Chemical Soil Stabilization - Pavement Design - Zain-Danny

-

Upload

fhassi-maulavi-anfiqi -

Category

Documents

-

view

14 -

download

0

description

Transcript of Chemical Soil Stabilization - Pavement Design - Zain-Danny

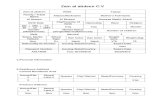

PAVEMENT DESIGN REPORT

CHEMICAL SOIL STABALIZATION:

AN INTRODUCTION TO SOIL STABALIZATION AND METHODS OF

CHEMICAL STABALIZATION

Zain Zahran Azzaino 1306437044

Danny Tirta 1306437025

CIVIL ENGINEERING DEPARTEMENT

ENGINEERING FACULTY

UNIVERSITAS INDONESIA

DEPOK 2015

Introduction to Soil StabilizationSoil stabilization is a general term for any physical, chemical, biological, or combined method

of changing the properties of natural soil to meet an engineering purpose (Winterkorn, 1991). Thus,

the primary objective of soil stabilization is to improve the California Bearing Ratio of in-situ soil.

Other objectives of soil stabilization are to improve on-site materials to create a soil and strong sub-

base and base courses to prevent the ingress of water into the treated layer, as water penetration and

heavy frosts are the cause of many road failures (TN Integrated Solutions, 2015). In modern times,

soil stabilization is almost always used to strengthen the sub-base and base courses of all types of

roads.

In the past, the binding properties of clay soils, soil cement, or compaction were used to

stabilize the soil. Now, common methods are through the mixing of soil with cement, lime, and

bitumen, such as asphalt and tar. The used method depends on nature of soil content, conditions of

mixing, compaction, curing and admixtures used (The Constructor, 2015).

There are many factors that need to be considered before applying stabilization methods to

the soil. The first factor is the presence of organic matter. In many cases, the top layers of most soil

constitute large amount of organic matters. Soil organic matters react with hydration product e.g.

calcium hydroxide (Ca(OH)2) resulting into low pH value. The resulting low pH value may retard the

hydration process and affect the hardening of stabilized soils making it difficult or impossible to

compact (Makusa, n.d.).

Another factor that needs to be analyzed is the density of the soil before stabilization.

Stabilized mixture has lower maximum dry density than that of unstabilized soil for a given degree of

compaction. The optimum moisture content increases with increasing binders. In cement stabilized

soils, hydration process takes place immediately after cement comes into contact with water. Any

delay in compaction may result in hardening of stabilized soil mass and therefore extra compaction

effort may be required to bring the same effect. On the other hand, delay in compaction for lime-

2

stabilized soils may have some advantages. Lime stabilized soil require mellowing period to allow

lime to diffuse through the soil thus producing maximum effects on plasticity (Sherwood, 1993).

Finally, it is necessary to consider the moisture content and temperature. In stabilized soils,

enough moisture content is essential not only for hydration process to proceed but also for efficient

compaction. Fully hydrated cement takes up about 20% of its own weight of water from the

surrounding; on other hand, Quicklime (CaO) takes up about 32% of its own weight of water from the

surrounding. Insufficient moisture content will cause binders to compete with soils in order to gain

these amounts of moisture and will ultimately affect the final strength (Sherwood, 1993). Some

stabilization methods are also severely affected by the temperature. For example, Pozzolanic reaction

is sensitive to changes in temperature. In the field, temperature varies continuously throughout the

day. Pozzolanic reactions between binders and soil particles will slow down at low temperature and

result into lower strength of the stabilized mass. In cold regions, it may be advisable to stabilize the

soil during the warm season (Sherwood, 1993).

Introduction to Chemical Stabilization

A method of soil stabilization that is becoming increasingly popular is the usage of chemicals.

With chemical stabilization, it is possible to control the setting and curing time. As other methods of

soil stabilization, chemical soil stabilization provides greater strength to soil, increases the density of

the soil, and improves the permeability of the soil. The degree of each of these improvements depends

on the factors. For example, when using Calcium chloride, it is necessary to use roughly 0.5% of the

total weight of the soil. However, when using Sodium chloride, it is required to use about 1% of the

total soil weight. Overall, when using chemical stabilization, it is necessary to verify the quantity

needed to be mixed with the soil (Civil Engineers Forum, 2015).

There are also several disadvantages to using chemical stabilization compared to other

stabilization methods. One disadvantage is that chemical stabilization is relatively expensive. In

addition, depending on the chemical used, the treated soil may lose strength when exposed to air or

3

ground water. Chemical stabilization is also still uncommon in certain parts of the world. Finally, it is

difficult to apply chemicals as they cannot be used directly to the surface thus requires workers with

more experience. This report will discuss in further details about pozzolan, particular fly ash, a

popular type of chemical stabilizer that is commonly used in the construction of pavement (Civil

Engineers Forum, 2015).

PozzolanPozzolan is a finely divided siliceous, or siliceous and aluminous, material which by itself

possesses little or no cementing value. In the presence of moisture, however, it will chemically react

with lime at ordinary temperatures to form cementing compounds. Natural pozzolans from different

geographical regions nevertheless have diverse properties due to their respective chemical

compositions which could lead to varying results in the products treated by these additive materials

(A. H. Vakili, 2013).

However, there are drawbacks in using pozzolan. To prevent possible drawbacks, it is

common to simultaneously use pozzolan, slag, and/or cement together with lime. In a study conducted

at Universiti Teknologi Malaysia, soil samples mixed with 4 percent cement alone, and with 1.5

percent cement plus 5 percent pozzolan simultaneously have given the lowest dispersion potentials,

which demonstrates the quick effect brought about by the cement in the treatment. It was also found

that the best overall result in reducing dispersion potential has come from one with 1.5 percent cement

plus 5 percent pozzolan and of 35 days of curing (A. H. Vakili, 2013). A mixture with such

compositions was better than any one singly treated with cement or pozzolan. Finally, in general, if

used alone in controlling dispersive soils, cement was better than pozzolan. Treatment with 2 percent

cement and 7 days of curing has produced a completely nondispersive soil. On the other hand,

treatment with 5 percent pozzolan has taken 90 days of curing in producing a non-dispersive soil (A.

H. Vakili, 2013). From these results , it is clear that pozzolan is best used with other stabilization

materials.

4

Fly AshFly ash is a commonly used pozzolan and is a by-product of coal combustion in power plants.

The burning of coal results in over 117 million tons of coal combustion by-products, most of which is

in the form of fly ash. Although utilization of fly ash is continuing to grow, less than 32% of coal

combustion by-products are recycled. The remainder of fly ash and other coal combustion by-

products are wasted in sluice ponds or landfills, taking up valuable space. When used for soil

stabilization, fly ash can be used to modify engineering properties as well as produce rapid strength

gains in unstable soils.

Picture 1. Fly Ash before mixed into the soil

There are multiple primary benefits for using self-cementing fly ash for soil stabilization. One

primary benefit is environmental incentives, because the usage of fly ash for soils stabilization means

that the material is not wasted and disposed of. Another advantage is the fact that fly ash is usually

cheaper than cement and lime and thus is more cost effective when used for soil stabilization. Finally,

due to the fact that fly ash is considered a waste material, it is highly available and the supply for fly

ash usually is greater than the demand. It is also easy to store, as it can be hydrated or conditioned

with water, and then used when required.

5

Fly ash contains silica, alumina, and different oxides and alkalis in its composition. Its general

appearance is light to dark gray powder and the size is the same as silt. The specific gravity of fly ash

ranges from 1.9 to 2.5 (Makusa, n.d.). Fly ash has been used successfully in many projects to improve

the strength characteristics of soils. Fly ash can be used to stabilize bases or subgrades, to stabilize

backfill to reduce lateral earth pressures and to stabilize embankments to improve slope stability. The

primary reason fly ash is used in soil stabilization applications is to improve the compressive and

shearing strength of soils.

Fly ash that has at least some self-cementitious properties can be engineered to perform in

transportation projects. It reduces the potential of a plastic soil to undergo volumetric expansion by a

physical cementing mechanism, which cannot be evaluated by the plasticity index. Fly ash controls

shrink-swell by cementing the soil grains together much like a Portland cement bonds aggregates

together to make concrete. By bonding the soil grains together, soil particle movements are restricted

(Makusa, n.d.).

A high-calcium fly ash is influenced by the types of clay minerals present in the soil and their

adsorbed water. It has been found to be very effective drying agents, capable of reducing soil moisture

content by 30 percent or more. The fly ash dries the soil by two basic mechanisms, chemical reactions

that consume moisture in the soil and by simple dilution. Class C fly ashes contain tricalcium

aluminate (C3A), which is highly reactive with water. C3A is the chemical compound present in

ordinary Portland cement which is responsible for early strength. The C3A present in fly ash reacts

with the water, lowering the overall moisture content of the soil (Makusa, n.d.). The drying effect of

fly ash in wet soil is very rapid and immediate, permitting the contractor to quickly proceed with

construction. In addition to the speeding up of the construction process the use of fly ash provides

several other benefits, such as making the soil more resistant to additional water infiltration, provides

additional support for traffic, creates a more stable work platform and reduces dusting from

construction traffic.

6

Parameters of Fly Ash

MixingWhen using fly ash as a soil stabilizer, it is necessary to determine how to achieve thorough

and uniform mixing with the soil. Currently, there are two approaches for the mixing: off-site mixing

and on-site mixing. Off-site mixing uses continuous or batch type mixing and has the advantage of

achieving more uniform mixtures because the amount of materials batched can be controlled to a

greater extent than with on-site mixing. However, fly ash rapidly settles in as little as ten minutes and

thus there is a decrease in strength if there are any delays in compaction. Continuous off-site mixing

requires mixing plants brought in on a conveyor system to a mixer, where they are combined with

water and then loaded directly into a truck. Batch-type off-site mixing is similar to the mixing of

Portland cement, where the batch is mixed in the truck while on the way to the construction site.

On-site mixing does not require the establishment of a mixing plant and thus is more likely to

be able to use the full extent of the strength of fly ash. For this method, fly ash is trucked to the site

and then spread directly onto the subgrade or base soil. The mixing is then completing using a

pulvamixer or disk. The usage of equipment depends on the type of soil. Construct disks are shown to

be effective when used for fine grained soil or unstable subgrades (David J. White, 2005).

Picture 2. Pulvamixer

7

Application of WaterIt is also important to analyze the addition of water during the mixing of soil and fly ash.

When using a mixing plant, the recommended suggestions for water is from 80% to 110% of the

optimum water content, based on the moisture-density relationship of the stabilized mixture, to obtain

proper density at the time of compaction. However, when using on-site mixing, water has to be added

directly onto the subgrade or base soil. This is more difficult, as the addition of water may cause the

subgrade to become more unstable. Thus, it is also possible to add water onto the soil after the fly ash

has been incorporated into the soul. Another effective method is to add the water directly into the

mixing drum of the pulvamixer; this method produces the most uniform mixture and the least amount

of delay in the construction progress (David J. White, 2005).

Compaction and CuringTo increase the relative compacting of fly ash soil, it is recommended that the initial

compaction is done with a sheepsfoot or padfoot roller and finished with a pneumatic roller.

Compaction delay time also needs to be considered since the stabilized material can lose strength gain

capacity if the fly ash hydrates while in an uncompacted state. Class F fly ash only has a maximum

compaction delay time of up to four hours. It is recommended that compaction should commence

immediately after the final mixing and completed within two hours.

To cure the fly ash soil, it is necessary to seal the completed sections before overlaying

pavement sections to allow the fly ash to hydrate and gain required strength. Availability of moisture,

temperature during curing, and length of cure time all affect the strength gain of fly ash-stabilized

soils. Typically, mixtures are cured by sprinkling with water or by coating with a thin layer of

emulsion or cutback asphalt. It is recommended that the sealer is applied within one day of

completing the section. The section should be cured for three to seven days before the pavement

sections are placed. While curing, the air temperature should remain below 40 degrees Fahrenheit.

With lower temperatures, the strength gain will be slower. However, with higher temperatures, the

compressive strength will also decrease (David J. White, 2005).

8

Quality Testing of Fly Ash Soil

In Place Density DeterminationCompacted density is a primary quality control parameter, as the maximum strength cannot

be accomplished with the fly ash soil is not compacted into the dense state. It is recommended that the

density is from 90% to 95% based on the standard proctor maximum density. To determine the

density of the soil, the possible tests are sand cone, rubber balloon, nuclear gauge, and drive cylinder.

The advantages of these tests are that the removed materials can be used directly to measure the

density. However, these tests have the disadvantage of being time consuming and requiring a

significant amount of time to gather the moisture results (David J. White, 2005).

Picture 3. Sand Cone

Moisture Content DeterminationAnother important parameter to measure accurately is the moisture of the stabilized soil. The

maximum strength and compaction cannot be achieved without the proper moisture content. An

accurate method to determine the moisture content of fly ash soil is through the direct heating method,

where the samples are taken back to a laboratory and dried either through an oven or direct heating.

The moisture content can be determined thorough the change in weight of the sample after heating.

Another method is “Speedy Moisture Tester” from ASTM D4944 but has been known to be unreliable

9

and variable. Finally, a quick and easy method to determine the moisture content is through the usage

of a nuclear moisture gauge. However, this method also has the disadvantage of having measurements

subject to errors. It is possible to use this method as long as calibrations and corrections are

determined. Overall, there are methods to determine the moisture content, and the usage of these

methods depends on the amount of available time for testing (David J. White, 2005).

Stability of Compacted MaterialTo measure the stability of the soil stabilized with fly ash, there are two methods: the Clegg

Impact Test (ASTM D5874) and the Dynamic Core Penetrometer. The Clegg Impact Value is

correlated to the CBR of the material. These values are taken at the surface of the stabilized layer, and

the test itself takes less than one minute to complete. The correlation between the Clegg Impact Value

and CBR is based on the following equation:

CBR=12.241 e0.0572CIV

Alternatively, it is possible to determine the stability through the Dynamic Core Penetrometer

method. This test involves plotting a graph of material stability versus depth. The correlation between

DCP depth in mm/blow and CBR is based on the following equation:

CBR= 292DCP1.12

10

Works CitedA. H. Vakili, M. R. S. a. H. M., 2013. Effects of Using Pozzolan and Portland Cement in the Treatment of Dispersive Clay. The Scientific World Journal, Volume 2013.

A. Maghchiche, ,. A. H. B. I., 2010. Use of polymers and biopolymers for water retaining and soil stabilization in arid and semiarid regions. Journal of Taibah University for Science, Volume 4, p. 9–16.

Civil Engineers Forum, 2015. Chemical Stabilization of Soils. [Online] Available at: http://civilengineersforum.com/chemical-stabilization/[Diakses 5 October 2015].

David J. White, D. H. a. Z. T., 2005. Fly Ash Soil Stabilization for Non-Uniform Subgrade Soils, Volume I: Engineering Properties and Construction Guidelines. Center for Transportation Research and Education.

Ellis, H. B., 1963. Stabalization of soil with lime and sodium silicate, s.l.: Iowa State University.

Hossein Moayedi, B. B. K. H. S. K. S. D., 2012. Stabilization of organic soil using sodium silicate system grout. International Journal of Physical Sciences, Volume 7.

Makusa, G. P., t.thn. SOIL STABILIZATION METHODS AND MATERIALS. Lulea, Sweden: Luleå University of Technology.

Peters Chemical Company, 2006. Dust Control and Base Stabilization with Liquidow Calcium Chloride. [Online] Available at: http://www.peterschemical.com/dust-control-and-base-stabilization-with-liquidow-calcium-chloride/[Diakses 5 October 2015].

Sherwood, P., 1993. Soil Stabalization with Cement and Lime. London: s.n.

The Constructor, 2015. SOIL STABALIZATION METHODS AND MATERIALS. [Online] Available at: http://theconstructor.org/geotechnical/soil-stabilization-methods-and-materials/9439/[Diakses 4 October 2015].

TN Integrated Solutions, 2015. What is Soil Stabilizing?. [Online] Available at: http://aggrebind.com/about/what-is-a-polymer-what-is-soil-stabilizing/[Diakses 4 October 2015].

Winterkorn, H. F. a. S. P., 1991. Soil Stabilization and Grouting. 2nd penyunt. New York: VanNostrand Reinhold.

11