Buss plan(1)

-

Upload

amrita-jha -

Category

Documents

-

view

222 -

download

0

Transcript of Buss plan(1)

-

8/7/2019 Buss plan(1)

1/19

READY MADE GARMENTS

Page 1

A A S S S S I I G G N N M M E E N N T T T T H H E E M M E E ::

D D E E T T A A I I L L E E D D P P R R OO J J E E C C T T R R E E P P OO R R T T ( ( D D P P R R ) )

R R E E A A D D Y Y M M A A D D E E G G A A R R M M E E N N T T S S ( ( R R M M G G ) )

S S U U B B M M I I T T T T E E D D B B Y Y ::

G G ee ee t t aa B B .. ( ( 5 5 ) )

A A mm r r ii t t aa J J ( ( 2 2 3 3 ) )

J J yy oo t t ss nn aa N N ( ( 3 3 88 ) )

M M aa nn ii ss hh V V ( ( 5 5 7 7 ) )

K K aa vv ii t t aa T T ( ( 5 5 5 5 ) )

S S U U B B M M I I T T T T E E D D T T OO ::

P P r r oo f f .. B B hh aa vv nn aa mm aa mm

S S U U B B M M I I S S S S I I OO N N D D A A T T E E ::

1 166 t t hh M M aa r r cc hh ,, 2 2 0 0 11 11

-

8/7/2019 Buss plan(1)

2/19

READY MADE GARMENTS

Page 2

DD EE TT AA II LL EE DD PP R R OO JJ EE CC TT R R EE PP OO R R TT

-- GG EE NN TT SS R R EE AA DD YY MM AA DD EE GG AA R R MM EE NN TT SS

II NN TT R R OO DDUU CC TT II OO NN::

Readymade garment industry has occupied a unique place in the industrial scenario of our

country by generating substantial export earnings and creating lot of employment. Its

contribution to industrial production, employment and export earnings is very significant.

This industry provides one of the basic necessities of life. The employment provided by it is a

source of livelihood for millions of people. It also provides maximum employment with

minimum capital investment. Since this industry is highly labour-intensive, it is ideally suited

to Indian condition. This project report is prepared for the manufacture of gents shirts, gents

trousers as they find wide acceptance in local and international markets. Such establishments

can be easily set up by any person having the knowledge of cutting and stitching operations.

MM AA R R K K EE TT PP OO TT EE NN TT II AALL ::

Readymade garments are the choice of urban people. It is also gaining wider acceptance in

semi urban and rural areas. The huge charges made by tailors and delay in delivery have

made people to switch over to readymade garments. In domestic market and export market, it

has made spectacular progress in the last decade. This industry is becoming very vibrant and

lot of foreign investment pouring in this industry because of low risk and high earning nature

of this industry. As these products are fashion oriented, entrepreneurs should always keep in

mind the changing fashion styles. Considering its advantageous position, it is assumed that

there will be no constraint in marketing of gents readymade garments.

-

8/7/2019 Buss plan(1)

3/19

READY MADE GARMENTS

Page 3

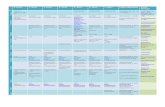

SSII TT EE II NN VV EE SSTT II GG AA TT II OO NN BBAA NN GG AA LL OO R R EE

R R EE AA DDYY MM AADD EE GG AAR R MM EE NNTT SS IINN DD UUSSTT R R YY IINN PP EE R R SSPP EE CC TT II VV EE

AANN DD II TT SS PP R R EE SSEE NN TT SSCC EE NNAA R R IIOO II NN TT HH EE SSTT AA TT EE .. The garment industries in the State are concentrated in Bangalore where some of the largest

export houses of the country are existing. Today overseas buyers view Bangalore as an

important location for sourcing of garments after Bombay and Delhi. Brand images are being

felt in this region and there is a great potential for production of value added goods. Ready

made garment industries are also concentrated in Bellary district. The units in Bellary are

specialized in manufacture of jeans and other leg wears for men. The next place of

concentration of this industry is Shimoga district followed by Dharwad district as per the

information furnished by the Directorate of Industries and Commerce. There is also a

concentration of hosiery industry in Belgaum. The district wise distribution of registered

readymade garment units in SSI sector in the State is given below:

-

8/7/2019 Buss plan(1)

4/19

READY MADE GARMENTS

Page 4

(Source: Directorate of Industries and Commerce, Govt. of Karnataka, Bangalore)

Field studies have showed that there are approximately 40,000 readymade garment-

manufacturing units in India. Around three five million people are working in the industry.

Many leading world fashion labels are being associated with Indian products. India is being

looked upon as a major supplier of high quality fashion apparels, which are being appreciated

in major international markets. The credit for this goes to our garment exporters. However,

till today our clothing industry is dominated by subcontracting and consists mainly of small

units with a few machines of medium quality, relatively high fashion, but small volume

business. Thus the need of the hour is to enlarge both manufacturing as well as the marketing

base. Tapping new markets especially Central Africa CIS, East European Countries, Latin

America, Australia and I South Africa is also essential for growth and development of Indian

garment industry.

-

8/7/2019 Buss plan(1)

5/19

READY MADE GARMENTS

Page 5

DDEE SSCC R R II PP TT II OO NN OO FF TT HH EE CC LL UU SSTT EE R R

Garment industries in Bangalore started from the period of British. M/s. Bangalore

dressmaking Co. was the first unit, started to manufacture garment in Bangalore during 1940,

which was started by Mr. Vittal Rao. During the rule of British, there was a need of clothing

dress materials. This led to the development of R.M.G industries in Bangalore. Apart from

RMG industries, there were silk weaving industries in Bangalore, which led to the

development of silk exporters also. After Indias independence in 1947, the industries started

picking up slowly to cater the needs of dresses of the common man and local market. The

industry started flourishing. Most of RMG industries are concentrated in Bommanahalli and

Peenya industrial estate. After the dereservation of garments, big players like Mafthlal,

Aravind Mills, etc. started entering the field and occupied places in the sector which

indirectly effected the small scale sector. There are about 2500 RMG units in and around

Bangalore. Most of the buying agencies in the world have established their branch office in

the city. Apart from this, Apparel Park, at Doddaballapur has started functioning in a big

way. Some of the leading exporters like Gokaldas Images, Raymond, Pooja garments, have

already taken the plot for their units in the apparel park. There are 28 garment units including

processing industries have taken the plots. This has contributed in a big way to the

development of clusters of RMG industry. In India, RMG units are concentrated in the cities

like Delhi, Mumbai, Kolkotta, Bangalore, Chennai, Jaipur, Tirupur, Ludhiana. There is a

different in the end products manufactured at Bangalore and other places. RMG are mainly

made for export house. There are many SSI units mainly doing job work providing supports

to the SME like GE, Aravind fashion, Sonal Holding, Texport Syndicate units in the cluster.

The technology and manufacturing process are same as used in other regions.

-

8/7/2019 Buss plan(1)

6/19

READY MADE GARMENTS

Page 6

BBR R OO AADD PP R R OO DD UU CC TT GG R R OO UU PP II NNGG

In Bangalore, garment units are mainly concentrated in the following area

1. Bommanahalli

2. Bommasandra

3. Peenya

4. Yeswanthpur

5. Rajajinagar Indl Estate and Industrial town

PP rr oodd uu cc tt ss:: --

LL aa dd iieess

i. Jacket

ii. Blouses

iii. Chooridar

iv. Petticoats

GG eenn tt ss::

i. Trousers

ii. Shirts

iii. Coatsiv. T Shirts

RMG units in Bangalore are mainly manufacturing ladies/gents dresses, kids

sweaters are normally received from other cities like Kolkotta, Delhi, Indoor etc.

-

8/7/2019 Buss plan(1)

7/19

READY MADE GARMENTS

Page 7

CC UU R R R R EE NN TT OO UU TT PP UUTT

There has been increase in the number of RMG units in Bangalore since 1990. At present

there are about 800 active readymade garment manufacturers and exporters, still number is

likely to increase as per the reports of apparel park at Doddaballapur, near to Bangalore.

Karnataka Industrial Area Development Board is in the process of acquiring SISI Bangalore 8

the lands for the further expansion of the park. There are about 1600 fabricators who are

doing job work for these exporters, apart from domestic market needs. There are 50

embroidery units who are supporting these units for value addition. As per the reports

received from AEPC, total export upto December was around Rs.3050 Crores.

Total output from this cluster is about 3500 crores of which about 3000 crores are exported

and rest are consumed in the domestic market. Broad sub grouping of the products is as

follows:

1. Readymade garments for Gents, : 60%

2. RMG for ladies : 30%

3. RMG for kids : 10%

-

8/7/2019 Buss plan(1)

8/19

READY MADE GARMENTS

Page 8

FF AA CC TT OO R R SS II NN CC OO NNSSII DDEE R R AA TT II OO NN

GG eeooggrr aa pp hh iiccaa ll II nn dd iiccaa tt iioonn

Development of RMG units in Bangalore was started in the year 1970 onwards by leadingexporters like Gokaldas export, Ashoka export, Gokadas Images, continental exports, Leela

Fashions etc. Later, small industries (fabricators) were started by taking the orders from large

scale. Most important reasons for developments of RMG is the availability and sourcing of

export fabrics from places like Salem, Erode, Coimbatore which are nearest to Bangalore

(About 5 to 7 hours journey). The other reasons, which contributed for the development of

industries, are also as follows:

AA vvaa iillaa bb iilliitt yy oof f sspp aa ccee:- Space is no bar around Bangalore for the development of

industries. There are 10 industrial estate developed by KSSIDC. KIADB is also providing the

necessary support by giving plots to the industries for construction. Apart from this there are

private industrial estates, which are supporting the growth of industries, and further garment

complex has been constructed at Rajajinagar exclusively for garment industries. Land and

sheds are available in Bommanahalli and in and around peenya.

AA vvaa iillaa bb iilliitt yy oof f rr aa ww mm aa tt eerr iiaa ll :: - Fabrics, which are required for these industries are

available from Salem, Erode, Chennai, Mumbai, and Ahmedabad and also from local

suppliers (Agents). There is no problem in this area, which is helping the industries in a SISI

Bangalore great way. There is no weaving or spinning mills in and around Bangalore. Hence

all the exporters are sourcing fabrics from other places, as said above.

SS k k iilllleedd llaa bb oouu rr : - Low-income group of family adopted tailoring as the main source of

income for their livelihood. Tailors were abundantly available in the city. Some of the leading

training institutes also helped in this area by contributing (trained) skilled labours. This is themain factor that led to growth of this industry. But recently during the visits it is found that

there is severe scarcity of skilled labours and machine operators, which has effected

production schedule heavily. This has to be taken up very urgently to avoid the cancellation

of export orders as suggested by the units.

-

8/7/2019 Buss plan(1)

9/19

READY MADE GARMENTS

Page 9

EE xxiisstt eenn ccee oof f aa iirr pp oorr tt //ccaa rr ggoo ccoonn tt aa iinn eerr dd eepp oott //iinn f f rr aa sstt rr uu cc tt uu rr ee:: --

Bangalore being the Silicon valley of India have all the facilities of handling passengers and

presence of cargo container department further facilitated the growth of the cluster. Presence

of high way NH-4 and 7, ring road connecting the industrial estates, road transportation

within the city facilitated the growth of the industries. One of the most important factors is

the proximity of Chennai Port/international airport to this city. This helped a lot to the

industries for transporting the goods quickly. This has really contributed in flourishing the

export import business not only for RMG Enterprises but also for those involved in other

trades. Union Ministry of state for Road Transports and highways has announced that

construction of four lane elevated expressway between Bangalore and electronic city will be

commenced during current financial year. This will further add support for the exporters for

quick movement of goods. Apart from this international airport is in

progress at Devenahalli, near to Bangalore (30Kms).

FF llee xxiibb llee sspp eecciiaa lliizzaa tt iioonn :: --

The entrepreneurs in the cluster are capable of manufacturing wide range of garments with

different designs, different materials, different sizes etc. Subcontracting arrangements have

made the manufacturing more flexible and specialized. The cluster can handle huge orders.

Most of the buyers in the world have their branch offices in the city. Entrepreneurs can easily

approach them for suggestions and advice. This is most important in terms of time anddelivery.

EE nn tt rr eepp rr ee nn eeuu rr sshh iipp :: --

Bangalore is well known for these enterprises. Since Bangalore is a metropolitan city and no

language barrier. It is also noticed that most of the owners of the garment industries are from

North India. Officers and skilled workers are local and some SISI Bangalore of them are from

neighboring states. Growth of these industries resulted due to weather condition of the city,

which was pleasant and cool. As a result most of the industrialist from North settled in

Bangalore and established RMG units. Apart from these, leading textile mill manufacturers

opened dealers/trader for supplying fabrics like Century Mills, Aravind mills, Nahar mills

etc. All these have contributed for the emergence and growth of RMG clusters in Bangalore.

-

8/7/2019 Buss plan(1)

10/19

READY MADE GARMENTS

Page 10

BB AASS II SS AANNDD PP R R EE SSUU MM PP TT II OO NN SS ((OO VVEE R R AA LL LL PP R R OO JJ EE CC TT ))

1. This project is based on single shift basis and 300 working days in a year.

2. Since this industry is labour intensive, the working efficiency is considered at 75%.

3. Costs of machinery and equipment/material indicated refer to a particular make and

approximately to those prevailing at the time of preparation of this project.

4. Installation and electrification cost is taken @ 10% of cost of machinery and equipment.

5. Non-refundable deposits, project report cost, trial production, security deposits with

Electricity Board are taken under preoperative expenses.

6. Depreciation has been considered:

(a) On Building @ 5%

( b) On plant and machinery @ 10%

(c) On office furniture and fixtures @ 15%(d) On other fixed assets @ 15%.

7. Interest on capital investment has been taken @ 14% per annum.

8. Minimum 25% of total investment is required as margin money.

----------------------------------------------------------------------------------------------------------------

II MM PP LL EE MM EE NN TT AA TT IIOO NN SS CC HH EE DD UULL EE

Implementation period in months for executing

this project in stage-wise is given in the table.

-

8/7/2019 Buss plan(1)

11/19

READY MADE GARMENTS

Page 11

TT EE CC HH NN II CC AA LL AA SSPP EE CC TT SS

PP R R OO CC EE SSSS OO FF MM AA NNUU FF AACC TT UU R R EE ::

The process involves the following steps:

Procurement of Fabric : Dyed/ bleached/printed cotton/synthetic fabrics as per demand are

to be procured from the open market. The fabric will be inspected by laying on the inspection

table against light before cutting so that unevenness in colour/ shade or any other fault, if any

visible in the fabric are eliminated.

Cutting and Stitching : The inspected fabric is placed on the cutting table in layers and

then the different parts of the respective garments are demarked by a chalk as per differentsizes. Cutting is carried out by the cutting machine. Stitching is carried out for individual

portion of the garments by skilled workers with the help of overlock, lock stitch machines

etc.

W ashing, Checking, Pressing and Packing: All garments are charged into washing

machine containing mild detergent and washed for 4 hours in order to remove dirt and stains

acquired during the manufacturing process. After washing, the garments are hydroextracted

to remove excess water and after this, these garments are dried in tumbler dryer. Final

checking is done before pressing and packing on the checking table so that any fault in the

piece may be removed and protruding threads eliminated. The individual pieces are pressed

by steam presses to remove any wrinkle marks and packed in the carton boxes.

-

8/7/2019 Buss plan(1)

12/19

-

8/7/2019 Buss plan(1)

13/19

READY MADE GARMENTS

Page 13

QQ uu aa llii tt yy CC oonn tt rr ooll aa nn dd SStt aa nn dd aa rr dd ss

The quality of garments mainly depends on quality of fabric used. Therefore, care must be

taken while purchasing fabrics to ensure good colour fastness properties, uniformity in shade

etc. Generally garments are made as per customers specification in respect of size, design

and fashion.

MM oott iivvee PP ooww eerr

Total 55.5 HP is required to run this unit at installed capacity.

PP oolllluu tt iioonn CC oonn tt rr ooll

The process of manufacture does not generate pollution. However, entrepreneurs are to

contact State Pollution Control Board for necessary guidance.

EE nn eerr ggyy CC oonn sseerr vvaa tt iioonn

Maximum care should be taken while selecting the machinery and other electrical equipments

so as to ensure minimum power consumption.

-

8/7/2019 Buss plan(1)

14/19

READY MADE GARMENTS

Page 14

FF II NN AA NN CC II AA LL AA SSPP EE CC TT SS

-

8/7/2019 Buss plan(1)

15/19

READY MADE GARMENTS

Page 15

-

8/7/2019 Buss plan(1)

16/19

READY MADE GARMENTS

Page 16

-

8/7/2019 Buss plan(1)

17/19

READY MADE GARMENTS

Page 17

-

8/7/2019 Buss plan(1)

18/19

READY MADE GARMENTS

Page 18

-

8/7/2019 Buss plan(1)

19/19

READY MADE GARMENTS

AA DD DD R R EE SSSS EE SS OO FF MM AACC HH II NN EE R R YY AA NN DD EE QQ UU II PP MM EE NNTT SS UU PP PP LL II EE R R SS

1. M/s. Paras Special Machine Co.

Madhopur Kucha No. 7,

Rohan Road, Ludhiana.

2. M/s. Vijay Sewing (P) Ltd.

17-D, Everest House,

46-C, Chowringhee Road, Kolkata.

3. M/s. Industrial Machines Pvt. Ltd.

1/23 B, Asaf Ali Road, New Delhi-2

4. M/s. Apparel and leather

Techniques Pvt. Ltd.

Kaikondanahalli,Sarjapur Road,

Near Bellaandur Gate, Bangalore-35.

5. M/s. Industrial Sewing Systems

30, Ramakrishna Street, North

Usman Road, T. Nagar, Chennai.

R R AA WW MM AA TT EE R R II AALL SS UU PP PP LL II EE R R SS

1. M/s. Vardhman Threads

Mahavir Spinning Mills Ltd.

Chandigarh Road,

Ludhiana-141001.

2. M/s. Powerloom Cloth

Manufacturing Centre

Erode, Bhiwandi, Mumbai, Surat etc.