Capsules

-

Upload

malla-reddy-college-of-pharmacy -

Category

Documents

-

view

333 -

download

2

Transcript of Capsules

TO MY PRESENTATIO

N By

mohammed fahimuddin

M pharmacy(pharmaceutics)

Malla reddy college of pharmacy

TOPIC

CAPSULES

HISTORY

• In 1730, the Pharmacist De PAULI from Vienna developed oval shaped capsules for covering up the unpleasant taste of the pure turpentine used for the treatment of gout

• In 1834, the Pharmacist JOSEPH DUPLANC from FRONCOIS MOTHES were granted Patent which covered a method for the producing , single piece , olive shaped , gelatin capsules which were closed after filling by a drop of concentrated warm gelatin solution

• In 1846, the Frenchman JULES LEHUBY first to suggest Tow- Piece Capsule produced by dipping silver coated metal pins into a gelatin solution and then drying them quickly

• In 1931, the author COLTON Designed a machine to manufacture bodies and caps and fitted them to form hard gelatin capsule.

WHAT ARE

CAPSULES

capsules

• These are solid dosage forms in which the medication is enclosed within a gelatin shells.

• The medication may be a powder, a liquid or a semisolid mass.

• Capsules are usually intended to be administered orally by swallowing them whole. Occasionally, capsules may be administered rectally or vaginally.

Raw materials

RAW MATERIALSRaw materials1. Gelatin

2. FD & C and D & C colorant

3. Sugar

4. Water - 12 to 16 % (may vary depending on the storage condition )

5. Sulfur dioxide (15%) - prevent decomposition during manufacture

6. Colorants / Opacifying agent : There are two types A) water soluble dyes – e.g. erythrosine B) pigments – e.g. iron oxides , titanium dioxide (make the capsule opaque to provide protection against light)

7. Preservatives: To prevent microbial growth during manufacture

• Diluents: lactose, mannitol, sorbitol, starch etc• Lubricants and Glidants : talc, magnesium

stearate & calcium stearate• Wetting agents: sodium laurial sulphate• Disintegrants• Anti – dusting agent : inert edible oils

Raw materials

GELATIN• It is a protein substance derived from collagen, a natural protein

present in the tendons, ligaments, and tissues of mammals. It is produced by boiling the connective tissues, bones and skins of animals, usually cows and pigs.

• It is the major component of the capsule. The reason for this is that gelatin possesses five basic properties:

A- Non-toxic. B- Soluble in biological fluids at body temperature. C- It is a good film-forming material. D- Solutions of high concentration, 40% w/v, are mobile at 50°C. E- A solution in water changes from a sol to a gel at temperatures only a few degrees above ambient (Others require volatile solvents or large quantities of heat).

Raw materials

Type A Type B

- Obtained from bone - Obtained pork skin- Derived from acid treated - Derived from alkali treated precursor precursor- Isoelectric point in the - Isoelectric point in the region of pH 9 region of pH 4.7

gelatin

PROCESS OF GELATIN PRODUCTION

TYPE A

TYPE B

MAJOR SUPPLIERS OF EMPTY GELATIN

• Eli Lilly and Company, Indianapolis, IN ;

• Capsugel, Greenwood, SC ;

• R.P. Scherer Corporation, Troy, MI

INDIAN SUPPLIERS•Karishma Pharma Machines, Mumbai

•Healthy Life Pharma Private Limited, Mumbai

•Akhil Healthcare Private Limited, Vadodara

•Caps & Chemicals, Indore

•Asoj Soft Caps Private Limited, Halol

• Austro Labs, New Delhi etc etc etc ….

SOFT GELATIN CAPSULES

( ONE PIECE )

HARD GELATIN

CAPSULES( TOW PIECE )

capsules

Hard gelatin capsules

Hard gelatin capsules• It consists of two pieces in the form of cylinders which is closed at one end and open from the other: - the shorter piece “cap” and - the longer piece “body”.• The shells consist largely of gelatin, sugar and water.

CAP

BODY

Capsule shell filling:

- typically filled with dry solids (powders, granules, pellets, tablets) and semisolids.- Fixed oils and other liquids that do not dissolve gelatin may be filled into hard gelatin capsules with a pipette or calibrated dropper, then capsules are sealed by moisturizing the lower part of the caps with water.- Liquids may often be sorbed onto inert carrier powders to form dry powders suitable for capsule filling.

00 0 1 2 3 4 5

1.01mL 0.68mL 0.49mL 0.37mL 0.28mL 0.21mL 0.13mL

Hard gelatin capsules

1 Bloom value - is a measurement of the gelling power and the strength of the resulting gel. - Gelatin generally falls between 50 and 300 bloom strength.

2 Gelling power - the key function of gelatin. - The gelling power varies depending on the grade of gelatin - its measured in terms of bloom value. The higher the bloom value, the greater the ability to form gels & the stronger the gel strength. 3 Viscosity - In general the higher the bloom, the greater the viscosity - Beef bone grades tend to have higher viscosity. - Viscosity is determined by measuring the flow time of a 6.67% solution of gelatin through a U-tube viscometer at 60 °C. Viscosity measurement is given in millipoise units and varies between 20 and 70 mps.

4. Foamability - In general pigskin grades tend to have better foaming properties - Gelatin lowers the surface tension, allowing for the incorporation of air, and stabilizes

the foam once aerated - Gelatin will also prevent crystal formation of sugars in the foam and maintain smoothness

in texture.

GENERAL CHARACTERISTICS OF GELATIN

5. Melting point - Lower melting point gelatins dissolve faster in the mouth, therefore

releasing the flavors more quickly for an instant taste sensation. -Lower bloom grades tend to have lower melting points.

6. Color and odor -The gelatin should be as clear as possible in solution. - Clarity is measured using a turbidimeter . -The gelatin should be without odor.

7. Conductivity - is a key parameter in photographic applications and grades of the highest purity

with minimal or no conductivity are required. De-ionized grades have an advantage because of their low conductivity.

8. pH -. pH is measured using a pH meter on a 1% solution and typically for gelatin

solutions falls between ph 4.5 and 6.5.

GENERAL CHARACTERISTICS OF GELATIN

manufacture

The process of capsule shell production with the pin method: Dipping→ Drying → Stripping→ Trimming→ Joining → Polishing

EMPTY capsule SHELL PRODUCTION

Capsules FILLING

Hard gelatin capsulesFILLING MACHINES

FILLING EQUIPMENTSCOMPANIES MANUFACTURING FILLING EQUIPMENTS•Eli lilly and company, indianapolis

•Farmatic snc, bologna, italy

•Hoflinger and karg, germany

•Mg2 s.p.a, bologna ,italy

•Osaka, japan

•Parke davis and copany, detroit

•Perry industries, green bay

•Zanasi nigris, bologna ,italy

Hard capsule FILLING

1) Bench scale filling

•For small scale filling

•Manual filling machine

2) Industrial scale-filling

•Comes in varying shapes and sizes

- semi automatic machine

- fully automatic machine

Bench scale filling

Bed – 200-300 holes

Powder tray

Sealing plate with rubber top

leverloading tray with 200-300 holes

Pin plate with 200-300 holes

scraper

Cam handle

Industrial scale fillingSemi auto mated capsule filling machine

Semi automated capsule filling machine

FEATURES:•Suitable for filling capsules of all sizes with powder, granules and pellets.•minimizes operator attention and ensures maximum production.•Choice of four auger speed with variable speed of filling table •Auto drug hopper in feed mechanism, reduces weight variation and improves productivity.•easy to maintain and clean.•Quality and precision manufacturing meets the requirement of CGMP.•Both, PLC controlled panel or digital controlled panel, with auto capsule loader closing system available to meet customers requirement.

FULLY AUTOMATED capsule filling machine

1. Empty Capsule hopper 2. Rectifying roller 3. Magazine 4. Cap Segment5. Body disc6. Powder filling hopper 7. Unopened Capsules rejection unit 8. Joining station 9. Discharge chute 10.Segment cleaning 11.Weight Control unit 12.Control station 13.Auger Motor 14.Auxiliary powder hopper

SOFT GELATIN CAPSULES

SOFT GELATIN CAPSULES

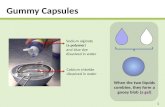

•Soft Gelatin capsules are one piece, hermetically sealed, soft gelatin shells containing a liquid, a suspension, or a semisolid.•They have long been preferred dosage form for those, taking Health & Nutritional supplements

DEFINITION

ADVANTAGES

• A typical gel mass formula for making soft gelatine capsules would be:

• Gelatine 35-45%• Plasticizer 15-25% (glycerine or sorbitol)• Water ~40%• Dye / Pigment as needed• Opacifier as needed• Other (flavour, sugar,) as needed

SOFT GELATIN CAPSULES COMPOSITION

SHAPES AND SIZES OF SOFT GELATIN CAPSULE

SOFT GELATIN CAPSULES SIZES

PRODUCTION PROCESS OF SOFT GELATIN CAPSULE

Preparing of gelatin solutions.

Preparing and filling of soft-gelatin capsules.

Packing and labeling.

Stage of capsules production

SOFT GELATIN CAPSULEPRODUCTION MACHINE

SOFT GELATIN CAPSULE PRODUCTION MACHINE

ROTARY DIE PROCESS

EVALUATION OF

CAPSULES

EVALUATION OF CAPSULES

1.UNIFORMITY OF WEIGHT

2.CONTENT OF THE API IN CAPSULES

3.DISINTEGRATION TEST

4.DISSOLUTION TEST

DISINTIGRATION TEST• Place one capsule in each basket

• Set the temperature of water to 37 +/- 2

•Use disc if HGC floats whereas for soft gelatin use the disc

•Operate the apparatus for 30 min for HGC and 60 min for SGC

• The test is said to pass if no residue is left on the screen of the apparatus

•Repeat the test for 12 capsules if more than 1 or 2 capsules fails to disintegrate

•The test passes if 16 out of 18 capsules disintegrate or else fail

DISSOLUTION TEST

• Place 1000ml of watr free from disolevied air having temp. of 36.5 to 37.5

•Place specified no. of capsules in each basket

•Start motor and adjust speed 100 rpm as per monograph

•Withdraw the required volume of solution after 45 min or as specified in the monograph.

•Filter and weigh the amt of active ingredient by the method specified in the mongraph

•Repeat four times

• The test is said to pass ifthe amt of actve ingredient is not less than 70% of the stated amt given in the monograph