C t ff ti i tCost effective, environment-fi dlfriendly ...€¦ · C t ff ti i tCost effective,...

Transcript of C t ff ti i tCost effective, environment-fi dlfriendly ...€¦ · C t ff ti i tCost effective,...

DELNORTH I dDELNORTH Introduces:

A G l ®ArmorGalv®

Thermal Diffusion Galvanizing.C t ff ti i t f i dlCost effective, environment-friendly

corrosion protection pRoHS compliant

Winner of EPA ‘S (NPPR) 2006 MVP2

ASTM - A1059 A/M( )

Award (Most Valuable Pollution Prevention)1

What is ArmorGalv®

Thermal Diffusion Galvanizing?ArmorGalv® is the trade name for aArmorGalv is the trade name for a technology developed by the DistekGroup in 1993 It is a method of applyingGroup in 1993. It is a method of applying a uniform, sacrificial, zinc- iron or zinc-aluminum alloy coating using aaluminum alloy coating using a metallurgical vapor diffusion process.A G l ® b li d f tArmorGalv® can be applied on many surface types:

Powder Metal Steel Stainless Steel Castings& Forgings 2

Structure of ArmorGalv® coatingStructure of ArmorGalv coating

®ArmorGalv® forms multiple layers of zinc‐iron alloy, from asuper corrosion resistant gamma layer to a compact deltalayer and then the zeta layer– like an onion with each layerlayer and then the zeta layer– like an onion, with each layerharder and more corrosion resistant than the previous one.

3

Characteristics of ArmorGalv®Coatingg• The ArmorGalv® zinc iron alloy coating is sacrificial,

providing Galvanic protection to the steel parts.

• The coating is hard non magnetic weldable and spark free

• It is highly corrosion and abrasion resistant.

• It is chip proof and amenable to crimping bending andf i

• The coating is hard, non magnetic, weldable and spark free.

forming.

• It has very good anti‐galling properties and low co‐efficient offriction It is a replacement for CADMIUMfriction. It is a replacement for CADMIUM.

• Highly heat resistant ‐ working temp. to 12000F (6500C)

• Excellent substrate for paint, e‐coat and over‐molding withrubber or plastic

ll d h l f• Totally non‐toxic and heavy metal free – RoHScompliant 4

ArmorGalv® at the Dead Sea!North Sea 35 g/l salinityDead Sea 350 g/l salinity

Badly CorrodedNo Corrosion Badly Corroded

2 mils of Hot‐Dip Galvanized bolts after 3 years in the aggressive Dead

1 mil of ArmorGalv® after 3 years in the aggressive Dead Sea atmosphere.

Sea atmosphere. Fasteners are corroded to base metal.

Please note white salt encrustation. Fasteners still have original gray color

5

Some actual test resultsBoth tests are being run at a certified A2LA laboratory at Chemplate Industries. Tests are still under way as of July.01.2009 d ill i f iand still no signs of corrosion.

6

ArmorGalv® coating is particularly interesting for fasteners and other complex parts with internal threads

• Below is a picture of a fastener with a captive washer and aBelow is a picture of a fastener with a captive washer and a Rivnut that were coated by ArmorGalv® .

• Notice that the Thermal Diffusion coating is extremely uniform, obviating the need to designate portions of a fastener as “i i ifi t” Th ENTIRE f t i i ifi t d t d!“insignificant”. The ENTIRE fastener is significant – and coated! Salt spray results of greater than 1,000 hours are common.

7

ArmorPlex®:Thermal Diffusion + Paint

ArmorGalv® surface is not smooth like that ofelectroplated zinc (or hot dip galvanized), but is rather“geographic”, as illustrated in the photo below.

ArmorGalv® surface Electro-plated Zinc surfaceArmorGalv surface Electro plated Zinc surfaceThe ArmorGalv® surface results in superior adhesion of any topcoat. The smooth surface of electro‐plating requires variouspreparations such a chromating and primers to provide basicadhesion of paint. 8

ArmorGalv® & Powdered Metal

ArmorGalv® is particularly effective for coating parts

ArmorGalv & Powdered MetalNo Pre‐Impregnation Required

ArmorGalv® is particularly effective for coating partsmade of powdered metal, castings, forgings, and alsoassembliesassemblies.

Before ArmorGalv® 50 microns of ArmorGalv®

Note how the voids are filled10

Increase part life by coating With A G l ®

A G ®

ArmorGalv®

ArmorGalv®

Results after 1500 hours in Salt Spray Chamber (45 microns)Electro Galvanized Hot Dipped-Galvanized ArmorGalv®

The service life of ArmorGalv® is higher than that of electro‐plating, mechanical platingg p g, p g

or hot dip galvanizingwhen exposed to industrial &marine atmospheres.

11

Get better performance with®

pArmorGalv®

Coating ThicknessRange(i h)

Corrosion Resistance

ThicknessUniformity

HydrogenEmbritl

RecessFill

TopCoatdh i

WeldAble?

AntiGalling

Heat Resist

AbrasionResist

Hard?

(inch) tlment Adhesion ance ance

Hot Dip 0.001‐0.002

Moderate Poor Yes Yes VeryPoor

No No low Poor No

Mechanical 0.0001‐0.003

Moderate Poor No YesGlassBeads

Poor No No low Poor No

Dip/Spin 0.00075‐ Moderate Poor No Yes Good No No low Very Nop/ p0.001

yPoor

ElectroPlating

0.0001‐0.0005

Moderateto Goodfor Alloys

VeryPoor

Yes No Moderate

No No low Poor No

ArmorGalv®

Thermal Diffusion

0.0005‐0.006

Excellent Excel‐lent No No Excellent Yes Yes Yes to1200F

Excellent

Yes 38/42HRC

ArmorGalv® out‐performs other coating systems in every category,p g y y g y,from lifecycle to uniformity, coating thickness and functionality.

12

How is ArmorGalv® applied?How is ArmorGalv applied?ArmorGalv® is applied bytumbling parts with apatented zinc Powder in acylinder that is very slowlyrotated inside an oven.Process temperatures are6000F to 8500F600 F to 850 F.

ArmorGalv® diffusion occurs when the ArmorGalv®

powder sublimates at low temperature, (below 5000F) penetrating the steel structure to form zinc/iron alloy. p g y

14

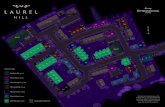

ArmorGalv® plant ‐MDS 450Typical layout 1. Parts loading system

2. Cylinder in loading cradle

45

65

3. Part bin4. Cylinder in ready position5 MDS 450 oven

2

5. MDS 450 oven6. Cylinder in unloading

system

77. Separation vibrator –

excess powder removal 8. Parts polishing and first

1

10 11 11

3

8. Parts polishing and first passivation

9. Parts/media separator10 S d i i /1298 10. Second passivation/top

coating11. Final dryingy g12. Finished parts bin.

15

ArmorGalv® isEnvironment Friendly

The EPA in 2006 conducted an extensiveThe EPA, in 2006, conducted an extensivestudy of ArmorGalv® technology. The EPA

d h h “ hstated that the process “approaches zerodischarge”.

The ArmorGalv® Thermal Diffusion process is the winner of the 2006 Most Valuableis the winner of the 2006 Most Valuable Pollution Prevention Award (MVP2)

16

Some real life numbers from processing 33 million lbs of electroplated parts

Solid waste Wastewater

Solid Zinc

17

ArmorGalv® is not “new”ArmorGalv® is not new

Th f f A G l ®• The forerunner of ArmorGalv®

is called Sherardizing. Invented by a British metallurgist SherardBritish metallurgist Sherard Cowper‐Coles in 1901. It has been used extensively in the UK and Inventor of “Sherardizing”used extensively in the UK and Europe ever since, for high corrosion resistance.

Inventor of SherardizingSherard Cowper- Coles

corrosion resistance.

In Europe, the best known applicator of Sherardizing hasapplicator of Sherardizing has been Bodycote Int’l. For the past five years Bodycote has been a

1916 Sherardizing Plantfive years Bodycote has been a licensee of DiSTeK’s ArmorGalv®

18

SomeSome ArmorGalv® ApplicationsApplicationsSomeSome ArmorGalv ApplicationsApplications

Springs Tempered and Hardened Parts p g p

No Hydrogen EmbrittlementNo Hydrogen Embrittlement No loss of hardness or tensileNo loss of hardness or tensile 19

Some high profile projects, using g p p j , gArmorGalv® coated fasteners and hardware

Hong-Kong new underwater tunnel

Kansai airport – JapanRoof pivot pins

25

Mining roof support hingeMining roof support hingepins – a standard Application in Great BritainSome other current applications:Some other current applications:• North Sea Oil rigs – Fasteners• German railway – rail fasteners and

hardwarehardware• The tunnel channel

Barcelona fish sculpture. 200 tons of ArmorGalv® coated

26

tons of ArmorGalv® coated Fasteners hold it together.

f A G l ®Cost of ArmorGalv®

A G l ® i i iArmorGalv® is cost competitive with high corrosion resistant alloywith high corrosion resistant alloy plating and hot dip galvanizing.

ArmorGalv® cost of thickness application is not linear as with zinc electroplating Higher coatingzinc electroplating. Higher coating thickness only reflects material ycost. 27

Where can ArmorGalv® fit in militaryWhere can ArmorGalv fit in military applications?

ArmorGalv® offers a unique combination of properties thatmake it suitable for numerous applications in army navy andi f It idair‐force. It can provide:‐ Replacement for Cadmium and other toxic coatings,

wherever they are used for corrosion protection andwherever they are used for corrosion protection andto prevent galling.

‐ Corrosion and wear protection for fasteners in allCorrosion and wear protection for fasteners in allareas.

‐ Combination of corrosion protection and low frictionpsurface for hinge pins, pivoting shafts, tank tread pinsetc.

‐ Protection for ship‐board hardware such as tie‐downchains, lifting rigs tensioners etc. 28

‐ Protect structural elements, particularly for marine i idi l l i Aenvironments, providing long lasting structures. A

system can be developed for building modular steel t t t t d b ArmorGal ® d th b lt dstructures, protected by ArmorGalv® and then bolted together. Such structures could offer a cost effective building system which has a very long life cycle lowbuilding system which has a very long life cycle, low maintenance cost and great shelf life for structures that are stored and then shipped overseas to be assembled.are stored and then shipped overseas to be assembled.

ArmorPlex® is a duplex system, involving special paints or barrier type coating applied over ArmorGalv®. This type of coating is used extensively in the off shore oil fields for extreme conditions and can serve well for all high performance marine systems.

29

ArmorGalv® Testing/Approvals

Standards• ASTM A 1059 A/M

ArmorGalv Testing/Approvals

Tests• ASTM A‐1059 A/M

• ASTM A641‐98

•Dade county PA114 Appendix E Sec. 2 (ASTM G85/A5) – ACQ Lumber•DIN 50021 and DIN 50018

• ASTM A‐123

• ASTM A‐153

•South Africa EDS evaluation•Michigan State University‐ ACQ Test

US E i t l P t ti A (US EPA)• ASTM A‐153

• European Community Standard‐BS EN 13811:2003

•US Environmental Protection Agency (US EPA), USA‐B117•Siemens Laboratories, Germany

D d C i I i G

• Israeli Standard‐4271 Road barriers and infrastructure.

•Dresden Corrosion Institute, Germany•Brussels Metallurgical Laboratory, Belgium

•Russian Machine Building Laboratory l•Israel Standard Institute

•Swedish National Institute of Testing •National Product Development Centre SA

30

ArmorGalv®ArmorGalv

DELNORTH PTY LTD26 Firebrick Dr.Thornton NSW 2322AUSTRALIA

Contact:

Wayne SharmanPh 02 4028 6760Ph: 02 4028 6760Fax: 02 4028 6759E-mail [email protected]

31