Cargo Pod Design Kyle Bergen Ejvin Berry Cody Candler Mike Gavanda.

-

Upload

bryanna-moss -

Category

Documents

-

view

218 -

download

2

Transcript of Cargo Pod Design Kyle Bergen Ejvin Berry Cody Candler Mike Gavanda.

Cargo Pod Design

Kyle BergenEjvin Berry

Cody CandlerMike Gavanda

Individual Report

• Ejvin Berry• 68 hours• Tasks

– Initial Aerodynamics Optimization– Quick Prototype Modeling– Final Concept Modeling

Cirrus SR22 Cargo Pod

Cargo Pod Guidelines

With 2 passengers (including pilot), 4 hours of fuel, carry one of the following:

• 2 sets of skis with equipment– Required volume of 12in x 6in x 79 in

• 2 sets of golf clubs (with drivers)– Required volume of 35in x 11in x 50in

• Minimum 8” offset from firewall

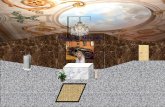

Pod on Fuselage

Clearance/ Tail Strike Envelope

Bottom View

Attachment View

Front Fairing (2)

Rear Fairing

Conclusions

• Demonstrates – Practicality

• Meets required tasks, loads

– Ease of Operation• Location specific

– Aesthetic Quality– Aerodynamics

Recommendations

• Study feasibility of manufacturing contoured pod surfaces to mesh with fuselage.– Increased capacity – Fit CG envelope better– Aerodynamics Improved

Attachment Methods

Individual Report by Kyle Bergen80 hours worked

Attachment to Longerons

• Three points of attachment for stability and ease of attachment

• Use longerons as hard points to anchor mounting brackets which extend to belly.

• One piece assembly screwed to belly attachment.

• Bolts secure attachment pieces together from embedded pieces in pod fiberglass

Front Mounting Brackets (Two)

Rear Mounting Bracket (one)

Under belly attachment from bracket to Pod (three)

Embedded in Top of PodSlides into underbelly attachment

Belly Plugs when Pod is not attached

General Analysis

• Cosmos Express in Solid Works was used to diagnose the stresses on parts

• Maximum forces were used with total weight of Pod with load (120 lbs), with 4 G’s applied and safety factor of 1.5. Total force of 720 lbs.

• C.G. of front loaded pod (two golf bags) calculated

General Analysis Cont.

• 216 lbs on each front attachment and 288 lbs on rear attachment.

• All bolts to the longerons and to the pod/belly attachments are ¼ in.

• Screws to the belly bracket attachments are in. 8

3

Allowable Loads• Allowable Load=(Allowable Stress/Safety Factor)(Area)• For Bolts and Screws of 304 Stainless Steel, Tensile Strength

Yield is used as 31200 psi, a shear strength of half the yield is used, 15600 psi, though online sources show it much higher, I will use a low number.

• Bolts through under belly attachments are in double shear so we see an allowable load of 2297 lbs.

• Screws in Tension see the yield strength of 31200 psi, we see allowable load of 2297 lbs as well. (since in double shear we use twice the area and Yield strength is twice the shear strength we see the same result.)

• These allowable loads are well above what the pod would see.

Stresses in bolts to longerons

• Since there are two bolts into the longerons on each front attachment we take the Total force on each bolt to be 216/2 on the front for a force of 108 lbs. For the rear bracket each bolt sees 72 lbs.

• These bolts have a smaller area so we see an allowable load of 510.5 lbs in shear for each bolt.

• These requirements are met by the 304 Stainless Steel bolts of ¼ inch diameter.

Deformation Picture of front attachment

• Multiplied many times for show• Safety factor of 2.47

Statistics

• Piece was run with both 304 S.S. and Alloy 2018.

• 2018 is chosen because of lower weight and higher yield

• Weight of Piece is .22 lbs• Max Stress in Piece 18560 psi• Max Displacement is .005 inches at base.

Deformation Picture of Rear Attachment

• Lowest Factor of Safety in design is 4.82

Statistics

• Piece was run with both 304 S.S. and Alloy 2018.

• 2018 is chosen because of low weight (3 times less) and higher yield

• Weight of piece is 1.4 lbs• Max Stress in piece is 13880 psi• Max Displacement is .005 inches

Deformation in Under belly attachment to pod piece

• Safety Factor of 1.95

Statistics

• Piece was run with both 304 S.S. and Alloy 2018.• 2018 is demonstrated here• Data taken was for 288 lbs, so pieces are not

exclusive to one attach point, three identical pieces.• Weight of piece is .31 lbs• Max Stress in piece is 1798 psi• Max Displacement in piece is .00005 inches

Displacement of Embedded Pod Piece

• Safety Factor 25.48

Statistics

• The piece was run testing both 304 Stainless and Alloy 2018.

• 2018 is recommended because of its slightly higher yield strength and much less weight

• Weight of piece is .32 lbs• Max Stress in piece is 1804 psi• Max displacement is .00005 inches.

Final Statistics

• Total weight of the attachment method is 3.73 lbs• 304 SS would have worked for all pieces as well, and even

reduced some of the displacement, however, the weight would have been significantly increase.

• 304 SS is used for bolts since that is a primary use of 304 SS.• Alloy 2018 is chosen because it is a high strength alloy. It is

very easily machined and is a tough alloy that can be used for heavy duty structural parts.

Conclusions• The attachment methods as designed work for the support of the cargo

pod.• Front attachments are placed on the inside of the longerons at 19 inches

behind firewall and rear attachment is placed between longerons at 69 inches behind firewall. Inspection of longerons looked to be good placement.

• Would have liked to do further analysis on the Longerons and get more accurate dimensions.

• Wish we would have nailed down a design sooner since a lot of the semester was spent on investigation of workable/do-able pod designs.

• Further work would include optimization of current design pieces and trying different designs.

• I would like to thank my team and Steve Hampton for all the support throughout the project!

Individual Report

• Mike Gavanda• 70 hours• Worked on

– Ground clearance– Tail strike clearance– Pod access

Solid works attached Pod model

01:29 PM

Clearance

01:29 PM

Solid Works model

01:29 PM

Clearance/ Tail Strike Envelope

Pod wheel Clearance

01:29 PM

Golf Bag

Width 10 in

Height Bag 34 in

Height with clubs 50 in

Average Golf Bag Size

01:29 PM

Golf Bag Clearance

01:29 PM

SkisLength (cm) 173 180

Side cut tip(mm) 130 135

Waist (mm) 96 99

Tail (mm) 124 125

Weight (g for one ski) 1970 2210

http://www.salomonski.com/us/products/XW-Sandstorm-1-1-1-788918.html01:29 PM

Skis and pod

Access

Access Seal

*www.aircraftspruce.com/catalog/hapages/camloc4002.php**www.trimlok.com/detail.aspx?ID=933

Camloc 4002 Studs*2600 and 2700 series made of steel Shear: 1050 lbs. (ultimate)Tensile strength: 700 lbs. (rated)Rated to 450° F

Example of watertight hatch seal**

Conclusion

• Meets clearance and size goals– Clears fully loaded landing– Clears tail strike– Safe distance from exhaust– Fits a pair of golf bags or 2 pairs of skis

• Easy access

Recommendations

• Find more on how the exhaust affects pod• See if clearance can be increased for landing

and tail strike• More study of water tight seal on access door

Individual Report

• Cody Candler• 70 Hours• Tasks

– Location of the center of gravity• Ensure it meets ground requirements

– Aerodynamics Analysis– Range Optimization

Reference points of the front and back of the cargo pod while attached(Figure 6-1 out of the Cirrus Manual)

C.G. of the aircraft with the pod attachedSample Loading• Pilot – 200 lbs• Passenger – 200 lbs• Fuel – 486 lbs (full tank)• Cargo Pod – 100 lbs

Center of Gravity Limits

• No Luggage

• Luggage – 25 lbs

• Luggage – 50 lbs

C.G. of pod located at FS 148.0

Moment Limits

Used Component Buildup Method out of Aircraft Design: A Conceptual Approach by Raymer

Approach used:Find flat-plate skin-friction drag coefficient (Cf)

– Assumed complete turbulent flow

Find the component “form factor” (FF)– estimates the pressure drag due to viscous separation– assumed the pod to be a fuselage

where

– Amax is the maximum cross-sectional area of the pod which is 3.224 ft2

– l is the length of the cargo pod (6.583 ft)

Estimate CD for cargo pod

65.0258.210 144.01log

455.0

MRC f

600

601

3

f

fFF

max/4 A

l

d

lf

CD Estimate cont…

Determine interference effects on the component drag (Q)– Raymer says if the component is mounted less than one diameter away from the

fuselage then the Q factor is 1.3

Find the wetted area (Swet)

– Total exposed surface area

2674.292

4.3~ ftAA

S sidetopwet

Calculate total component drag

Sref of SR-22 wing is 144.9 ft2

Result:CD = 0.002577

ref

wetf

subsonicD S

SQFFCC

0

Extra power needed with pod attached• Use general power required equation

PR = TRV∞

• In steady, unaccelerated flightTR = Drag (in our case, drag is increased drag from pod)

• For each altitude, I used the cruise performance data from the Cirrus manual – I only used data where engine was operating at 2700 RPM since the engine has a rating of 310 hp at 2700

RPM– This gives a conservative estimation of the additional power needed to travel at the same velocity with

the pod attached as when it isn’t attached

0

5

10

15

20

25

0 2000 4000 6000 8000 10000 12000 14000 16000 18000

Altitude (ft)

Ad

dit

ion

al

Po

we

r (h

p)

Effects on Velocity• Calculate an approximate CD of the SR-22 using the cruise performance data out of the Cirrus manual

• Add the cargo pod component drag coefficient to the total aircraft drag coefficient

• At 2700 RPM and same power, calculate velocity of aircraft with the pod attached and without the pod attached

Result• 7% decrease in velocity with the pod attached

270

275

280

285

290

295

300

305

310

315

320

0 5000 10000 15000 20000

Altitude (ft)

Vel

oci

ty (

ft/s

)

Velocity with Pod Attached

Velocity w/o Pod

Sample streamlines around the cargo pod

Sample Pressure Distribution on Pod

Sample Pressure Distribution on the pod with a crosswind

Crosswind

Crosswind

Maximum Speed with Cargo Pod Attached

Conditions:•Get to a location as fast as possible•4 hours endurance•81 gallons of usable fuel•Weight: 3400 lbs•Take off from sea-level•No wind

Results w/o Pod:Optimal Cruise Altitude: 12000 ft• Fuel to taxi: 1.5 gal• Fuel to climb: 4.4 gal• Fuel to cruise: 59.8 gal @ 15.4 GPH• 45 min IFR fuel reserve: 9.8 gal• Airspeed: 178 KTAS• Range: 785 nautical miles

Adjusted results for attached cargo pod:• Airspeed: 166.4 KTAS (7% reduction)

• Range: 730 nautical miles• Endurance of 4.3 hours

Maximum Range with Cargo Pod Attached

Conditions:• Maximum range• 81 gallons of useable fuel• Weight: 3400 lbs• Takeoff from sea level• No wind

Results w/o Pod:Optimal Cruise Altitude: 14000 ft• Fuel to taxi: 1.5 gal• Fuel to climb: 5.3 gal• Fuel to cruise: 57.8 gal @ 11.3 GPH• 45 min IFR fuel reserve: 9.8 gal• Airspeed: 169 KTAS• Range: 1006 nautical miles

Adjusted results for attached cargo pod:• Airspeed: 143.7 KTAS (7% reduction)

• Range: 935 nautical miles •Endurance of 5.8 hours

Conclusions

• Due to the restriction of the center of gravity of the cargo pod (FS 148.0) a weight of at least 25 lbs must be added to the luggage compartment for the SR-22 to be safe to fly

• A 4 – 8% increase in power is needed to travel at the same speed with the cargo pod attached as it would without the pod attached

• The cargo pod decreases the velocity of the SR-22 by approximately 7% when attached

• The maximum range of the SR-22 with a full tank of fuel and the cargo pod attached is 935 miles

• The customer would need to sacrifice range or use more fuel when operating with the cargo pod attached

Recommendations• Mesh top of pod to the bottom of the fuselage to

reduce the drag area and increase performance– Free up room to move the pod further back on the

fuselage, which would move the C.G. aft and maybe eliminate the need for a requirement of 25 lbs of luggage

• Spend more time studying pressure hot spots– Contour the front of the pod more to further reduce drag– Revise the back half of the pod to prevent flow separation

and reduce drag

Individual Report

• Dan Poniatowski• 75 hours of work• Accomplishments

– Documented and managed schedule and Gantt Chart– Documented requirements– Facilitated communication between the team and the

sponsors– Coordinated trips to the Cirrus factory in Duluth – Facilitated FMEA and Environmental/Societal Impact

analysis– Produced a Design Summary for the belly pod consistent

with Cirrus’ method of documentation

Problem Probability Severity Mitigation

High Lift Device Flutter due to failure Low High Pull Parachute.

High Lift Device Flutter due to aerodynamics Medium High

Test for natural frequencies. Avoid frequencies of prop and install dampening.

Cable/Mechanical Failure Low High Pull Parachute.

High Lift Device Extension/Retraction Failure Low Low Install mechanical indicator to inform pilot.

Spin Entry Medium Medium Install warning placards and mandate anti-spin pilot training.

High Lift Device Detachment Low High Design fasteners to release when a partial failure occurs. Pull Parachute.

Icing High Varies Incorporate existing deicing equipment into new design.

Collision Damage Medium Medium Reinforce leading edge. Pull Parachute.

Wing Detachment Low Very High Pull Parachute.

Internal Fuel Leak Low MediumInstall fluid detector and warning device. Instruct pilot to deactivate electronics and land immediately.

External Fuel Leak Low Low Instruct pilot to land immediately.

Lightning Strike Medium Medium Install dissipating mesh in the wing and high lift devices.

Heat Damage Medium Low List warnings in Pilot's Operating Handbook.

Problem Probability Severity Mitigation

Pod hits the ground Medium Low Fasteners designed to shear off and release pod.

Partial Attachment Failure Low High Remaining attach points designed to shear off.

Foreign Object Collision Medium Low Reinforce the nose of the pod.

Front End Overheating High Medium Attach a metal heat sheild to the nose.

High G Failure Medium High Designed to withstand a 3G manuever.

CG Out of Balance Due to Loading High High Warn the pilot in the Pilot's Operating Handbook and install placards.

Failure Modes and Effects Analysis

Problem Category Severity Mitigation

High performance wing causes society to distrust general aviation as a result of accidents. Society Low Press releases on the advantages of the new wing design.

Wing performs well enough to edge competitors out of the market. Global Low Sharing of new wing technology.

Complexity of high lift device design deters new pilots. Society Low Simplification of pilot interface.

Problem Category Severity Mitigation

Pod is used for smuggling drugs. Society Low

Pod is used by terrorists to deliver weapons. Society High

Pod is used as a chemical distribution tank. Environment Medium

Additional power required for use of pod consumes more fuel. Environment Very Low Make pod easy to remove when not in use.

Environmental, Societal, and Global Impacts

Pod Design Summary

• Follows Cirrus’ Method of Documentation• Documents design requirements and goals.• Documents the design concepts along with

pros, cons, risks and mitigation. • Documents the design process to provide

insight to further investigation.

Pod Design SummaryDesign Summary

ATA : Add ATA 4 Digit CodeAdd ATA 4 Digit Code

Project : SR24

Title : SR-22 Cargo Pod

Author : Daniel Poniatowski

Created : Nov. 4, 07

Modified : Dec. 12, 07

Pod Design Summary

Concept 2: Streamlined Closed Pod.

Sketch

Pros

Excellent aerodynamic performance

Holds goal cargo in one pod

Excellent Aesthetics

Cons

Sealing the pod to the fuselage is high risk.

Pod has poor utility.

Pod is not optimized for user friendliness.

Risks & TBD & New Items

1. Sealing the pod to the fuselage is expensive and prone to major failure during use.

2. Pod will not be a success with consumers because it is difficult to use.

Risk Mitigation

1. Change design to a closed pod to remove the need for a seal system.

2. Closed pod design will increase user friendliness and accessibility. Aerodynamics has become secondary to utility, safety and user friendliness.

Key Characteristics

1. Pod satisfies design requirements.

2. Pod satisfies design goals.

3. Pod has acceptable aerodynamic performance while optimizing user friendliness and utility.

4. Pod is optimized for ease of production and profit.

5. Pod is optimized for ease of removal to give the consumer flexibility and increase satisfaction.

Compromises

1. Less than optimal aerodynamic performance.

2. Pod is less stylish than previous designs.

Design Review: Comments & Sign Off. Text.

Design CE: ____________________ Date: ________________

Tool Lead: ____________________ Date: ________________

Production Lead: ___________________ Date: ________________

3 Detail Design / Model

Drawing File

File Names:

Conclusions and Recommendations

• Gantt chart was useful for planning purposes• Wiki was useful for common file sharing• Requirements were recorded in a common location,

a more stringent process would be useful. • Schedule more time for risk mitigation• Schedule more reviews during the design process• Be more aggressive in achieving results and ensuring

metrics are being met.