Carbon Prepreg Orthoses made using the Malmö Technique · Carbon Prepreg Orthoses made using the...

Transcript of Carbon Prepreg Orthoses made using the Malmö Technique · Carbon Prepreg Orthoses made using the...

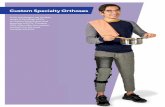

Carbon Prepreg Orthoses made using the Malmö TechniqueModern, lightweight, and custom-made

Information for Technicians

2 Ottobock | Carbon Prepreg Orthoses made using the Malmö Technique

Carbon Prepreg Orthoses made using the Malmö Technique

Ottobock uses the modern Malmö technique for a custom-made orthosis based on your specifications. Thanks to the combination of flexible and rigid parts, Malmö orthoses can be adapted perfectly to the needs of the user. Ottobock Service Fabrication supports you with precisely fitting leg, knee, and ankle-foot orthoses based on modern prepreg carbon fibre technology.

Advantages of Malmö orthoses:• Graduated thickness of material to optimise

weight and aesthetic appearance• Meet requirements for torsional and bending

stiffness• Optimal stability with low wall thickness• Excellent torsional flexibility• Improved dynamics• Multiple options for fastener flaps, tongues

and pockets• Flexible cuffs, flexible connecting elements

and more flexibility at the seat• Customised forefoot and heel properties

You can also use all knee and ankle joints in our product line for the orthosis design.

IndicationsMalmö orthoses are the ideal solution for many situations. Take advantage of this modern technology, for example for users with the following indications:

• Poliomyelitis• Post-polio syndrome• Neuropathies• Osteoarthritis• Pseudoarthrosis• Spina bifida• Ligament instability• Ruptured cruciate ligaments

Carbon Prepreg Orthoses made using the Malmö Technique | Ottobock 3

Indications and Design Proposals

Type of orthosis Description Possible diagnosis

Knee ankle foot orthosis KAFO

2 brackets and1 front element or 2 brackets, each with knee andankle joint

SF28K=L-KAFOSF28K=R-KAFO

Paralytic diseases involving the entire leg

When a high degree of guidance is required:Osteogenesis imperfecta,poliomyelitis,ICP

Knee ankle foot orthosis KAFO

with flexible connecting element and knee joint

SF28K=L-KAFO-1SF28K=R-KAFO-1

Paralytic diseases of the entire leg

The torsional flex connecting element optimises pelvic movement while walking: Poliomyelitis, progressive muscular dystrophy, severe knee osteoarthritis

Knee ankle foot orthosis KAFO

with length reduction,without ankle joint, with knee joint

SF28K=L-KAFO-2SF28K=R-KAFO-2

Paralytic diseases of the entire leg and stiffness of the ankle joint with a shortened leg:poliomyelitis,traumas, osteogenesisimperfecta

Type of orthosis Description Possible diagnosis

Dynamic ankle foot orthosisSpiral DAFO

SF28F=L-DAFOSF28F=R-DAFO

Paralysis of the peroneal nerve following a stroke

Dynamic ankle foot orthosis

DAFO with dorsiflexion assist

SF28F=L-DAFOSF28F=R-DAFO

Paralysis of the peroneal nerve with ligament instabilityin the ankle joint and systemic diseases

Dynamic ankle foot orthosis DAFO

SF28F=L-DAFO-1SF28F=R-DAFO-1

Spina bifida, ICP, foot deformities,stiff ankle

Dynamic ankle foot orthosis DAFO

SF28F=L-DAFO-1SF28F=R-DAFO-1

Pseudarthrosis, complete immobilisation of the lower leg

Ankle foot orthosis AFO with joint

SF28F=L-AFOSF28F=R-AFO

Paralytic diseases of the leg:Poliomyelitis, severe ligament instability

Knee orthosis

KO with joint

SF28K=L-KOSF28K=R-KO

Ligament instability,knee osteoarthritis

4 Ottobock | Carbon Prepreg Orthoses made using the Malmö Technique

Ankle foot orthosis Spiral DAFO

Knee ankle foot orthosis KAFO with system ankle and knee joint

Ankle foot orthosis AFO with ankle joint

Carbon Prepreg Orthoses made using the Malmö Technique | Ottobock 5

Easy to order – Overview of procedure

Make a plaster positive of the affected leg and mark the desired design options on it. Please also fill out the order form.

Use the free pick-up service to send your plaster positive to Ottobock Service Fabrication using the order form (on pages 9/10).

Ottobock Service Fabrication makes your Malmö orthosis within 10 working days and sends it to you afterwards.

You receive an orthosis with an exact fit and optimised material characteristics.

6 Ottobock | Carbon Prepreg Orthoses made using the Malmö Technique

The first steps to the orthosis:Plaster positive and trial orthosis

Your plaster positive is the basis for the Malmö orthosis. Therefore, we would like to assist you with some important tips. For example, remember to cast a metal rod extending at least 10 cm beyond your positive and to shape projections on the positive.

The plaster positive must not be sealed with varnish or covered with thermoplastic padding. We recommend rubber cork as a padding dummy (620P3). Please also make a memory impression of your model, as the sample provided to Service Fabrication may be damaged by heat and pressure during fabrication.

The plaster positive should reproduce the defini-tive position of the orthosis. Mark all the positions of supports, bars, and straps and indicate the individual edge positions.

Particular precision is required for this because the material used in a Malmö orthosis cannot be thermally modified later. We therefore recommend checking the fit with a trial orthosis to determine the exact shape of the final plaster positive. Ottobock Service Fabrication can make the trial orthosis for you. Your patient should try on the trial orthosis without any pad-ding to avoid concealing any potential pressure points.

When you make the plaster positive from the trial orthosis and wish to insert joints, please use the adapter sleeve (743Y48). This gives you a square profile in the positive where the adapters of the joint alignment fixture (743R6) can be inserted.

Padding distance

e.g. 3 mm

Carbon Prepreg Orthoses made using the Malmö Technique | Ottobock 7

And now – options and customised designMark flexible sections such as the forefoot and mould them level. We fabricate the forefoot region using Dyneema coated carbon according to your need for flexibility or stiffness. The tongues and flaps are made of Dyneema, allowing high flexi-bility.

You can simply note extras and comments on the plaster positive. Please mark for example:• Extra padding distances, if needed• Position and size of spacers• Properties of forefoot, heel and springs• All areas for tongues, flaps, and attachmentsfor fasteners.

The surface of the orthosis can also be designed according to your wishes. You can choose from:• Carbon fibre look• Fabric look

The Malmö orthosis: Tips for customised finishingPlease note when providing all information on fabrication and custom design that thermoplastic modification of the orthosis is not possible later. When finishing the orthosis (e.g. grinding or drilling), please ensure that the weight-bearing structures and profile materials are not damaged.

From the positive to the custom designAfter you have made the positive, there are many design options available. They allow you to include the user's individual requirements and demands, for example weight, height, and activity level. Simply use the order form to specify the desired options and then fax it to us.

8 Ottobock | Carbon Prepreg Orthoses made using the Malmö Technique

Shipping to Ottobock Service FabricationPlease pack your plaster positive in a well padded box and send it with the package service of your choice to the Ottobock Service Farbication.

Delivery of your Malmö orthosisOttobock Service Fabrication produces your Malmö orthosis within 10 working days and delievers it to you afterwards.

The Malmö orthosis: finalisation and modifi-cation options after deliveryPlease consider that thermoplastic modification of the orthosis is not possible at a later date. You can grind the orthosis to modify edges but the thickness of the material should not be changed significantly. Cuts or other damage to the surface can lead to weakened areas with an increased risk of breakage. Please also ensure that you do not damage the weight-bearing structures or profile materials when grinding or drilling.

As a final step, you can give the orthosis its individual look and add padding. You can now also add hollow rivets or screws and setting nuts to the fasteners. By applying an outer coating of Pedilin® you ensure that the carbon material does not fray any clothing worn.

The most important criteria for every Malmö orthosis is the user's satisfaction. We wish you success in helping your patient obtain an ideal solution.

Otto Bock HealthCare GmbH · Max-Näder-Str. 15 · 37115 Duderstadt, Germany T +49 5527 848-3030 · F +49 5527 848-1585 · [email protected] · www.ottobock.com

Orthoses made using the Malmö TechniqueOrder form

Information on the fitting

Patient: Age: Height: m Weight: kgWorn for Everyday use Work Sports Competitive sports

Restrictions:

Diagnosis: Other diseases:

Trial orthosis (made of thermoplastic resin)Model

Ankle foot orthosis without joint

DAFO — left DAFO — right

Ankle foot orthosis with joint

AFO — left AFO — right

Definitive orthosis

Knee orthosis

KO — left KO — right

Knee ankle foot orthosis

KAFO — left KAFO — right

Comments:

Contact person Customer number Date

Customer Shipping address (if different from customer address)

Company Company

Street Street

Postal code/city Postal code/city

E-mail Phone

Patient ID

Otto Bock HealthCare GmbH · Max-Näder-Str. 15 · 37115 Duderstadt, Germany T +49 5527 848-3030 · F +49 5527 848-1585 · [email protected] · www.ottobock.com

Orthoses made using the Malmö TechniqueOrder form

Padding dummy

Prepare the orthosis directly on the positive model, without allowing for any padding distance. The model is shaped without padding distance. Please take into account a padding distance for the:

Thigh of mm Lower leg of mm Foot of mm

Joints

Knee joint: yes Art. no. With system lamination joint bars no Without system lamination joint bars Ankle joint: yes Art. no. With system lamination joint bars no Without system lamination joint bars

Sole rollover without resistance dynamic stiff 1 soft 2 3 4 5 stiffForefoot characteristics:

1 soft 3 5 stiffHeel:

Tongues or flaps

On the foot yes Single tongue Single tongue Double tongue no medial fixed lateral fixed On the lower leg yes Single tongue Single tongue Double tongue no medial fixed lateral fixed On the thigh yes Single tongue Single tongue Double tongue no medial fixed llateral fixed

Surface design

Unfinished carbon design Finished glossy carbon design (surcharge) Socket decor look (poss. surcharge) Art. no. (from 646K1 Material Catalogue)

Bemerkungen:

Contact person

Customer number Date

© O

ttobo

ck ·

646A

115=

GB

-02-

1311

· Te

chni

cal c

hang

es a

nd p

rintin

g er

rors

rese

rved

.

Otto Bock HealthCare GmbH Max-Näder-Straße 15 · 37115 Duderstadt, Germany T + 49 5527 848-3030 · F + 49 5527 848-1585 [email protected] · www.ottobock.com

![Prepreg technology[1]](https://static.fdocuments.net/doc/165x107/5550156eb4c90535638b4d56/prepreg-technology1.jpg)