Chapter 16 Design of Pumping Stations

description

Transcript of Chapter 16 Design of Pumping Stations

-

Produced by: Fisheries andAquaculture Department

Title: Inland Aquaculture Engineering... More details

Chapter 16 Design of Pumping StationsJ. KepenyesFish Culture Research InstituteSzarvas, Hungary

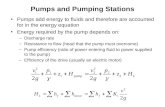

1. GROUPING OF PUMPING STATIONS2. PUMP WELL3. SETTING OF PUMPS4. CHARACTERS OF PUMP SETTING5. CAPACITY OF THE PUMP STATION6. CALCULATION OF HEAD7. PIPE SYSTEM IN THE PUMP HOUSE8. VALVES9. PUMPS10. AUXILIARY FACILITIES

1. GROUPING OF PUMPING STATIONS

Pumping stations can be grouped as follows:

- pumping water from a water source such as a river;- for lifting water (high quantity, low pressure) from a well;- for pumping water into a supply system, elevated water tank orwater tower;- to increase pressure.

Pumping stations for the first two functions are generally of 2-20 m liftingcapacity. Pumping stations for obtaining water from a water source have twotypes depending on the source:

- pumping from surface water (river, canal, lake, reservoir, etc.);

- pumping from subsurface water (soil water, deep seated spring,cavern water, spring water, marginal water, etc.) as shown on Figure2.

For the water supply to fish ponds the first two types are the most commonlyused. The construction of these two types are largely the same. The generalarrangement of these two types are shown in Figures 1 and 3.

For the water supply to hatcheries, recirculation systems and central pumping

-

stations of fish farms, pumps to catch subsurface water are used as shown inFigure 4.

A pressure intensifier device inserted into the water supply systemcompensates for lack of pressure, which can be done by:

- discharge air chamber (Figure 7 b)- revolution control of the pumps (Figure 7 a).

2. PUMP WELL

Obstacles to the operation of the pump should be removed, such as branches,sand, pebbles, etc. The pump well for the inlet pipe should be furnished with agrid of 20 mm mesh in case of smaller pumps, and with a grid of 20-50 mmmesh in case of pumps with capacity higher than 1 000 l/sec. The inlet pipe ofsmaller pumps can be furnished with an inlet rose head for protection.

The size of the pump well should be ten times the water discharge/min. A pumpwell of bigger size may promote swirling of water.

The difference between the lowest possible water level in the pump well and theinlet part of the suction pipe, can be calculated as follows:

(m)

where

v = is velocity of water in the suction pipe (m/s)g = 9.81 m/sec2 gravitational acceleration.

Generally

h = 0.5 dt (m)

wheredt is the maximum diameter of the bell mouth entry but at least h = 0.3 m.

Figure 1. Pump houses

-

Figure 2. Pump wells

-

Figure 3. Pump houses

-

Figure 4. Deep tubewell

Pumps or suction pipes with a vertical shaft should not be arranged in series,since swirling of water at the first bell mouth entry may disturb the function ofthe others, An arrangement, where the water flows perpendicular to the centreline of the bell mouth entry is more favourable. The centre line of the bell mouthentry should be fairly close to the opposite wall of the inlet chamber (the optimaldistance is 0.75 dt). Examples for optimal arrangement of pump wells are shown

-

in Figures 5 and 6.

In cases of pumps with large delivery a guide cone should be inserted under thebell mouth entry on the bottom of the pump well so as to control the waterstream. Thus the distance between the bell mouth entry and the bottom of thepump well is 0.8 to 1.0 dt (which is 0.35 to 0.5 dt without the guide cone).

3. SETTING OF PUMPS

There are three ways of setting, considering the type of pump and the inletchamber.

(a) Pumps of vertical shaft sunk in the water of the pump well;(b) pumps with vertical or horizontal shafts set in a dry chamberlocated beside the pump well;(c) pump of generally horizontal shaft located above the water level.

Within the arrangement mentioned in (a) three further cases are possible:

- Pump is under water and the driving motor is above the water level

In this case the electric motor is directly joined to thevertical shaft of the pump and is located in a water-free,dry place. The advantage of this solution is the relativelysmall space-requirement (there is no suction pipe andfoot valve) and the easy start and operation (priming isnot needed because air can not penetrate into thesuction pipe). Its shortcomings are, especially in case ofa large level difference between the motor and thepump, the difficulties in fitting the bearings in thevertical shaft, loss in efficiency (due to the several guidebearings), increased corrosion, and difficulty ofchecking, maintenance and repair (the pump should bedrained first). This setting is illustrated in Figure 1. Incases of small delivery sometimes flexible shaft-drivenpumps can be used.

- Driving motor and main pump are above the water and the firststage under the water level

By applying a first stage submerged part, the pump getsinflow water. No priming is necessary before starting.The level of water delivery is controlled by the upperpart, thus the pump in fact, has a double stage made upof a low-pressure (.submerged stage) and a higher-pressure stage. This solution partly eliminates theabove-mentioned shortcomings, by having severaladvantages (power take-off shaft with lower capacity,main part of the pump is easy to maintain).

This solution is applied mostly to pumps of highpressure.

- Pump and driving motor under the water level

To these belong the submerged and deep-well pumps.

-

Characteristic settings of these types of pumps areshown in Figure 4, where a submerged pump is set in adriven well, and in Figure 3, where a lifting submergedpump of high delivery is illustrated.

Installing and setting expenses of a pump placed separately in a dry chamber(cf. (b)) are high. Its mechanical construction, operation and maintenance,however, are more economical. The advantage of this arrangement is that nopriming or foot valve is necessary. For automatic operation this is the mostsuitable solution.

Figure 5. Arrangements of pump wells

Figure 6. Arrangements of pump wells

-

Figure 7 a. Revolution control of pumps

-

Figure 7 b. Discharge air chamber

-

Pumps working above the inlet level (cf. also (c) above) are of mostly horizontalarrangement, with lower building and installation cost. Its disadvantage, besidesuction difficulties (e.g. leakage, air - or gas development - caused water break,vacuum, cavitation), is that foot-valve and priming is necessary before starting -and all the extra costs coming from these difficulties, and in automatic starting.There are many pumps of this type working well with a suction head of 5-7 m,nevertheless, suction head higher than 3-4 m should be avoided.

4. CHARACTERS OF PUMP SETTING

The pump stations can be:

- permanently set or- mobile (Figure 8).

A permanently set pump station should be used if:

(a) the pumping delivery is extremely high;(b) the annual utilization of the pump station is high (close to 600hrs);(c) high operational safety is needed.

A mobile pump station should be used if:

(a) the use of the pump is occasional only, and the utilization is lessthan 200 hrs annually;(b) the location of pumping is not permanent.

There is an in-between solution, a temporary set pump station, where thestructural parts (tubes, mountings) are built, and the driving motor and pump aremobile.

5. CAPACITY OF THE PUMP STATION

-

The water delivering capacity, and thus the number of pumps, is defined by theamount of water to be pumped and its actual fluctuation in time and quantity(daily average, minimum or maximum).

The total capacity of a pump station should be established in such a way thatthe minimum water discharge is ensured even if several pumps are brokendown.

The following Table gives data on the number of pump units and spares makingup the total installation.

Table 1

Pump units Totalnumber

Delivery of spare pumps as a % of thetotal number

necessary for maximumdelivery

forreserve

1 1 2 502 1 3 333 1 4 254 2 6 335 2 7 296 2 8 257 2 9 22.58 2 10 20

Figure 8. Mobile pump

The reserve pump is the so-called operational reserve ready to work. In smallpump stations, where there is a proper staff, half of the spares are ready to workand the other half in store.

If no significant fluctuation can be expected in consumption, there are generallythree pump units of the same delivery, two of them are operating and the thirdone is the reserve.

6. CALCULATION OF HEAD

6.1 Entrance Loss:6.2 Resistance of Suction Screen6.3 Resistance of Foot Valve6.4 Pressure Loss Coming from Pipe Friction (h3)6.5 Valves Built in the Pipeline (Gate Valve, Check Valve, etc.)6.6 Pressure Loss from Inversion (h7)

To determine the total head of a pump, the geodetic level difference between theinlet-side and delivery-side water levels and the pressure affecting them (e.g. ina discharge air chamber) should be known as well as the various hydrauliclosses during lifting.

(m)

-

where

H = total head (m)hg = geodetic lifting level (m)h0 = entrance loss (m)h1 = resistance of the filter (m)h2 = resistance of the foot valve (m)h3 = loss by pipe friction (m)h4 = loss from increase in cross section (m)h5 = loss from reduction in cross section (m)h6 = loss from valves (m)h7 = loss from inversion (m)Ps = external pressure on the inlet-side water (Pa)Pd = external pressure on the delivery-side water (Pa)r = density of water 1 000 kg/m3g = 9.81 m/sec2 gravitational acceleration

If atmospheric pressure affects the water levels of both inlet and delivery sidesthe last item is:

6.1 Entrance Loss:

(m)

where

v = velocity of water on entering the inlet of the pump (m/sec)x 0 = value in case of not rounded inlet part: 0.8 - 1.0; in case of properly roundedinlet 0.04, i.e. the entrance loss is practically equal to the value which isnecessary to accelerate the water.

6.2 Resistance of Suction Screen

(m)

where

x 1 = value depends on the suction screen; according to preliminarycalculation can be 2-3.

In case of a suction screen of proper size and shape with free surface this losscan be markedly reduced.

-

6.3 Resistance of Foot Valve

(m)

which is equal to the specific valve-loading, and the loss-factor is graduallydecreasing along with the increasing velocity if the valve is automatic

if v = 1 2 3 4thenx 2 = 6.9 1.7 0.77 0.43

6.4 Pressure Loss Coming from Pipe Friction (h3)

If is higher than 2320, in case of turbulent water stream,

where

l = pipe friction constantl = length of the pipe-line (m)v = water velocity in the pipe (m/s)d = inner diameter (m)l = kinematic viscosity (m3/sec) as a function of water temperature.

It is 1.3 . 106 at 10C and 1 . 106 at 20C

Pipe friction constant according to the latest research data should be calculatedwith consideration of Re and wall roughness of pipe. The International Congresson Water Supply held in Paris in 1952 accepted the formula of Colebrook forcalculating the pipe-friction constant.

Which is

where

k= the absolute roughness of the pipe which can be selected fromTable 2.

Values of pressure loss by pipe friction are determined with approximateequations, nomograms or tables. Figure 9 shows the resistance values in casesof steel and polyethylene pipes, while in Table 3 different approximate equationsare collected.

Figure 9. Pipe flow diagrams

-

Table 2 Absolute values of pipe friction

Type of pipe Condition of the pipe k absoluteroughness

(mm)drawn glass-, brass-, lead-, copper-,aluminium-, polyethylene pipes

new, with smooth wall 0 (glazed)

- 0.0015drawn steel pipe new, with different smoothness 0.01-0.05welded steel pipe new 0.05-0.1

corroded 0.1 -0.2heavily corroded up to 3.0

galvanized steel pipe new 0.02-0.12asbestos cement pipe new 0 - 0.1concrete pipe, tube from concrete new concrete, with smoothing,

prestressed0 - 0.15

new, without smoothing 0.2-0.3 orreinforced concrete mains withsmoothing after few years operating

0.2-0.3 orabove

In case of gradual (increasing) of cross-section (diffusor), the pressure loss is;

(m)

where the length of diffusor piece is at least six times the difference indiameters

x 4 = 0.15 - 0.24

v = the velocity value of the smaller cross-section

If the increase in cross-section is very sudden, i.e. Bordas's loss:

(m)

where

x 4 = 1.2 - 1.3v1 and v2 are the velocity values belonging to the larger and smallercross-sections, respectively.

In case of a reduction in cross-section (confusor) the pressure loss is:

(m)

where

x 5 = 0.02 - 0.05

-

v = the velocity measured at the narrowest section.

6.5 Valves Built in the Pipeline (Gate Valve, Check Valve, etc.)

(m)

the value of x 6, for a gate valve depends on A/A0 where A is the whole, and A0 isthe gate-valve reduced cross section of the pipe.

If A/A0 = 1.05 1.1 1.4 1.8 2.5 3.0 5.0 7.0 10.0thenx 6 = 0.1 0.21 1.15 4.0 9.7 15.0 42.0 72.0 121.0

If a flap valve or regulating flap is used,x 6, values depending on the constructiono installation of the flap valve or regulating flap are 1.0-10.0, where the highervalues correspond to pipe diameter of 80-300 mm and the lower ones to thediameter of 400 mm or more. As an average, a value of 2-3 can beapproximated, but the exact number can be give experimentally only.

For the x 6 value of a butterfly valve, denoting the angle between the plate of thevalve and the axis of the pipe

If CT = 0 10 20 30 40 45 50 60 65 70thenx 6 = 0.1 0.52 1.54 3.91 10.8 18.7 32.6 118 256 750

6.6 Pressure Loss from Inversion (h7)

In case of a bend in the pipe

(m)

where

x 7 depends on the relation of pipe diameter and radius r of the pipe bendmidline, and on the central angle of the bent pipe, that is the degree of inversion.

Using a standard bend of 90 (r = d mm + 100 mm) x 7 = 0.2 if the angle ofbending is

s = 22 45 60 90thenx 7 = 0.045 0.075 0.09 0.10

If there is a direction-break (r = 0), the pressure loss in the pipe-line 2

(m)

-

where

x 7 = 0.7 - 1s = the vectoral difference between the velocity values before (v1)and after (v2) the breaking point.

Practically speaking v1 = v2 = v, that is the cross-section of the pipe is constant,thus there is no change in the velocity.

If a = 22 30 45 60 90thens = 0.37 v 0.5 v 0.75 v 1.41 v

With T-profile - the pressure loss corresponds to a 90 direction-breakwith Y-profile - the pressure loss is of the 90 direction-break.

Values given for pressure loss are related to clean water. With sandy or muddywater these values have to be increased according to the extent of pollution.

Table 3 Approximate calculation of pipe friction factor for different types ofpipes

l A . da . Reb

where

d = inner diameter of the pipe (m)

Type of pipe Fault A a b Limit of applicationSteel 10% 0.094 - 0.055 - 0.14New cast-iron 10...13 % 0.053 - 0.2 - 0.08 Re < 106 eConcrete 0.0156 ha k = 0.4 - 0.2 0

0.0180 ha k = 0.70.218 ha k = 1.50.29 ha k = 4.0

Asbestos-cement 0.22 0 - 0.21 104 < Re

-

passing through the pump from the inlet to the outlet. The minimumoverpressure is around the entrance of the impeller. Steam bubbles arise here, ifthe pressure of the delivered water decreases below the pressure value ofsaturated steam with the same temperature (cf. Table 4). In the course of energyconversion in the pump, the pressure increases again along the stream whenthe water is passing through the pump and when it exceeds the pressure of thesteam the bubbles are crushed (cavitation) thus starting to destruct the impellermechanically. To prevent cavitation at the inlet of the pump the minimum inflowpressure should be maintained.

Each pump has a minimum suction head value, at which it can still work. Thisvalue is always smaller than the atmospheric pressure value expressed inpressure head of the liquid to be delivered. This value is known in the Anglo-American literature as the necessary "net positive suction head" - that is theNPSH of a pump.

This value can be considered as a loss factor and must be always subtractedfrom the theoretical suction head. Manufacturing companies always indicatethese values for different deliveries and revolutions, since along with theincrease of delivery these values increase as well. To apply properly thesevalues, the NPSHa value of the pump under the actual conditions should becalculated with the following formula:

(m)

where

hs geod = geodetic suction head (m)hs = head loss on the inlet side (m)Pd = steam pressure of the liquid (Pa)

Checking of NPSH of a working system should be performed as follows:

(NPSH)a = Hs - Pd (m)

NPSHa NPSH is necessary for cavitation prevention and vibrationlessoperation.

The actual value of (NPSH)a necessary depends on the characteristics of theliquid, the total height of delivery, the rpm, the delivery and on the shape of theimpeller.

7. PIPE SYSTEM IN THE PUMP HOUSE

A suction screen with as small resistance as possible should be used on thesuction pipe. With suction pipes, especially if the pump is not of inflow system, itis very important to reduce the losses to achieve the lowest possible suctionhead and perfect sealing. Resistance of suction pipe can be reduced with anample cross-section and short-suction piece, and with the avoidance of sharpcurves and directional changes. Velocity on entrance should be 0.8-1.0 m/secand 1-2 m/sec in the suction pipe so as to decrease entrance loss. The suctionpipe should be connected to the inlet of the pump with the shortest possible

-

reducing piece so as to avoid the decrease of velocity below 0.8 m/sec, and toprevent air segregation and corrosion. With the application of the shortestpossible vertically or slightly (1-2%) declining suction pipe, the formation of airlocks can be prevented.

If air segregation occurs at any part of the pipeline, it should be solved with de-aeration of the actual part by properly connecting it to a deaerator. Reducingpieces built in a horizontal suction pipe should be asymmetric to the upper,horizontal mounting. Suction pipe after connecting should be checked withhydrostatic tests to prevent leakage. Subsurface suction pipes and syphonsshould always be made of welded steel.

In the case of delivery pipes in the pump house, a velocity of 2 m/sec is themost economic. Connection to an external pipeline of bigger cross-sectionshould be done outside of the pump house. Velocity higher than 2 m/sec isadmissible for temporary fluctuations of water amount only, and for as shorttime as possible.

In ease of marked fluctuation of the water amount, two delivery pipes should beapplied, which besides ensuring an even velocity, results in a safer operation. Inthis case all the pumps should be attached to a common collecting main to bothends of which delivery pipes are connected. With the help of a gate valve in themiddle of the collecting main, the two delivery pipes and the pump units can beoperated separately.

A suitable gate valve or other cut off device should be inserted in the deliverypipe of each pump possibly close to the outlet of the pump or in case of aninflow system before the inlet of the pump as well, in order to cut off the pump.To prevent reflux of water in the delivery pipe, in case of a sudden stop of thepump, especially if several pumps are operated on a common delivery pipe, aflap valve or regulating flap should be inserted between the pump and the gatevalve on the delivery side.

Pipes in the pump house should be made of flange joint cast iron or weldedsteel. Use of flanges meaning extra cost and source of operational faults shouldbe restricted to connections to pumps and pipe fitting.

To render dewatering of the common delivery pipe possible, a gate valveregulated branch pipe should be inserted at the deepest part of the commondelivery pipe depending upon its size and the quantity of the water to be drained.

8. VALVES

To cut off the pipeline as well as to control the amount of water passing throughdifferent valves such as gate valves, ring valves or flap/butterfly valves areapplied. They are manually operated. If the gate valve is bigger than 800 mmand fast and frequent operation is expected, or automatic or distant-control isneeded, the device can be run by hydraulic or electric control.

In case of distant operation, a jam proof wedge gate valve should be applied or aparallel slide valve, cup valve or flap valve. If the space is limited, a butterflyvalve or flap valve can be used with manual, electric or hydraulic operation. Toensure smooth operation and safety shut off of pipelines with high pressure andcross-section of 400 mm or more ring or cup valves can be inserted.

-

If the pump stops, efflux can be prevented with a flap valve, or regulating flap.Automatic butterfly valves or a ring valve cause less pressure loss or resistancethan flap valve does.

With intake pipes of pools and wells, with a pressure of 0-2 m water column, acatch mounted on the end of the tube should be applied, with automatic cut off.

To take unilateral pressure or to cut off intake pipes of wells, sluices movingbetween the walls of the well or sliding sluice-valves are used. They areoperated with spindle-drive up to 3-4 m water pressure. At higher waterpressure, diameter rack-drive or sliding sluices, or sluice valves provide the bestsolution. The sluices are generally controlled manually. Electric or hydraulicdrive is only occasionally used (e.g. at very quick cut off, or open, in case ofautomatic operation).

9. PUMPS

9.1 Choice of the Proper Type of Pump9.2 Control of Delivering Capacity

9.1 Choice of the Proper Type of Pump

For water delivery rotary pumps are used almost exclusively. For watercatchment, for primary lifting of a small amount of water at little heights (2-12m), and for amounts higher than 200 l/sec, by providing the proper possibilitiesas to inflow, the propeller pump is the most suitable in one or two-stepoperation. The same type can be applied in case the delivery requirements arehigher than 500 l/sec at changing lifting heights, with adjustable blades.

Water level fluctuation can be as high as 8-11 m at plants for water catchment.In such places, a pump with a steep characteristic is favourable, but if a pump ofproper type and capacity cannot be mounted, separate pumps should beinstalled for the lower or higher lifting levels. At a lifting level higher than 30 mup to approximately 150 l/sec capacity multi-stage pumps should be applied.For higher lifting levels, up to 150 m, one stage pumps are optimal especially fordelivery of water amounts more than 150-200 l/sec. Pumps at such lifting levelsshould be set under the water level, so as to prevent vacuum formation, and toensure the inflow prescribed by the manufacturer. To pump water of a drivenwell, a submerged pump should be used.

9.2 Control of Delivering Capacity

Capacity of a pump station can be controlled with the simultaneous applicationof pumps of different delivery capacity. For one delivery pipe a maximum ofthree pumps, with intermittent running, with revolution control throttling, andbypass can be used. The most simple is throttling in the delivery pipe (Q, H), andthus the amount of water delivered can be reduced according to the throttlingcurve. It should be kept in mind, however, that this type of control results in aloss of efficiency, therefore it can only be temporarily applied. Control withthrottling is not feasible with pumps of propeller or wing blade, due to theoverloading of the motor. Control is made with adjustable blades with highcapacity pumps with wind blades.

-

Permanent pumps usually are driven by directly connected electric motors withconstant speed. Mobile pumps are generally driven by Otto or Diesel engines.

10. AUXILIARY FACILITIES

10.1 Priming10.2 Cranes

10.1 Priming

For centrifugal pumps, where the suction level is under the pump, i.e. there is noinflow, and a foot valve cannot be used because of the high delivering capacityor other reasons, priming is necessary before starting. For priming, electricmotor driven watering vacuum pumps are the most suitable. With the pumps ofsmaller stations, starter tanks, or extra-resistance forming, self-priming pumpsare applied.

10.2 Cranes

To make installation and mounting easier, above the machines in the pumphouse of smaller stations a crane with suspended pulley block should bemounted above the pumps. In pump stations of several pumps of high capacityan overhead electric traveller should be installed.

Table 4

Temperature of water Steam pressure Density of watert

CTK

Pdbar

r kg/dm3

0 273.15 0.006107 0.99981 274.15 0.006566 0.99992 275.15 0.007056 0.99993 276.15 0.007577 1.00004 277.15 0.008131 1.00005 278.15 0.008722 1.00006 279.15 0.009349 0.99997 280.15 0.010016 0.99998 281.15 0.010725 0.99989 282.15 0.011477 0.9997

10 283.15 0.012275 0.999611 284.15 0.013122 0.999512 285.15 0.014020 0.999413 286.15 0.014971 0.999314 287.15 0.015979 0.999215 288.15 0.017045 0.999016 289.15 0.018174 0.998817 290.15 0.019367 0.998718 291.15 0.02063 0.998519 292.15 0.02196 0.9984

-

20 293.15 0.02337 0.998221 294.15 0.02486 0.997922 295.15 0.02643 0.997723 296.15 0.02808 0.997524 297.15 0.02982 0.997225 298.15 0.03166 0.997026 299.15 0.03360 0.996727 300.15 0.03564 0.996428 301.15 0.03778 0.996129 302.15 0.04004 0.995830 303.15 0.04241 0.995631 304.15 0.04491 0.995232 305.15 0.04753 0.994933 306.15 0.05028 0.994634 307.15 0.05318 0.994235 308.15 0.05621 0.993936 309.15 0.05939 0.993537 310.15 0.06273 0.993238 311.15 0.06623 0.992939 312.15 0.06990 0.992640 313.15 0.07374 0.992241 314.15 0.07776 0.991842 315.15 0.08197 0.991443 316.15 0.08638 0.991044 317.15 0.09099 0.990645 318.15 0.09581 0.990246 319.15 0.10084 0.989847 320.15 0.10611 0.989348 321.15 0.11161 0.988949 322.15 0.11735 0.988550 323.15 0.12334 0.988051 324.15 0.12959 0.987752 325.15 0.13611 0.987253 326.15 0.14292 0.986754 327.15 0.15001 0.986255 328.15 0.15740 0.985756 329.15 0.16509 0.985257 330.15 0.17311 0.984758 331.15 0.18146 0.984359 332.15 0.19015 0.983760 333.15 0.1992 0.983261 334.15 0.2086 0.982662 335.15 0.2184 0.982163 336.15 0.2285 0.981664 337.15 0.2391 0.981165 338.15 0.2501 0.9805

-

66 339.15 0.2615 0.980067 340.15 0.2733 0.979468 341.15 0.2856 0.978869 342.15 0.2984 0.978370 343.15 0.3116 0.977771 344.15 0.3253 0.977172 345.15 0.3396 0.976673 346.15 0.3543 0.976074 347.15 0.3696 0.975475 348.15 0.3855 0.974876 349.15 0.4019 0.974377 350.15 0.4189 0.973778 351.15 0.4365 0.973079 352.15 0.4547 0.972580 353.15 0.4736 0.971881 354.15 0.4931 0.971382 355.15 0.5133 0.970683 356.15 0.5342 0.969984 357.15 0.5557 0.969485 358.15 0.5780 0.968786 359.15 0.6011 0.968187 360.15 0.6249 0.967488 361.15 0.6495 0.966789 362.15 0.6749 0.966090 363.15 0.7011 0.965391 364.15 0.7282 0.964792 365.15 0.7561 0.964093 366.15 0.7849 0.963394 367.15 0.8146 0.962695 368.15 0.8453 0.961996 369.15 0.8769 0.961297 370.15 0.9094 0.960498 371.15 0.9430 0.959899 372.15 0.9776 0.9590

100 373.15 1.0132 0.9583102 375.15 1.0878 0.9568104 377.15 1.1667 0.9555106 379.15 1.2504 0.9540108 381.15 1.3390 0.9526110 383.15 1.4326 0.9510112 385.15 1.5316 0.9496114 387.15 1.6361 0.9480116 389.15 1.7464 0.9464118 391.15 1.8627 0.9448120 393.15 1.9853 0.9431122 395.15 2.1144 0.9415

-

124 397.15 2.2503 0.9398126 399.15 2.3932 0.9382

128 401.15 2.5434 0.9365130 403.15 2.7011 0.9348132 405.15 2.8667 0.9332134 407.15 3.041 0.9314136 409.15 3.223 0.9296138 411.15 3.414 0.9279140 413.15 3.614 0.9261145 418.15 4.155 0.9217150 423.15 4.760 0.9169155 428.15 5.433 0.9122160 433.15 6.180 0.9074165 438.15 7.008 0.9024170 443.15 7.920 0.8973175 448.15 8.925 0.8921180 453.15 10.027 0.8869185 458.15 11.234 0.8814190 463.15 12.552 0.8760195 468.15 13.989 0.8703200 473.15 15.551 0.8647