CHAPTER II HISTORICAL REVIEW OF CEMENT INDUSTRY IN...

Transcript of CHAPTER II HISTORICAL REVIEW OF CEMENT INDUSTRY IN...

CHAPTER II

HISTORICAL REVIEW OF CEMENT INDUSTRY IN INDIA

AND PROFILE OF THE CEMENT FACTORIES IN

SOUTH TAMIL NADU

2.1 Introduction

2.2 History of the Cement Industry

2.2.1 Historical Usage of Cement

2.2.2 The Working Group on Cement Industry

2.2.3 The Manufacturing Process and Technology

2.2.4 Major Varieties of Cement

2.2.5 Exports of Indian Cement Industry

2.3 Profile of the Study Units

2.3.1 Geographical Area of the Study Units

2.3.2 Madras Cements Limited (MCL)

2.3.3 India Cements Limited (ICL)

2.3.4 Tamil Nadu Cements Corporation (TANCEM)

2.3.5. Labour Welfare Facilities

44

CHAPTER II

HISTORICAL REVIEW OF CEMENT INDUSTRY IN INDIA

AND PROFILE OF THE CEMENT FACTORIES IN

SOUTH TAMIL NADU

2.1 INTRODUCTION

The present chapter is devoted for the presentation of a brief account about the

origin and growth of cement industry in India as well as in the State of Tamil Nadu.

It also reviews the profile of the three cement factories located in the study area

namely, South Tami Nadu.

2.2 CEMENT INDUSTRY IN INDIA

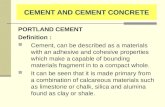

2.2.1 Cement – Meaning and Definition

The word ‘cement’ had come from the Latin Verb ‘to cut’ and originally it

might had some reference to the stone cuttings used in the production of lime mortar.

Thus it is logical that during the middle ages the lime mortar itself had been used as

cement. In its modern usage, cement generally refers only to the chemical binder, and

the term might be used with respect to any material serving such a purpose.1

According to Robert G. Blezard,2

Cement may be defined as “adhesive substances

capable of uniting fragments or masses of solid matter to a compact whole”.

45

2.2.2 The Working Group on Cement Industry

The development and growth of the cement industry is considered as one of

the important indicators of a country’s economic development. Hence, India is

giving very importance to cement production.3

The first cement factory was

established in India in the year 1904 by the South India Industries Limited, Madras,

to produce Portland Cement. But the factory had failed to take off and it was closed.

The first successful cement unit in India came into being in the year 1912-1913 at

Porbandar in the Gujarat State. In 1914, this unit was said to have produced about

1000 tonnes of cement per annum. In 1947, the Indian Standard Specifications (ISS)

were applied to test the quality of cement instead of the British Standard

Specifications (BSS).4

In the same year, the installed capacity of the cement industry

rose to the level of 2.2 million tonnes per annum.

After the partition of the country, five of the cement producing units had gone

to the Pakistan territory and the total installed capacity of the 18 units that had

remained in India was 1.5 million tonnes per annum.5

The cement industry had gone through a phase of planned development during

the period of the five-year plans in India. The working group on cement industry was

constituted by the Planning Commission for enabling the growth and development of

the cement industry during the Tenth Plan period. It had projected a growth rate of 10

46

per cent for the cement industry and had recommended the creation of an additional

capacity of 40 to 62 million tonnes, mainly through the expansion of the existing

plants during the Tenth Plan period.6

A profile of the cement industry’s

development during the five-year plan periods is presented in Table 2.1.

TABLE 2.1

GROWTH OF CEMENT INDUSTRY IN INDIA THROUGH

FIVE YEAR PLANS

Five Year

Plan

Year Capacity Actual

Production

Percentage

of Capacity

Utilisation

Average

Annual

Growth

Rate

I Plan 1955-56 5.02 4.60 91.63 --

II Plan 1960-61 9.30 7.97 85.69 85.26

III Plan 1965-66 12.00 10.97 91.42 39.78

IV Plan 1973-74 19.76 14.66 74.19 64.67

V Plan 1978-79 22.58 19.42 86.00 14.27

VI Plan 1984-85 42.00 30.13 71.74 86.00

VII Plan 1989-90 61.55 45.41 73.78 46.55

Annual Plan 1990-91 64.36 48.90 75.98 4.57

Annual Plan 1991-92 65.56 53.61 81.77 1.86

VIII Plan 1992-93 70.19 54.08 77.05 7.06

1993-94 76.96 57.96 75.31 9.65

1994-95 83.79 62.35 74.41 8.87

1995-96 95.76 69.63 72.71 14.29

1996-97 105.25 76.22 72.42 9.91

IX Plan 1997-98 110.51 83.16 75.25 4.98

1998-99 118.97 87.91 73.89 7.66

1999-00 118.16 100.29 84.88 0.68

2000-01 132.47 100.11 75.57 12.11

2001-02 145.99 106.90 73.49 10.21

X Plan 2002-03 151.17 116.35 76.97 3.55

2003-04 157.48 123.50 78.42 4.17

2004-05 164.69 133.57 81.10 4.14

Source: CMA – Annual Report, 2004-2005.

Note : Mini Cement Plants are also included.

47

Table 2.1 reveals that the productive capacity of the cement factories in India

had increased from 5.02 million tonnes in 1955-56 to 164.69 million tonnes in

2004-05, which had accounted for an increase of nearly 32 times between the First

and Tenth Plans. But the actual production had gone up from 4.60 million tonnes to

133.57 million tonnes during the same period and this accounted for an increase of

nearly 28 times. It had shown that the actual production of cement had not increased

to the level of its full capacity. A declining trend could be noticed in the percentages

of actual achievement, as shown in Table 2.1 which had proved the fact that there

had been a relatively lesser growth in the actual production of cement as compared to

that of the installed capacity of the cement industry in India during the plan periods.

India had emerged as the second largest cement producer in the world, next

only to that of China in the year 2006.7

At present, India produces around 128

million tonnes (about 6.4 per cent of the world’s production of 2000 million tonnes)

of cement and has an installed capacity of about 155 million tonnes.8

Most of the

existing cement plants in India had modified their plants from the wet process of

production to the energy efficient dry process. At present, out of the 157 cement kilns

in the country, 117 are dry process-based, 32 are wet process based and eight units

are semi dry process-based. At present 93 per cent of the total installed capacity in

the industry is using the modern environment-friendly dry process technology and

only the remaining 7 per cent of the installed capacity is based on the old wet and

48

semi-dry process technologies. The induction of the advanced technology process

had helped the industry in reducing its requirements of power and fuel and in saving

the material inputs to a considerable extent. The cement industry in India was free

from price and distribution controls from the 1st March 1989. It was also de-licensed

on the 25th

of July 1991.9

2.2.3. The Manufacturing Process And Technology

Cement is manufactured in two stages – Clinkering and Grinding. At the

Clinkering stage, limestone and clay are mixed proportions in specified and burnt in

a kiln to produce the clinker. The clinker is then ground along with gypsum to obtain

cement.10

There are two major processes in the manufacturing of cement; the wet

process and the dry process. In the wet process, the mixture of the limestone and clay

is fed into the kiln in a semi-liquid form as compared to the dry process where the

mixture is fed into the kiln in the form of a dry powder. There is relatively a lower

level of energy consumption in the dry process of producing the cement. Hence, the

dry process is considered to be more energy efficient as compared to the wet process

in the manufacturing of cement.11

2.2.4 Major Varieties of Cement

The three major varieties of cement are Ordinary Portland Cement (OPC)

Portland Pozzolona Cement (PPC) and Portland blast furnace Slag Cement (PBFSC).

49

Besides these varieties, specially cements like white cement, oil well cement,

rapid hardening cement, hydrophobic cement, high alumina cement and sulphate

resistant cement are also manufactured for specific applications and for specific uses.

TABLE 2.2

MAJOR VARIETIES OF CEMENT

Ordinary

Portland Cement

(OPC)

Portland

Pozzolana Cement

(PPC)

Portland Blast Furnace

Slag Cement (PBFSC)

Ingredients

Clinker 95 per cent +

Gypsum 5 per cent

Clinker 70 per cent

+

Flayash upto 25 per

cent

+ Gypsum 5 per cent

Clinker 30 to 75 per cent

Blast furnace slag upto

25 to 65 per cent +

gypsum 5 per cent

Application Best suited for all

kinds of Masonary

work and for small

concrete works

High strength cement

suitable for mass

concrete works like

dams and large

foundations.

Ideal for

construction in hot

and humid areas.

Source: CMA Annual Report 2004-05.

Table 2.2, exhibits that the ingredients of the ordinary portland cement

consists of 95 per cent of clinker, which is a combination of limestone and gypsum.

The limestone is a costly material and it is also a depleting resource. Hence, the

production of blended cement (PPC + PBFSC) is more than that of the OPC in the

world.

50

2.2.5 Export Performance of Indian Cement Industry

Apart from meeting the domestic demand, the cement industry also exports

cement and clinker. Because of its world class quality Indian cement had found

favour with the overseas markets also. Cement exports from India had commenced in

the year 1988-89 and it had risen steadily till the year 1993-94. The exports of

cement were steady at around 2.5 to 3.0 million tonnes between 1993-94 and

1996-97. The exports had declined from 4.40 million tonnes in 1997-98 to 3.14

million tonnes in the year 1999-2000 due to excess capacity in the East Asian region

and the depressed demand for cement following the East Asian Financial Crisis.12

The export prospects of cement and clinker from India had improved

considerably in the years 2004-05 and 2005-06 with a boom in the construction

activities in West Asia. The exports of cement rose by about 21 per cent and clinker

by about 6.2 per cent in the year 2004-05. Indian cement industry exports around 4

million tonnes of cement annually. At present Ultra Tech Cement (UTC) is the

India’s largest exporter of cement and clinker. It exports over 3 million tonnes of its

products annually accounting for 40 per cent of India’s total exports.13

Cement is exported by India to her neighbouring countries such as

Bangladesh, Myanmar, Nepal, Indonesia, Malaysia and Srilanka while clinker is

exported to the Middle East, West Asia and the African countries. The Indian cement

51

is costlier in the world market due to its higher input costs and higher taxes, and other

levies and royalty charges and also due to its high transport costs. The export

performance of the cement industry for the period 1995-96 to 2004-05 is presented in

Table 2.3 which is followed by a graph.

TABLE 2.3

EXPORTS OF CEMENT AND CLINKER

(Million tonnes)

Year Cement Annual

Growth

Rate

Clinker Annual

Growth

Rate

Total

1995-96 1.51 -- 0.90 -- 2.41

1996-97 1.71 13.25 0.94 4.44 2.65

1997-98 2.68 56.73 1.72 82.98 4.40

1998-99 2.06 -23.13 1.45 -15.70 3.51

1999-00 1.95 -5.34 1.19 -17.93 3.14

2000-01 3.15 61.54 2.00 68.07 5.15

2001-02 3.38 7.03 1.76 -12.00 5.14

2002-03 3.47 2.66 3.45 96.02 6.92

2003-04 3.36 -3.17 5.64 63.48 9.00

2004-05 4.07 21.13 5.99 6.21 10.06

Source: CMA Annual Report 2004-05.

52

Table 2.3 clearly discloses that the cement exports of India had increased from

1.51 million tonnes in the year 1995-96 to 4.07 million tonnes in 2004-05 which had

accounted for a 169.54 per cent growth on exports of cements. Exports of clinker had

registered a 565.55 per cent increase during the same period. However, total exports

had gone up by 317.43 per cent during the period under review. It would be further

evident from Table 2.3 that the exports of cement and the exports of clinker had

recorded a steady growth albeit slight ups and downs during the period 1997 to 2000.

2.3 PROFILE OF THE STUDY UNITS

The cement industry is basically a capital-intensive industry serving as the

backbone for the infrastructural growth of the economy. It is an industry which has

the highest backward and forward linkages with the economy and is closely related to

the overall economic growth of the country.

In this part, the researcher had made an attempt to provide a profile of the

study units in terms of their location, installed capacity, the presence of trade unions

and the labour welfare facilities provided by each of the study units.

2.3.1 Study Area

For the present study, the South Tamil Nadu has been selected as the study

area. Traditionally South-Tamil Nadu was construed as the area comprising of the

53

Madurai, Ramnad and the Tirunelveli Districts (MRT Districts). The Government of

Tamilnadu had divided these districts (MRT Districts) into a number of other districts

also for the sake of administrative convenience. Those three districts had now

become nine districts, namely, Ramanathapuram, Sivaganga, Virudhunagar,

Madurai, Theni, Dindigul, Tirunelveli, Tuticorin and Kanniyakumari. Hence, these

nine districts constitute the geographical area for the purpose of the present study.

There are only three cement factories situated in the study area considered for

the present study. Of them, one is the Madras Cements Limited Ltd., (MCL) located

at Ramasamy Raja Nagar, Thulukkapatty and the second one is the Tamilnadu

Cements Corporations (TANCEM) located at Alangulam. Both of them are located in

the Virudhunagar district. The third one is India Cements Ltd., (ICL) located at

Sankar Nagar (Thalayuthu) in the Tirunelveli district.

2.3.2 Madras Cements Limited (MCL)

The Madras Cements Limited (MCL) is the flagship company of the Ramco

group of industries having a capital worth of Rs. 1200 crores. It was founded in the

year 1957 by the late Sri. P.A.C. Ramasamy Raja who was a Philanthropist. The

company is managed by a Board consisting of 10 Directors. The Group is presently

being headed by the Chairman and Managing Director, Shri. P.R. Rama Subramaniya

Rajha, son of its founder. He had been associated with a group of companies from the

54

year 1963 onwards and under his able leadership the Group had achieved many

laurels. In Particular, The Madras Cements Limited had scaled very great heights.

The company has three cement plants, one at Ramasamy Raja Nagar, in the

Virudhunagar district in the State of Tamil Nadu, which is one of the study units; the

second one is located at Jayanthipuram, Krishna District in the State of Andhra

Pradesh and the third one is situated at Alathiyur, in the Ariyalur District in the State

of Tamil Nadu. However, the present study had taken into consideration only,

Ramasamy Raja Nagar unit, as the location of the other two units do not come under

the description, the Southern part of Tamilnadu.

TABLE 2.4

VARIOUS PLANTS OF MADRAS CEMENTS LIMITED

Sl.

No.

Plant Location State Year of

Inception

Present

Productive

Capacity in

000’ tonnes

1. Ramasamy

Raja Nagar

R.S. Raja

Nagar* Tamil Nadu 1961 750.00

2. Jayanthipuram Jaggayyapet** Andhra

Pradesh 1986 1600.00

3. Alathiyur

Works – I Alathiyur** Tamil Nadu 1997 1360.00

Alathiyur

Works - II Alathiyur** Tamil Nadu 2001 1 760.00

Source: Annual Report 2004-05, Cement Manufacturers’ Association.

* Located in the study area.

** Not located in the study area.

55

The R.R. Nagar factory was the first cement plant to be set up by the Madras

Cements Limited at Ramasamy Raja Nagar. It was a wet process cement plant with

an annual productive capacity of 0.20 million tonnes and had commenced its

operations in the year 1961. Another wet process kiln with an annual installed

capacity of 0.35 million tonnes was installed in the year 1963. In a major move

towards technology upgradation, the existing two wet process kilns were scrapped on

1977 and production was switched over to the dry process. Currently, the capacity of

this plant is 0.75 million tonnes per annum. This factory got its ISO 9002 certificate

from the Bureau of Indian Standard (BIS) on October 16th

, 1994. This is the first

factory which had adopted the dry process in cement production in India. The

company was also the first in India to install the use of the X-ray analysis for the

hour to hour quality monitoring about the raw materials. The limestone quarry which

supplies raw-materials for cement production is fully mechanised with the latest giant

excavators, loaders and hauling dumpers. The electrostatic precipitators had been

installed at all strategic stages for purposes of pollution control.

The limestone, the basic raw-material that was required for the production of

cement in the Ramasamy Raja Nagar factory was being extracted from the main lime

stone quarry at Pandalkudhi, Near Aruppukottai, in the Virudhunagar district in the

State of Tamil Nadu. Nearly 100 workers are engaged in the lime stone quarry for the

extraction of lime stone. At present 499 workers are working in the factory in

56

different types of work on a permanent basis. The permanent workers are being paid

under the wage board system. The wages of the workers would be revised every five

years by the National Wage board settlement process. In addition to the permanent

workers, about 150 workers are also appointed on a contract basis for carrying out

various terms of works. However, the present study had taken into consideration only

the permanent workers for the reason that the number of temporary workers is not a

fixed one and they were employed either on an hourly basis or on a daily basis. The

factory had reduced the strength of the workers by enforcing the Voluntary

Retirement Scheme (VRS). In order to carry out the managerial functions 55

managerial persons are working in the different departments of the factory.

It is a practice among the workers to join any of the trade unions as members

according to their will and pleasure wish. The following three trade unions were

functioning in this factory at the time of the research study.

1) Madras Cements National Workers’ Union (INTUC).

2) Madras Cements Dravidian Employees Progressive Union (DMK).

3) Madras Cements Anna Thozhilalar Sangam (ADMK).

The personnel department of this factory had been regularly arranging for

periodical training programmes to all its workers. It was expected to develop a

57

cordial relationship and promote the mutual understanding between the workers and

the Management.

2.3.3 India Cements Limited (ICL)

India cements was founded in the year 1946 jointly by Late

S.N.N.Sankaralinga Iyer and Late T.S. Narayanaswami. Since then, the India

cements limited had started its march towards the attainment of excellence. The

company is managed by a Board consisting of 10 directors. Experts from various

fields such as Administration, Banking, Law and Finance are included as members in

the Boards of Directors. Besides, it also includes the nominee of the Industrial Credit

Investment Corporation of India (ICICI) Limited, Unit Trust of India (UTI), Life

Insurance Corporation of India (LIC) and the Industrial Development Bank of India

(IDBI). The present Chairman N. Sankar and the Managing Director and Vice

Chairman N. Srinivasan have contributed much to the development and growth of the

factory. The Managing Director. N. Srinivasan had been the President of the

“Cement Manufacturers’ Association” (CMA) also, since 2000.

The India Cements company has seven cement factories located in the

different parts of our country. Among the seven factories, India cements- Sankar

Nagar factory is one of our study units. Table 2.5 presents a the clear picture of the

58

seven cement factories of India Cements Ltd., located in the different parts of our

country.

TABLE 2.5

DETAILS ABOUT THE FACTORIES OF INDIA CEMENTS LIMITED

Sl.

No.

Plant Location State Year of

Inception/

Acquisition

Present

Production

Capacity

in 000’

tonnes

Acquired

from

1. Sankar

Nagar Talayuth*

Tamil

Nadu 1946 1550.00 --

2. Sankar

Durg Sankaridurg**

Tamil

Nadu 1963 720.00 --

3. Chilamkur

Works Chilamkur**

Andhra

Pradesh 1990 1300.00

Coromandal

Fertilizers

Ltd.

4. Dalavoi Trichi** Tamil

Nadu 1997 1300.00 --

5. Visaka

Cement Tandur**

Andhra

Pradesh 1998 1120.00

Acquired

through the

subsidiary

6. Yerragunta Yerragunta** Andhra

Pradesh 1998 520.00

Cement

Corporation

of India

(CCI)

7. Rasi

Cement Wadapally**

Andhra

Pradesh 1998 2300.00

Rasi

Cement

Ltd.

Source: Annual Report 2004-05, Cement Manufacturers’ Association (CMA).

* Located in the study area.

** Not located in the study area.

Sankar Nagar unit is the first cement factory to be commissioned by the India

cements limited at Sankar Nagar, in the Tirunelveli District. The initial capacity was

59

0.12 million tonnes per annum in the year 1946. The first increase in the installed

capacity was made in the year 1956 from 0.12 million tonnes to 0.46 million tonnes.

In a major move towards technology upgradation, this plant was switched over to the

dry process of production. Currently the capacity of this plant is 1.55 million tonnes.

The factory has a lime stone deposit of 20 million tonnes. Based on current

production levels, the lime stone reserves are expected to last for another 10 years.

The cost of lime stone extraction is relatively high due to the advanced stage of the

mines

At present, there are 458 wage board employees working in the Sankar Nagar

factory. To look after the managerial activities of the factory 52 officers are

employed as managerial personnel. Only two trade unions are functioning in the

factory. One is the India Cements General employees union and the other one is

India cements National workers’ union.

2.3.4. Tamil Nadu Cements Corporation (TANCEM)

The Tamil Nadu Cements Corporation Limited is the public sector

undertaking in the sphere of cement production in Tamil Nadu. In 1970, The Tamil

Nadu Industrial Development Corporation had established its first cement factory at

Alangulam, which is an industrially backward area in the Virudhunagar district. The

company is managed by a Board consisting of nine Directors. The Government of

60

Tamil Nadu had nominated an officer from the Indian Administrative Service to act

as its Chairman and Managing Director. Besides, the nominees from the public works

department, the finance department, the Tamilnadu Housing Board, Tamil Nadu

Water Supply & Drainage Board, the Commissioner of Geology and the Joint

Secretary to Government of the Industries department are also on the Board. The

Tamil Nadu Cements Corporation Limited has two cement factories. One is at

Alangulam and the other one is at Ariyalur in the State of Tamil Nadu. The

Alangulam unit is one among the study units of the present research work. Table 2.6

presents the details about the two cement factories of the Tamilnadu Cements

Corporation located at different places.

TABLE 2.6

DETAILS OF THE FACTORIES OF TANCEM LIMITED

Sl.

No.

Plant Location District State Year of

Inception

Present

Production

Capacity in

000’ tonnes

1.

Alangulam

Cements

Works

Alangulam* Virudhunagar Tamil

Nadu 1970 400.00

2.

Ariyalur

Cement

Works

Ariyalur** Ariyalur Tamil

Nadu 1979 500.00

Source: Annual Report 2004-05, Cement Manufacturers’ Association.

* Located in the study area.

** Not located in the study area.

Alangulam Cement Works is the first state owned cement industry set up by

the Tamilnadu Industrial Development Corporation (TIDCO). The Alangulam

61

cement works, which is a wet process cement plant, was set up with an installed

capacity of 0.40 million tonnes of cement per annum at a capital cost of Rs.6.66

crores in the year 1970. The plant is located at Alangulam which is in between

Rajapalayam and Sivakasi in the Virudhunagar District in the Tamil Nadu State.

At present there are 543 workers working in this factory. This factory is also

paying wages to its employees on the basis of the wages fixed by the National Wage

Board Settlement. Though it is a public sector state owned government undertaking,

it employs contract labourers for carrying out different types and items of work. They

are paid only low wages.

TABLE 2.7

OFFICERS’ AND WORKERS’ STRENGTH DURING 1975 TO 2005

Sl.No. Year No. of

Officers

No. of

Workers

Total

1. 1975 46 1370 1416

2. 1980 60 1416 1476

3. 1985 58 1552 1610

4. 1990 137 1439 1576

5. 1995 129 1167 1296

6. 2000 97 917 1014

7. 2005 94 543 637

Source: Records maintained in the Personnel Department of TANCEM..

62

From Table 2.7 it could be understood that the strength of the labour force had

been reduced gradually during the period 1975 to 2005. Modernisation and

mechanisation had been the important reason among others for the declining strength

of the employees in this unit.

Compared to the other two private cement factories, a larger number of trade

unions has been functioning in the Alangulam cement factory. During the period of

the research study ten trade unions were functioning in this factory, namely,

1. Alangulam Socialist worker’s union.

2. Tamil Nadu Cements’ National Worker’s Union (INTUC)

3. All India Forward Block Tholilalar Munnetra Sangam (AIFB)

4. Kamarajar Mavata Cement Quarry workers’ union.

5. Anna Tholilalar Sangam. (ADMK).

6. SC and ST Employees’ Association (SC&ST).

7. Labour Progressive Federation (DMK).

8. Tamil Nadu Cements Alai Tholilalar Munnetra Sangam.

9. Arasu Cement and Asbestos Dravida Uliyar Munnetra Sangam.

10. Tamil Nadu Cements Administrative and Technical Staff Association.

63

2.3.5. Labour Welfare Facilities

The following labour welfare facilities had been provided by the respective

managements of the study units.

1. Provision of Uniforms

All employees including the officers and the administrative staff were

supplied two sets of terrycotton uniforms every year. The workmen who were

covered under the work load were given additional set of cotton uniforms per year.

Each employee except the officers and who were supplied uniforms were also paid

Rs. 250/- per year towards stitching charges.

2. Provision of Shoes

All the employees including the officers and the administrative staff were

supplied at the rate of one pair of shoes per year.

3. Payment of Dust Allowance

All the employees, including the officers and the administrative staff were

supplied a minimum quantity of 500 grams of Jaggery and 500 grams of coconut oil

per month. The workmen working in certain sections such as the packing section and

64

in the kiln selection were given a larger quantity of coconut oil and jaggery as

disclosed in Table 2.8.

TABLE 2.8

SUPPLY OF COCONUT OIL AND JAGGERY TO WORKERS

Sl. No. Name of the Section Coconut oil Jagger

1. Kiln Section

(Workers for maintenace)

600 gms 600 gms

2. Kiln heat area (coal mill) 800 gms 800 gms

3. Packing House

Packers

Loading mazdoors

Operators

900 gms

800 gms

600 gms

1560 gms

1560 gms

1560 gms

Source: Records maintained in the Personnel Department of Study Units.

4. Provision of Blue Cloth and Turkey Towel for Workers

All the workmen and technical staff except the administrative staff and the

officers were supplied with one Turkey Towel every six months and with one metre

of blue cloth once a year. Workmen in the packaging section were supplied one

metre of blue cloth every month along with two turkey towels a year.

5. Provision of Soap

All the workers and technical staff were supplied two cakes of soaps of 100

grams each every month. But only one cake of toilet soap was supplied to the officers

and the administrative staff.

65

6. Payment of Heavy Vehicle Allowance for Factory Workers and Quarry

Workers

All the heavy vehicle drivers were paid Rs. 20/- per month, except the dumper

operators and the PC 650 operators who were paid at the rate of Rs. 5/- per shift as a

heavy duty allowance.

7. Provision for Heat Allowance

I. 5 per cent of the basic pay is paid as the heat allowance to the

employees working in the following places:

1. Burner’s platform.

2. Clinkers Shakers.

3. Fuller coolers.

4. Slag drier.

5. Operators.

6. Loco Fireman and attendant’s and Millers working in the hot air furnace

for coal mills.

II. 2.5 per cent of basic pay is paid by way of heat allowance to the

employees engaged in

1. Greasing

2. Lubricating

3. Kiln rollers’ Greasing and those working in fluxo pits in the cement mills.

66

8. Provision for Night Shift Allowance

All the workers working in the shifts ending after 6 P.M. but not beyond

midnight were supplied one cup of tea free of cost as the night shift allowance. For

workers working in shifts ending beyond midnight, a night shift allowance of Re.1/-

per such shift was paid. Hence, the night shift allowance includes both cash

payments and tea supplies.

9. Provision of Conveyance Allowance

Employees covered by the Wage Board were being paid a conveyance

allowance of Rs. 875/- per month.

The non-wage board employees were paid a conveyance allowance for

maintaining their vehicles depending upon of vehicles used by them.

Motor Car Rs. 870/- per month.

Motor Cycle Rs. 360/- per month.

Moped Rs. 280/- per month.

10. Payment of Acting Allowance

If an employee was called upon to act and perform the duties of a higher post,

he was paid the difference in the amount between the minimum of his scale of pay

67

and the minimum of the higher grade scale of pay. Such an allowance would be

payable only if he had worked in the higher post for not less than seven days in a

month.

11. Payment of Periodical Allowances

A sum of Rs.100 per month was paid to all the wage board employees as a

periodical allowance.

12. Provision for Educational Allowance

All wage board employees, whose children were studying in schools, colleges,

or technical institutions were paid a sum of Rs. 450 per month by way of education

allowance irrespective of the number of children studying in the institutions.

13. Provision for Leave Travel Allowance

A sum of Rs.500 per month was paid by way of leave travel allowance to all

the cement wage board employees. The non-wage board employees were eligible to

avail themselves of the leave travel allowance once in four years as per the State

Government rules.

14. Availability of Leave Facilities

The leave facilities available in the study units for the employees are presented

below:

68

For workers -

Casual Leave - 15 days per year

Medical Leave - 18 days for every completed one year of service.

Earned Leave - 1/17 days of the total number of working days.

For Officers and Staff

Casual Leave - 15 days per year.

Medical Leave - 18 days for every completed year of service.

Earned Leave - 1/11 days of the total number of working days.

Besides, the officers and staff were eligible for 4 days of National Holidays

and 5 days of festival holidays in a year.

15. Provision of Washing Allowance

All the wage board employees who were supplied with uniforms were paid

a sum of Rs. 35/- per month by way of a washing allowance.

16. Payment of Graduate Allowance

The administrative staff who had completed their degrees were eligible for a

sum of Rs. 20/- per month by way of a graduate allowance.

69

17. Provision for House Building Advance

The workmen and staff were allowed to avail themselves of house building

loans from HDFC/LIC/ or the Co-operative Societies and the interest amounts of

over and above the level of 6 per cent was borne by the employer as a welfare

measure, that is, as a subsidy given by the management. The non-wage board

employees were allowed such a concession as per their service rules.

18. Provident Fund Contribution

E.P.F. (Employees Provident Fund) contribution at the rate of 12 per cent

from the salary (inclusive of Basic Pay, Dearness Allowance and Additional

Dearness Allowance) was recovered from the salaries of the workers and an equal

contribution was also made by the concerned managements and deposited in the

worker’s provident fund account.

19. Provision for Gratuity

As per the payment of Gratuity Act, 1972, Gratuity was also paid to the

employees at the rate of 15 days of salary excluding the House Rent Allowance, for

every completed year of service. As per the Group Gratuity scheme for the deceased

employees, Gratuity was calculated upto the anticipated date of retirement based on

the salary drawn at the time of death.

70

20. Group Insurance Scheme Facility

All employees in study units had been covered by the group insurance scheme

of the LIC of India and on the death of an employee an amount of Rs. 1,50,000 was

paid under the scheme. A nominal subscription of Rs. 30/- per month was collected

from every employee.

21. Provision of Medical Benefits

A full fledged dispensary with two medical officers was functioning in each of

the study units. A few beds had been provided and the in patients were supplied daily

free milk. The medicines bought outside, as prescribed by the medical officers was

reimbursed as per Government rules and rates. One Ambulance Van was provided

for each dispensary to facilitate the conveyance of the patients.

The treatment charges for the treatments taken outside was reimbursed subject

to a maximum of half month’s salary in a year for workers and one month salary for

the administrative staff and for the officers. Medical tie ups with private hospitals

like the Meenakshi Mission and the Appollo hospitals had also been established for

special treatment for the following nine diseases.

1. Tuberculosis

2. Leprosy

3. Cancer

71

4. Major Operations

5. Major Fractures

6. Major Neurological problems.

7. Uretaric and Renal Stone formations

8. Absestosis, and

9. Mesothelima.

22. Provision of Canteen Facilities

A well equipped canteen was run by the respective managements in each of

the study units. Food was supplied to the workmen at subsidised rates. Tea and

Snacks were supplied at their work spots.

23. Provision for Consumption of Free Electricity

All the employees who were residing in the allotted quarters provided by the

respective managements, were allowed to use electricity free of cost to the extent of

480 units for a period of six months.

24. Contribution to Tamil Nadu Labour Welfare Board

Regular contributions were made to the Tamil Nadu Labour Welfare Board

every year. The employees were contributing at the rate of Rs. 3/- per head per year

and the management was also contributing at the rate of Rs. 6/- per head per year.

72

The employees of all the study units were availing themselves of the various benefits

provided by the Tamil Nadu Labour Welfare Board. For the benefit of the employees

and their families, a tailoring centre and a child care centre were also run by the

Tamil Nadu Labour Welfare Board in the respective premises of the study units.

25. Workers’ Education Programme

Workers’ Education classes had been organised by the Central Board of

Workers. Education Programmes were also conducted by all the three study units.

26. Employees’ Thrift and Credit Society

A thrift and credit society was also functioning in each of the three study

units. The members could invest a sum of Rs. 100/- per month by way of thrift and

an employee could avail of loans upto Rs. 1,00,000/- which was recoverable in a

maximum number of 60 instalments.

27. Recreation Club Facilities

A recreation club was also functioning in each of the sample units of the

study. The members were charged a sum of Re.1/- per head per month by way of

subscription. Newspapers, periodicals and other magazines were supplied to the

recreation club. Film shows were screened once a week in the open air auditorium by

the recreation clubs. Other cultural activities such as sports, dramas, fancy dress

73

competitions, orchestras were also undertaken on all important days and functions by

the recreation clubs.

28. Provision of Educational Facilities

Matriculation Higher Secondary Schools were run by the managements of the

Sankar Cement and the TANCEM in their respective premises and an elementary

school was run by the management of the Madras Cements Limited, at R.R. Nagar

for the education of the children of the employees of the respective units.

29. Availability of Safety Equipments

The following safety equipments as required for the employees of the different

units of study depending up on the nature of their duties, had also been provided in

the respective units.

30. Provision of Rain Coat

All the mines’ employees were supplied with one rain coat once in five years.

In the factory, security guards and canteen workers were also supplied with rain coats

once in five years.

74

31. Provision of Goggles

The drillers in the mines and the packers and the loading mazdoors in the

factory were supplied with a pair of Goggles every year.

32. Provision of Helmet

The work load employees in the mines were supplied with one helmet each

once in five years.

33. Provision of Aprons

The drillers and the welders in the mines are supplied with Aprons. Aprons

were also provided at the kiln section for common use.

34. Provision of Respirator

Drillers were supplied with respirators in the mines.

35. Supply of Leather

The work load employees in the mines were supplied with leather Skinguards

once in two years.

75

36. Provision of Torch Light and Torch Cell

The foremen, the inmates and the electricians working in the mines were

supplied with torch lights and torch cells. Adequate number of Torch lights were

been kept in the various sections of the factories for common use.

37. Welding Goggles and Welding Shields

Adequate number of welding goggles and welding shields had been provided

to the various sections for the use of welders.

76

REFERENCES

1. Encyclopedia Britannica, Vol. 5, William Benton Publishers, 1978, p. 153.

2. Robert G. Blezard, The History of Calcareous Cements, p. 1., Lea’s

Chemistry of Cement and Concrete, Fourth Edition, Edited by Peter C.

Hawlett,

3. M. Guruprasad, “Cement Taking Technology in its Stride”, Market Survey,

April 2005, p. 31.

4. The Associated Cement Companies Limited, Data on Cement Industry 1985,

Bombay, 1985, p. 1.

5. Kothari Enterprises, Madras, India, Kothari’s Industrial Directory of India,

1992, 38th

Edition, p.4.2.

6. Vikas Singal, Cement and Cement Products, Indian Industry, 2006, p. 78.

7. Ibid.

8. Ibid., p. 79.

9. Cement Industry, ICFAI Journal of Industrial Economics, Vol. 3, No. 2,

May 2006, pp. 25-26.

10. Ibid., p.80.

11. India, Published by Ministry of Information, p. 553.

12. CRISL Sector Review, Cement, Executive Summary, CRISL online, p. 2,

13. Vikas Singal, op.cit., 2006, p. 79-80.