Chapter Chapter ---- 2222 - Shodhgangashodhganga.inflibnet.ac.in/bitstream/10603/31351/9/09_chapter...

-

Upload

truongdien -

Category

Documents

-

view

216 -

download

0

Transcript of Chapter Chapter ---- 2222 - Shodhgangashodhganga.inflibnet.ac.in/bitstream/10603/31351/9/09_chapter...

Chapter Chapter Chapter Chapter ---- 2222

Experimental TechniquesExperimental TechniquesExperimental TechniquesExperimental Techniques for for for for

Materials CharacterizationMaterials CharacterizationMaterials CharacterizationMaterials Characterization

II-1

Experimental Techniques for Materials Characterization

21 Introduction

Materials synthesis and characterization are the most important aspects in

experimental condensed matter physics and materials science research On application

side it is essential to fabricate good quality thin films of materials which are

characterized by variety of techniques The quality of films depends to a great extent on

the film growth method used In addition the proper selection of synthesis parameters

helps to carry out desired properties in the film along with desired applicability

Structure surface morphology grain growth electron transport within material and the

magnetic properties depend on method of synthesis used For the bulk synthesis of

oxides Solid State Reaction (SSR) route has been extensively used and for

nanostructures various methods such as Sol-Gel route Co-precipitation method Citrate

Route Nitrate Route etc are used In laboratory to realize high quality films with desired

properties by precise control on the growth parameter Pulsed Laser Deposition (PLD) is

the most suitable technique In order to characterize the polycrystalline bulk and thin

films of functional oxides various techniques such as X-ray diffraction (XRD) for

structure scanning electron microscopy (SEM) atomic force microscopy (AFM)

transmission electron microscopy (TEM) for microstructure dc four probe resistivity

and I-V measurements for transport and SQUID for magnetic properties are employed

In addition X-ray photoemission spectroscopy (XPS) and Valence band spectroscopy are

used to investigate the detailed electronic structure and doping induced modifications in

the valence band

This chapter presents a detailed description of the experimental techniques used to

characterize the samples prepared during present course of work to study their

functionalities

22 Synthesis Techniques

The synthesis of materials with desired physical properties has been an area of

increasing vitality and importance since many years In the PLD technique dense and

single-phase bulk target is used for the ablation process to make good quality films

Therefore the selection of sample preparation method is a crucial factor The synthesis of

II-2

Experimental Techniques for Materials Characterization

polycrystalline bulk target samples is broadly divided into two categories namely 1)

solid state reaction method and 2) chemical route comprising sol-gel technique nitrate

route co-precipitation technique etc [1-3] In order to prepare a single-phase sample the

synthesis conditions used during any reaction are very important During synthesis the

parameters such as temperature pressure gas flow and time for the reaction are needed to

be varied according to the phase requirements in the sample Mapping of all variables has

to be made to select the conditions which are best suited for each material and phase

221 Solid State Reaction (SSR)

The most common method of synthesizing inorganic solids is the direct reaction

of the component materials at elevated temperatures All the bulk polycrystalline targets

of pure and doped BiFeO3 BaTiO3 SrTiO3 and pure and doped ZnO samples used to

deposit respective films during present course of work were synthesized using SSR

method Mixing of the required oxide or carbonate powders in stoichiometric

proportions calcinations pelletization and sintering of bulk pellet are main steps

involved in SSR method There are two factors namely thermodynamic and kinetic

which are important in solid state reaction the former determines the possibilities of any

chemical reaction to occur by the free energy considerations which are involved while the

later determines the rate at which the reaction occurs [1 4] The atoms diffuse through

the material to form a stable compound having minimum free energy In order to prepare

a single-phase sample the conditions during any reaction are very important During

synthesis the parameters such as temperature pressure gas flow and time for the

reaction are needed to be varied according to the phase requirements in the sample

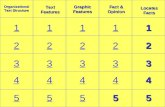

Figure 21 shows flow chart of SSR method used for synthesis of Multiferroic BiFeO3

As Bi-is volatile element and evaporation temperature of Bi is quite low ~830˚C

formation time and temperature is lower than that generally used in oxide synthesis For

BaTiO3 calcination at 800degC (10 hrs) and 1050degC (5 hrs) were carried out followed by

and final sintering at 1250degC (5 hrs) and for SrTiO3 calcination at 1000degC (24 hrs) then

1200 was followed by sintering at 1250degC (each at 24 hrs)

II-3

Experimental Techniques for Materials Characterization

Figure 21 Flow chart of various steps involved in conventional solid state reaction

route

The advantages of SSR method are listed below

(i) The solid reactants react chemically without the presence of any solvent at high

temperatures yielding a stable product

(ii) The final product in solid form is structurally pure with the desired properties

depending on the final sintering temperatures

(iii) It is environment friendly and no toxic or unwanted waste is produced after

getting final product

222 Sol - Gel technique

Out of several methods for synthesizing polycrystalline ZnO based DMS

materials Sol-Gel is the cost-effective method easy to handle and yields

stoichiometrically predefined compounds It offers a variety of starting materials as

precursors to choose In Sol-Gel technique materials are obtained from chemical solution

via gelation The process involves conversion of monomers into a colloidal solution (sol)

II-4

Experimental Techniques for Materials Characterization

that acts as the precursor for an integrated network (gel) of either discrete particles or

network polymers For nanomaterial synthesis it is necessary to have control over grain

size and also on the phase formation at much lower temperature which can be achieved

by using such chemical methods The different processing stages of Sol-Gel technique

are given below in figure 22

Figure 22 Typical flow chart of Sol-Gel method used for synthesis of pure and Co-

doped ZnO

Key points of the sol-gel method

1 Gelatinous materials as a precursor play a role of an anticoagulant of growing

particles The preparation of monodispersed particles systematically controlled in

mean size and shape have been difficult by conventional methods In this method

under the conditions of high ionic strength growing particles are easily

aggregated and thus uncontrolled in size and shape On the other hand by the sol-

gel method network of a gelatinous precursor prevents the particle aggregation

II-5

Experimental Techniques for Materials Characterization

2 The supersaturation of the system can be kept at a low level by gradual

dissolution of the precursor and the separation of the nucleation and growth stage

is performed The essential conditions to form monodispersed particles are thus

achieved

3 The solid precursor plays an important role as a reservoir of metal ions andor

anions of the product which makes it possible to produce monodispersed particles

in large quantities

During the present course of work polycrystalline Zn1-xCoxO (x = 00 05 and

015) samples were synthesized using sol-gel method Stoichiometric quantities of

Zn(CH3COO)22H2O and Co(CH3COO)24H2O were dissolved in acetic acid and double

distilled water in 11 volume ratio at 90degC resulting in 04 M solution After condensation

and gelation the mixture was dried in air at 150degC and the resulting powder was calcined

at 400degC for 6 hrs and then palletized and sintered at 900degC for 6 hrs

223 Pulsed Laser Deposition (PLD)

For depositing device grade thin films in a laboratory Pulsed Laser Deposition

(PLD) technique is the most suitable and advantageous over other deposition techniques

such as RF Sputtering Metal Oxide Chemical Vapor Deposition (MOCVD) or spray

pyrolysis etc Moreover high energy density of Laser is able to vaporize hardest

materials and therefore useful for the deposition of the oxide materials such as

Superconductors Multiferroics Manganite and Semiconductor [5 6] With the use of

PLD technique one can deposit very high quality thin films with precise control over the

thickness of the film

In the present work for the fabrication of multiferroic thin films and BTO based

FeFET PLD method has been used by employing KrF excimer gas laser using PLD

facility at UGC-DAE CSR Indore National Institute of Technology Hamirpur and

IISER Bhopal The details of optimized conditions and parameters used during PLD are

given in the relevant chapters

A typical PLD system consists a pulsed laser a vacuum chamber a rotating target

holder and a substrate heating block There are several kinds of lasers which are

II-6

Experimental Techniques for Materials Characterization

commercially available such as Excimer lasers (XeCl KrF ArF) are widely used to

deposit high TC superconducting films and other complex oxide films because of the

larger absorption coefficient and small reflectivity of materials at their operating

wavelengths Frequency tripled NdYAG lasers are also effective from the same point of

view

Various steps involved in the PLD process

High power pulsed laser beam is focused inside a vacuum chamber to evaporate

matter from a target surface such that the stoichiometry of the material is preserved in the

interaction As a result a dynamic supersonic jet of plasma (plume) is ejected normal to

the target surface The dynamic plasma plume expands away from the target with a

strong forward directed velocity distribution of the different particles and is transported

over large distances due to quasi free expansion processes and shock wave propagation in

the presence of some background gas [7] The dynamic interactions in the plume can be

modelled using a shock wave model that leads to a quantitative scaling law PD3 =

constant relating the two prominent parameters ie the pressure P and the

target-to-substrate distance D In the case of oxide films oxygen is the most common

background gas For pressures in the range of 100ndash400mTorr the ablated atoms and ions

which attain high kinetic energies (few 10 eV) in the vicinity of the target are

thermalized due the scattering at a particular target-to-substrate distance that is called the

lsquoplume rangersquo (L) and finally condensed on the substrate placed opposite to the target

The plume range L defines two distinct regions in the DndashP diagram for the morphology

and the microstructure and appears as a relevant deposition parameter for the growth of

single crystal films with low roughness and large grains by the PLD technique [8]

Further in most materials the ultraviolet radiation is absorbed by only the outermost

layers of the target up to a depth of ~ 1000 Aring The extremely short laser pulses each

lasting less than 50 ns cause the temperature of the surface to rise rapidly to thousands of

degrees Celsius but the bottom of the target remains virtually unheated close to room

temperature Such un-equilibrium heating produces a flash of evaporated elements that

deposit on the substrate producing a film with composition identical to that of the target

surface Rapid deposition of the energetic ablation species helps to raise the substrate

II-7

Experimental Techniques for Materials Characterization

surface temperature In this respect PLD tends to demand a lower substrate temperature

for crystalline film growth Figure 23 shows the schematic diagram of PLD apparatus

along with target holder substrate holder focusing lens etc which involves evaporation

of a solid target material in an Ultra High Vacuum (UHV) chamber by means of short

and high energy laser pulses

Figure 23 A schematic representation of PLD apparatus

Conventional arrangement for PLD for the synthesis of thin solid films is

characterized by the following features

1 Focused laser beam is directed to the target to ablate the material

2 The target holder is rotated along an axis or (x y) - scanned in the focal plane of

the laser beam to achieve a stationary ablation rate The vacuum chamber is made

of stainless Chamber is evacuated down to 10-6 bar by using a turbo pump

3 Well polished substrate located at a typical separation from the target is stationary

or rotated for homogenization of the deposited material To form a film with

required stoichiometry film growth regimes and the temperature of the substrate

may be selected between room temperature and 1000o C

4 A gas supply is often provided to produce desired chemical reactions during film

growth

II-8

Experimental Techniques for Materials Characterization

Each stage in PLD is critical to the formation of thin films with epitaxial

crystalline structure stoichiometry and smooth surface

Advantages of the PLD technique

(1) The capability for stoichiometric transfer of material from target to substrate ie the

exact chemical composition of a complex material such as YBa2Cu3O7-δ (YBCO) can

be reproduced in the deposited film ie the vaporization is congruent A qualitative

explanation for congruence is that the heating rate provided by pulsed laser irradiation

is so fast that the material removal occurs before the individual components of the

target material can segregate out into low and high vapour pressure components

(2) Relatively high deposition rates typically ~10 nm per minute can be achieved at

moderate laser fluence with film thickness controlled in real time by simply turning

the laser on and off

(3) The fact that a laser is used as an external energy source results in an extremely clean

process without filaments Thus deposition can occur in both inert and reactive

background gases

(4) The use of multiple target holders enables multilayer films to be deposited without the

need to break vacuum when changing between materials

(5) Non requirement of a working gas as in sputter deposition

(6) High flexibility in laboratory scale applications as only small targets (10-12 mm in

diameter with 2-3 mm thick) are needed (in contrast to sputtering where large sized

targets (2Prime - 4Prime diameter and 5-6 mm thick) are required)

(7) Ability to deposit in reactive gas environments (in contrast to conventional

evaporation where hot filaments andor crucibles could contaminate the source

material)

23 Structural Characterizations

It is very essential to study structural properties of any material in order to verify

single phasic nature before carrying out further studies Structural properties are closely

related to the chemical characteristics of the atoms in the material and thus form the basis

II-9

Experimental Techniques for Materials Characterization

on which detailed physical understanding is built Various techniques are used to

ascertain single phasic nature of the samples and detect deviations from the main

structure as well as extracting the actual structure Various techniques have different

advantages and disadvantages and thus complement to each other To study the

crystalline formation of a material X-Ray diffraction measurements are widely used

231 X - ray Diffraction (XRD)

X-ray diffraction (XRD) is non-destructive analytical technique for identification

and quantitative determination of the various crystalline forms known as phases of

compounds present in the powdered and solid samples [9] X-rays are electromagnetic

radiation with typical energies in the range of 100 eV - 100 keV For the purpose of

XRD only short wavelength X-rays ~ 1Aring ie comparable with the size of inter-atomic

distance are used Since the wavelength of X-rays is of the order of 1Aring they are most

ideal for probing the crystalline arrangement of atoms in the polycrystalline bulk as well

as in the thin film forms Generally in the XRD facility the Cu target is used which

emits ~8 KeV X-rays with wavelength of 154Aring X-rays primarily interact with electrons

in atoms

A crystal lattice is a regular array of atoms in space These are arranged in space

to form a series of parallel planes separated from each other by distance d which varies

according to the nature of materials For any crystal planes oriented in different direction

has different d spacing When a monochromatic X-ray beam with wavelength λ is

incident on the lattice planes in the crystal at an angle θ diffraction occurs only when the

distance travelled by rays reflected from successive phases differs by a complete number

lsquonrsquo of λ That is the Braggrsquos condition given by

n λ = 2dsin θ

By varying θ the Braggrsquos law can be satisfied by different lsquodrsquo spacing in a

polycrystalline material (figure 24) Plotting angle position and intensity of the resultant

diffraction peaks produces a pattern which is characteristic of the sample For a sample

containing a mixture of phases the XRD pattern is formed by addition of individual

patterns

II-10

Experimental Techniques for Materials Characterization

Figure 24 Diffraction of X-rays by a crystal planes (Braggrsquos law)

Figure 25 Schematic representation of X-ray diffractometer

Figure 25 represents schematics of X-ray diffractometer The three basic

components of an X-ray diffractometer are x- ray source specimen and x- ray detector

They all lie on the circumference of a circle which is known as the focusing circle The

angle between the plane of the specimen and the X-ray source is θ the Bragg angle The

angle between the projection of the X-ray source and the detector is 2θ For this reason

the X-ray diffraction patterns produced with such geometry are often known as θ-2θ scan

[10]

PAN Analytical PW304060 Xrsquopert PRO X-ray diffractometer (XRD) was used in

the present work to verify the single phasic nature of the samples studied

II-11

Experimental Techniques for Materials Characterization

232 φφφφ - Scan Measurements

Texture measurements are used to determine the orientation distribution of

crystalline grains in the polycrystalline sample One can see textured state of a material

(generally in the form of thin films) A material is called as textured if the grains are

aligned in a preferred orientation along certain lattice planes The texture measurements

have been performed on thin films at a fixed scattering angle and consists of a series of φ

- scans (in-plane rotation around the center of the sample) at different chi-angles (ψ) as

illustrated in the figure 26

Figure 26 Schematic diagram depicting - θ ψ and φ angles during XRD

measurements on films

24 Microscopic Characterizations

Morphological studies are important for understanding the growth and packing

density of grains in thin films or polycrystalline bulk materials There are various

techniques known to explore the science related to surface and morphology of a material

are Scanning Electron Microscopy (SEM) Atomic Force Microscopy (AFM) or

Scanning Probe microscopy (SPM) Tunneling Electron Microscopy (TEM) [11]

241 Scanning Electron Microscopy (SEM)

Scanning electron microscope (SEM) is used for studying the surface topography

microstructure and chemistry of metallic and nonmetallic specimens at magnifications

from 50 up to ~ 100 000 X with a resolution limit lt 10nm (down to ~ 1nm) and a depth

II-12

Experimental Techniques for Materials Characterization

of focus up to several microm (at magnifications ~ 10 000 X) In SEM a specimen is

irradiated by an electron beam and data on the specimen are delivered by secondary

electrons coming from the surface layer of thickness ~ 5nm and by backscattered

electrons emitted from the volume of linear size ~ 05microm Due to its high depth of focus

SEM is frequently used for studying fracture surfaces High resolving power makes SEM

quite useful in metallographic examinations Sensibility of backscattered electrons to the

atomic number is used for the detection of phases of different chemistry Electron

channeling in SEM makes it possible to find the orientation of single crystals by electron

channeling pattern (ECP) or of grains by selected area channeling pattern (SACP)

Figure 27 Schematic block diagram of SEM

242 Atomic Force Microscopy (AFM)

AFM is one of the foremost tools for imaging measuring an

at the nanoscale [figure 2

forces between a tip and the sample [1

surface with a mechanical probe Piezoelectric elements that facilitate tiny but accurate

and precise movements on (electronic) command enable very precise scanning AFM

consists of a microscale cantilever with

the specimen surface [fig

with a tip radius of curvature of the order of nanometers

proximity of a sample surface forces between the tip and the sample lead to a deflection

of the cantilever according to Hookersquos law Depending on the situation forces which are

measured in AFM include mechanical contact force van der waals forces capillary

forces chemical bonding electrostatic forces magnetic forces etc Typically the

deflection is measured using a laser spot reflected from the top surface of the cantilever

into an array of photodiodes

Figure 28 (a) AFM set up (b) Working of AFM

If the tip is scanned at a constant height a risk of tip colliding with the surface

exists causing the damage Hence in most cases a feedback mechanism is employed to

adjust the tip to sample distance to maintain a constant force between the tip and the

sample Traditionally the sample is mounted on a piezoelectric tube which can move the

Experimental Techniques for Materials Characterization

Atomic Force Microscopy (AFM)

AFM is one of the foremost tools for imaging measuring and manipulating matter

28 (a)] AFM is operated by measuring the attractive or repulsive

forces between a tip and the sample [12] The information is gathered by feeling the

surface with a mechanical probe Piezoelectric elements that facilitate tiny but accurate

and precise movements on (electronic) command enable very precise scanning AFM

consists of a microscale cantilever with a sharp tip (probe) at its end which is used to scan

the specimen surface [figure 28 (b)] The cantilever is typically silicon or silicon nitride

with a tip radius of curvature of the order of nanometers When the tip is brought into

surface forces between the tip and the sample lead to a deflection

of the cantilever according to Hookersquos law Depending on the situation forces which are

measured in AFM include mechanical contact force van der waals forces capillary

bonding electrostatic forces magnetic forces etc Typically the

deflection is measured using a laser spot reflected from the top surface of the cantilever

into an array of photodiodes

(a) AFM set up (b) Working of AFM

If the tip is scanned at a constant height a risk of tip colliding with the surface

exists causing the damage Hence in most cases a feedback mechanism is employed to

adjust the tip to sample distance to maintain a constant force between the tip and the

sample Traditionally the sample is mounted on a piezoelectric tube which can move the

II-13

Experimental Techniques for Materials Characterization

d manipulating matter

AFM is operated by measuring the attractive or repulsive

The information is gathered by feeling the

surface with a mechanical probe Piezoelectric elements that facilitate tiny but accurate

and precise movements on (electronic) command enable very precise scanning AFM

a sharp tip (probe) at its end which is used to scan

(b)] The cantilever is typically silicon or silicon nitride

When the tip is brought into

surface forces between the tip and the sample lead to a deflection

of the cantilever according to Hookersquos law Depending on the situation forces which are

measured in AFM include mechanical contact force van der waals forces capillary

bonding electrostatic forces magnetic forces etc Typically the

deflection is measured using a laser spot reflected from the top surface of the cantilever

If the tip is scanned at a constant height a risk of tip colliding with the surface

exists causing the damage Hence in most cases a feedback mechanism is employed to

adjust the tip to sample distance to maintain a constant force between the tip and the

sample Traditionally the sample is mounted on a piezoelectric tube which can move the

II-14

Experimental Techniques for Materials Characterization

sample in the Z direction for maintaining a constant force and the X and Y directions for

scanning the sample Alternatively a tripod configuration of three piezo crystals may be

employed with each responsible for scanning in the X Y and Z directions This

eliminates some of the distortion effects seen with a tube scanner

AFM can be operated in number of modes depending upon the application In

general possible imaging modes are divided into static modes (also called contact

modes) which can be used for Lateral Force Microscopy (LFM) measurements and a

variety of dynamic modes (or non-contact modes) where the cantilever is vibrated

243 Transmission Electron Microscopy (TEM)

In this technique a beam of electrons is transmitted through an ultra thin

specimen interacting with the specimen as it passes through it [13 14] An image is

formed from the electrons transmitted through the specimen magnified and focused by

an objective lens and appears on an imaging screen a fluorescent screen in most TEMs

plus a monitor or on a layer of photographic film or to be detected by a sensor such as a

CCD camera The first TEM was built by Max Knoll and Ernst Ruska in 1931 while the

first commercial TEM was available in 1939

Figure 29 shows the TEM with its components The electron source of the TEM

is at the top where the lensing system focuses the beam onto the specimen and then

projects it onto the viewing screen A TEM is composed of several components which

include a vacuum system in which the electrons travel an electron emission source for

generation of the electron stream a series of electromagnetic lenses as well as

electrostatic plates The latter two allow the operator to guide and manipulate the beam as

required

TEM is used mostly in both material sciencemetallurgy and the biological

sciences In both cases the specimens must be very thin and able to withstand the high

vacuum present inside the instrument Preparation techniques to obtain an electron

transparent region include ion beam milling and wedge polishing The focused ion beam

(FIB) is a relatively new technique to prepare thin samples for TEM examination

Because the FIB can be used to micro-machine samples very precisely it is possible to

II-15

Experimental Techniques for Materials Characterization

mill very thin membranes from a specific area of a sample such as a semiconductor or

metal Materials having dimensions small enough to be electron transparent such as

powders or nanotubes can be quickly produced by the deposition of a dilute sample

containing the specimen onto support grids The suspension is normally a volatile

solvent such as ethanol ensuring that the solvent rapidly evaporates allowing a sample

that can be rapidly analyzed

Figure 29 Schematic of Transmission Electron Microscope (TEM)

II-16

Experimental Techniques for Materials Characterization

25 Spectroscopic Characterizations

252 X - ray Photoelectron Spectroscopy (XPS)

X-ray photoelectron spectroscopy (XPS) is surface analytical technique that

bombards the sample with photonselectrons or ions in order to excite the emission of

photons electrons or ions In XPS the sample is irradiated with low energy (~15 keV)

X-rays in order to provoke the photoelectric effect (figure 210) The energy spectrum of

the emitted photoelectrons is determined by means of a high-resolution spectrometer

XPS offers unique advantages such as unique combination of surface sensitivity and

chemical specificity as well as relatively straight forward means of quantification

Figure 210 Schematic of X-ray Photoelectron Spectroscopy

In the present study X-ray Photoemission Spectroscopy and Valence Band Spectroscopy

(VBS) measurements were carried out using AIPES beamline of UGC DAE CSR at

INDUS ndashI RRCAT Indore Figure 211 shows experimental setup of XUV beamline at

INDUS-I Specifications and other details of beam line are as follows-

Beamline Specifications- A toroidal grating monochromator TGM 2631 with three gratings of 200 600 and

1800 linesmm Wavelength range 60 - 1600 (8 - 200 eV) Pre - and Post - mirrors of toroidal type Final spot size at sample lt 1 mm2 Angle integrated photoelectron spectroscopy station Average resolving power of 300

Figure 211 Experimental setup of XUV beamline at INDUS

Energywavelength range

Wave length range Gratings

Linesmm Coating

540-1600 Adeg 200

180-540 Adeg 600

60-180 Adeg 1800

UHV compatible angle integrated photoelectron spectrometer comprising of

a Hemispherical analyser having mean radius of 95mm

b Ion gun for sample cleaning

c Sample manipulator with XYZ motion

d Sample heating up to 900oC and cooling up

e Sample preparation chamber with quick load lock and sample transfer system

Photoelectron Spectrometer

The experimental station of

spectrometer which was designed and fabricated indigenously This consists of (1) the

energy analyzer (2) the experimental chamber with in

arrangement of the sample mounted on XYZ sa

Experimental Techniques for Materials Characterization

Experimental setup of XUV beamline at INDUS-I

Energywavelength range

Gratings Linesmm Coating

Spectral resolution

lDl measured with discharge source

200 Pt 650 at 584 Adeg

600 Pt 950 at 304 Adeg

1800 Pt

UHV compatible angle integrated photoelectron spectrometer comprising of

Hemispherical analyser having mean radius of 95mm

Ion gun for sample cleaning

Sample manipulator with XYZ motion

Sample heating up to 900oC and cooling up to LN2 temperature

Sample preparation chamber with quick load lock and sample transfer system

Photoelectron Spectrometer

The experimental station of AIPES beamline is an angle integrated photoelectron

spectrometer which was designed and fabricated indigenously This consists of (1) the

(2) the experimental chamber with in-situ heating and cooling

arrangement of the sample mounted on XYZ sample manipulator (3) sample preparation

II-17

Experimental Techniques for Materials Characterization

Spectral resolution

measured with discharge source

UHV compatible angle integrated photoelectron spectrometer comprising of

Sample preparation chamber with quick load lock and sample transfer system

beamline is an angle integrated photoelectron

spectrometer which was designed and fabricated indigenously This consists of (1) the

situ heating and cooling

mple manipulator (3) sample preparation

II-18

Experimental Techniques for Materials Characterization

chamber equipped with quick load-lock magnetic sample transfer system ion gun for

controlled etching of the sample and diamond file type scrapper and (4) the associated

electronics as well as the data acquisition system A brief description of the spectrometer

is given below A schematic diagram of the typical photoelectron spectrometer is shown

in figure 212

Figure 212 Schematic of typical XPS spectrometer

The electron energy analyzer is the most important part of the spectrometer The

complete analyzer system consists of the following parts the electrostatic lens the

hemispherical elements and the detector The lens is a three-piece cylindrical system The

lens is used to transport the electrons from the emission area to the hemispherical

analyzer through the entrance slit of the analyzer plate The most common configuration

of the three-piece lens is an einzel lens in which the outer electrodes are held at the

ground potential and beam focusing is achieved by varying the potential on the centre

electrode This type of lens is commonly used in electron spectrometers Each cylinder is

machined out of stainless steel and mirror polished and coated with gold for excellent

transmission of the beam All the pieces are then mounted inside a stainless steel shield

which in turn is mounted on the analyzer plate

The inner and outer hemispheres of the analyzer are machined out of aluminum in

a numerically controlled universal milling machine to an accuracy better than

II-19

Experimental Techniques for Materials Characterization

+0001mm The surfaces are then polished and coated with gold This ensures uniform

potential energy surfaces and prevents surface charging The hemispheres are mounted on

a fringe plate (H-plate) also machined out of aluminum which has entrance and exit

slits slit width can be varied from 1mm to 3mm in discrete steps of 1 mm The entire

analyzer assembly is mounted such that the inner hemisphere outer hemisphere and the

H-plate are insulated from touching each other by using teflon washers and bushes

Electrons are focused to the entrance slit of the analyzer through the entrance aperture by

the lens system Energy dispersion takes place as the electrons travel through the

electrostatic field between the inner and outer hemispheres There are six concentric rings

made out of stainless steel mounted on the H-plate to correct the fringe field which

improves the resolution of the analyzer These rings are positioned within the annular

space (gap between the two hemispheres) equidistantly The inner and the outer

hemispheres have a radius of 65 mm (r1) and 125 mm (r2) respectively The mean radius

of the analyzer is 95 mm and the annular space is 60 mm

The detection of electrons is carried out by applying a high voltage to the channel

electron multiplier (X719BL Philips make) mounted at the exit slit of the analyzer A

single turn of enameled copper wire is carefully mounted surrounding the analyzer This

can be used to fine-tune the focusing of the beam into the analyzer entrance slit A Mu

metal shield surrounds the analyzer and lens for shielding it from earthrsquos magnetic field

The spectrometer chamber is also shielded by the mu metal

The electronics system consists of a spectrometer control unit to provide various

voltages to the energy analyzer a pulse amplifier to amplify the detected signal a rate

meter to count the number of electrons per second The total electronics system is

interfaced to an IBM compatible personal computer A windows based software program

is then run which scans the spectrometer and acquires the data and stores it in a file for

further analysis

The function of the analyzer is as follows When the sample is kept at ground

potential electrons ejected from a state with binding energy Eb are emitted with a true

kinetic energy Ek given by Ek = hν- Eb -f where f is the work function of the sample

The ejected electrons pass through the lens and are then retarded by an amount R

II-20

Experimental Techniques for Materials Characterization

determined by the lens voltages before entering the analyzer The retardation of kinetic

energy to pass energy is necessary to achieve the required resolution Therefore the

electrons which have been transmitted by the analyzer with a retardation R and pass

energy HV would have a kinetic energy given by the equation-

E = R + HV + f ---- (1)

Here the H which is 1403 for our analyzer is the analyzer constant

The inner hemisphere is applied a positive potential with respect to the outer The

analyzer is scanned by varying the retard voltage applied to the analyzer plate while

holding the analyzer pass energy constant This ensures a constant resolution for the

whole range of kinetic energies The absolute resolution is usually measured as the full

width at half-maximum (FWHM) height of a chosen observed peak

Resonant Photoemission Spectroscopy

If the core electron is resonantly excited to the high energy continuum well above

the absorption threshold (as in the process of X-ray photoemission spectroscopy) this

type of PES is denoted as resonant X-ray emission spectroscopy (RPES) [15] In order to

perform RPES measurements high intensity tunable X-ray source is required Resonance

phenomenon occurs in photoemission when the energy of incident photons is close to the

energy difference between a fully occupied core level and a partially occupied shell such

as 3d shell in transition metals 4f shell in rare earths or 5f shell in actinides In the

present study RPES study on Co-doped ZnO has been carried out using AIPES beamline

of UGC-DAE CSR at INDUS-I RRACAT Indore The resonance process in the case of

Cobalt can be interpreted as originating from the interference between the normal

photoemission process and the indirect process induced by the photo induced excitation

The reactions involved in the resonance phenomena are as follows direct process

Co3p63d7 + hνrarr Co3p63d6 + e and indirect process Co3p63d7 + hνrarr [Co3p53d8]

followed by the emission of a Co 3d electron through a super Koster-Kroning decay

[Co3p53d8] rarr Co3p63d6 + e The interference between the two channels of

photoemission leads to an increase in the photoemission intensity as the photon energy is

swept through the Co 3p-3d threshold

II-21

Experimental Techniques for Materials Characterization

26 Transport Characterizations

The knowledge about the electrical properties of the bulk materials thin films and

artificial devices is essential in determining their applicability and usefulness The

resistivity must be measured accurately since its value is critical from application point of

view The samples in the present thesis work were characterized for their electrical and

magneto transport properties by the DC four-probe resistivity technique as described

below

261 Current vs Voltage (I-V) measurements

Since last few years the efforts have been made on the fabrication of devices

based on oxide thin films and multilayers having potential applications To understand

the transport behavior of such single crystalline and polycrystalline thin film and devices

I-V characteristics emerge as a most comprehensive tool In addition many important

parameters can be extracted from I-V measurements For practical application of the

insulating oxide films the leakage current controls the charge retention property which is

very important affecting factor for the consideration in practical memory application

Figure 213 Current Perpendicular in plane (CPP) geometry for I-V measurements

During the present work the I-V behavior of the oxide thin film heterostructures

amp p-n junction diodes was studied using the dc two probe method by varying the

applied voltage and observing the variation in current Figure 213 show the schematic of

contact geometry used in the I-V measurements All the measurements were taken from

the AuAg electrodes For multiferroic thin films hysteretic I-V measurements were

taken at various temperatures and varying plusmnVmax Effect of doping concentration and

thickness variation has been studied on hysteretic behavior of I-V curves

27 Electrical Characterizations

271 Dielectric measurements

Dielectric is an electrical

field When a dielectric is placed in an electric field

the material but only slightly shift from their average equilibrium positions

causing dielectric polarization

displaced toward the field and negative charges sh

creates an internal electric field which reduces the overall field within the dielectric

itself If a dielectric is composed of weakly bonded molecules these molecules not only

become polarized but also reorient so tha

While the term insulator implies low

used to describe materials with a

called the dielectric constant

obstruction while the term dielectric is used to indicate the energy storing capacity of the

material (by means of polarization) A common yet notable example of a dielectric is

the electrically insulating material between the metallic plates of a

Figure 214 Schematic diagram of a parallel plate capacitor with dielectric spacer

Dielectric constant

of the material The temperature and frequency dependent capacitance was measured

using Agilent 4284A precision LCR meter In order to avoid any parasitic impedance

Experimental Techniques for Materials Characterization

Electrical Characterizations

Dielectric measurements

is an electrical insulator that can be polarized by an applied

When a dielectric is placed in an electric field electric charges do not flow through

the material but only slightly shift from their average equilibrium positions

dielectric polarization Because of dielectric polarization positive charges are

displaced toward the field and negative charges shift in the opposite direction This

creates an internal electric field which reduces the overall field within the dielectric

If a dielectric is composed of weakly bonded molecules these molecules not only

become polarized but also reorient so that their symmetry axis aligns to the field

While the term insulator implies low electrical conduction lsquodielectricrsquo is typically

used to describe materials with a high polarizability The latter is expressed by a number

dielectric constant The term insulator is generally used to indicate electrical

obstruction while the term dielectric is used to indicate the energy storing capacity of the

material (by means of polarization) A common yet notable example of a dielectric is

y insulating material between the metallic plates of a capacitor

Schematic diagram of a parallel plate capacitor with dielectric spacer

Dielectric constant for the sample can be calculated by measuring the capacitance

of the material The temperature and frequency dependent capacitance was measured

A precision LCR meter In order to avoid any parasitic impedance

II-22

Experimental Techniques for Materials Characterization

by an applied electric

electric charges do not flow through

the material but only slightly shift from their average equilibrium positions

Because of dielectric polarization positive charges are

ift in the opposite direction This

creates an internal electric field which reduces the overall field within the dielectric

If a dielectric is composed of weakly bonded molecules these molecules not only

t their symmetry axis aligns to the field

lsquodielectricrsquo is typically

The latter is expressed by a number

The term insulator is generally used to indicate electrical

obstruction while the term dielectric is used to indicate the energy storing capacity of the

material (by means of polarization) A common yet notable example of a dielectric is

capacitor (figure 214)

Schematic diagram of a parallel plate capacitor with dielectric spacer

for the sample can be calculated by measuring the capacitance

of the material The temperature and frequency dependent capacitance was measured

A precision LCR meter In order to avoid any parasitic impedance

II-23

Experimental Techniques for Materials Characterization

shielded test leads were used for electrical connection from the analyzer to sample First

films were heated at 100degC for 1hour for homogenization of charge carrier and remove

the moisture content For making a capacitor type arrangement sample surfaces were

coated using silver paste which act as a good contact for measuring dielectric properties

The value of the dielectric constant (εrsquo) was calculated using formula

εrsquo = CC0 helliphelliphelliphelliphelliphelliphellip (21)

where εrsquo is the real part of dielectric constant C is the capacitance of the material

inserted between the electrodes and C0 is the capacitance of the medium as air or no

medium between the electrodes The C0 for the parallel plate capacitor can be calculated

using the following relation

C0 = ε0 A t helliphelliphelliphelliphelliphelliphellip (22)

where ε0 is permittivity in vacuum ~ 885 times 10-12 C2N m2 t is the thickness of the

sample and A is the area of the specimen in sqm

Now using eq (1) amp (2) the dielectric constant can be calculated as

εrsquo = C times t ε0 A helliphelliphelliphelliphelliphelliphellip (23)

The imaginary component of dielectric constant (εrsquorsquo) is calculated using the formula

εrsquorsquo = εrsquo tanδ helliphelliphelliphelliphelliphelliphellip (24)

where tanδ is loss tangent proportional to the lsquolossrsquo of energy from the applied field into

the sample in which energy is dissipated into heat and therefore known as a dielectric

loss

272 Polarization - Electric field (P - E loop) measurements

Ferroelectricity is usually defined as irreversibility of the spontaneous

polarization by an applied electric field P - E hysteresis loop is the essential

characteristic of ferroelectric materials From the P - E loop one can get the information

about the saturation polarization (PS) remnant polarization (Pr) and coercive field (EC)

which help us to understand the effect of applied electric field with frequency Figure

215 shows the schematic diagram of typical P - E hysteresis loops observed in

II-24

Experimental Techniques for Materials Characterization

ferroelectric materials Depending on types of samples shape of the P - E loop changes

according to their ferroelectric behaviour There are four types of shape (i) linear P - E

loop (ii) resistive capacitor loop (iii) lossy hysteresis and (iv) non-linear hysteresis loop

Figure 215 Typical types of ferroelectric loops (a) linear P - E loop (b) resistive P - E

loop (c) lossy P - E loop and (d) non-linear P - E loop

The most often quoted method of hysteresis loop measurement is based on a

Sawyer and Tower circuit in which the field applied across the sample is attenuated by a

resistive divider and the current is integrated into charge by virtue of a large capacitor in

series with the sample Both these voltages are then fed into the X and Y axes of an

oscilloscope to generate the P - E loop The applied voltage is usually a sinusoidal at

mains frequency Also there are commercially available high voltage amplifiers which

allow frequencies other than those tied to the mains frequency and also enable waveforms

other than sine waves to be used Sine waves are most often used since these can be

easily produced however a triangle wave drive is more attractive for frequency

dependent measurements since dEdt is constant

II-25

Experimental Techniques for Materials Characterization

28 Magnetic characterizations (M-T amp M - H)

SQUID magnetometer is the most widely used instrument for magnetic

characterization in material science It has been proved as a boon to elucidate many

interesting results in superconductors manganites and ferrites [16] The superconducting

quantum interference device (SQUID) consists of two superconductors separated by thin

insulating layers to form two parallel Josephson junctions The device may be called as a

magnetometer to detect incredibly small magnetic fields The SQUID has as its active

element one or more Josephson junctions

Figure 216 A schematic diagram of SQUID magnetometer

A Josephson junction is a weak link between two superconductors that can

support a supercurrent below a critical value Ic The special properties of the Josephson

junction cause the impedance of the SQUID loop to be a periodic function of the

magnetic flux threading the SQUID so that a modulation signal supplied to the bias

II-26

Experimental Techniques for Materials Characterization

current is used with a lock-in detector to measure the impedance and to linearize the

voltage-to-flux relationship The net result is that a SQUID functions as a flux-to-voltage

converter with unrivaled energy sensitivity In most practical systems in use today the

SQUID is located inside a small cylindrical superconducting magnetic shield in the

middle of a liquid helium Dewar and shown in the figure 218 Superconducting pickup

coils typically configured as gradiometers that detect the difference in one component of

the field between two points are located at the bottom of the Dewar and the sample is

placed beneath the magnetometer The rest of the hardware is designed to minimize

helium boil off eliminate rf interference and to not contribute Johnson noise or distort

any external a c fields [16] The sensitivity of SQUID is associated with measuring

changes in magnetic field of one flux quantum as shown in figure 217

Figure 217 Variation of magnetic flux with change in voltage `

If a constant biasing current is maintained in the SQUID device the measured

voltage oscillates with the changes in phase at the two junctions which depends upon the

change in the magnetic flux The flux change can be evaluated by counting the

oscillations It may be noted that the sensitivity of SQUID is 10-14 Tesla which is

incredibly large to measure any magnetic signal

II-27

Experimental Techniques for Materials Characterization

REFERENCE

[1] EM Engler Chem Technol 17 542 (1987)

[2] SX Dou HK Liu AJ Bourdillon JP Zhou NX Tan XY Sun CC Sorrell

J Am Ceram Soc 71C 329 (1998)

[3] CJ Brinkered and GW Scherer ldquoSol-Gel Sciencerdquo Academic Press Inc Boston

(1990)

[4] AR West ldquoSolid State Chemistry and its Applicationsrdquo John Wiley and Sons

(1984)

[5] SP Gapanov BM Luskin NN Salaschenko Sov Tech Phys Lett 5 210

(1979)

[6] SP Gapanov A Gudkov AA Fraerman Sov Tech Phys Lett 27 1130

(1982)

[7] DB Geohegan Thin Solid Films 220 138 (1992)

[8] M Strikovski and J H Miller Appl Phys Lett 73 1733 (1998)

[9] BD Cullity and SR Stock ldquoElements of X-ray diffractionrdquo Prentice all Inc

New Jersey (2001)

[10] Doctoral Dissertation ldquoNovel room temperature ferromagnetic semiconductorsrdquo

by Amita Gupta LBNL-56596 eScholarship Repository University of California

(2004)

[11] EN Kaufmann ldquoCharacterization of Materialsrdquo John Wiley and Sons (2003)

[12] G Binning CF Quate and Ch Gerber Phys Rev Lett 56 930 (1986)

[13] Encyclopedia of Materials characterization Surface interface thin films Editors

CR Brundle CA Evans Jr and S Wilson Butterworth Heinemann (U S A)

(1992)

[14] D Shindo and T Oikawa ldquoAnalytical Electron Microscopy for Materials

Sciencerdquo Springer-Verlag Tokyo (2002)

II-28

Experimental Techniques for Materials Characterization

[15] A Kotani and S Shin Rev of Modern Phys 73 203 (2001)

[16] SQUID Manual by Quantum Design

II-1

Experimental Techniques for Materials Characterization

21 Introduction

Materials synthesis and characterization are the most important aspects in

experimental condensed matter physics and materials science research On application

side it is essential to fabricate good quality thin films of materials which are

characterized by variety of techniques The quality of films depends to a great extent on

the film growth method used In addition the proper selection of synthesis parameters

helps to carry out desired properties in the film along with desired applicability

Structure surface morphology grain growth electron transport within material and the

magnetic properties depend on method of synthesis used For the bulk synthesis of

oxides Solid State Reaction (SSR) route has been extensively used and for

nanostructures various methods such as Sol-Gel route Co-precipitation method Citrate

Route Nitrate Route etc are used In laboratory to realize high quality films with desired

properties by precise control on the growth parameter Pulsed Laser Deposition (PLD) is

the most suitable technique In order to characterize the polycrystalline bulk and thin

films of functional oxides various techniques such as X-ray diffraction (XRD) for

structure scanning electron microscopy (SEM) atomic force microscopy (AFM)

transmission electron microscopy (TEM) for microstructure dc four probe resistivity

and I-V measurements for transport and SQUID for magnetic properties are employed

In addition X-ray photoemission spectroscopy (XPS) and Valence band spectroscopy are

used to investigate the detailed electronic structure and doping induced modifications in

the valence band

This chapter presents a detailed description of the experimental techniques used to

characterize the samples prepared during present course of work to study their

functionalities

22 Synthesis Techniques

The synthesis of materials with desired physical properties has been an area of

increasing vitality and importance since many years In the PLD technique dense and

single-phase bulk target is used for the ablation process to make good quality films

Therefore the selection of sample preparation method is a crucial factor The synthesis of

II-2

Experimental Techniques for Materials Characterization

polycrystalline bulk target samples is broadly divided into two categories namely 1)

solid state reaction method and 2) chemical route comprising sol-gel technique nitrate

route co-precipitation technique etc [1-3] In order to prepare a single-phase sample the

synthesis conditions used during any reaction are very important During synthesis the

parameters such as temperature pressure gas flow and time for the reaction are needed to

be varied according to the phase requirements in the sample Mapping of all variables has

to be made to select the conditions which are best suited for each material and phase

221 Solid State Reaction (SSR)

The most common method of synthesizing inorganic solids is the direct reaction

of the component materials at elevated temperatures All the bulk polycrystalline targets

of pure and doped BiFeO3 BaTiO3 SrTiO3 and pure and doped ZnO samples used to

deposit respective films during present course of work were synthesized using SSR

method Mixing of the required oxide or carbonate powders in stoichiometric

proportions calcinations pelletization and sintering of bulk pellet are main steps

involved in SSR method There are two factors namely thermodynamic and kinetic

which are important in solid state reaction the former determines the possibilities of any

chemical reaction to occur by the free energy considerations which are involved while the

later determines the rate at which the reaction occurs [1 4] The atoms diffuse through

the material to form a stable compound having minimum free energy In order to prepare

a single-phase sample the conditions during any reaction are very important During

synthesis the parameters such as temperature pressure gas flow and time for the

reaction are needed to be varied according to the phase requirements in the sample

Figure 21 shows flow chart of SSR method used for synthesis of Multiferroic BiFeO3

As Bi-is volatile element and evaporation temperature of Bi is quite low ~830˚C

formation time and temperature is lower than that generally used in oxide synthesis For

BaTiO3 calcination at 800degC (10 hrs) and 1050degC (5 hrs) were carried out followed by

and final sintering at 1250degC (5 hrs) and for SrTiO3 calcination at 1000degC (24 hrs) then

1200 was followed by sintering at 1250degC (each at 24 hrs)

II-3

Experimental Techniques for Materials Characterization

Figure 21 Flow chart of various steps involved in conventional solid state reaction

route

The advantages of SSR method are listed below

(i) The solid reactants react chemically without the presence of any solvent at high

temperatures yielding a stable product

(ii) The final product in solid form is structurally pure with the desired properties

depending on the final sintering temperatures

(iii) It is environment friendly and no toxic or unwanted waste is produced after

getting final product

222 Sol - Gel technique

Out of several methods for synthesizing polycrystalline ZnO based DMS

materials Sol-Gel is the cost-effective method easy to handle and yields

stoichiometrically predefined compounds It offers a variety of starting materials as

precursors to choose In Sol-Gel technique materials are obtained from chemical solution

via gelation The process involves conversion of monomers into a colloidal solution (sol)

II-4

Experimental Techniques for Materials Characterization

that acts as the precursor for an integrated network (gel) of either discrete particles or

network polymers For nanomaterial synthesis it is necessary to have control over grain

size and also on the phase formation at much lower temperature which can be achieved

by using such chemical methods The different processing stages of Sol-Gel technique

are given below in figure 22

Figure 22 Typical flow chart of Sol-Gel method used for synthesis of pure and Co-

doped ZnO

Key points of the sol-gel method

1 Gelatinous materials as a precursor play a role of an anticoagulant of growing

particles The preparation of monodispersed particles systematically controlled in

mean size and shape have been difficult by conventional methods In this method

under the conditions of high ionic strength growing particles are easily

aggregated and thus uncontrolled in size and shape On the other hand by the sol-

gel method network of a gelatinous precursor prevents the particle aggregation

II-5

Experimental Techniques for Materials Characterization

2 The supersaturation of the system can be kept at a low level by gradual

dissolution of the precursor and the separation of the nucleation and growth stage

is performed The essential conditions to form monodispersed particles are thus

achieved

3 The solid precursor plays an important role as a reservoir of metal ions andor

anions of the product which makes it possible to produce monodispersed particles

in large quantities

During the present course of work polycrystalline Zn1-xCoxO (x = 00 05 and

015) samples were synthesized using sol-gel method Stoichiometric quantities of

Zn(CH3COO)22H2O and Co(CH3COO)24H2O were dissolved in acetic acid and double

distilled water in 11 volume ratio at 90degC resulting in 04 M solution After condensation

and gelation the mixture was dried in air at 150degC and the resulting powder was calcined

at 400degC for 6 hrs and then palletized and sintered at 900degC for 6 hrs

223 Pulsed Laser Deposition (PLD)

For depositing device grade thin films in a laboratory Pulsed Laser Deposition

(PLD) technique is the most suitable and advantageous over other deposition techniques

such as RF Sputtering Metal Oxide Chemical Vapor Deposition (MOCVD) or spray

pyrolysis etc Moreover high energy density of Laser is able to vaporize hardest

materials and therefore useful for the deposition of the oxide materials such as

Superconductors Multiferroics Manganite and Semiconductor [5 6] With the use of

PLD technique one can deposit very high quality thin films with precise control over the

thickness of the film

In the present work for the fabrication of multiferroic thin films and BTO based

FeFET PLD method has been used by employing KrF excimer gas laser using PLD

facility at UGC-DAE CSR Indore National Institute of Technology Hamirpur and

IISER Bhopal The details of optimized conditions and parameters used during PLD are

given in the relevant chapters

A typical PLD system consists a pulsed laser a vacuum chamber a rotating target

holder and a substrate heating block There are several kinds of lasers which are

II-6

Experimental Techniques for Materials Characterization

commercially available such as Excimer lasers (XeCl KrF ArF) are widely used to

deposit high TC superconducting films and other complex oxide films because of the

larger absorption coefficient and small reflectivity of materials at their operating

wavelengths Frequency tripled NdYAG lasers are also effective from the same point of

view

Various steps involved in the PLD process

High power pulsed laser beam is focused inside a vacuum chamber to evaporate

matter from a target surface such that the stoichiometry of the material is preserved in the

interaction As a result a dynamic supersonic jet of plasma (plume) is ejected normal to

the target surface The dynamic plasma plume expands away from the target with a

strong forward directed velocity distribution of the different particles and is transported

over large distances due to quasi free expansion processes and shock wave propagation in

the presence of some background gas [7] The dynamic interactions in the plume can be

modelled using a shock wave model that leads to a quantitative scaling law PD3 =

constant relating the two prominent parameters ie the pressure P and the

target-to-substrate distance D In the case of oxide films oxygen is the most common

background gas For pressures in the range of 100ndash400mTorr the ablated atoms and ions

which attain high kinetic energies (few 10 eV) in the vicinity of the target are

thermalized due the scattering at a particular target-to-substrate distance that is called the

lsquoplume rangersquo (L) and finally condensed on the substrate placed opposite to the target

The plume range L defines two distinct regions in the DndashP diagram for the morphology

and the microstructure and appears as a relevant deposition parameter for the growth of

single crystal films with low roughness and large grains by the PLD technique [8]

Further in most materials the ultraviolet radiation is absorbed by only the outermost

layers of the target up to a depth of ~ 1000 Aring The extremely short laser pulses each

lasting less than 50 ns cause the temperature of the surface to rise rapidly to thousands of

degrees Celsius but the bottom of the target remains virtually unheated close to room

temperature Such un-equilibrium heating produces a flash of evaporated elements that

deposit on the substrate producing a film with composition identical to that of the target

surface Rapid deposition of the energetic ablation species helps to raise the substrate

II-7

Experimental Techniques for Materials Characterization

surface temperature In this respect PLD tends to demand a lower substrate temperature

for crystalline film growth Figure 23 shows the schematic diagram of PLD apparatus

along with target holder substrate holder focusing lens etc which involves evaporation

of a solid target material in an Ultra High Vacuum (UHV) chamber by means of short

and high energy laser pulses

Figure 23 A schematic representation of PLD apparatus

Conventional arrangement for PLD for the synthesis of thin solid films is

characterized by the following features

1 Focused laser beam is directed to the target to ablate the material

2 The target holder is rotated along an axis or (x y) - scanned in the focal plane of

the laser beam to achieve a stationary ablation rate The vacuum chamber is made

of stainless Chamber is evacuated down to 10-6 bar by using a turbo pump

3 Well polished substrate located at a typical separation from the target is stationary

or rotated for homogenization of the deposited material To form a film with

required stoichiometry film growth regimes and the temperature of the substrate

may be selected between room temperature and 1000o C

4 A gas supply is often provided to produce desired chemical reactions during film

growth

II-8

Experimental Techniques for Materials Characterization

Each stage in PLD is critical to the formation of thin films with epitaxial

crystalline structure stoichiometry and smooth surface

Advantages of the PLD technique

(1) The capability for stoichiometric transfer of material from target to substrate ie the

exact chemical composition of a complex material such as YBa2Cu3O7-δ (YBCO) can

be reproduced in the deposited film ie the vaporization is congruent A qualitative

explanation for congruence is that the heating rate provided by pulsed laser irradiation

is so fast that the material removal occurs before the individual components of the

target material can segregate out into low and high vapour pressure components

(2) Relatively high deposition rates typically ~10 nm per minute can be achieved at

moderate laser fluence with film thickness controlled in real time by simply turning

the laser on and off

(3) The fact that a laser is used as an external energy source results in an extremely clean

process without filaments Thus deposition can occur in both inert and reactive

background gases

(4) The use of multiple target holders enables multilayer films to be deposited without the

need to break vacuum when changing between materials

(5) Non requirement of a working gas as in sputter deposition

(6) High flexibility in laboratory scale applications as only small targets (10-12 mm in

diameter with 2-3 mm thick) are needed (in contrast to sputtering where large sized

targets (2Prime - 4Prime diameter and 5-6 mm thick) are required)

(7) Ability to deposit in reactive gas environments (in contrast to conventional

evaporation where hot filaments andor crucibles could contaminate the source

material)

23 Structural Characterizations

It is very essential to study structural properties of any material in order to verify

single phasic nature before carrying out further studies Structural properties are closely

related to the chemical characteristics of the atoms in the material and thus form the basis

II-9

Experimental Techniques for Materials Characterization

on which detailed physical understanding is built Various techniques are used to

ascertain single phasic nature of the samples and detect deviations from the main

structure as well as extracting the actual structure Various techniques have different

advantages and disadvantages and thus complement to each other To study the

crystalline formation of a material X-Ray diffraction measurements are widely used

231 X - ray Diffraction (XRD)

X-ray diffraction (XRD) is non-destructive analytical technique for identification

and quantitative determination of the various crystalline forms known as phases of

compounds present in the powdered and solid samples [9] X-rays are electromagnetic

radiation with typical energies in the range of 100 eV - 100 keV For the purpose of

XRD only short wavelength X-rays ~ 1Aring ie comparable with the size of inter-atomic

distance are used Since the wavelength of X-rays is of the order of 1Aring they are most

ideal for probing the crystalline arrangement of atoms in the polycrystalline bulk as well

as in the thin film forms Generally in the XRD facility the Cu target is used which

emits ~8 KeV X-rays with wavelength of 154Aring X-rays primarily interact with electrons

in atoms

A crystal lattice is a regular array of atoms in space These are arranged in space

to form a series of parallel planes separated from each other by distance d which varies

according to the nature of materials For any crystal planes oriented in different direction

has different d spacing When a monochromatic X-ray beam with wavelength λ is

incident on the lattice planes in the crystal at an angle θ diffraction occurs only when the

distance travelled by rays reflected from successive phases differs by a complete number

lsquonrsquo of λ That is the Braggrsquos condition given by

n λ = 2dsin θ

By varying θ the Braggrsquos law can be satisfied by different lsquodrsquo spacing in a

polycrystalline material (figure 24) Plotting angle position and intensity of the resultant

diffraction peaks produces a pattern which is characteristic of the sample For a sample

containing a mixture of phases the XRD pattern is formed by addition of individual

patterns

II-10

Experimental Techniques for Materials Characterization

Figure 24 Diffraction of X-rays by a crystal planes (Braggrsquos law)

Figure 25 Schematic representation of X-ray diffractometer

Figure 25 represents schematics of X-ray diffractometer The three basic

components of an X-ray diffractometer are x- ray source specimen and x- ray detector

They all lie on the circumference of a circle which is known as the focusing circle The

angle between the plane of the specimen and the X-ray source is θ the Bragg angle The

angle between the projection of the X-ray source and the detector is 2θ For this reason

the X-ray diffraction patterns produced with such geometry are often known as θ-2θ scan

[10]

PAN Analytical PW304060 Xrsquopert PRO X-ray diffractometer (XRD) was used in

the present work to verify the single phasic nature of the samples studied

II-11

Experimental Techniques for Materials Characterization

232 φφφφ - Scan Measurements

Texture measurements are used to determine the orientation distribution of

crystalline grains in the polycrystalline sample One can see textured state of a material

(generally in the form of thin films) A material is called as textured if the grains are

aligned in a preferred orientation along certain lattice planes The texture measurements

have been performed on thin films at a fixed scattering angle and consists of a series of φ

- scans (in-plane rotation around the center of the sample) at different chi-angles (ψ) as

illustrated in the figure 26

Figure 26 Schematic diagram depicting - θ ψ and φ angles during XRD

measurements on films

24 Microscopic Characterizations

Morphological studies are important for understanding the growth and packing

density of grains in thin films or polycrystalline bulk materials There are various

techniques known to explore the science related to surface and morphology of a material

are Scanning Electron Microscopy (SEM) Atomic Force Microscopy (AFM) or

Scanning Probe microscopy (SPM) Tunneling Electron Microscopy (TEM) [11]

241 Scanning Electron Microscopy (SEM)

Scanning electron microscope (SEM) is used for studying the surface topography

microstructure and chemistry of metallic and nonmetallic specimens at magnifications

from 50 up to ~ 100 000 X with a resolution limit lt 10nm (down to ~ 1nm) and a depth

II-12

Experimental Techniques for Materials Characterization

of focus up to several microm (at magnifications ~ 10 000 X) In SEM a specimen is

irradiated by an electron beam and data on the specimen are delivered by secondary

electrons coming from the surface layer of thickness ~ 5nm and by backscattered

electrons emitted from the volume of linear size ~ 05microm Due to its high depth of focus

SEM is frequently used for studying fracture surfaces High resolving power makes SEM

quite useful in metallographic examinations Sensibility of backscattered electrons to the

atomic number is used for the detection of phases of different chemistry Electron

channeling in SEM makes it possible to find the orientation of single crystals by electron

channeling pattern (ECP) or of grains by selected area channeling pattern (SACP)

Figure 27 Schematic block diagram of SEM

242 Atomic Force Microscopy (AFM)

AFM is one of the foremost tools for imaging measuring an

at the nanoscale [figure 2

forces between a tip and the sample [1

surface with a mechanical probe Piezoelectric elements that facilitate tiny but accurate

and precise movements on (electronic) command enable very precise scanning AFM

consists of a microscale cantilever with

the specimen surface [fig

with a tip radius of curvature of the order of nanometers

proximity of a sample surface forces between the tip and the sample lead to a deflection

of the cantilever according to Hookersquos law Depending on the situation forces which are

measured in AFM include mechanical contact force van der waals forces capillary

forces chemical bonding electrostatic forces magnetic forces etc Typically the

deflection is measured using a laser spot reflected from the top surface of the cantilever

into an array of photodiodes

Figure 28 (a) AFM set up (b) Working of AFM

If the tip is scanned at a constant height a risk of tip colliding with the surface

exists causing the damage Hence in most cases a feedback mechanism is employed to

adjust the tip to sample distance to maintain a constant force between the tip and the

sample Traditionally the sample is mounted on a piezoelectric tube which can move the

Experimental Techniques for Materials Characterization

Atomic Force Microscopy (AFM)

AFM is one of the foremost tools for imaging measuring and manipulating matter

28 (a)] AFM is operated by measuring the attractive or repulsive

forces between a tip and the sample [12] The information is gathered by feeling the

surface with a mechanical probe Piezoelectric elements that facilitate tiny but accurate

and precise movements on (electronic) command enable very precise scanning AFM

consists of a microscale cantilever with a sharp tip (probe) at its end which is used to scan

the specimen surface [figure 28 (b)] The cantilever is typically silicon or silicon nitride

with a tip radius of curvature of the order of nanometers When the tip is brought into

surface forces between the tip and the sample lead to a deflection

of the cantilever according to Hookersquos law Depending on the situation forces which are

measured in AFM include mechanical contact force van der waals forces capillary

bonding electrostatic forces magnetic forces etc Typically the

deflection is measured using a laser spot reflected from the top surface of the cantilever

into an array of photodiodes

(a) AFM set up (b) Working of AFM

If the tip is scanned at a constant height a risk of tip colliding with the surface

exists causing the damage Hence in most cases a feedback mechanism is employed to

adjust the tip to sample distance to maintain a constant force between the tip and the

sample Traditionally the sample is mounted on a piezoelectric tube which can move the

II-13

Experimental Techniques for Materials Characterization

d manipulating matter

AFM is operated by measuring the attractive or repulsive

The information is gathered by feeling the

surface with a mechanical probe Piezoelectric elements that facilitate tiny but accurate

and precise movements on (electronic) command enable very precise scanning AFM

a sharp tip (probe) at its end which is used to scan

(b)] The cantilever is typically silicon or silicon nitride

When the tip is brought into