Ceramic Whistles!. Paul Linhares Ceramics - Another word for clay.

CERAMICS - hti.edu.eg · Ceramics used for engineering applications, can be divided into two...

Transcript of CERAMICS - hti.edu.eg · Ceramics used for engineering applications, can be divided into two...

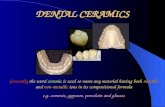

CERAMICS

What are Ceramic Materials?

Inorganic, nonmetallic materials that consist of metallic and nonmetallic elements bonded together primarily by ionic and/ or covalent bonds

Its chemical compositions vary considerably, from simple compounds to mixtures of many complex phases bonded together.

Ceramics used for engineering applications, can be divided into two groups: 1) Traditional ceramic materials

2) Advanced ceramic materials

Typically hard and brittle with low toughness and ductility

Usually good electrical and thermal insulators

Normally have relatively high melting temperatures and high chemical stability in many hostile environments

Ceramic Crystal Structure

Broader range on chemical composition than metals with more complicated structures

contains at least 2 and often 3 or more atoms

usually compounds between metallic ions (e.g. Fe, NI, Al) -called cations - and non-metallic ions (e.g. O, N, Cl) -called anions

Bonding will usually have some covalentcharacter but is usually mostly ionic

Example Ceramic Crystal Structure

*Classification of Ceramics based on APPLICATION

Traditional Ceramics

Made from three basic components: clay, silica (flint), and feldspar.

o The clay in traditional ceramics provides workability of the material before firing hardens it and constitutes the major body material.

o The silica has a high melting temperature and is the refractory component of traditional ceramics.

oPotash feldspar, has a low melting temperature and makes a glass when the ceramic mix is fired. It bonds the refractory components together.

A type of ceramic used in traditional applications such as construction, earthenware, and glassware.

Whitewares

Made from components of clay, silica, and feldspar for which the composition is controlled.

Example:◦ Electrical porcelain

◦ Dinner china

◦ Sanitary ware

Structural Clay Products

Made of natural clay, which contains all three basic components.

Example:◦ Building brick

◦ Sewer pipe

◦ Drain tile

◦ Roofing tile

◦ Floor tile

Brick and Tile

structural clay products, manufactured as standard units, used in building construction

is a small building unit in the form of a rectangular block, formed from clay or shale or mixtures and burned (fired) in a kiln, or oven, to produce strength, hardness, and heat resistance

Abrasives

is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away

a material often means polishing it to gain a smooth, reflective surface which can also involve roughening as in satin, matte or beaded finishes

Abrasives

Refractories

is one that retains its strength at high temperature

Example:okiln linings

ogas fire radiants

osteel

oglass making crucibles

RefractoriesKILN LININGS

Cements

is a binder, a substance that sets and hardens independently, and can bind other materials together

used in construction can be characterized as being either hydraulic or non-hydraulic

The most important uses of cement are as an ingredient in the production of mortar in masonry, and of concrete, a combination of cement and an aggregate to form a strong building material

Advanced Ceramics

Advanced ceramics are ideally suited for industrialapplications that provide a physical interface betweendifferent components due to their ability to withstandhigh temperatures, vibration and mechanical shock.

A type of ceramic exhibiting a high degree of industrialefficiency.

A type of ceramic used in specialized, recentlydeveloped applications.

Advanced ceramics often have simple chemicalcompositions, but they are difficult to manufacture.

Electroceramics

is a class of ceramic materials used primarily for their electrical properties.

Further classified to:

Dielectric ceramics

Fast ion conductor ceramics

Piezoelectric and ferroelectric ceramics

Dielectric Ceramics

are capable of storing large amounts ofelectrical charge in relatively small volumes.

Is an electrical insulator that can be polarizedby an applied electric field.

Dielectric materials can be solids, liquids, orgases.

Solid dielectrics are perhaps the mostcommonly used dielectrics in electricalengineering, and many solids are very goodinsulators.

sulfur hexafluoride (SF6)

Solid Dielectric Liquid Dielectric Gas Dielectric

are solids in which ions are highly mobile. These materials are important in the area of solid-state ionics, and are also known as solid electrolytesand superionic conductors.

These materials are useful in batteries and various sensors. Fast ion conductors are used primarily in solid oxide fuel cells.

Fast Ion Conductor Ceramics

Piezoelectric Ceramics

◦ Piezoelectric ceramic materials are categorizedas functional ceramics.

◦ In sensors they make it possible to convertforces, pressures and accelerations intoelectrical signals, and in sonic and ultrasonictransducers and actuators they convert electricvoltages into vibrations or deformations.

◦ Piezo-ceramics have a wide range of uses.Piezo-ceramics are used in the automotiveindustry in a number of applications such as inknock and oil level sensors or as actuators forprecise control of injection processes inengines.

◦ In medical technology piezo-ceramiccomponents can be found in lithotripters,devices for plaque removal and in inhalers.Common applications in mechanical engineeringinclude ultrasonic cleaning, ultrasonic weldingand active vibration damping.

Magnetic Ceramics

Magnetic ceramics are made offerrites, which are crystalline mineralscomposed of iron oxide in combinationwith some other metal. They are giventhe general chemical formulaM(FexOy), M representing othermetallic elements than iron. The mostfamiliar ferrite is magnetite, a naturallyoccurring ferrous ferrite (Fe[Fe2O4], orFe3O4) commonly known as lodestone.The magnetic properties of magnetitehave been exploited in compassessince ancient times.

Magnetic bracelet

Ceramic Magnets

Magnetic Ceramics

Soft Ferriteso Ferrites that are used

in transformer or electromagnetic cores contain nickel, zinc,and/or manganese compounds. They have a low coercivityand are called soft ferrites. The low coercivity means thematerial's magnetization can easily reverse direction withoutdissipating much energy (hysteresis losses), while thematerial's high resistivity prevents eddy currents in the core,another source of energy loss. Because of their comparativelylow losses at high frequencies, they are extensively used inthe cores of RF transformers and inductors in applicationssuch as switched-mode power supplies.

Magnetic Ceramics

Hard Ferriteso In contrast, permanent ferrite magnets are made of hard ferrites,

which have a high coercivity and high remanence aftermagnetization. Iron oxide and barium or strontium carbonate areused in manufacturing of hard ferrite magnets. The high coercivitymeans the materials are very resistant to becoming demagnetized, anessential characteristic for a permanent magnet. They alsoconduct magnetic flux well and have a high magnetic permeability.This enables these so-called ceramic magnets to storestronger magnetic fields than iron itself. They are cheap, and arewidely used in household products such as refrigerator magnets.

Optical Ceramics are polycrystalline materials produced through controlled

crystallization of base glass.

Glass-ceramic materials share many properties withboth glasses and ceramics.

Glass-ceramics have an amorphous phase and one ormore crystalline phases and are produced by a so-called"controlled crystallization" in contrast to a spontaneouscrystallization, which is usually not wanted in glassmanufacturing.

Glass-ceramics have the fabrication advantage of glass aswell as special properties of ceramics.

Glass ceramics has a variety of properties such as, highstrength, toughness, translucency or opacity, opalescence,low or even negative thermal expansion, high temperaturestability.

Optical Ceramics

Watch Glasses

High-pressure sodium-vapourlamp bulb

Optical Glass Lenses

Advance Structural Ceramics

ceramic materials that demonstrate enhancedmechanical properties under demanding conditions.Because they serve as structural members, oftenbeing subjected to mechanical loading, they are giventhe name structural ceramics. Ordinarily, forstructural applications ceramics tend to be expensivereplacements for other materials, such as metals,polymers, and composites.

Advance Structural Ceramics

Classified to:

o Nuclear Ceramics

o Bioceramics

o Tribological Ceramics

o Automotive Ceramics

Nuclear Ceramics

nuclear ceramics, ceramic materials employed in the generation of nuclear power and in the disposal of radioactive nuclear wastes.

In their nuclear-related functions, ceramics are of major importance. Since the beginning of nuclear power generation, oxide ceramics, based on the fissionable metals uranium and plutonium, have been made into highly reliable fuel pellets for both water-cooled and liquid-metal-cooled reactors. Ceramics also can be employed to immobilize and store nuclear wastes. Although vitrification (glass formation) is a favoured approach for waste disposal, wastes can be processed with other ceramics into a synthetic rock, or synroc, or they can be mixed with cement powder to make hardened cements. All these nuclear applications are extremely demanding. In addition to severe thermal and chemical driving forces, nuclear ceramics are continuously subjected to high radiation doses.

Nuclear Ceramics

The image above shows a vintification process or encapsulatingnuclear waste in glass is a possible method of containingnuclear wastes

Bioceramics

ceramic products or components employed in medical anddental applications, mainly as implants and replacements.

Bioceramics range in biocompatibility from the ceramicoxides, which are inert in the body, to the other extreme ofresorbable materials, which are eventually replaced by thematerials which they were used to repair.

Bioceramic materials are commonly subdivided by theirbioactivity. Bioinert materials, (such as Oxide ceramics,Silica ceramics, Carbon fiber) are non-toxic and non-inflammatory. These materials must be long lasting,structural failure resistant, and corrosion resistant.Bioceramics additionally must have a low Young'smodulus to help prevent cracking of the material.

Bioceramics Ceramics are now commonly used in the medical fields as dental,

and bone implants. Artificial teeth, and bones are relativelycommonplace. Surgical cermets are used regularly. Jointreplacements are commonly coated with bioceramic materials toreduce wear and inflammatory response. Other examples ofmedical uses for bioceramics are in pacemakers, kidney dialysismachines, and respirators.

Hip Prosthesis

Femoral Head of a Hip Prosthesis

Tribological Ceramics Tribological ceramics, also called wear-resistant

ceramics, ceramic materials that are resistant to friction andwear. They are employed in a variety of industrial and domesticapplications, including mineral processing and metallurgy.

Advanced structural ceramics offer unique capabilities astribomaterials.

They are being used today in diverse applications such as tipsfor ball-point pens, precision instrument bearings, and cuttingtool inserts.

Tribological applications of ceramics can be divided into severalcategories based on the properties of the ceramics. Theseinclude: resistance to abrasion and erosion; resistance tocorrosive wear; wear resistance at elevated temperatures; lowdensity; and electrical, thermal and magnetic properties.

Tribological Ceramics

Tip of a ball Point PenCeramic Instrumental Bearing

Automotive Ceramics

Automotive ceramics, advanced ceramic materials that are made into components for automobiles. Examples include spark plug insulators, catalysts and catalyst supports for emission control devices, and sensors of various kinds. Its powerful physical, thermal and electrical properties make it a reliable, highly durable and cost-effective alternative to metal. As the industry faces continued pressure to deliver innovative design, improved safety features and environment-friendly vehicles (while also reducing production costs), use of this material looks set to grow.

Spark Plug Insulators

Catalytic Converter

*Classification of Advanced Ceramics based on COMPOSITION

NITRIDE CERAMICS

Nitrides used in ceramics consistof nitrogen atoms bonded to elements suchas silicon and aluminum.

Silicon Nitride

is a chemical compound of the elements silicon and nitrogen,with the formula Si3N4. It is a white, high-melting-point solidthat is relatively chemically inert, being attacked bydilute HF and hot H2SO4. It is the most thermodynamicallystable of the silicon nitrides. Hence, Si3N is the mostcommercially important of the silicon nitrides and is generallyunderstood as what is being referred to where the term"silicon nitride" is used.

Silicon Nitride

Applications:o Wear Guideso Seals and Bearingso Grinding Media

Aluminum Nitride

a covalently bonded ceramic is synthesized from abundantlyavailable elements Al and N. The ceramic does not occurnaturally. AlN has a Wurtzite crystal structure and is stable ininert atmospheres at temperatures in excess of 2000°C. Itexhibits high thermal conductivity property while remaining astrong dielectric. This unusual combination of properties iswhat makes Al N a critical advanced materials for many futureapplications in Optics, lighting, electronics and greenenvironmental technologies.s an intermetallic inorganiccompound with the chemical formula Pb[ZrxTi1-x]O3 0≤x≤1).Also called PZT, it is a ceramic perovskite material that showsa marked piezoelectric effect, which finds practicalapplications in the area of electroceramics. It is a white solidthat is insoluble in all solvents.

Aluminum Nitride

opto-electronics

dielectric layers in optical storage media

electronic substrates, chip carriers where high thermal conductivity is essential

military applications

APPLICATION

Silicon Aluminum Oxynitride

are a specialist class of high-temperature refractory materials,with high strength (including at high temperature), goodthermal shock resistance and exceptional resistance towetting or corrosion by molten non-ferrous metals, comparedto other refractory materials such as, for example, alumina. Atypical use is with handling of molten aluminium. They alsoare exceptionally corrosion resistant and hence are also usedin the chemical industry. Sialons also have high wearresistance, low thermal expansion and good oxidationresistance up to above ~1000 °C.

Silicon Aluminum Oxynitride

APPLICATION

oThermocouple protection tubes for nonferrous metal meltingoImmersion heater and burner tubesoDegassing and injector tubes in nonferrous metals. Metal feed tubes in aluminum die castingoWelding and brazing fixtures and pins

*Classification of Advanced Ceramics based on COMPOSITION

SILICATE CERAMICS

Silicates are materials composed generally of silicon and oxygen. Silicate ceramic components are used in electronics and electrical engineering and act as electrical insulation in fuses, circuit breakers, thermostats and in lighting technology. The ability of silicate ceramic materials to provide thermal insulation is also utilized in heating, environmental and thermal engineering applications.

Porcelain

- is a ceramic material made byheating materials, generallyincluding clay in the form of kaolin,in a kiln to temperatures between1,200 °C (2,192 °F) and 1,400 °C(2,552 °F). The toughness,strength, and translucence ofporcelain arise mainly from theformation of glass and themineral mullite within the firedbody at these high temperatures.

Porcelain Vase

Porcelain Tile

Magnesium Silicate

• is a chemical compound consisting of magnesium, silicon,and oxygen. It exists in several forms, both natural andmanufactured. One of the most common forms of thiscompound is the mineral talc, which can be found indeposits around the world and is used in many industrialand everyday applications. Synthetic forms are also widelyused, especially as filters and additives in the foodindustry.

• The material is lower in cost than Alumina but offersreduced mechanical properties. However it has very goodelectrical resistance properties, which are retained at hightemperatures, along with moderate mechanical strengthand temperature resistance. It has been used in electricalinsulation for many years in both large-scale electricalsystems and electronic and domestic appliances.

Magnesium Silicate

Applications:

Bases for halogen lamps Switches and Plug Parts

Mullite

• Mullite is the mineralogical name given to the only chemicallystable intermediate phase in the SiO2 - Al2O3 system.

• Mullite is commonly denoted as 3Al2O3 .2SiO2 (i.e. 60 mol%Al2O3). However it is actually a solid solution with theequilibrium composition limits of 60 – 63mol % Al2O3 below1600o C.

• By far the largest use of mullite based products is inrefractories. The glass and steel industries are two mainmarkets.

• The good mechanical properties at high temperatures of highpurity mullites have made them potential high temperatureengineering ceramics, for example in turbine enginecomponents.

• Other applications include electronic substrates and protectivecoatings.

Mullite

Uniform 1micron thick protective mullite coating on a 15 micron . diameter SiC fiber

A selection of mullite-based refractory shapes for the

steel industry

*Classification of Advanced Ceramics based on COMPOSITION

CARBIDE CERAMICS

Carbide ceramics are extremely resistant against hightemperature, abrasion and corrosion. They have a highthermal and variable electrical conductivity, and are mainlyused in mechanical engineering, chemical, and powerengineering, microelectronics as well as space engineering.

Boron Carbide (B4C)

crystalline compound of boron and carbon. It is an extremely hard, synthetically produced material that is used in abrasive and wear-resistant products, in lightweight composite materials, and in control rods for nuclear power generation.

With a Mohs hardness between 9 and 10, boron carbide is one of the hardest synthetic substances known, being exceeded only by cubic boron nitride and diamond.

Boron Carbide (B4C)

o Padlocks

o Abrasives

o Cutting Tools

o Grit Blasting nozzles

APPLICATION

Silicon Carbide (SiC)

exceedingly hard, synthetically produced crystalline compound of silicon and carbon.

Its chemical formula is SiC. an important material for sandpapers, grinding wheels,

and cutting tools. More recently, it has found application in refractory linings

and heating elements for industrial furnaces, in wear-resistant parts for pumps and rocket engines, and in semiconducting substrates for light-emitting diodes.

Silicon Carbide (SiC)

APPLICATIONS:o Abrasives or Cutting Tools (e.g. Grinding Wheel, Sandpaper)

o Burner Nozzleo Spray Nozzleo Automobile Parts (e.g. Disc Brakes)

Tungsten Carbide

is an inorganic chemical compound (specifically, a carbide) containing equal parts of tungsten and carbon atoms.

In its most basic form, tungsten carbide is a fine gray powder, but it can be pressed and formed into shapes for use in industrial machinery, cutting tools, abrasives, armor-piercing rounds, other tools and instruments, and jewelry.

Tungsten Carbide

APPLICATION

oDrill Bitso Surgical Imstrumentso Jewelry

*Classification of Advanced Ceramics based on COMPOSITION

OXIDE CERAMICS

An oxide is a chemical compound made upof oxygen combined with at least one other element.Most of the Earth’s crust consists of oxides.