chainflex catalog intro - tests and more

-

Upload

inese-janauska -

Category

Documents

-

view

227 -

download

0

description

Transcript of chainflex catalog intro - tests and more

chainflex® lasts or your money back!!igus® tested!

22

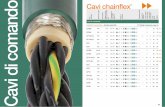

Control Cables 56

Data/Coax Cables 110

Bus Cables 128

Fibre optic cable (FOC) 150

Measuring system cables 160

Servo Cables 186

Power cables/Pneumatic hoses 202

Twistable cables 232

Special cables 254

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:41 Seite 1

chai

nfle

x®

cabl

e

Req

uire

men

ts

Trav

el d

ista

nce

Res

ista

nce

to o

il

CFBUS.PVC 4 1 2

CF210.UL 4 1 2

CF170.D 4 1 3

CF180 4 1 3

CFBUS.PUR 4 1 3

CF111.D 4 1 3

CF270.UL.D 4 1 4

CF130.UL 4 2 1

CF140.UL 4 2 1

CF240 4 2 2

CF240.PUR 4 2 3

CFLK 5 1 3

CF THERMO 5 2 3

CF5 5 3 2

CF6 5 3 2

CF211 (Daten) 5 3 2

CF211 (Mess) 5 3 2

CF21.UL 5 3 2

CF30 5 3 2

CF31 5 3 2

CF77.UL.D 5 3 3

CF78.UL 5 3 3

CF 77.UL.D (Robot) 5 3 3

CF ROBOT9 6 1 3

CF ROBOT2 6 1 3

CF ROBOT8 6 1 3

CF ROBOT4 6 1 3

CF ROBOT6 6 1 3

CF ROBOT7 6 1 3

CF ROBOT5 6 1 4

CF ROBOT 6 1 4

CF2 6 3 3

CF113 6 3 3

chai

nfle

x®

cabl

e

Req

uire

men

ts

Trav

el d

ista

nce

Res

ista

nce

to o

il

CF112 6 3 3

CF113.D 6 3 3

CF27.D 6 3 3

CF14 CAT5 6 3 4

CF9.UL 6 4 4

CF10.UL 6 4 4

CF11 6 4 4

CF12 6 4 4

CF Koax1 6 4 4

CFBUS 6 4 4

CF11.LC 6 4 4

CF11.LC.D 6 4 4

CF11.D 6 4 4

CF34.UL.D 6 4 4

CF35.UL 6 4 4

CF300.UL.D 6 4 4

CFPE 6 4 4

CF310.UL 6 4 4

CF BRAID 6 4 4

CF BRAID.C 6 4 4

CF CRANE 6 4 4

CFLG.2LB 7 3 4

CF9 7 4 4

CF10 7 4 4

CF98 7 4 4

CF99 7 4 4

CFLG.G 7 4 4

CF37.D 7 4 4

CF38 7 4 4

CF330.D 7 4 4

CF340 7 4 4

CF FLAT 7 4 4

More information Page 20/21

Selection chainflex® according to "Class" Selection chainflex® according to "Class"

chainflex® CF.INIsystems for initiators 314

readycable®

Harnessed Cables 330

Connectors 452

chainfixStrain Relief Devices 487

readychains®

Ready-made energy chain systems®

515

Designing with igus®

Data and Schedules 522

chainflex® video-/vision-/ bus technology 266

chainflex®

network technology 294

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:43 Seite 2

CF130.UL PVC 7,5-10 -5/ +70 5 -20/ +70 � � 3 2 20 2 - 42 0,25 - 6,0 58

CF140.UL PVC � 7,5-15 -5/ +70 7,5 -20/ +70 � 3 2 20 3 - 42 0,25 - 2,5 62

CF5 PVC 6,8-7,5 -5/ +70 4 -20/ +70 � � � � 10 5 80 2 - 42 0,25 - 2,5 66

CF6 PVC � 6,8-7,5 -5/ +70 4 -20/ +70 � � � 10 5 80 2 - 36 0,25 - 2,5 70

CF170.D PUR 7,5-10 -35/ +80 5 -40/ +80 � � � 3 2 20 3 - 30 0,50 - 10,0 74

CF180 PUR � 7,5-15 -35/ +80 7,5 -40/ +80 � � � 3 2 20 3 - 18 0,50 - 2,5 76

CF77.UL.D PUR 6,8-7,5 -35/ +80 4 -40/ +80 � � � � � 10 5 80 2 - 42 0,25 - 4,0 78

CF78.UL PUR � 6,8-7,5 -35/ +80 4 -40/ +80 � � � � 10 5 80 3 - 42 0,50 - 4,0 82

CF2 PUR � 5 -20/ +80 4 -40/ +80 � � � 10 5 80 3 - 48 0,14 - 1,5 86

CF9 TPE 5 -35/ +100 3 -40/ +100 � � � � 10 6 100 2 - 36 0,14 - 35,0 90

CF10 TPE � 5 -35/ +100 3 -40/ +100 � � � 10 6 100 2 - 25 0,14 - 4,0 94

CF9.UL TPE 5 -35/ +100 3 -40/ +100 � � � � 10 6 100 2 - 36 0,25 - 6,0 98

CF10.UL TPE � 5 -35/ +100 3 -40/ +100 � � � 10 6 100 2 - 25 0,25 - 4,0 102

CF98 TPE 4 -35/ +90 3 -40/ +90 � � � � 10 6 100 2 - 8 0,14 - 0,5 106

CF99 TPE � 4 -35/ +90 3 -40/ +90 � � � 10 6 100 2 - 8 0,14 - 0,34 108

chainflex® types chainflex® types

Control cables 56

These values are based on concrete applications or tests. These values do not represent the limit of what is technically feasible. chainflex® types mentioned in the catalogue as “resistant to bio oil“ have been tested by DEA following VDMA 24568 with Plantocut 8 S-MB.

Get online and use all the advantages of www.igus.eu

Download the eplan-library for any type of cableswww.igus.eu/eplan-download

Table of contents according to industries Page 550Table of contents according to part number Page 558

Chain – cable – guarantee!Ask for fully harnessed and preassembled ready-chains® – increase your cash-flow and profit immediately. The igus® system guarantee also coverscomponents delivered loose.www.readychain.eu

4 5

chai

nfle

x®

cab

le

Jack

et

Shi

eld

Tem

per

atur

e,m

ove

d

fro

m/t

o [°

C]

Min

imum

ben

din

gra

diu

s, fi

xed

[fa

ctor

x d

]

Tem

per

atur

e,fix

ed

fro

m/t

o [°

C]

Tors

ion

resi

stan

t

Hal

og

en-f

ree

UV-

resi

stan

t

Oil-

resi

stan

t

Fla

me-

reta

rdan

t

Ap

pro

vals

and

stan

dar

ds

Pri

ce in

dex

Min

imum

ben

din

gra

diu

s, m

oved

[fa

ctor

x d

]

v m

ax.

unsu

pp

ort

ed[m

/s]

v m

ax.

glid

ing

[m

/s]

a m

ax. [

m/s

2 ]

Num

ber

of

core

s

Cro

ss s

ectio

nØ

[mm

2 ]

Pag

e

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:43 Seite 4

CF240 PVC � 10-12 -5/ +70 5 -20/ +70 � � 3 2 20 3 - 24 0,14 - 0,34 112

CF240.PUR PUR � 10-12 -20/ +80 5 -40/ +80 � � � � 3 2 20 3 - 18 0,14 - 0,34 114

CF211 PVC � 7,5 -5/ +70 5 -20/ +70 � � 5 3 50 2 - 28 0,25 - 0,5 116

CF113 PUR � 10 -20/ +80 5 -40/ +80 � � � � 10 5 80 4 - 12 0,25 - 0,5 118

CF11 TPE � 6,8 -35/ +100 5 -40/ +100 � � � 10 6 100 2 - 36 0,14 - 2,5 120

CF112 PUR � 10 -20/ +80 5 -40/ +80 � � � � 10 5 80 4 - 12 0,25 - 0,5 122

CF12 TPE � 10 -35/ +100 5 -40/ +100 � � � 10 6 100 4 - 28 0,25 - 1,0 124

CF Koax 1 TPE 10 -35/ +100 7,5 -40/ +100 � � 10 5 100 1 - 5 126

CFBUS.PVC PVC � 12,5 -5/ +70 7,5 -20/ +70 � � � 2 30 2 - 8 0,15 - 0,5 134

CFBUS.PUR PUR � 12,5 -20/ +70 7,5 -40/ +70 � � � � 2 30 2 - 8 0,15 - 0,5 136

CF BUS TPE � 10-12,5 -35/ +70 5 -40/ +70 � � � 10 6 100 2 - 13 0,08 - 1,5 138

CF11.LC TPE � 10 -35/ +70 5 -40/ +70 � � � 10 6 100 2 - 9 0,25 - 1,0 144

CF11.LC.D TPE � 10 -35/ +70 5 -40/ +70 � � � 10 6 100 2 - 6 0,25 - 1,5 146

CF14CAT5 TPE � 12,5 -35/ +70 7,5 -40/ +70 � � � 10 6 100 4 - 10 0,14 - 0,25 148

chainflex® types chainflex® types

Data cables – Stranded in layers 110

Data cables – Twisted pair/Pair shield

Data cables – Twisted pair

Bus cables 128

Data cables – Coax

* New in this catalogue.6 7

These values are based on concrete applications or tests. These values do not represent the limit of what is technically feasible. chainflex® types mentioned in the catalogue as “resistant to bio oil“ have been tested by DEA following VDMA 24568 with Plantocut 8 S-MB.

Table of contents according to industries Page 550Table of contents according to part number Page 558

chai

nfle

x®

cab

le

Jack

et

Shi

eld

Tem

per

atur

e,m

ove

d

fro

m/t

o [°

C]

Min

imum

ben

din

gra

diu

s, fi

xed

[fa

ctor

x d

]

Tem

per

atur

e,fix

ed

fro

m/t

o [°

C]

Tors

ion

resi

stan

t

Hal

og

en-f

ree

UV-

resi

stan

t

Oil-

resi

stan

t

Fla

me-

reta

rdan

t

Ap

pro

vals

and

stan

dar

ds

Pri

ce in

dex

Min

imum

ben

din

gra

diu

s, m

oved

[fa

ctor

x d

]

v m

ax.

unsu

pp

ort

ed[m

/s]

v m

ax.

glid

ing

[m

/s]

a m

ax. [

m/s

2 ]

Num

ber

of

core

s

Cro

ss s

ectio

nØ

[mm

2 ]

Pag

e

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:43 Seite 6

CFLK PUR 12,5 -20/ +70 7,5 -25/ +70 � � � 10 5 20 1 980/1000 µm 154

CFLG.LB TPE 5 -40/ +60 5 -40/ +60 � � � 10 6 20 2 50 + 62,5/125 156

CFLG. G TPE 15 -40/ +60 8,5 -40/ +60 � � � 10 6 20 6 - 12 50 + 62,5/125 µm 158

CF211 PVC � 10 -5/ +70 5 -20/ +70 � � 5 3 50 6 - 16 0,14 -1,0 164

CF111.D PUR � 12 -35/ +100 6 -40/ +100 � � � 2 30 6 - 16 0,14 - 0,5 170

CF113.D PUR � 10 -20/ +80 5 -40/ +80 � � � � 5 3 50 4 - 17 0,14 -1,0 174

CF11.D TPE � 10 -35/ +100 5 -40/ +100 � � � 10 6 100 4 - 17 0,14 - 1,0 180

CF210.UL PVC � 10 -5/ +70 5 -20/ +70 � � � 10 50 6 - 8 188

CF21.UL PVC � 7,5 -5/ +70 4 -20/ +70 � � � 10 5 80 6 - 8 190

CF270.UL.D PUR � 10 -20/ +80 5 -40/ +80 � � � � 10 50 4 - 8 194

CF27.D PUR � 7,5 -20/ +80 4 -40/ +80 � � � � 10 5 80 4 - 8 198

chainflex® types chainflex® types

Measuring system cables 160

Servo cables 186

1,5 - 6 / Pairs 0,75 - 1,5

0,75 - 35 / Pairs 0,34 - 1,5

0,75 - 35 / Pairs 0,34 - 1,5

0,75 - 50 / Pairs 0,34 - 1,5

These values are based on concrete applications or tests. These values do not represent the limit of what is technically feasible. chainflex® types mentioned in the catalogue as “resistant to bio oil“ have been tested by DEA following VDMA 24568 with Plantocut 8 S-MB.

Table of contents according to industries Page 550Table of contents according to part number Page 558

Fibre optic cable (FOC) 150

8 9

chai

nfle

x®

cab

le

Jack

et

Shi

eld

Tem

per

atur

e,m

ove

d

fro

m/t

o [°

C]

Min

imum

ben

din

gra

diu

s, fi

xed

[fa

ctor

x d

]

Tem

per

atur

e,fix

ed

fro

m/t

o [°

C]

Tors

ion

resi

stan

t

Hal

og

en-f

ree

UV-

resi

stan

t

Oil-

resi

stan

t

Fla

me-

reta

rdan

t

Ap

pro

vals

and

stan

dar

ds

Pri

ce in

dex

Min

imum

ben

din

gra

diu

s, m

oved

[fa

ctor

x d

]

v m

ax.

unsu

pp

ort

ed[m

/s]

v m

ax.

glid

ing

[m

/s]

a m

ax. [

m/s

2 ]

Num

ber

of

core

s

Cro

ss s

ectio

nØ

[mm

2 ]

Pag

e

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:44 Seite 8

CF30 PVC 7,5 -5/ +70 4 -20/ +70 � � � � 10 5 80 4 - 5 1,5 - 50 204

CF31 PVC � 7,5 -5/ +70 4 -20/ +70 � � � 10 5 80 4 - 5 1,5 - 70 206

CF34.UL.D TPE 7,5 -35/ +90 4 -40/ +90 � � � � 10 6 80 3 - 5 1,5 - 50 208

CF35.UL TPE � 7,5 -35/ +90 4 -40/ +90 � � � 10 6 80 3 - 4 0,5 - 50 210

CF37.D TPE 7,5 -35/ +90 4 -40/ +90 � � � � 10 6 80 3 - 5 1,5 - 50 212

CF38 TPE � 7,5 -35/ +90 4 -40/ +90 � � � 10 6 80 3 - 4 0,5 - 50 214

CF300.UL.D TPE 7,5 -35/ +90 4 -40/ +90 � � � � 10 6 100 1 4 - 185 216

CFPE TPE 7,5 -35/ +90 4 -40/ +90 � � � � 10 6 100 1 1,5 - 35 218

CF310.UL TPE � 7,5 -35/ +90 4 -40/ +90 � � � 10 6 100 1 2,5 - 185 220

CF330.D TPE 7,5 -35/ +90 4 -40/ +90 � � � � 10 6 100 1 6 - 185 222

CF340 TPE � 7,5 -35/ +90 4 -40/ +90 � � � 10 6 100 1 4 - 185 224

CF CRANE igupren � 10 -20/ +80 7,5 -30/ +80 � � � 10 6 50 1 25 - 120 226

CFAIR PU 10 -25/ +80 8 -40/ +85 � � 10 6 50 4 - 16 228

CF Clean AIR PE 10 -25/ +60 8 -30/ +65 � � 10 6 50 4 - 16 230

chainflex® types chainflex® types

Pneumatic hose

These values are based on concrete applications or tests. These values do not represent the limit of what is technically feasible. chainflex® types mentioned in the catalogue as “resistant to bio oil“ have been tested by DEA following VDMA 24568 with Plantocut 8 S-MB.

Table of contents according to industries Page 550Table of contents according to part number Page 558

Power cables 202

10 11

chai

nfle

x®

cab

le

Jack

et

Shi

eld

Tem

per

atur

e,m

ove

d

fro

m/t

o [°

C]

Min

imum

ben

din

gra

diu

s, fi

xed

[fa

ctor

x d

]

Tem

per

atur

e,fix

ed

fro

m/t

o [°

C]

Tors

ion

resi

stan

t

Hal

og

en-f

ree

UV-

resi

stan

t

Oil-

resi

stan

t

Fla

me-

reta

rdan

t

Ap

pro

vals

and

stan

dar

ds

Pri

ce in

dex

Min

imum

ben

din

gra

diu

s, m

oved

[fa

ctor

x d

]

v m

ax.

unsu

pp

ort

ed[m

/s]

v m

ax.

glid

ing

[m

/s]

a m

ax. [

m/s

2 ]

Num

ber

of

core

s

Cro

ss s

ectio

nØ

[mm

2 ]

Pag

e

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:44 Seite 10

CF ROBOT9 PUR � 10 -25/ +80 4 -40/ +80 � � � � 10 10 4 - 34 0,25 - 1 236

CF77.UL.D PUR 6,8-7,5 -35/ +80 4 -40/ +80 � � � � � 10 5 80 2 - 42 0,25 - 4,0 238

CF ROBOT2 PUR � 10 -25/ +80 4 -40/ +80 � � � � 10 10 4 - 18 0,75 242

CF ROBOT8 PUR � 10 -20/ +70 7,5 -25/ +70 � � � � 10 10 2 - 8 0,14 - 0,35 244

CF ROBOT4 PUR � 10 -25/ +80 4 -40/ +80 � � � � 10 10 6 - 12 0,14 - 0,5 246

CF ROBOT5 TPE 12,5 -20/ +60 7,5 -25/ +60 � � � 10 10 2 50 + 62,5/125 µm 248

CF ROBOT6 PUR 10 -25/ +80 4 -40/ +80 � � � � 10 10 3 10 - 35 250

CF ROBOT7 PUR � 10 -25/ +80 4 -40/ +80 � � � � 10 10 3 - 12 0,25 - 4 250

CF ROBOT TPE � 10 -35/ +100 4 -40/ +100 � � � � 10 10 1 10 - 50 252

CFTHERMO PUR � 12,5-15 -20/ +80 5 -40/ +80 � � � � 2 1 20 2 - 5 0,23 - 0,5 256

CF FLAT TPE 5 -35/ +90 4 -40/ +90 � � � 10 6 100 1 2,5 - 4 260

CF BRAID TPE 7,5 -35/ +70 4 -40/ +70 � � � 10 6 80 8 2,5 262

CF BRAID.C TPE � 7,5 -35/ +70 4 -40/ +70 � � � 10 6 80 8 2,5 262

CFSP182 PUR � 10 -20/ +70 5 -40/ +70 � � � � 10 6 100 2 - 8 0,15 - 0,25 264

CFSP414 7,5 -10/ +80 5 -20/ +80 � � � 10 50 4 - 8 0,25 - 0,34 265

chainflex® types chainflex® types

Twistable cables 232

These values are based on concrete applications or tests. These values do not represent the limit of what is technically feasible. chainflex® types mentioned in the catalogue as “resistant to bio oil“ have been tested by DEA following VDMA 24568 with Plantocut 8 S-MB.

Table of contents according to industries Page 550Table of contents according to part number Page 558

12 13

chai

nfle

x®

cab

le

Jack

et

Shi

eld

Tem

per

atur

e,m

ove

d

fro

m/t

o [°

C]

Min

imum

ben

din

gra

diu

s, fi

xed

[fa

ctor

x d

]

Tem

per

atur

e,fix

ed

fro

m/t

o [°

C]

Tors

ion

resi

stan

t

Hal

og

en-f

ree

UV-

resi

stan

t

Oil-

resi

stan

t

Fla

me-

reta

rdan

t

Ap

pro

vals

and

stan

dar

ds

Pri

ce in

dex

Min

imum

ben

din

gra

diu

s, m

oved

[fa

ctor

x d

]

v m

ax.

unsu

pp

ort

ed[m

/s]

v m

ax.

glid

ing

[m

/s]

a m

ax. [

m/s

2 ]

Num

ber

of

core

s

Cro

ss s

ectio

nØ

[mm

2 ]

Pag

e

Special cables – Data cables 254

Special cables – Power cables

Special cables – Bus cables for hanging applications

New*

* New in this catalogue.

Special cables – Control cables for rail vehicles

New*

New*

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:45 Seite 12

Cable type Jacket Page

FireWire Ready-made cable TPE 268

USB Ready-made cable TPE 272

GigE Ready-made cable TPE 276

FOC Ready-made cable PUR 278

FOC Ready-made cable (Robotics) TPE 282

Coax Ready-made cable TPE 284

CFLG.6G Gradient fibre glass cable, ready-made TPE 296

CFLG.12G Gradient fibre glass cable, ready-made TPE 298

CAT5 Ethernet cable, ready-made PVC/PUR/TPE 300

CAT5 Ethernet cable, ready-made, L-/T-angle PVC/PUR/TPE 302

CAT6 Ethernet cable, ready-made TPE 306

Profibus Field bus cable, ready-made PVC/PUR/TPE 308

Direct line/Connecting cable TPE 316

Direct line/Connecting cable TPE 322

Direct line/Connecting cable TPE 324

Direct line/Connecting cable M23 TPE 328

Video-, vision engineering/bus technology (with camera reference list Page 288) 266

Network-/ethernet-/fibre cables (FOC)/fieldbus 294

Initiators CF9 - CF.INI (minimum bending radius 5 x d) 314

Initiators CF10 - CF.INI (minimum bending radius 5 x d) 360º shielded

Initiators CF98 - CF.INI (minimum bending radius 4 x d)

chainflex® cables for actuator/sensor distribution box

Selection table according to manufacturers Jacket Page

Allen Bradley Power-/servo-/brake cable PVC/PUR/TPE 338

B&R Servo-/resolver-/EnDat cables PVC/PUR/TPE 338

Baumüller Servo-/encoder-/pulse encoder-/

resolver cable PVC/PUR/TPE 338

Beckhoff Servo-/encoder-/resolver cables/

EtherCAT PVC/PUR/TPE 341

Berger Lahr Servo-/resolver cables PVC/TPE 341

Control Techniques Power-/servo-/encoder cables PVC/PUR/TPE 341

Danaher Motion Power-/servo-/signal cables PVC/PUR/TPE 343

ELAU Servo-/encoder cables PVC/PUR/TPE 345

Fagor Path measurement cable TPE 346

Fanuc Power-/signal cables PUR/TPE 346

Heidenhain Adapter cable PUR/TPE 347

Jetter Power-/servo-/resolver cables PVC/PUR/TPE 347

Lenze Servo-/encoder-/feedback-/

resolver-/decoder-/fan cable PVC/PUR/TPE 348

LTi DRiVES Servo-/encoder cables PVC/PUR/TPE 348

NUM Power-/servo-/encoder-/

sensor-/fan cable PVC/PUR/TPE 349

Omron Power-/encoder-/control cable PVC/PUR/TPE 350

Rexroth Power-/encoder cables PVC/PUR/TPE 350

SEW Power-/servo-/encoder cables PVC/PUR/TPE 352

Siemens Power-/servo-/signal cables PVC/PUR/TPE 353

Stöber Servo-/encoder cables PVC/PUR/TPE 354

Harnessed cables for Drive Technology 330

chainflex® readycable®chainflex® readycable®

"Allen Bradley" is a registered trademark of Rockwell Automation Inc, Greater Milwaukee / "B&R" is a registered trademark of Bernecker + Rainer Industrie-Elektronik Ges.mbH, Eggelsberg / "Baumüller" is a registered trademark of Baumüller Nürnberg GmbH, Nürnberg / "Beckhoff" is a registered trademark of Herrn Hans Beckhoff,Verl / "Berger Lahr" is a registered trademark of Schneider Electric MotionDeutschland GmbH & Co.KG, Lahr / "Danaher Motion" is a registered trademark of Danaher Motion Technology LLC, Delaware / "ELAU" is a registered trademark of Elektronik-Automations-AG, Marktheiden -feld / "Fagor" is a registered trademark of FAGOR Electronic Components Inc, New York / "Fanuc" is a registered trademark of Fanuc Ltd., Tokyo/Yamanashi / "Heidenhain" is a registered trademark of Dr.Johannes Heidenhain GmbH,Traunreut / "Jetter" is a registered trademark of Jetter AG, Ludwigsburg / "Lenze" is a registered trademark of Lenze GmbH & Co. KG, Extertal / "Omron" is a registered trade-mark of Omron Corp., Kyoto / "Rexroth" is a registered trademark of Bosch Rexroth AG, Lohr/ "SEW" is a registered trademark of SEW-EURODRIVE GmbH & Co KG, Bruchsal / "Siemens" is a registeredtrademark of Siemens AG, München / "Stöber" is a registered trademark of Stöber Antriebstechnik GmbH & Co. KG, Pforzheim

14 15

New*

New*

New*

New*

* New in this catalogue.* New in this catalogue.

New*

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:46 Seite 14

Page Page

Test order – test igus®! 453

SERIE A Signal connector 454

SERIE B Power connector 458

SERIE B Power connector 460

SERIE M17 Signal- and power connector 461

SERIE C Power connector 464

SERIE D Power connector 466

SERIE S Power connector 468

Tools, accessories 470

SUB-D Signal connector 472

Yamaichi Y-CONKIT 476

Glands 478

chainfix strain relief | Parameters | Overview 492

Clamps and stainless steel clamps – for maximum pull forces 494

C-profiles 500

Tiewrap plates – for universal tiewrap, bolted or clip-on 502

Tiewrap plates, with clip-on connection for the C-profile 504

Clips – high pull forces, plug-in 506

Strain relief separators - with integrated teeth 508

Nuggets – for top hat rail and C-profile 510

Blocks – Special strain relief for hoses 511

igus® readychain® Ready-made energy chain systems® 516

Connectors 452

chainfix Strain Relief 487

chainflex® accessory

readychain® 515

Designing with igus®

Cables and Hoses – General rules for cables and hoses in energy chains® 524

Cables and Hoses – Separation in energy chains® 525

Cables and Hoses – Further information on the separation of cables 526

Electrical Round Cables 527

Electrical Round Cables – Information on assembly and strain relief of electrical round cables 528

Pneumatic hoses 529

Data and SchedulesDIN 47100 colour code/Copper wire dimensions according to Anglo-American AWG numbers 530

Calculation of the copper surcharge 530

Load-Carrying Capacity of Cables 531

Electrotechnical data 532

Chemical resistance 538

InformationsThe General Conditions 542

User information, Disclaimer, KTG, Product illustrations 542

Technical notes 542

Approbation and Approvals 544

Configure and order cables online, igus® & eplan 546

More igus® products 548

igus® at www.igus.eu 549

According to industries 550

Table of contents according to part number 558

Contact igus®

Fax – Customer-specific cables for energy chain systems® 554

Fax – System Planning 555

Fax – Harnessing 556

Fax – Order 557

igus® worldwide 564

Give us your oppinion – Catalogue improvement Cover (back)

Definition of the icons used in the catalogue Cover (back)

chainflex® cables classification Cover (ahead)

What does the chainflex® "class"(ification) mean? 20

Technical Data and Schedules/user information/contact 522

chainflex®

16 17

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:46 Seite 16

How to use the catalog: chainflex® Cables

Short descriptionProduct data and brief description of the selectedchainflex® cable.

Product illustrationDescription of the chainflex®

cable design structure anddetailed product illustration.

Delivery programTable with part no., num-ber of cores and conduc-tor nominal cross section, copper index and weight.

ExampleQuicklink www.igus.eu/en/CF340Direct link to this product's online catalog:Free CAD-data, pdf files and more.

Product designationDesignation of the selectedchainflex® cable.

Cable classesClassifcation of chainflex® cablesaccording to requirements,resistance to oil and travel distance

Jacket materialand cable type Cable name

Chapter colourEvery cable type has its owncolour allowing faster catalogbrowsing.

Application areaDescription of typical cable applicatons.

Technical dataDetailed description of the chainflex® cable, practical illustration by means of icons.Including all information, e.g. ontemperature ranges, speeds,tensions, a description of the cable design.

Order example

Approvals/standards

Contact

18 19

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:47 Seite 18

igus® has been supplying cables for permanent movement ine-chains® for more than 20 years now – chainflex® cables,which are quite simply good for one thing:Reliable function.

To achieve this, all chainflex® cables in all e-chain® applicationshave to cope with demanding requirements, e.g. very smallbending radii, high cycle rates, compact design spaces, awide range of chemical influences and dynamic parameters. igus® carries out basic cable qualification tests according toigus® standards at its own Technical Centre and in the testinglaboratory. These chainflex® qualification standards includeseries of tests which then lead to assignment to the respec-tive igus® "class".

1.chainflex® standard qualification"Materials"

Materials that are to be used for the series production of chain-flex® cables must pass a whole series of endurance tests ine-chains® in addition to passing standard cable-specific tests(such as permanent alternate bending tests, ageing, abrasi-on, media resistance, flame resistance if appropriate etc.). These endurance tests, which can last up to 3 years, arealways based on movement tests in and with e-chains®/ e-chain® materials and include:

� Permanent bending tests in e-chains® at room tempe-rature and with gliding and freely suspended travel distances.

� Permanent bending tests in e-chains® at low temperaturesand a travel distance of 8 m (at temperatures as low as -40 °C depending on the material)

� Permanent bending tests in e-chains® in different liquidmedia with a travel distance of approx. 0.5 m.

� Abrasion tests combined with chain materials.

2.chainflex® standard qualification"Design"

These series of tests, which can take between 1-3 years depen-ding on the defined objective (e.g. double strokes), are alwaysbased on movement tests in and with e-chains® and include:

� Permanent bending tests in e-chains® at room temperatureand with gliding and freely suspended travel distances. Theradii are significantly smaller than those later defined in thecatalogue.

� Permanent bending tests in e-chains® with varying tem-perature curves between -40 °C and +60 °C – dependingon design and material – with gliding travel distances andsmaller radii than those later defined in the catalogue.

� Permanent torsion tests in triflex® e-chains® with ±180 °/mwith torsion cables on the torsion test stand, using 1 m triflex® e-chain®.

� Permanent torsion tests in triflex® e-chains® with movementprograms on 6-axis robots.

20 21

What does the chainflex®

"class"(ification) mean?

igus® has recently significantly expanded its testing laboratoryfor energy chains® and cables to 1,030 square metres. Newstandard products and customer-specific energy chains® cannow be tested at more than 70 different test stands.

The chainflex® class is composed of 3 parts:

Requirements Travel distance Resistance to oil1 to 7 1 to 4 1 to 4

Resistance to oil

1: 1: No resistance to oil

2: Oil-resistant (following DIN EN 50363-4-1)

3: Oil-resistant (following DIN EN 50363-10-2)

4: Oil-resistant (following DIN EN 60811-2-1), bio-oil-resistant (following VDMA 24568 with Plantocut 8 S-MB tested by DEA)

Travel distance

1: Freely suspended

2: Freely suspended and gliding up to 50 m

3: Freely suspended and gliding up to 100 m

4: Freely suspended and gliding up to 400 m and more

Requirements

1: Flexible cables

2: Highly flexible cables

3: Chain-suitable cables without special structure (e.g. stranding in layers) for the use in e-chains®.

4: Cables with special structure for permanent movement in e-chains® for medium requirements and radii from 7.5 x d,speed up to 3 m/s

5: Cables for permanent movement in e-chains® for high-load requirements and radii from 6.8 x d, speed up to 10 m/s

6: Cables for permanent movement in e-chains® for highest load requirements and radii from 5 x d, speed up to 10 m/s

7: Cables for permanent movement in e-chains® for highest load requirements and smallest radii, indoor and outdoor, radiifrom 4 x d, speed up to 10 m/s and more

To make the choice easier for you, we have classified all chainflex® cables according to the criteria "requirements, oil-resistanceand travel distance". The higher the number the better the cable.

Example: You are looking for a cable which is suitable for the highest mechanical load. In addition, it should be oil-resistantfollowing DIN EN 50363-10-2. The travel distance should be up to 100 m for freely suspended and gliding applications.

You choose from the classification overview:

Requirements: 6Travel distance: 3Resistance to oil: 3

This results in the cable's class – here "Class 6.3.3", that you can find on each product's page.

In theory the following classes would be possible: lowest "Class 1.1.1", highest "Class 7.4.4"

3.chainflex® standard qualification"Approvals"

These series of tests are based on the standards specifiedby the approval authorities and are carried out according tothese specifications.

4.chainflex® standard qualification "Production optimisation"

Following several years of qualification for the design andmaterials, the production methods are broken down and defined to machine level for qualification in order to keep thepotential production tolerance as tight as possible.Cables are of course also taken systematically and continuallyfrom current production and subjected to a batch test. Atigus®, the term batch test is used to mean the following:

� Recording and examination of the production parametersof the chainflex® cable.

� Execution of permanent bending tests in e-chain® testsystems over short fast travel distances.

On the basis of these series of tests, igus® has introducedthe new selection and cable qualification system "class" tomake it easier for customers to select the cable they requirefrom among almost 1000 moving e-chain® cables.

This "class"(ification) allows a fast and straightforward choiceof cable for the application on hand.

The "class" describes the load to be expected, the traveldistance and the required oil/media resistance.

The higher the class, the more complex the design principlesand materials used. The lower the class, the more favourablypriced are the cables with the same key electric data.

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:47 Seite 20

Stranding in bundles tried and tested expensivelyand efficiently millions of times since 1989

Stranding in bundles eliminates these problems by means of its very

sophisticated, multiply stranded internal structure. Here, the litz wires are

stranded with a special pitch length first and then the resulting cores are

stranded into single core bundles. For large cross sections, this is done

around a strain relief element. The next step is the renewed stranding of

this core bundle around a tension-proof center – a genuine center cord.

(see picture 2)

Due to this multiple stranding of the cores, all cores change the inner radius

and the outer radius of the bent cable several times at identical spacing

distances. Pulling and compressing forces balance one another around the

high-tensile center cord that gives the stranded structure its necessary inner

stability. Accordingly, the stranding remains stable even under maximum

bending stress (see picture 3).

What are EMC problems and shield wirebreakage?

In principle, cable shields must fulfil two tasks:

� Protecting the cables from external interferences

� Shielding any interferences before transmitting them to the outside

Both tasks are equally important because faulty signals can cause

considerable consequential damage in the system itself as well as in any

external systems. Furthermore, this is an especially problematic point due

to the fact that incorrect shielding usually cannot be detected from out-

side, and this is something that makes the trouble-shooting procedure

extremely difficult. How can these kinds of problems arise in the first

place?

Once again, the answer is to be found in the internal structure of the cable

itself: Is the shielding designed for the movements of the cable? Although

it may be very easy to shield a fixed cable, it is much more difficult to

guarantee the permanent shielding of a moving cable.

In the case of so-called "chain-suitable" cables, for example, the stran-

ding bond of an intermediate layer is wrapped up with foils or fleeces.

This stranding bond is supposed to guarantee the separation between

the cores and the shield braid. But something that functions quite well

for the fixed installation of cables is often quite insufficient in the case of

moving cables. This has to do with the fact that the foils and fleeces do

not create a bond between the stranding, shield and jacket and may fall

apart under stress. Consequently, the metallic shield then rubs on the

insulation of the cores – short circuits are then to be expected.

chainflex®...The tricks and ingenious features of...

lasts or your money back!...the chainflex® design and why we feel so confident about this design

Picture 1: Chain-suitablecable stranded

in layers

From the customer's point of view, a flexible energy supply system only

needs to function properly. However, this demand presupposes the perfect

operation of all components, including the cables being used in this

system. And this is exactly where problems came up in the early 1980s.

Due to constantly – and frequently even tremendously – increasing loads

resulting from the application of automation technology, guided cables

often failed although the energy supply system itself was functioning per-

fectly. In extreme cases, failures caused by "corkscrews" and core ruptures

brought the entire production process to a standstill and resulted in high

costs.

In order to find a solution to this unsatisfactory situation for its customers,

igus® decided to take the initiative. As the first company worldwide, igus®

began to develop complete energy chain systems®. chainflex® cables and

energy chains® are now being offered as a delivery from a single source

and with a system guarantee depending on the application in each case.

Based on the increasing know-how gained since 1989 and on the very

sophisticated series of tests that have been conducted since then, design

principles were and are still being created that help prevent machine down-

times in factories throughout the world today.

How can "corkscrews" be prevented?

Here, the term "corkscrew" does not refer to a useful instrument for wine

connoisseurs. Instead, it refers to the permanent deformation of guided,

moved cables caused by excessive stressing – which, in most cases,

results in core rupture almost immediately afterwards. How does this hap-

pen? How can "corkscrews" be prevented? An important factor here – in

addition to a sensible design of the total energy chain system® – is the

construction of the guided cables. Basically speaking, a clear distinction

can be made between cables stranded in bundles and cables stranded

in layers (see picture 4).

Properties of stranding in layers

Stranding in layers is significantly easier to produce and is therefore offered

on the market in so-called "chain-suitable" cables at low cost. But what

appears to be tempting at first glance can quickly turn into an expensive

mistake when a "corkscrew" immobilizes the system being operated with

these cables. How do these problems arise? A look at the cable structure

can be quite helpful (see picture 1).

In the case of stranding in layers, the cable cores are mostly stranded

more or less firmly and relatively long in several layers around a center

and are then provided with a jacket extruded to the form of a tube. In the

case of shielded cables, the cores are wrapped up with fleece or foils.

But what, for example, happens to a similarly structured 12-core cable

during normal operation?

The bending process compresses, in the movement of the core, the inner

radius of the cable and stretches the core in the outer radius. Initially, this

works quite well because the elasticity of the material is still sufficient.

But very soon, material fatigue causes permanent deformations, and then,

due to excursion from the specified paths, the cores make their

"own compressing and stretching zones": The corkscrew is created, then

followed rather quickly by core ruptures most of the time.

Fleece

Extruded, non-tension-proof centre element

Cores strandedin Layers

Highly abrasion-resistant, gusset-filled extrudedjacket

Centerelement forhigh tensilestresses

Centerelement forhigh tensilestresses

Single-wire bundleswith short pitchlengths

Total shield withoptimized braiding angle

Gusset-filledextrudedinner jacket

22

Picture 2: Litz wire and

core structures of a chainflex® cable

Picture 3: igus®

stranding in bundles around

center cord

Dictionary of defectsCore ruptureFailure of electric conductivity due to broken copperwires as a result of subjecting the individual cores tomechanical overload/ tensile load under constant bending stress. In most cases, the causes are incorrect litz wires and/or incorrect stranding pitchdirections and lengths.

Insulation damageShort circuits due to damage to the insulation abovethe conductor. The cause can be material fatigue underconstant bending stress or material abrasion within thestranded structure. Single-wire breakage of the conductor or the shield braid result in perforation ofthe insulation.

CorkscrewAn externally detectable screw-like deformation of theentire cable due to broken copper wires as the resultof subjecting the individual cores to mechanical overload/ tensile load during the bending process. Inmost cases, the causes are unfavorable superstructureproperties (stranding in layers, missing center, loosejackets extruded to the form of a "tube") and subjectingthe cables to high bending stress.

Jacket abrasionThe jacket is rubbed off down to the stranding or downto the total shield. In most cases, the causes are incorrect selection of materials and/or unfavorableextrusion processes resulting in detrimental surfaceproperties so that abrasion is an unavoidable effect.

Jacket swelling/ jacket breakageJacket becomes soft and deformed or breaks until thestranding/shield can be seen. The cause can be theincorrect selection of materials with respect to the oilsor other chemical substances being used.

Shielding losses/ EMC problemsElectromagnetic interferences inside or outside anelectric cable. In most cases, the cause is shield wire

breakage due to mechanical overload with incorrectshield braid angles. Other causes include loose braidsover foils without supporting effects or very open cover-ings.

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:47 Seite 22

But the production of the shield itself is very time-consuming and

cost-intensive and may have been the reason for the use of open braid

shields or even simple wire wrappings. The disadvantages are quite

obvious: Open shields only possess a limited shielding effect in their

moved state – motion and expansion reduce this effect even further. The

type of shield is therefore an important point that is not even mentioned

in some catalogues.

In its up to approx. 70% linearly and approx. 90% optically covered cables,

igus® eliminates these weak points by means of an optimized internal

structure. In virtually all shielded chainflex® cables, a gusset-filled extru-

ded inner jacket over the stranded structure is therefore used. This "second

jacket" fulfils two tasks:

� It holds the stranded structure together and guides the individual

cores as in a channel.

� It serves as a firm, round base for a very tight-fitting shield.

Shield wire breakage – and how this can beprevented

And even during the production of the shield, there are many things thatcan be done correctly – or incorrectly. Here, an important parameter isthe braiding angle.In the case of "chain-suitable" cables, a tensile load of the shield wires inthe outer radius of the cable must usually be taken into account. If anunfavorable braiding angle is to be added, the tensile load increases evenfurther and shield wire breakage is the result. The consequences rangefrom reduced shielding effects right up to short circuits whenever thesharp wire ends penetrate through the fleeces or foils into the cores. Here,a useful tip: If, after the insulation has been stripped off, the shield canbe easily pushed back over the jacket, the shield is then usually unsuitablefor use in moved flexible energy supply systems! This is a problem thatigus® has now solved with its direct approach:

� The shield braiding angle determined in long-term tests efficiently neutralizes the tensile forces and is therefore highly suitable for energy chains®.

� Due to the stable inner jacket, the shield cannot wanderuncontrolled.

� The shield itself has a torsion protection effect on the stranded structure.

Jacket abrasion/ jacket breakage

Whereas defects in the internal structure are hardly detectable on the out-side, jacket problems strike the eye immediately. The jacket is the firstprotection for the complicated internal structure. This is why broken, wornand swollen jackets are a serious quality defect. To prevent this problem,the igus® customer can select among 7 acket materials to adapt his energychain® cables to suit the conditions of the respective environment.

1. Strain-relieving centerClear space is created in the center of a cable accordingto the number of cores and the cross section of eachcable. This center should be filled, as far as possible, witha genuine center cord (and not, as frequently the case,with fillers or dummy cores consisting of waste materials).These measures will then efficiently protect the strandedstructure situated above and prevent the stranding fromwandering into the middle of the cable.

2. Litz wire structureWith respect to the selection of litz wires, the maximumflexibility has proved to be the best solution. Although veryflexible conductors can be made using very thin individualwires, these conductors tend toward extreme formationof kinks. Long-term series of tests provided the result ofa shielded combination of single-wire diameter, pitch lengthand pitch direction as the best bending-resistant solution.

3. Core insulationThe insulation materials must be made so that they do notstick to one another within the cable. Furthermore, theinsulation is also required to support the stranded indivi-dual wires of the conductor. Accordingly, only the highest-quality, high-pressure-extruded PVC or TPE materials thathave proved their tested reliability in millions of core kilo-meters are then used in energy chain® applications.

4. StrandingThe stranded structure must be stranded around a stable,tension-proof center with an optimized short pitch length.

However, due to the insulating materials being used, thisstranded structure should still be defined in mobile formwithin the stranding. Starting from a quantity of 12 cores,however, the method of stranding in bundles should beapplied.

5. Inner jacketA gusset-filled extruded inner jacket must be used insteadof inexpensive fleeces, fillers or accessory fillers. This mea-sure ensures that the stranded structure is efficiently gui-ded in longitudinal direction. Moreover, the stranded struc-ture cannot fall apart or wander off.

6. ShieldingThe total shield should be made tight using an optimizedshield braiding angle over an extruded inner jacket. Looseopen braids or wrapped stranding reduce the EMC pro-tection considerably and can fail very quickly due to shieldwire breakage. A tight total braid shield also has a torsionprotection effect on the stranded structure.

7. Outer jacketThe material-optimized outer jacket can fulfil many diffe-rent requirements: From UV-resistant to low-temperatu-re-flexible, and from oil-resistant to cost-optimized. Butthese outer jackets must have one thing in common: Ajacket material must be highly abrasion-resistant but notbe allowed to stick to anything. It must be flexible but alsoprovide a supporting function. In any case, the jacketshould also be extruded under pressure (gusset-filled).

7 basic rules for a good cable

2524

chainflex®...The tricks and ingenious features of...

lasts or your money back!...the chainflex® design and why we feel so confident about this design

Jacket breakage at (36x0.142)after only 900.000 to-and-frocycles with a bending factorof 7.8 x d

Gusset-filled extruded jacket

Here, not only the material is an important factor but also the pro-

duction process. In the case of the so-called "chain-suitable" cables,

the jackets are usually produced extruded to the form of a tube

and therefore do not provide the stranded structure with the neces-

sary support for constant bending processes. The stranded struc-

ture can fall apart.

Therefore, igus® is the first manufacturer of energy chain systems®

to offer the so-called the "gusset-filled extruded" jacket.

Here, the jacket material is injected between the core stranding

powdered with talc and ensures that the stranded structure does

not open up and also makes sure that the cores are guided as in

a channel. The special characteristic of this type of production is

that the intermediate spaces, which are created between the cores

during the stranding process, are completely filled with jacket mate-

rial by the high extrusion pressure. As a result, the jacket material

creates a channel-like guide which allows the cores to carry out a

defined longitudinal movement. The jacket also provides a sup-

porting function for the stranding.

The quality bundles of igus® chainflex® cables� Strain-relieving center

� Stranding in bundles

� Gusset-filled extruded inner jacket in shielded cables

� Enclosed shield braid

� Optimized shield braiding angle

� Gusset-filled extruded jacket

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:47 Seite 24

Sectional views through the igus® cable typesDetailed structure of igus® control, data, servo and motor cables

chainflex® control cable,unshielded chainflex® FOC

gradient fibre cable

chainflex®

control cable, shieldedchainflex®

servo cable, shielded

chainflex® data/sensor cable, shielded

chainflex®

power cable, shielded

Individual bundles with optimized pitchlength and pitch direction

Center element for high tensile stresses

Single-wire diameter optimized for energy chains®

Highly abrasion-resistant, gusset-filledextruded jacket

Supporting braid made of glass-yarn-stranded GRP rods

Gel-filled fibre sheath

FOC fibres

Highly abrasion-resistant TPE jacket

Integrated torsion protection

Total shield with optimized braidingangle (covering approx. 70% linear,

approx. 90% optical)

Optimized single-wire diameter

Center element for high tensile stresses

Gusset-filled extruded inner jacket

Pair braid shield over optimized stranded core pair

Stranding with optimized pitch length and pitch direction

Highly abrasion-resistant pressure extruded jacket

Total shield with optimized braiding angle (covering approx. 70% linear, approx. 90% optical)

Gusset-filled extruded inner jacket supports stranding

Center element for high tensile stresses

Tension-proof center element in individual bundles

Pressure extruded jacket

Total shield with optimized braidingangle (covering approx. 70% linear,approx. 90% optical)

Stranded elements with optimized pitch length and pitch direction

Gusset-filled extruded inner jacketsupports stranding

Center element for high tensile stresses

Pair braid shield

Pressure extruded jacket

Total shield with optimized braidingangle (covering approx. 70% linear,

approx. 90% optical)

Gusset-filled extruded inner jacket

Center element for high tensilestresses

Optimized single-wire diameter

Stranding with optimized pitchlength and pitch direction

Highly abrasion-resistantpressure extruded jacket 2726

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:48 Seite 26

chainflex® are thespecial cables for energychain systems® – tested,tested, tested andtested.

Partial view of igus® experimental laboratory – testing, testing, testing of chainflex® cables

Testing of a chainflex®

CF5: 25 x 1 in "short"and "long" distancesof travel comparedwith other cables. CF5with 4,3 x d bendingradius

number of double strokes

igus® tested

Testing of a chainflex®

CF5: 7 x 1 in "short"and "long" distancesof travel comparedwith other cables. CF5with 4,3 x d bendingradius

* Cables OK, test abandoned.

number of double strokes

"Short Travel"

"Long Travel"

* Cables OK, test abandoned.

"Short Travel"

"Long Travel"

As a manufacturer of energy chains® and special energy

chain® cables, igus® uses the possibility of testing many

different types of chains and cables on a practice-oriented

basis. At the company-own technical training center in

Cologne, numerous series of tests are carried out on a

parallel basis under the most difficult conditions. At the

present time, there are more than 35 test setups with

their test results being summarized in databases. This

extensive, current data pool provides precise, reliable

information on the actual service life and is also the basis

of new product developments at the company. The test

data for energy chains® and cables, but also for ready-

made systems, are, however, described in such detailed

form that igus® confirms a functional guarantee for its

energy chain systems®.

2928

More sensitive applications with high clock cycle numbers,

velocities and accelerations as well as sophisticated envi-

ronmental conditions call for, especially in the field of energy

management, tried-and-tested systems that are functional-

ly efficient for a long period of time. EMC safety and the ful-

fillment of standards and directives such as UL, CSA, VDE,

Interbus and Profibus are a necessary requirement today.

After all, your automation system is supposed to function

correctly non-stop and worldwide even on a low-cost basis.

That’s the igus® mission.

Quick availability throughout the world is a significant purchase

criterion. Advantages of our cables: successful tests,

presence in more than 40 countries around the world and

deliverability ex warehouse. This saves time, money, stora-

ge capacity and applies to each one of our 950 cable types

which you can order without any minimum quantity purcha-

ses or surcharges. Which further advantages can be included

is something that depends on your specific conditions of use.

No contradiction:Good cables cost less.

Purpose of every chainflex®

cable

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:48 Seite 28

Example 1: tested,tested, tested!Servo cable structure

Comparison between the igus®

solution with the gusset-filledinternal jacket and the fleece ver-sion with fillers

Here, the servo cables are highly flexible motor connectioncables with a complete copper shield and an integrated,shielded pair of control cores. This cable type was selecteddue to the fact that here the problematic case of an out-of-round braid form due to the different core cross sectionsis a significant factor and that the various bending behaviorsof the production methods are therefore emphasized.

n Sample A: CF27.100.10.02.01.D (igus® GmbH)

(4x10 mm2) + (2x1,0 mm2)

n Sample B: experimental

(4x10 mm2) + (2x1,0 mm2)

Both cables are provided with identical nominal cross sectionsand insulation materials. Cable A is equipped with an internaljacket and cable B with a fleece taping and fillers.

The experimental production (sample B) already shows theformation of a corkscrew after 145.000 double strokes. Inthe case of a cable, the so-called corkscrew refers to awave-shaped deformation like the one that can be seenin the following picture on sample B.

Whereas, in the case of cable A, the internal jacket fills upthe gussets and a round braid structure is created as aresult, cable B requires fillers in the gussets. Like the core,the fillers also consist of filbrated polyethylene. They areeasy to compress and are therefore hardly capable of takingover any supporting effects. Whereas the internal jacket,which is made of TPE, and the cable A center, which consists of cordage, hold the cores in a defined position,the cores of cable B are able to move about uncontrolled.During the bending process, a core has detached itselffrom the composite braid structure and has been shiftedin the inner bending radius with respect to the center andon the outer bending radius with respect to the jacket. Thisresults in corkscrew-type deformations that repeat them-selves periodically with the pitch length.

AssessmentDespite the extremely low bending factor of 4,76, no signs of wear can be detected in sample A(CF27.100.10.02.01.D) even after 5 million double strokes.Sample B, on the other hand, with its fillers and fleecetaping succumbs to a corkscrew formation already after145.000 double strokes. Accordingly, the result thereforejustifies the extra expenditure of the cable with thegusset-filled internal jacket.

Sample A with internal jacketigus® chainflex®

CF27.100.10.02.01.D

Sample B with fleece and fillerexperimental production4x10+(2x1,0) C

The purpose of the test is to deter-mine the advantages of the moreexpensive internal jacket in shieldedservo cables versus the less expen-sive fleece taping with fillers.In the case of flexible shieldedcables, the shield is usually separatedfrom the composite core structure.On the one hand, this is done inorder to achieve a rounder braidform and, on the other hand, thefriction of the core insulation sheathagainst the braided shield structureis prevented due to the separationof the cores and shield. This can beachieved with an internal jacket ora fleece taping which is wrappedaround the composite core structure.The internal jacket is more sophi-sticated and is therefore moreexpensive to produce. Following thetwisting process, the composite corestructure must run through theextruder in which the internal jacketis then put on. In contrast to thismethod, the fleece tape can be puton between the twisting point andthe reeling-up device during the twi-sting process and therefore doesnot require an own work operation.

Sample A: CF27.100.10.02.01.D

Sample B

5.000.000

4.000.000

3.000.000

2.000.000

1.000.000

750.000

500.000

250.000

100.000

50.000

0

145.000

5.000.000

Num

ber

of

do

uble

str

oke

s

Sample A

Sample B: experimental production

3130

�������

��������

������

�������

��������

������

�������

��������

������

�������

��������

������

Conductor

core insulation sheath made of TPE

fleece

polyester foil

aluminum-coated polyester foil

shield

center

filler

Inner jacket made of TPE-E

external jacket made of TPE-E

Product informationCF27.D

Page 198

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:48 Seite 30

Example 2: tested, tested, tested! TechnicalData Properties CAT5

High transmission rates of up to 100 Mbit/s place high demandson the cable structure and its materials. The use of the cablesin energy chains® subjects these materials to additional stressand results in long-lasting alterations of the electrical properties.A CF 14.02.04.02.CAT5 cable was selected as a cable to be ins-pected for high transmission rates. Even when subjected to anapplication of stress with the minimum bending radius, the cablemust also be able to meet the electrical requirements of the IEC61156-6 standard. In the case of the CF14.02.04.02.CAT5 cable,four pairs of cores are stranded with one another, with each corepair possessing a nominal cross section of 0,25 mm2. The con-ductor consists of bare copper wires and is surrounded by aninsulation sheath consisting of foamed PE.

The following items were inspected:

n Characteristic wave impedance of single pairs

n Single-pair attenuation

n Return loss of single pairs

n Near-end crosstalk attenuation of

single pairs versus one another

The test is to be carried out in order to determine whether thelimit values of the IEC standard are complied with by the cableafter being subjected to bending stress.

Alteration of the electrical trans-mission properties of a CAT5 cablewhen subjected to an application ofstress with the minimum bendingradius

Attenuation

The maximum values of the individual attenuation for each pair ofcores are specified for the corresponding nominal characteristicwave impedance in dB/100m in the DIN IEC 61156-6 standard.Accordingly, the cables are subdivided into several categories accor-ding to the transmission frequency planned to be used. For thecable being inspected, transmission frequencies of up to 100 MHzare planned to be used, which corresponds to the category 5e.

Test result

The attenuation, as a measure of the reduction of the transmittedelectrical energy of a signal on the cable, remains, even after morethan 1,5 million double strokes, below the specified limit value whilebeing subjected to the application of stress of the minimum ben-ding radius. The characteristic electrical transmission quantities such as cha-racteristic wave impedance, return loss and near-end crosstalk arefulfilled so that, despite applications of high mechanical stress, theelectrical values of the IEC standard are complied with for a cableof the category 5.

MHz

dB/100 m

3332

max. norm value

new condition

according to 332.269 double strokes

according to 686.767 double strokes

according to 1.561.281 double strokes

0 10 20 30 40 50 60 70 80 90 100

0

-5

-10

-15

-20

-25

-30

-35

Product informationCF14 CAT5 Page 148

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:48 Seite 32

Example 3: tested,tested, tested! “Millionsof double strokes” in an energy chain

For users, it is hard to get an overview of the cable market.Competition between cable suppliers is intensifying and manu-facturers are outshining one another in their promises to “guarantee service life for cables used in energy chains”.Catalogues claim ten million - or even as many as 50 million- double strokes when it comes to the service life of cablesused in applications involving movement.

On taking a closer look at figures claimed, one must ask howtesting was done, or how realistic tests carried out actuallywere (for example length of travel, test radii, etc.) in order tobe able to provide such a guarantee. Even information stating that cables are tested in accordancewith VDE (Association of German electrical engineers) 0472,Part 603, test method H, is not helpful when it comes to deter-mining the service life of a cable in energy chains, since theroller testing stand cannot provide any conclusive results andthere is no VDE test for special cables in energy chains.

Picture: Sliding application as the basis of the test structure

Structure and materialsThe main reason for the major differences in service life is thediffering structural parameters of test item “A“ and test item“B“ (CFBUS.001), as well as the different materials used forproducing the cables. The conductor insulation of the buscomprised of a foam material for all the test items. The electrical assets of this material ensured better transmissionproperties were achieved. A disadvantage of this material,however, was its weakness under reverse stresses. The forces which affect the bus pair should be absorbed by theelement sheathing in order to alleviate the mechanical stressof the conductor insulation.

Highly-elastic element sheathingFor this reason, test item “B“ (igus®) was provided with amechanically superior, extruded TPE inner, or element, gap-filling sheathing, in order to protect the bus pair against mecha-nical influences during the bending procedure. The elementsheathing must be highly elastic. A mechanically inferior ele-ment sheathing made of inexpensive filling material only ser-ves to make the bus pair round, just like frequently used fil-lers or banding. It is not able to protect the buses from thehigh degree of mechanical stress present in the chain.Tensile and compression forces which occur mainly influen-ce those parts of the cable core in which there is a break inthe element sheathing.

The sheathing of test item ”B“ (CFBUS.001) is on the onehand characterized by a mechanically superior, gusset-filledTPE element jacket, which mechanically relieves the bus pair,fixes the cores in a defined position and bends. The sheathingof test item ”B“ (CFBUS.001) is on the one hand characterizedby a mechanically superior, gusset-filled TPE element jacket,

Differences in service lifeAt the beginning of 2002, a test to determine the service lifeof profibus cables in a real application was commissioned inigus’ test laboratory. The aim was to examine any differen-ces in the service life of igus’ CFBUS.001 chainflex® cableand another market leading profibus cable. The parametersrequired for the test were selected on the basis of data con-tained in the competitor’s catalogue:

Test parameters according to catalogue data of the competition

A gliding application was chosen as a suitable test structuresince profibus cable systems are usually used here becauseof their data integrity, particularly over long lengths of traveland long transmission distances.

In order to be able to carry out non-destructive testing andhence achieve a large number of bending cycles in a shortperiod of time, a genuine profibus transmission path was erected. In a PC at the fixed end of the test chain there wasa profibus master insert card. A connection to a profibus slavewas located on the moving end. This enabled the transmissionrate to be determined with the help of a diagnosis program.Any data packets which might have been transmitted incorrectly could be indicated. The highest-possible trans-mission rate of 12 megabits/s was set.

The fundamental test, which commenced at the beginningof 2002 and is still in progress today, showed that only a relatively low number of cycles (420.000) resulted in the totalfailure of test item “A“, which, according to the competitor’scatalogue, should have functioned safely for at least 4.0 million cycles. Thus the real lifetime reaches only about 10%of the stated catalogue value.

On the other hand test item “B“, the CFBUS.001, is still under-going testing without any faulty data transmissions. So far, it has accomplished more than 14.0 million cycles.

Catalogue details

Cross section

Guaranteed lifetime

Bending radius

DiameterCatalogue details

Test item “A” Twin-core

profibus cable

(2 x AWG24)C

Min. 4,0 Mio. Cycles

> = 60 mm

8,0 mm

Issue 2002

Test item “B”igus® chainflex®

CFBUS.001

(2 x 0,25 mm2)C

To be determined ina test

85 mm

8,5 mm

Issue 2002

which mechanically relieves the bus pair, fixes the cores in adefined position and bends. The extremely short pitch of thecore strands and special cable also ensure that no great tensileor compression force has an effect on a long length of core.

UL and CSA approvalchainflex® CFBUS cables are now also available for all stan-dard field bus systems, complete with UL and CSA approvaland DESINA compliance. The highly abrasion-resistant, flame-retardant TPE outer jacket is extruded onto the fully braidedshield with an adjusted twisted angle in order to provide thecable with additional stability.

The bus elements braided with a particularly short strand pitchare protected by means of a gap-filling, extruded TPE innerjacket. The bus parameters required are fulfilled by means ofa choice of coordinated insulating materials and productionprocedures.

As with all chainflex® cables, the new standard field bus cablesof the CFBUS series are now available ex stock, without anycutting costs or extra charges for small quantities.

Profibus cables in permanently-moving industrial use

3534

Test parameters

Distance of travel:

Speed, approx.:

Acceleration, approx.:

Radius, approx.:

S = 5,0 m

V = 3,5 m/s

a = 7,5 m/s2

55 mm

Fig. 3: A mechanically low-quality element jacket can’t protect the bus pair against the high mechanical loads inside the energy chain®.

Number of double strokes

Test item “A” CFBUS.001,Test item “B”

Position of the brokenelement jacket

Position of the brokencore insulation

Product informationCFBUS Page 138

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:49 Seite 34

Example 4: tested, tested, tested!CF98 with < 4xd!

3736

Test 1:Inspection of four different cable designs

Four different cable constuctions has been analyzed:Test item A – conductor with special conductor alloyTest item B – conductor same as test item A, but in copperTest item C – conductor in braided structureTest item D – conductor in stranded construction

This long-term inspection, which was carried out over a period of 2 years, provided the following results:

For users of very small energy supply chains with mostlyvery narrow bending radiuses, the question for a suitablecable for very high stroke numbers has come up frequentlyin the past.

At bending radiuses of less than 5xd, copper quickly rea-ches its physical limits, which necessitated the search forsuitable substitute conductor materials or for fundamen-tally different conductor superstructures.

Many series of tests with a variety of conductor super-structures and materials were performed in order to findout how cables must be manufactured in order to be ableto endure several millions of bending operations in e-chains®, even at bending radiuses of less than 4xd.

Test set-up:Horizontal, short distance of travel

Test 2:Two different cable designs were tested, whereby different corenumbers and cross-sections were selected in comparison withtest 1:Test item A – conductor with special conductor alloyTest item B – conductor in copper

In this case, test item B was manufactured completely iden-tical to test item A except for the conductor material. The test showed that not a single case of wire breakage couldbe detected for test item A even after 28 million double stro-kes. Test item B, however, only achieved approx. 1,4 milliondouble strokes before complete destruction of the conductorwas determined. This test also demonstrates that the alloyconcept clearly surpasses the life of the copper conductor bymore than 19 times and achieves these extraordinary resultsin the mechanically critical area of very small cross-sections!

Conductivity of alloysHowever, the outstanding mechanical properties of thisalloy have to do with a reduced conductivity versus copper,which can be compensated by means of slightly increasedcross-sections. This means that the cross-sections mentionedin the catalog meet the electrically defined cross-sectionsdefined using the conductivity value. The conductor diameterof the alloyed conductor increases slightly compared to theconductor diameter of a copper conductor.

This compromise results in a 10% greater external diameterfor the CF98 series versus a comparable CF9 type, alt-hough the service life differences to be expected betweenthe CF98 versus the CF9 speak for themselves and increaseby a multiple factor in comparison with other so-calledchain-suitable cables.

As in the case of the CF9 series, further characteristics ofthe chainflex® CF98 include the highly abrasion-resistant,gusset-filled extruded TPE outer jacket, the oil resistanceand the UV resistance as well as the absence of any PVCand halogen compounds. Especially in areas of applicati-on that only possess minimum construction space but alsodemand a large number of strokes, the igus® cable offersan increased degree of operational safety and efficiency.Areas of application are available in the semiconductor andcomponent parts industry, in the automation sector as wellas in the automotive and bank sector. New possibilities ofapplication can also be found in automatic doors for motorvehicles and trains as well as in automatic food and self-service machines and in the packaging industry.

Test parameters

Distance of travel:

Speed, approx.:

Acceleration, approx.:

Radius, approx.:

S = 0,8 m

V = 1,5 m/s

a = 0,5 m/s2

18 mm

Test item A

Test item BTest item CTest item D

Number ofdouble strokes

47.434.277

450.000

638.000

2.350.000

Cross section

7x0,20

7x0,20

7x0,25

7x0,25

d [mm]

5,8

5,6

7,3

7,3

Testradius

3,1xd = 18

3,2xd = 18

2,5xd = 18

2,5xd = 18

Test item ATest item B

Number ofdouble strokes

28.267.000

1.450.000

Cross section

2x0,14

2x0,14

d [mm]

3,9

2,9

Testradius

4,6xd = 18

6,2xd = 18

Number of double strokes

Bend

ing

radi

us =

4 x

d

Test item A3,1xd

Testradius Test item B3,2xd

Test item A4,6xd

Testradius Test item B6,2xd

Test item C2,5xd

Test item D2,5xd

Number of double strokes

Product informationCF98 Page 106

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:49 Seite 36

Example 5: tested!Dispersion and attenuationPlastic fibre-optic cables in energy chains®

Plastic fibre-optic cables have been introduced for datatransmission in industrial applications due to their excellentinterference-proof properties against electro-magnetic fieldsand further advantages such as the possibility of reducingdimensions and weights. The application as flexible linklines particularly in energy supply chains places highdemands on plastic fibre-optic cables. The most important characteristic values of a fibre-opticcable are dispersion and attenuation. Dispersion is the termused to describe the scattering of the travel time of the signalin the fibre-optic cable. In plastic fibre-optic cables this isessentially caused by the mode dispersion, which arisesfrom the different travel times of individual light beams.Dispersion determines important transmission propertiessuch as bandwidth, cut-off frequency or maximum bit rate.Significant changes in dispersion could not be ascertainedin any of the investigations carried out.The industrial application of igus® chainflex®-cabes with plas -tic fibre-optic cables in supply chains for example is there-fore unproblematic with regard to changes in dispersion.The second important characteristic property, attenuation,determines the maximum possible length of a transmissi-on path.The attenuation of a plastic fibre, like that of the glass fibre,is also strongly dependent on the wavelength of the lightused. For this reason all the investigations were carried outwith a wavelength of 660 nm.Depending on the output of the transmitter and the sensi-tivity of the receiver the operator has a certain "attenuationbudget" available for the complete transmission path including all junction and transition regions. This attenuati-on budget (typical value approx. 20dB) must not be excee-ded if a secure transmission of the data is to be guaran-teed.For this reason it is of great interest to the user to knowwhether and to what extent increases in attenuation are tobe expected for his particular application so that these canbe taken into account in the compilation of his own attenua-tion budget.In addition to continuous bending stress, which is typicalfor operation in an energy supply, further mechanical stres-ses that can occur during installation or operation must betaken into account. Thus, for example, relatively large tensileforces can occur when integrating the line into an energysupply. The fixing of the cables at the ends of the energychain using cable clamps leads to permanent transverseloads. The test of the behaviour under transverse load is carriedout following DIN VDE 0472, Part 223. Since the cableclamps only exercise pressure in an area covering a fewcentimetres, increases in attenuation are relatively low.Attenuation under tensile load depends to a great extentof course on the composition of the line. Cabes with inte-grated copper conductors or strain relief elements do notreveal a noticeable increase in attenuation until very muchgreater tensile forces are applied than is the case with purefibre-optic cables.

Figure 1 represents test results for a chainflex®-cable with6 fibre-optic cables. The length of the test sample is 1mand the maximum tensile load 250 N.

The tensile forces required to integrate fibre-optic cablesin energy chains® are usually much lower than 250 N. Theincrease in attenuation was 0,17 dB at maximum tensileforce and disappeared completely after the tensile load wasreleased. Thus no effect on attenuation should be expected.In the case of plastic fibre-optic cables that are bent veryoften, as is the case in applications with energy chains®,then further influencing factors such as material fatigue,dulling of the materials, micro-cracks right through to com-plete fibre fracture must be feared, and their influence onattenuation can only be investigated in extensive practicaltests such as those carried out by igus®.

Figure 2: Course of the increase in attenuation as a func-tion of the number of cycles.

The excellent test results, shown in part here, of the chainflex®

-cabes must not be taken for granted, as investigations offibre-optic cables from other manufacturers showed, someof which even failed with complete breaks in the fibres.The investigations revealed that chainflex® fibre-optic cablesare not influenced in their function by mechanical loadssuch as tensile, transverse or bending stresses in energychains®. Therefore they are perfectly suitable for use in thesometimes rough industrial environments for the interferen-ce-proof transfer of information between drive and controlelements of machines.

Bibliography: [1] Plastic fibre-optic cables for flexible Energysupply systems: Bernfried Späth, Frank Blase

3938

Course of the increase in attenuation as a function of the tensile force

Force F in N

A in

dB

A in

dB

Number of cycle's n x 100.000

Increase in attenuation as a function of the number n of travel movements

Product information FOC Page 278

EU-CF-INHALT 2012-06_EU-CF-INHALT 2012-06 21.05.12 00:49 Seite 38

40

Example 7: tested!EMC tests

The subject of "electromagnetic compatibility (EMC)" is becoming increasingly important. For one thing, this is dueto a increase in the electromagnetic interference fields in thelong-distance range caused in particular by modern telecommunications and communication technology as wellas in the local range caused by energy technology.

The "electromagnetic compatibility" of chainflex® cables

On the other hand, the requirements for data transmissionare also increasing. The signals are becoming more suscep-tible to interference and the electromagnetic environmentalinfluencing factors more diverse. This can be especially problematic for the coupling between cables which, as is frequently the case in energy-conducting chains, are conducted on a parallel basis over a certain distance. A heavy-current cable with interference acts as a producer of an electromagnetic interference field which, in turn, acts uponanother cable, normally a signal cable, and then causes cable-conducted interference there.