cAMeron international corporation - · PDF filet he company’s present name—...

Transcript of cAMeron international corporation - · PDF filet he company’s present name—...

www.c-a-m.com

cAMeron international corporation—raising performance. togethertM.

040

041

Quality and Preservation of value:

State-of-the-art technology for Proven and Brand-new ComPressorsWith its history spanning 180 years, CAMERON International Corporation, Houston, Texas, USA, is one of the world’s conglomerates with the richest tradition. The company’s approximately 18,000 employees feel committed to their history—and consequently to the corporate maxims that already guided the actions of CAMERON’s predecessor, COOPER Industries: quality and performance. TEXT: Ludwig Schönefeld · PHOTOS: Ralf Baumgarten IlluSTraTIOnS: CAMERON International Corporation

the company’s present name— CAMERON—dates back to the acquisition of CAMERON Iron Works by COOPER Industries in 1989. This was the most

momentous acquisition in the history of the industrial enterprise that was founded in 1833 by the COOPER brothers, Charles and Elias, in Mount Vernon, Ohio, and has been managed from Houston, Texas, since 1967. Presently, the company achieves sales of more than 5 billion dollars with its three Business Divisions—Drilling & Production Systems, Valves & Measurement, and Process & Compression Systems. Approximately two thirds of CAMERON’s business comes from outside the United States. China is increasingly gaining in importance—both as a sales market and as a production location.

a Balanced PortfolioAs Director Product Engineering, Development & Quality, Everette Johnson is in charge of global development of reciprocating compressors. Offering proven technological solutions, both for the production and for the transport and use of natural gas in the process industry, CAMERON is positioned well: “We have a balanced portfolio covering gas compression from the source to the end user.”

Over the last few years, CAMERON invested primarily in the continual optimization of the portfolio. Initially, the efforts were centered around boosting the efficiency of CAMERON compressors: “We invested heavily in the development of highly efficient products,” Johnson reported. Another focal area was the minimization of greenhouse gases from diffuse emissions at the compressors: “The pressure toward lower emissions standards will continue unabated in the coming years. We’re wellprepared.”

aJaX®—a champion in the gas fieldTo this day, the AJAX® Integral Engine Compressor contributes significantly to CAMERON’s success around the globe: “The AJAX® compressor is one of the oldest, yet also one of the most successful machines in the world,” explained Everette Johnson. The AJAX® brand harkens back to AJAX® Iron Works. Founded in 1892 in Corry, Pennsylvania, USA, the company started to produce gas compressors in 1895. After World War II, the compact design of the AJAX® compressor helped make it the leading compressor model in the U.S. oil and gas industry. With a power spectrum between 30 and 360 horsepower, the AJAX® was able to satisfy virtually all requirements of industry at the time.

In 1963, AJAX® was acquired by COOPER. COOPER and CAMERON systematically expanded the product line—all the way to the current top model, the 845horsepower AJAX® 2804. At a maximum of 525 revolutions per minute, AJAX® compressors are slowspeed compressors. What’s special about the AJAX® principle is that the drive and compressor are combined on a common frame. The simplistic design principle promises minimized mechanical losses as a result of the matched synchronization of all components and resulting low vibrations. Recently developed is an electric drive AJAX® compressor that utilizes many of the same components as the integral engine compressor, including the high efficiency lineup of AJAX® cylinders.

Intrinsic Value and InnovationThe technical design of the AJAX® compressor, the fundamentals of which were developed at the beginning of the 20th century, is still applied to this day. This is partly due to the simple design and the intrinsic value of the construction. In addition, AJAX®, COOPER and CAMERON have always managed to successfully refine their machine through continuous inno vation. To accomplish this, CAMERON relies on strong partners like HOERBIGER. Everette Johnson stated: “Our partnership with HOERBIGER has existed for quite some time and is very inspiring for both sides. We purchase all valves as well as the packing and sealing rings for the AJAX® compressors from HOERBIGER.”

HOERBIGER and CAMERON collaborated for a period of three years with the CAMERON AJAX division in Oklahoma City, Oklahoma, USA, on a joint project that was aimed at further improving the performance and reliability of the AJAX integral® compressors by developing a more reliable, antiscuff, power ring design. The development centered on replacing the previous tapered ring design with a barrel faced Ferrox ring. To improve performance, the top ring’s running surface has several circumferential grooves which are filled with Ferrox. This prevents scuffing and enables the ring face to retain oil. As a result, wear is reduced both on the ring face and the cylinder bore.

“for a life cycle that can easily span 50 years or more, all that’s required of the operator of an aJaX® compressor is an annual oil change and very few special tools.” 2012 aJaX® product brochure

A cross-sectional view of

the AJAX® DPC-2804LE:

the current top model

also remains true to the

simple design principle.

042

043

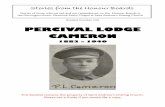

Everette Johnson in the CAMERON exhibition

hall behind a historic AJAX® model.

The Houston, Texas, site of HOERBIGER Corporation of America has collaborated with CAMERON AJAX with field tests. The new ring packs showed consistently successful results at several field locations. The Ferrox ring style is a not a new concept. It has been around for many years, successfully benefiting many other legacy natural gas engines, and it will continue to be a reliable scuff resistant piston ring design for the future.

Quality and PerformanceFor COOPER, quality and performance were the strongest arguments of the marketing strategy, and they have been for CAMERON to this day. “We want to sell value to our customers,” Everette Johnson explained. “Because the HOERBIGER brand is synonymous with reliable and lasting quality, we rely on this value proposition.” For decades, HOERBIGER Corporation of America has been CAMERON’s major provider of valves, rings and packings. Everette Johnson added: “For us, the quality of the product is paramount. And we have always been able to rely on HOERBIGER’s quality.”

More than effective MarketingAnother example of the close collaboration between CAMERON and HOERBIGER is the Reignite™ project. In October 2009, HOERBIGER Engineering Services, Houston, Texas, USA, and CAMERON signed an agreement to jointly market technology that would upgrade aged

integral gas engine compressors using CAMERON’s distribution channels. “This was far more than a joint marketing initiative,” Everette Johnson reported. “We were convinced that together we would succeed in engineering an outstanding product for legacy compressors.” The Reignite™ project focuses on the immense COOPERBESSEMER® integral engine compressors. The majority of these compressors have been in operation for decades.

cooPer-BeSSeMer®— the heavyweightCOOPER introduced the first design principle for this heavy machinery in 1909, which combines the drive and compressor in one machine. The basic idea was given a major boost in 1929, when COOPER acquired Bessemer Gas Engine Company founded in 1899 by Edwin J. Fithian and John Carruthers in Grove City, Pennsylvania. Based on the knowhow of both companies —not without reason was the acquisition of Bessemer later referred to as a “history merger”— COOPER continued to develop the compressor. The result was a machine in which the vertically mounted cylinders of the engine acted on the horizontally mounted cylinders of the compressor via the common crankshaft.

The first COOPERBESSEMER® integral gas engine compressor was shipped in 1938 and put to work on a pipeline. The Varrangement of the

eVerette JohnSonDirector of engineering

cAMeron internAtionAl corporAtion

Interested in all things mechanical at a

young age, Everette Johnson did his

Mechanical Engineering basic training at

Purdue University. After that he went on for

brief stints involving Research and

Development at Schwitzer (automotive

turbocharger manufacturer), then on to

Detroit Diesel and to Cummins Engine Com

pany, before landing in Mount Vernon, Ohio,

in 1975, where he worked with some indus

try legends such as Mel Helmich, John

Konkler and Norm Shade, at COOPER

BESSEMER ENGINE COMPANy. In his

early years with COOPER, Everette Johnson

worked in both Rotating Products and in

Reciprocating Products, with the bulk of his

career spent working on Turbochargers as

applied to Large Bore Two Stroke Engines.

In 1999, Johnson went to work with the

Centrifugal Compressor group which was

purchased by RollsRoyce and so he ended

up in the UK as Director of Europe, Africa

and the Middle East. Upon his return in

2003, he found his way back to CAMERON

where he works today as the Director of

Engineering for the Process Systems and

Reciprocating Compression team.

“The supply of energy in ChiCago is primarily based on gas. They use Cooper-bessemer® Compressors, whiCh in some Cases have been in operaTion for more Than 70 years. have you ever read in The paper ThaT The gas supply in ChiCago wenT down? reliabiliTy, availabiliTy and preser-vaTion of value. ThaT’s whaT maTTers in our busi-ness. and we, aT Cameron, vouCh for ThaT.” everette Johnson

Thanks to the jointly developed ReigniteTM

solution, legacy COOPER-BESSEMER® integral

engine compressors satisfy the latest stringent

environmental standards—a sustainable

investment instead of a new purchase.

044

045

drive and compressor generated an increase in power of 38 percent, which was revolutionary at the time. Because of its design, the new compressor’s outward appearance was more reminiscent of a marine diesel engine than the reciprocating compressors customary until then. The dimensions and weight of the COOPERBESSEMER® integral engine compressors necessitated a special infrastructure. For the operators, purchasing the compressor and providing the infrastructure to support it were associated with a capitalintensive investment. The interest among current owners in the continued and longest possible use of these reliable machines is accordingly high. However, this will only be possible if the engines continue to satisfy all emissions guidelines. “This was a challenge for us all,” reported Everette Johnson. Because Reignite™ was intended to optimize existing compressors, no modifications were allowed in terms of the basic design. With the support of HOERBIGER Engineering Services, CAMERON optimized the positions of the injection valves at the combustion chamber. HOERBIGER supplied a newly developed gas injector and an innovative ignition system, the Electronic PreChamber Control System (ePCC).

The results of the collaboration were far better than anticipated. Machines retrofitted with the Reignite™ package safely meet even the most stringent environmental standards. Relative to

performance, the investment that is required from the operator is no more than 25 percent of the amount that a new machine would cost. Everette Johnson added: “Together, we managed to convince our customers that the investment in reconditioning a legacy compressor creates new value—and additionally, an exceptionally reliable machine.”

ambivalent ProspectsEverette Johnson is concerned about the economic environment of the traditional gas industry. “By continually advancing our technology, we offer the best conditions for optimizing the value added in our markets.” The problem is the pressure on the price of natural gas: “The low gas prices will be one of the biggest challenges in the years to come for us all.” To a significant extent, this can be attributed to the global availability of shale gas now being within reach. While problems related to the production of shale gas are far from being resolved, the sector is investing in this type of natural gas. This contrasts with reduced or deferred investments in traditional technology as a result of the lower gas prices. For those who, like CAMERON, are active both in the conventional gas business and in shale gas, the “Golden Age of Gas” definitely offers development opportunities. Everette Johnson added: “People will rely more heavily on natural gas than in the past as the primary resource for energy generation. This will benefit us, even if the intensity with which the new gas fields are developed will initially still suffer from the general economic conditions.”

Everette Johnson has been rooted in the oil and gas industry for decades. And he’s a realist. He knows that the development of new oil and gas

fields as well as the installation of the necessary infrastructure will be among the greatest challenges for the economical use of the newly uncovered natural gas resources. Moreover, he also sees the changes on the global gas market through the eyes of an engineer: “The gas we have delivered until now was dry gas.” Shale gas, in contrast, is wet gas. Adapting the existing compressor technology to the requirements of the wet gas will require development expenditure that is not to be underestimated.

reorganization of the gas IndustryNorth America, CAMERON’s home market, is rich in shale gas deposits. Nonetheless, the distribution of shale gas formations will result in a reorganization of the gas industry worldwide. CAMERON has already laid the groundwork for this trend. “Longterm, we have geared up for the new situation and searched intensively for business models that matched our portfolio and would allow the use of shale gas. The economical use of shale gas will start in North America and Europe,” Johnson stated. “However, we must also develop products for India and China in equal measure—with different performance levels, both for gas extraction and gas distribution.” When it comes to the development of these new compressors, CAMERON relies on the expertise the company has acquired over the decades with the highspeed compressors from the SUPERIOR® portfolio.

A cross-sectional view of the COOPER-BESSEMER®

W-330C3: the engine and compressor are driven

on the same crankshaft.

Part

For decades, HOERBIGER has supplied CAMERON In-

ternational Corporation with state-of-the-art com-

pressor components. For the high-speed couple-free

compressor, CAMERON’s latest development,

HOERBIGER adapted the innovative CP valve. The CP

valve is marked by high efficiency and strength.

Its core is the aerodynamically profiled valve

plate made of a carbon-fiber-reinforced

plastic material developed by HOERBIGER’s

research. It assures low maintenance costs

and a long service life.

www.hoerbiger.com

Part ofWith a production volume of approximately 650 billion cubic

meters and domestic consumption of approximately 680 bil-

lion cubic meters of natural gas (2011 and 2010 figures), the

United States of America is one of the largest natural gas na-

tions in the world. COOPER, now CAMERON, has supported

the evolution of the gas industry in the USA since the close of

the 19th century. Some of the legacy machines have been in

use reliably for more than 100 years. CAMERON vouches that

both these tried and tested machines, as well as the new

compressors being built today, will be a sustainable invest-

ment for their operators. Because of continuous innovation

and modernization of the technical design, CAMERON

compressors are considered leading technology to this day.

Innovative solutions for the upgrade of legacy machines

preserve the value of the financial investment.

www.c-a-m.com

PartnerShIPHOERBIGER is a premium supplier of the major CAMERON

compressor brands: COOPER-BESSEMER®, AJAX® and

SUPERIOR®. When it comes to valves and packing and sealing

rings, HOERBIGER has repeatedly contributed to the refine-

ment of proven compressors by offering new technical

designs and innovative materials. CAMERON and HOERBIGER

Engineering Services, Houston, Texas, USA, have collabo-

rated since 2005 on the upgrade of COOPER-BESSEMER®

integral engine compressors. Since 2009, CAMERON and

HOERBIGER have jointly marketed the Reignite™ brand—

technology that significantly boosts the efficiency, flexibility

and reliability of integrals. The costs for upgrading integrals

are approximately 25 percent of the investment that would

be required for a new compressor with comparable power.

In addition to the low-speed models from the AJAX® series,

CAMERON’s portfolio offers high-speed compressors under the

SUPERIOR® brand. More than 10,000 of these compressors

have been produced so far.

046

047

being incorporated in the development of new compressors for the global market. The most recent development is a highspeed couplefree compressor, for which prototypes are presently manufactured at the Houston, Texas, site in the United States. In the future, these compressors will be manufactured in Houston and a new plant in Gaomi, was recently completed in the eastern Chinese province of Shandong, China. “China is a great opportunity for CAMERON,” Everette Johnson explained. “We are convinced that, in the future, China, will play a significant role for the gas industry.” HOERBIGER Corporation of America not only supported the development of the couplefree series from the very start, but also assured the technology transfer to China. The valves, rings and packings for the couplefree compressors that CAMERON will produce in China will be supplied by HOERBIGER Shanghai Co. Ltd., one of the most modern production plants in the HOERBIGER Group. The technical specifications will exactly reflect the design developed between HOERBIGER and CAMERON in the USA, as guaranteed by HOERBIGER’s global quality standards.

the global Player“We engineer a new couplefree compressor primarily with shale gas applications in mind, which place high demands on the machine,” Everette Johnson expounded. This included the valves and packings as much as the life span of the cylinders. An important aspect that had to be taken into account was the wide range of pressure fluctuations that occurs during the production of shale gas. Everette Johnson commented: “We were looking for a partner that can help us solve these problems: HOERBIGER was there for us immediately.” Under comparable requirements, HOERBIGER has already collected excellent experience in pilot applications with the newly developed CP valve. The overall design, and notably the aerodynamically profiled valve plate made of carbonfiberreinforced polymer material, are compelling, especially with respect to pressure resistance. The application developers of HOERBIGER Corporation of

Superior compressors are

manufactured in Houston,

Texas, and in a CAMERON’s

newest manufacturing

facility in Gaomi, China.

Critical parts are supplied

by HOERBIGER in the US

and China. The series was

specifically developed for

shale gas applications.

SUPerIor®— the Premier BrandThe history of the SUPERIOR® brand stretches back to a company founded in 1889 by Patrick J. Shouvlin in Springfield, Ohio, USA, which in 1892 became Superior Engine and Compressor Company. In addition to building compressors with outputs of 20 to 100 horsepower, in the years that ensued the business was primarily engaged in the production of diesel engines. In 1928, the company was acquired by its strongest distribution partner, National Supply Company, Pittsburgh, Pennsylvania, USA, which was founded in 1894. The new owner focused on the manufacture of engines. The compressor business, on the other hand, was sold to AJAX

Iron Works in 1945. In 1955, National Supply also divested the Diesel Division, selling it to White Motor Company in Cleveland, Ohio.

White Motor Company recognized the synergies that engines and compressors had to offer. It reactivated the knowhow that the company had acquired and at the beginning of the 1960s began to develop highspeed compressors for the rapidly growing natural gas industry in North America. Enjoying a long tradition, the SUPERIOR® brand was used from then on to offer compressors—either turbine or motordriven—ranging from 400 to 2,600 horsepower. After having been reorganized for the compressor business in 1965, White Superior Division was faced with financial difficulties around the mid1970s. COOPER Industries recognized the opportunity of becoming active in the growing highspeed compressor market by way of acquisition. In 1976, the year when the company for the first time surpassed the magic half billion dollar mark, COOPER Industries was ultimately able to take over the SUPERIOR® portfolio as a result of the acquisition of the White Superior Division.

Production in chinaCOOPER/CAMERON have since produced more than 10,000 SUPERIOR® compressors with outputs as high as 9,000 horsepower. The experience that CAMERON collected as a result is now

America designed a new variant of the CP valve for the new compressors. The valves have undergone rigorous testing since the end of 2012 in light of the upcoming series production.

Over the course of 2012, CAMERON and HOERBIGER together overcame the last technical hurdle of the new compressor series. “Shale gas not only has a wide variety of BTU values, but depending on the reservoir, some of it contains extremely corrosive elements,” Everette Johnson explained. To solve the problem, CAMERON developed a special inside coating for the cylinders—and HOERBIGER contributed the matching piston rings. “Our goal is to achieve more than 50,000 hours of service without maintenance as a result of the coating piston ring combination,” said Johnson.

global Partnership“CAMERON sees itself as a solutions provider from the source to the end user,” Everette Johnson continued. The company considers longstanding and reliable partners that can guarantee global quality standards an indispensable asset in its efforts to live up to this performance claim. In addition to offering proven concepts and products, for the future it is also vitally important to continually explore new solutions. The objective: to make the best even better. “We need companies that continue to invest in the oil and gas industry, in new products that offer high value for OEMs and their customers.” HOERBIGER is that kind of a partner—and has been for decades. So there is only one concern left for Everette Johnson, the experienced chief developer at CAMERON: the “Silver Tsunami.” “Our sector is facing a generational change,” he explained. “The majority of us will retire soon, and we barely have enough experienced junior professionals.” HOERBIGER was able to score points yet again: “HOERBIGER has experienced research and development employees and the right talent around the world to meet our expectations in the future.”