arc between

a metal stud or similar part and the work piece. Once the

surfaces of the parts are properly heated, that is the end

of the stud is molten and the work has an equal area of

molten pool, they are brought into contact by pressure.

Shielding gas or flux may or may not be used.

• SW is limited to welding insulation and refractory support

pins to tanks, pressure vessels and heater casing.

•RP-577 Welding Inspection and

Metallurgy

52 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

5.7 Flux Cored Arc Welding (FCAW)

• Advantages

- Faster than manual welding

- All position process

• Limitations

- Primarily suited for carbon and low alloy steels

- Used only in a few applications

•RP-577 Welding Inspection and

Metallurgy

53 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

1. A welding process that uses a consumable electrode and

whose shielding gas is generated by the decomposition of

the rod covering is the process ________.

a. GMAW

b. FCAW

c. SMAW

d. GTAW

2. The welding process that is well suited to making superior

root passes because of good penetration is _________.

a. FCAW

b. SAW

c. GMAW-S

d. GTAW

•Class Quiz

54 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

3. Globular transfer can be utilized with the ________

process.

a. FCAW

b. SMAW

c. GMAW

d. GTAW

4. The welding process in which the welding arc is not

normally visible is the _________ process.

a. GMAW-S

b. SAW

c. FCAW

d. GTAW

•Class Quiz

55 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

1. A welding process that uses a consumable electrode and

whose shielding gas is generated by the decomposition of

the rod covering is the ________ process.

c. SMAW

2. The welding process that is well suited to making superior

root passes because of good penetration is the _________.

d. GTAW

3. Globular transfer can be utilized with the ________

process.

c. GMAW

4. The welding process in which the welding arc is not

normally visible is the _________ process. b. SAW

•Solutions

56 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Appendix A Terminology and Symbols

Page 71

We will defer the NDE and Metallurgy coverage for now and

stay with the welding topics from RP-571. Appendix A

consists of 5 pages of graphics. The topics are;

A.1 Weld Joint Types

A.2 Weld Symbols

A.3 Weld Joint Nomenclature

A.4 Electrode Identification

•RP-577 Welding Inspection and

Metallurgy

57 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

A.1 Weld Joint Types

• You may be required to identify any of these joints

based on a description or a sketch.

•RP-577 Welding Inspection and

Metallurgy

58 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

A.1 Weld Joint Types

•RP-577 Welding Inspection and

Metallurgy

59 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

A.2 Weld Symbols

•RP-577 Welding Inspection and

Metallurgy

60 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

A.3 Weld Symbols

•RP-577 Welding Inspection and

Metallurgy

61 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

A.4 Weld Joint Nomenclature

•RP-577 Welding Inspection and

Metallurgy

62 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

A.5 Weld Joint Nomenclature

•RP-577 Welding Inspection and

Metallurgy

63 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

A.6 Electrode Identification

SMAW

You can be required answer Closed Book questions on the

AWS Classification shown in these figures.

•RP-577 Welding Inspection and

Metallurgy

64 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

A.7 Electrode Identification

GMAW/GTAW

•RP-577 Welding Inspection and

Metallurgy

65 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

A.8 Electrode Identification

FCAW

•RP-577 Welding Inspection and

Metallurgy

66 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

A.9 Electrode Identification

SAW

•RP-577 Welding Inspection and

Metallurgy

67 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

1. The type of electrode that has an AWS designation that

is represented as E X X X X is used with the_____

process.

a. GMAW

b. SMAW

c. GTAW

d. SW

2. A rod is designated as ER-70 S. It would be used with

the ___ process and has a deposited tensile strength

of___ psi.

a. GTAW - 70,000

b. GMAW - 70,000

c. Both a and b above.

•Class Quiz

68 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

3. For the ____ process the electrode has the form E X X T-

X. The T represents ____ and the second X indicates ___.

a. FCAW -Tubular - Position

b. GMAW - Position - Position

c. FCAW – Position - Position

d. GMAW – Tubular - Position

4. For SAW the F in the designator means ______.

a. the flow rate of shielding gas used.

b. the flux used

c. it will use a ferrous flux

b. the electrode is ferrous

•Class Quiz

69 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

1. The type of electrode that has an AWS designation that is

represented as E X X X X is used with the_____ process.

b. SMAW

2. A rod is designated as ER-70 S. It would be used with the

___ process and has a deposited tensile strength of___ psi.

c. Both a and b above.

3. For the ____ process the electrode has the form E X X T-

X. The T represents ____ and the second X indicates ___.

c. FCAW – Position – Position

4. For SAW the F in the designator means ______.

b. the flux used

•Solutions

70 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Appendix B

Actions To Address Improperly Made Production Welds

The following flow charts are the recommended method of

addressing problems during welding. Here again we have

case of just having to try and remember where this

information is and possibly answer a Open Book question as

regards the proper corrective action based on the listed

circumstances.

•RP-577 Welding Inspection and

Metallurgy

71 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Appendix B – Actions to Address Improperly

Made Production Welds

Production welds made by an unqualified welder or an

improper welding procedure should be addressed to assure

the final weldments meet the service requirements. A welder

may be unqualified for several reasons including expired

qualification, not qualified for the thickness, not qualified in the

technique, or not qualified for the material of construction.

Figure B-1 details some potential steps to address the

disposition of these welds.

A welding procedure may be improper if the weldment is

made outside the range of essential variables (and

supplementary essential variables, if required) qualified for the

WPS. Figure B-2 details some potential steps to address

weldments made with an improper welding procedure.

72 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Figure B -1 Suggested Actions for Welds Made by an Incorrect Welder

73 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Figure B-2 Steps to Address Production Welds Made to an Improper WPS

74 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Appendix D Page 95

Expect “Look Up Questions” from these tables.

75 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Expect “Look Up Questions” from these tables.

76 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Expect “Look Up Questions” from these tables.

77 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Expect “Look Up Questions” from these tables.

78 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Section 9 Non-Destructive Examination

In this section we will primarily cover the NDE process not

covered in ASME Section V. For classroom instruction we

will only go over the highlights, strengths and weakness of

the given processes.

Once again this is a subject that will demand a lot of

personal study for the candidate to fare well on the exam.

Expect to put many hours into this and the previous welding

material.

•RP-577 Welding Inspection and

Metallurgy

79 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Section 9 Non-Destructive Examination

Be warned, as regards the examination the amount of detail

about the actual practice of NDE in Section 9 is huge, when

taken as a whole. It is really only an overview of the common

NDE processes.

There are about 13 pages of text, a dozen or so Tables, and

approximately 40 Figures. This is going to take a lot of study.

•RP-577 Welding Inspection and

Metallurgy

80 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Section 9 Non-Destructive Examination

Page 21

Discontinuities

The following statements from this section should give a

good clue as to how the API committee will handle questions

from this area.

“The inspector should choose an NDE method capable of

detecting the discontinuity in the type of weld joint due to the

configuration. Table 2 and Figure 11 lists the common types

and location of discontinuities and illustrates their positions

within a butt weld. The most commonly used NDE methods

used during weld inspection are shown in Table 3.”

•RP-577 Welding Inspection and

Metallurgy

81 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Section 9 Non-Destructive Examination

Discontinuities

“Table 4 lists the various weld joint types and common

NDE methods available to inspect their configuration.

Table 5 further lists the detection capabilities of the most

common NDE methods. Additional methods, like

alternating current field measurement (ACFM), have

applications in weld inspection and are described in this

section but are less commonly used.”

•RP-577 Welding Inspection and

Metallurgy

82 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Section 9.1 Non-Destructive Examination

Discontinuities

“The inspector should be aware of discontinuities common

to specific base metals and weld processes to assure

these discontinuities are detectable. Table 6 is a summary

of these discontinuities, potential NDE methods and

possible solutions to the weld process.”

•RP-577 Welding Inspection and

Metallurgy

83 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Table - 2 Common Types of Discontinuities

Study these tables extensively

•RP-577 Welding Inspection and

Metallurgy

84 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Table - 2 Common Types of Discontinuities

Numbers in Circles refer to Table 2

•RP-577 Welding Inspection and

Metallurgy

85 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Table 3 Commonly Used NDE Methods

Study these tables extensively

•RP-577 Welding Inspection and

Metallurgy

86 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Table 4 - Capability of the Applicable

Method for Weld Types

Study these tables extensively

•RP-577 Welding Inspection and

Metallurgy

87 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Table 5 - Capability of the

Applicable Method Vs. Discontinuity

Study these tables extensively

•RP-577 Welding Inspection and

Metallurgy

88 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Table 6 - Discontinuities Commonly Encountered in Welding

Processes

•RP-577 Welding Inspection and

Metallurgy

89 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Table 6 - Discontinuities Commonly Encountered in Welding Processes

•RP-577 Welding Inspection and

Metallurgy

90 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

9.2 MATERIALS IDENTIFICATION

During welding inspection, the inspector may need to verify

the conformance of the base material and filler metal

chemistries with the selected or specified alloyed materials.

This may include reviewing the certified mill test report,

reviewing stamps or markings on the components, or require

PMI testing. It is the responsibility of the owner/user to

establish a written material verification program indicating

the extent and type of PMI to be conducted. Guidelines for

material control and verification are outlined in API RP 578.

•RP-577 Welding Inspection and

Metallurgy

91 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

9.3 VISUAL EXAMINATION (VT)

9.3.1 General

Visual examination is the most extensively used NDE

method for welds. It includes either the direct or indirect

observation of the exposed surfaces of the weld and base

metal. Direct visual examination is conducted when access is

sufficient to place the eye within 6 in. – 24 in. (150 mm –

600 mm) of the surface to be examined and at an angle not

less than 30 degrees to the surface as illustrated in Figure

12.

Mirrors may be used to improve the angle of vision.

Remote visual examination may be substituted for direct

examination.

•RP-577 Welding Inspection and

Metallurgy

92 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

9.3 VISUAL EXAMINATION (VT)

9.3.1 General

Remote examination may use aids such as telescopes,

borescopes, fiberscope, cameras or other suitable

instruments, provided they have a resolution at least

equivalent

to that which is attained by direct visual examination. In

either case, the illumination should be sufficient to allow

resolution

of fine detail. These illumination requirements are to be

addressed in a written procedure.

•RP-577 Welding Inspection and

Metallurgy

93 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Figure 12 – Direct Visual Examination Requirements

•RP-577 Welding Inspection and

Metallurgy

94 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

9.3 VISUAL EXAMINATION (VT)

• Complete your studies by becoming familiar with all of the

remaining topics in this section.

9.3.2.1 Optical Aids

9.3.2.2 Mechanical Aids

9.3.2.3 Weld Examination Devices

• Concentrate on the various figures and the name of each

inspection device, how it is used, and what it is used for.

Also be aware that pictures can be part of the exam.

•RP-577 Welding Inspection and

Metallurgy

95 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

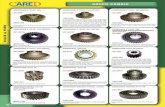

Example:

The inspection tool in the picture below is

______________.

1. a Bridge Cam Gauge

2. a T-Fillet Weld Gauge

3. a Weld Fillet Gauge

4. an Adjustable Fillet Weld Gauge

96 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

9.5 Alternating Current Field Measurement (ACFM)

Page 36

Principle of Operation

• The ACFM technique is an electromagnetic non-contacting

technique that is able to detect and size surface breaking

defects in a range of different materials and through coatings

of varying thickness.

• This technique is ideal for inspecting complex geometries

such as nozzles, ring-grooves, grind-out areas or radiuses. It

requires minimal surface preparation and can be used at elevated

temperatures up to 900°F (482°C).

• With its increased sensitivity to shallow cracks, ACFM is

used for the evaluation and monitoring of existing cracks.

•RP-577 Welding Inspection and

Metallurgy

97 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

9.5 Alternating Current Field Measurement (ACFM)

• ACFM uses a probe similar to an eddy current probe and

introduces an alternating current in a thin skin near to the

surface of any conductor. When a uniform current is

introduced into the area under test, if it is defect free, the

current is undisturbed.

• If the area has a crack present, the current flows around

the ends and the faces of the crack. A magnetic field is

present above the surface associated with this uniform

alternating current and will be disturbed if a surface-breaking

crack is present.

•RP-577 Welding Inspection and

Metallurgy

98 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

9.9.6 Automated Ultrasonic Testing (AUT)

Principle of Operation

Volumetric Inspection of welds may be performed using

one of the three automated ultrasonic weld inspection

techniques:

a. Pulse Echo Raster Scanning: This technique inspects with

zero degree compression and two angle beam transducers

interrogating the weld from either side simultaneously. The

compression transducers examine for corrosion or laminar

defects in the base metal and the angle beam transducers

scan the volume of the weld metal.

•RP-577 Welding Inspection and

Metallurgy

99 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

9.9.6 Automated Ultrasonic Testing (AUT)

Principle of Operation

b. Pulse Echo Zoned Inspection: The zoned inspection is a

Line Scan technique. The technique uses an array of

transducers on either side of the weld with the transducer

angles and transit time gates set to ensure that the complete

volume of the weld is inspected.

c. Time of Flight Diffraction (TOFD): This is a line scan

technique used in the pitch-catch mode. The multi-mode

transducers are used to obtain the maximum volume

inspection of the weld region. More than one set of

transducers may be required for a complete volumetric

inspection.

•RP-577 Welding Inspection and

Metallurgy

100 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

9.9.7 Discontinuity Evaluation and Sizing

This paragraph details the various methods by which

discontinuities can be evaluated. The highlights are;

• One commonly used sizing technique is called the “intensity

drop” technique. This sizing technique uses the beam

spread to determine the edges of the reflector. The 6 dB drop

technique is commonly used to determine length of the

reflector.

• Using this technique, the transducer is positioned on the

part such that the amplitude from the reflector is maximized.

This point is marked with a grease pencil. The UT instrument

is adjusted to set the signal to 80% full screen height (FSH).

•RP-577 Welding Inspection and

Metallurgy

101 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

9.9.7 Discontinuity Evaluation and Sizing

• The transducer is then moved laterally until the echo has

dropped to 40% FSH (6dB). This position is also marked.

• The transducer is then moved laterally in the other direction,

past the maximum amplitude point, until the echo response

again reaches 40% FSH. This point is marked with the grease

pencil. The two outside marks represent the linear

dimension of the reflector.

•RP-577 Welding Inspection and

Metallurgy

102 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

9.9.7 Discontinuity Evaluation and Sizing

• The intensity drop sizing technique can also be used to

determine the through thickness of the reflector. However

the transducer is moved forward and backwards from the

reflector and the corresponding time base sweep position

from the UT instrument is noted at each of the positions.

• This information is then plotted to determine the

discontinuity location with respect to the inside or outside

diameter of the part being examined, and the through

thickness dimension of the reflector.

•RP-577 Welding Inspection and

Metallurgy

103 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

9.9.7 Discontinuity Evaluation and Sizing

Paragraph 9.9.7 has the following sub-paragraphs covering

other flaw sizing methods.

9.9.7.1 The ID Creeping Wave Method

9.9.7.2 The Tip Diffraction Method

9.9.7.3 The High Angle Longitudinal Method

9.9.7.4 The Bimodal Method

•RP-577 Welding Inspection and

Metallurgy

104 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

9.9.7 Discontinuity Evaluation and Sizing

Before the exam you must be able to recognize each

technique‟s description and be able to distinguish the

differences between them.

•RP-577 Welding Inspection and

Metallurgy

105 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

1. The method of evaluating the size of a discontinuity that

uses a global approach and divides into thirds a section

thickness is_____________.

a. Tip Diffraction

b. High Angle Longitudinal

c. ID Creeping Wave Method

d. Intensity Drop Technique

2. The technique that uses an array of transducers on

either side of the weld is ____________.

a. Time of Flight Diffraction

b. The Bimodal Method

c. Pulse Echo Raster

d. Pulse Echo Zone

•Class Quiz

106 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

1. The method of evaluating the size of a discontinuity that

uses a global approach and divides into thirds a section

thickness is _____________.

c. ID Creeping Wave Method

2. The technique that uses an array of transducers on either

side of the weld is ____________.

d. Pulse Echo Zone

•Solution

107 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10 Metallurgy

Solid metals are crystalline in nature and all have a

structure

in which the atoms of each crystal are arranged in a

specific

geometric pattern. The physical properties of metallic

materials including strength, ductility and toughness can be

attributed to the chemical make-up and orderly

arrangement of these atoms.

•RP-577 Welding Inspection and

Metallurgy

108 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10 Metallurgy

• Metals in molten or liquid states have no orderly

arrangement

to the atoms contained in the melt. As the melt cools, a

temperature is reached at which clusters of atoms bond

with

each other and start to solidify developing into solid crystals

within the melt. The individual crystals of pure metal are

identical except for their orientation and are called grains.

• As the temperature is reduced further, these crystals

change in form eventually touch and where the grains

touch an irregular transition layer of atoms is formed, which

is called the grain boundary. Eventually the entire melt

solidifies, interlocking the grains into a solid metallic

structure called a casting.

•RP-577 Welding Inspection and

Metallurgy

109 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10 Metallurgy

• Knowledge of cast structures is important since the welding

process is somewhat akin to making a casting in a foundry.

• Because of the similarity in the shape of its grains, a weld

can be considered a small casting.

• A solidified weld may have a structure that looks very much

like that of a cast piece of equipment. However, the thermal

conditions that are experienced during welding produce a

cast structure with characteristics unique to welding.

•RP-577 Welding Inspection and

Metallurgy

110 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10 Metallurgy

10.2.3 Welding Metallurgy

Page 57

We will begin our discussion here with Welding Metallurgy.

Previous sections about the structures of metals are very

general in nature, reading these a time or two should be

sufficient preparation.

•RP-577 Welding Inspection and

Metallurgy

111 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.2.3 Welding Metallurgy

Some Important Points

• Most typical weld metals are rapidly solidified and, like the

structure of a casting described earlier, usually solidify in the

same manner as a casting and have a fine grain dendritic

microstructure.

• The solidified weld metal is a mixture of melted base metal and

deposited weld filler metal, if used.

• The heat-affected zone (HAZ) is adjacent to the weld and

is that portion of the base metal that has not been melted, but

whose mechanical properties or microstructure have been

altered by the preheating temperature and the heat of welding.

•RP-577 Welding Inspection and

Metallurgy

112 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.2.3 Welding Metallurgy

Some Important Points

• There will typically be a change in grain size or grain

structure and hardness in the HAZ of steel.

• The size or width of the HAZ is dependent on the heat

input used during welding.

• For carbon steels, the HAZ includes those regions heated

to greater than 1350°F (700°C). Each weld pass applied will

have its own HAZ and the overlapping heat affected zones

will extend through the full thickness of the plate or part

welded.

• The third component in a welded joint is the base metal.

•RP-577 Welding Inspection and

Metallurgy

113 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.3 Physical Properties

Some Important Points

• The physical properties of base metals, filler metals and

alloys being joined can have an influence on the efficiency

and applicability of a welding process.

• Examples of physical properties of a metal are the melting

temperature, the thermal conductivity, electrical conductivity,

the coefficient of thermal expansion, and density.

•RP-577 Welding Inspection and

Metallurgy

114 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.3.1 Melting Temperature

Some Important Points

• The melting temperature of different metals is important to

know because the higher the melting point, the greater the

amount of heat that is needed to melt a given volume of metal.

• A pure metal has a definite melting temperature that is just

above its solidification temperature. However, complete melting

of alloyed materials occurs over a range of temperatures.

• Alloyed metals start to melt at a temperature, which is just

above its solidus temperature, and, because they may contain

different metallurgical phases, melting continues as the

temperature increases until it reaches its liquidus temperature.

•RP-577 Welding Inspection and

Metallurgy

115 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.3.2 Thermal Conductivity

Some Important Points

• The thermal conductivity of a material is the rate at which

heat is transmitted through a material by conduction or

thermal transmittance. In general, metals with high

electrical conductivity also have high thermal conductivity.

• Materials with high thermal conductivity require higher

heat inputs to weld than those with lower thermal

conductivity and may require a pre-heat.

• Steel is a poor conductor of heat as compared with

aluminum or copper. As a result it takes less heat to melt

steel.

•RP-577 Welding Inspection and

Metallurgy

116 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.3.2 Thermal Conductivity

Some Important Points

• Aluminum is a good conductor of heat and has the ability

to transfer heat very efficiently. This ability of aluminum to

transfer heat so efficiently also makes it more difficult to

weld with low temperature heat sources.

•RP-577 Welding Inspection and

Metallurgy

117 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.3.3 Electrical Conductivity

Some Important Points

• The electrical conductivity of a material is a measure of its

efficiency in conducting electrical current. Aluminum and

copper have high electrical conductivity as compared to iron

and steel.

• The ability of steel to carry an electrical current is much

less efficient and more heat is produced by its high

electrical resistance.

• Steel can be heated with lower heat inputs than necessary

for aluminum or copper because of its lower electrical

conductivity and higher electrical resistance.

•RP-577 Welding Inspection and

Metallurgy

118 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.3.4 Coefficient of Thermal Expansion

Some Important Points

• Metals with a high coefficient of thermal expansion are

much more susceptible to warping and distortion problems

during welding.

• The increases in length and shrinkage that accompany the

heating and cooling during welding should be anticipated,

and procedures established which would assure that proper

tolerances are used to minimize the effects of thermal

conditions.

•RP-577 Welding Inspection and

Metallurgy

119 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.3.4 Coefficient of Thermal Expansion

Some Important Points

• The joining of metals in which their coefficients of thermal

expansion differ greatly can also contribute to thermal

fatigue conditions, and result in a premature failure of the

component.

• Welding procedures are often employed, which specify

special filler metals that minimize the adverse effects

caused by inherent differences between the metals being

joined.

•RP-577 Welding Inspection and

Metallurgy

120 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.3.5 Density

Some Important Points

• The density of a material is defined as its mass per unit

volume.

• Castings, and therefore welds, are usually less dense

than the wrought material of similar composition.

• Castings and welds contain porosity and inclusions that

produce a metal of lower density.

• This is an important factor employed during RT of welded

joints.

•RP-577 Welding Inspection and

Metallurgy

121 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.4 Mechanical Properties

10.4.1 Tensile Strength

Some Important Points

Tensile testing is used to determine mechanical properties

of metals;

• Ultimate Strength (point of failure)

• Yield Strength (place where it will not return to original

shape)

• Elongation ( after yielding the value of increase in length)

• Strain is defined as the amount of deformation under load

or change of shape

•RP-577 Welding Inspection and

Metallurgy

122 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.4 Mechanical Properties

10.4.2 Ductility

Some Important Points

In tensile testing, ductility is defined as the ability of a

material to deform plastically without fracturing, measured

by elongation or reduction of area.

•RP-577 Welding Inspection and

Metallurgy

123 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.4.3 Hardness

Some Important Points

The hardness of a material is defined as the resistance to

plastic deformation by indentation.

• Indentation hardness may be measured by various

hardness tests, such as Brinell, Rockwell, Knoop and

Vickers.

•RP-577 Welding Inspection and

Metallurgy

124 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.4.4 Toughness

Some Important Points

• The toughness is the ability of a metal to absorb energy

and deform plastically before fracturing. An important

material property to tank and pressure vessel designers is

the “fracture toughness” of a metal which is defined as

the ability to resist fracture or crack propagation under

stress. It is usually measured by the energy absorbed in a

notch impact test.

• The primary test method is the Charpy Impact Test

•RP-577 Welding Inspection and

Metallurgy

125 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.5 Preheating

Some Important Points

• Preheating is defined as heating of the weld and

surrounding base metal to a predetermined temperature prior

to the start of welding.

• The primary purpose for preheating carbon and low-alloy

steels is to reduce the tendency for hydrogen induced

delayed cracking. It does this by slowing the cooling rate,

which helps prevent the formation of martensite in the weld

and base metal HAZ.

•RP-577 Welding Inspection and

Metallurgy

126 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.5 Preheating

Some Important Points

Usually preheating is performed because:

a. A preheat or interpass temperature is required by the

WPS.

b. It reduces shrinkage stresses in the weld and base metal,

which is especially important in weld joints with * high

restraint. * high restraint is often due to thick base metals,

thinner base metals will distort and relieve stresses

c. Reduce the cooling rate to prevent hardening and a

reduction in ductility of the weld and base metal HAZ.

•RP-577 Welding Inspection and

Metallurgy

127 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.5 Preheating

d. Maintain weld interpass temperatures.

e. Eliminate moisture from the weld area.

f. Meet the requirements of the applicable fabrication code,

such as the ASME Boiler and Pressure Vessel Code,

depending on the chemistry and thickness of the alloy to be

welded.

•RP-577 Welding Inspection and

Metallurgy

128 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.5 Preheating

Some Important Points

When preheating is a requirement of the WPS, the

inspector should monitor preheating closely.

By using;

• Thermocouples

• Contact Pyrometers

• Infrared instruments

• Temperature Crayons (Temp Sticks)

Remember when preheat is specified it also applies to tack

welds, arc gouging and thermal cutting.

•RP-577 Welding Inspection and

Metallurgy

129 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.5 Preheating

Some Important Points

The most common Preheating methods are;

• Electrical Resistance Coils

• Oxy Acetylene and Natural Gas flame.

Preheat should be carried for at least 2” (51 mm) on each

side of the weld. When joining metals with different preheat

temperature requirements normally the higher preheat is

used.

•RP-577 Welding Inspection and

Metallurgy

130 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.6 Post-Weld Heat Treatment

The need for PWHT is dependent on many factors

including; chemistry of the metal, thickness of the parts

being joined, joint design, welding processes and service or

process conditions.

The temperature of PWHT is selected by considering the

changes being sought in the equipment or structure.

For example, a simple stress relief to reduce residual

stresses will be performed at a lower temperature than a

normalizing

heat treatment.

•RP-577 Welding Inspection and

Metallurgy

131 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.6 Post-Weld Heat Treatment

Some Important Points

• The primary reason for post-weld heat treatment is to

relieve the residual stresses in a welded fabrication.

• Stresses occur during welding due to the localized

heating and severe temperature changes.

• PWHT releases these stresses by allowing the metal to

creep slightly at the elevated temperature.

•RP-577 Welding Inspection and

Metallurgy

132 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.6 Post-Weld Heat Treatment

Some Important Points

• PWHT (stress relief) can be applied by electrical resistance

heating, furnace heating, or if allowed by the code,

local flame heating.

• Temperatures should be monitored and recorded by

thermocouples attached to the part being heated.

• Adequate support should be provided during any post-weld

heat treatment to prevent the sagging that could occur

during the heat treatment.

•RP-577 Welding Inspection and

Metallurgy

133 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.7 Hardening

Hardening or hardenability is defined as that property of a

ferrous alloy that determines the depth and distribution of

hardness induced by quenching.

It is important to note that there is no close relation between

hardenability and hardness, which is the resistance to

indentation.

Hardness depends primarily on the carbon content of the

material, where as hardenability is strongly affected by the

presence of alloying elements, such as chromium,

molybdenum and vanadium, and to a lesser extent by

carbon content and alloying elements such as nickel,

copper and silicon.

•RP-577 Welding Inspection and

Metallurgy

134 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.7 Hardening

• For example at standard medium carbon steel, such as

AISI 1040 with no alloying elements has a lower

hardenability then AISI 4340 low-alloy steel which has the

same amount of carbon, but contains small amounts of

chromium, nickel, molybdenum and silicon as alloying

elements.

• Other factors can also affect hardenability to a lesser

extent than chemical composition; these include grain

structure, alloy homogeneity, amount of certain micro-

structural phases present in the steel and overall micro

cleanliness of the steel.

•RP-577 Welding Inspection and

Metallurgy

135 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.7 Hardening

Welding variables, such as;

• heat input

• interpass temperature

• size of the weld bead being applied

All affect the cooling rate of the base metal HAZ which in

turn affect the amount of martensite formation and

hardness.

•RP-577 Welding Inspection and

Metallurgy

136 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.7 Hardening

Hardening of the weld and base metal HAZ are important

because of hydrogen assisted cracking that occurs in

carbon and low-alloy steels. As the hardness of the base

metal HAZ increases so does the susceptibility to hydrogen

assisted cracking. The hardness limits currently

recommended for steels in refinery process service are

listed in Table 11.

•RP-577 Welding Inspection and

Metallurgy

137 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.7 Hardening

•RP-577 Welding Inspection and

Metallurgy

138 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.8 Material Test Reports

Materials test reports, sometimes can be a very valuable

tool for the inspector and welding engineer.

These are typically notarized statements and are legally

binding.

There are typically two types of test reports, a heat

analysis and a product analysis.

•RP-577 Welding Inspection and

Metallurgy

139 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.8 Material Test Reports

• A heat analysis, or mill certificate, is a statement of the

chemical analysis and weight percent of the chemical

elements present in an ingot or a billet.

• A product analysis is a statement of the chemical

analysis of the end product and is supplied by the

manufacturer of the material.

•RP-577 Welding Inspection and

Metallurgy

140 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.8 Material Test Reports

A few of the items to be found on the MTR are;

a. Manufacturer of the heat of material.

b. Date of manufacture.

c. Heat Number of the material.

d. Applicable National Standard (s) to which the heat

conforms,

such as ASTM, ASME or MIL-STD.

e. Heat treatment, if applicable.

f. Chemistry of the heat.

g. Mechanical properties, at a minimum those required by

the applicable National Standards.

•RP-577 Welding Inspection and

Metallurgy

141 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.8 Material Test Reports

Some Important Points

• The inspector should review the material test report to

confirm that the material (s) being used for fabrication of

new equipment or repair of existing equipment meet the

requirements specified by the user.

• The chemical analysis given in the test report can be used

to calculate the carbon equivalent for that material.

• It is important to note that materials test reports are not

generally supplied to the purchaser unless requested.

•RP-577 Welding Inspection and

Metallurgy

142 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.9 Weldability of Steels

The American Welding Society defines weldability as “the

capacity of a metal to be welded under the fabrication

conditions imposed, into a specific, suitably designed

structure, and to perform satisfactorily in the intended

service.” Weldability is related to many factors including the

following:

a. The metallurgical compatibility of the metal or alloy being

welded, which is related to the chemical composition and

microstructure of the metal or alloy, and the weld filler metal

used.

•RP-577 Welding Inspection and

Metallurgy

143 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.9 Weldability of Steels

b. The specific welding processes being used to join the

metal.

c. The mechanical properties of the metal, such as

strength, ductility and toughness.

d. The ability of the metal to be welded such that the

completed weld has sound mechanical properties.

e. Weld joint design.

•RP-577 Welding Inspection and

Metallurgy

144 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.9.1 Metallurgy and Weldability

Some Important Points

• A primary factor affecting weldability of metals and alloys

is their chemical composition. Chemical composition not

only controls the range of mechanical properties in carbon

steel and alloy steels, it has the most influence on the

effects of welding on the material.

• The addition of carbon generally makes the metal more

difficult to weld. Carbon content has the greatest effect

on mechanical properties, such as tensile strength, ductility

and toughness in the base metal heat affected zone and

weldment.

•RP-577 Welding Inspection and

Metallurgy

145 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.9.1 Metallurgy and Weldability

Some Important Points

• Carbon content influences the susceptibility of the metal

to delayed cracking problems from hydrogen. The

carbon content or carbon equivalent of carbon steel that

determines the necessity for pre-heat and post-weld heat

treatment.

• Some alloying elements, such as manganese, chromium,

nickel and molybdenum are added to provide beneficial

effects on strength, toughness, and corrosion resistance.

•RP-577 Welding Inspection and

Metallurgy

146 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.9.1 Metallurgy and Weldability

Some Important Points

• Some of these elements are beneficial in non-heat treated

steel while others come into play during heat treatments

necessary to produce the desired mechanical properties.

• These alloying elements can have a strong effect on

hardenability, so they can also affect the weldability of the

metal being welded.

•RP-577 Welding Inspection and

Metallurgy

147 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.9.1 Metallurgy and Weldability

Some Important Points

• There are some elements present in carbon and alloy

steels that are not deliberately added that can have an affect

on weldability. These include sulfur, phosphorus, tin,

antimony and arsenic. These elements will sometimes be

referred to as tramp elements.

•RP-577 Welding Inspection and

Metallurgy

148 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.9.1 Metallurgy and Weldability

Some Important Points

One tool has been developed to help evaluate the

weldability of carbon and alloy steel and that is the carbon

equivalent (CE) equation. The CE calculates a theoretical

carbon content of the metal and takes into account not

only carbon, but also the effect of purposely added alloying

elements and tramp elements. Several different equations

for expressing carbon equivalent are in use.

•RP-577 Welding Inspection and

Metallurgy

149 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.9.1 Metallurgy and Weldability

Some Important Points

One common equation is:

*** It is not anticipated that the equation will be part of the

exam.

15

CuNiSi

5

VMoCr

6

Mn C CE

•RP-577 Welding Inspection and

Metallurgy

150 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.9.1 Metallurgy and Weldability

Some Important Points

• Typically, steels with a CE less than 0.35 require no

preheat. Steels with a CE of 0.35 – 0.55 usually require

preheating, and steels with a CE greater than 0.55 require

both preheating and a PWHT.

•RP-577 Welding Inspection and

Metallurgy

151 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.9.2 Weldability Testing

Some Important Points

One of the best means to determine weldability of a metal

or combination of metals is to perform direct weldability

testing.

Direct tests for weldability are defined as those tests that

specify welding as an essential feature of the test specimen.

Weldability testing provides a measure of the changes

induced by welding in a specified steel property and to

evaluate the expected performance of welded joints.

•RP-577 Welding Inspection and

Metallurgy

152 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.9.2 Weldability Testing

Some Important Points

It is beyond to the scope of this document to describe each

test in detail; however, a general overview of different types

of tests and what types of defects they can detect are given

in Table 12.

•RP-577 Welding Inspection and

Metallurgy

153 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

Table 12 – Weld Crack Tests

•RP-577 Welding Inspection and

Metallurgy

154 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.10 Weldability Of High-Alloys

This section will give information about welding of high

alloy metals, such as austenitic stainless steels,

precipitation hardening stainless steels and nickel based

alloys. These materials are not as common as carbon and

low-alloy steels, such as 11/4 Cr-1/2 Mo and 9Cr-1Mo, but

may still be used in some processes within the oil industry.

•RP-577 Welding Inspection and

Metallurgy

155 Cairo Inspection Company (CIC) Www. CIC-Egypt.com Eng. Ibrahim Eldesoky

10.10.1 Austenitic Stainless Steels

Some Important Points

• Austenitic stainless steels are iron-based alloys that