burlington Office in Ramsey County, Minnesota · Construction Products Silica fume, also known as...

Transcript of burlington Office in Ramsey County, Minnesota · Construction Products Silica fume, also known as...

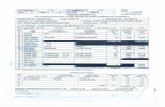

In 2011, Minnesota’s Ramsey County

Regional Railway Authority approved

plans to purchase the head house of

the St. Paul Union Depot (SPUD), as

part of a $250 million effort to return

trains to the city. While SPUD’s scope

of work included carriageway and

tunnel restoration, the bulk of the

work would be completed in the

Southwest parking structure.

In early 2011, RAM Construction

Services of Livonia, Minnesota, was

awarded the contract to rehabilitate

the structure. RAM used hydro-

demolition methods to remove over

30,000 ft2 of deteriorated concrete

and the company’s proposal to

replace the concrete using King

MS-D1 Shotcrete was accepted by the

project engineers.

Using one nozzleman and two

finishers, RAM showed great respect

for the original formwork of this

historical structure, through the use

of a fabricated form-board to ensure

that the repairs would match the

pattern created 80 years earlier.

“The key to a successful shotcrete

repair,” says Richard Maxwell,

RAM’s Director of Operations, “lies

exclusively with your crew, of which

the most important individual is

your nozzleman”. As such, RAM

takes its shotcrete repair projects

seriously, and utilizes the services of

15 ACI Certified Nozzlemen.

The project was completed in early

2013, and will ease parking conges-

tion in and around the refurbished

head house of the St. Paul Union

Depot. The project recently received

the American Shotcrete Association

award for “Outstanding Rehabilitation

and Repair Project” and supports what

city officials hope will become the

Grand Central Station of the Midwest.

Dave Sawyer,Technical Sales Representative, Construction Products

St. Paul Union Depot (SPUD) in Ramsey County, MinnesotaKing anD RaM awaRDeD “OUtStanDing RePaiR anD RehabilitatiOn” PROjeCt at 2013 aMeRiCan ShOtCRete aSSOCiatiOn banqUet in laS VegaS.

Construction Products group

issue 7 | Spring 2013

R&D Update

Jobsite Technical Challenge

The Masonry Corner

The Underground Column

Technical Advances

technical talk - Shotcrete (Continued)

why Silica Fume?

K i n g pac Kag e d

m at e r i a l s c o m pa n y

1-800-461-0566www.kingshotcrete.com [email protected]

burlington Office3385 Harvester Rd.

Burlington (ON) L7N 3N2

Phone: (905) 639-2993

Fax: (905) 333-3730

boisbriand Office3825 rue Alfred-Laliberté

Boisbriand (QC) J7H 1P7

Phone: (450) 430-4104

Fax: (450) 430-6855

brantford Office541 Oak Park Rd.

Brantford (ON) N3T 5L8

Phone: (519) 756-6177

Fax: (519) 756-7490

Sudbury Office644 Simmons Rd.

Dowling (ON) P0M 1R0

Phone: (705) 855-1155

Fax: (705) 855-1122

Matthew CroutchTechnical SaleS RepReSenTaTive

King Packaged Materials Company is pleased to announce that Matthew Croutch has joined the technical sales staff of our Construction Products Group. Matthew will be responsible for the sales and promotion of our construction products to the GTA (Toronto) and Southern Ontario markets.

Shannon Polk SaleS & MaRkeTing cooRdinaToR

King Packaged Materials Company is pleased to announce that Shannon Polk has been appointed to the position of Sales & Marketing Coordinator for the Construction Products Group. Shannon will be responsible for all aspects of the Construction Products marketing program and will also be taking on sales support roles for the Construction and Masonry Products sales team.

liam ireland Technical SaleS RepReSenTaTive

King Packaged Materials Company is pleased to announce that Liam Ireland has joined the technical sales staff of our Construction Products Group. Liam will be responsible for the sales and promotion of our construction products to Eastern Ontario, Quebec, and the Maritime provinces.

annOUnCeMentS

King has begun a phased approach to include social media services in

its marketing strategy. The integration of social networking sites into the

promotional plan for King Construction Products began in October of

2012 with the introduction of a corporate Facebook page, and continued

in January of 2013 with the launch of a company Twitter page. The

division also released a corporate social media policy, to take a proactive

stance toward social media governance on the web.

Shannon Polk, Sales & Marketing Coordinator, Construction Products

Silica fume, also known as Microsilica, is a fine powder collected as a

by-product of silicon alloy production, and has been used in cementitious

materials for over 30 years. Silica fume is used in many of King’s concrete

repair products, as the benefits to using silica fume as a mineral admixture

improve the performance and durability of shotcrete, concrete, mortar

and grout. The main mechanism behind the improved performance, is

the small silica fume particle size (approximately 150 nm or 100X smaller

than a Portland Cement particle) and the pozzolanic nature of the material.

These properties allow the silica fume particles to fit into the interstitial

spaces that exist between individual cement grains, and to form additional

calcium silicate hydrate, which strengthens the cementitious matrix further.

technical talk - Shotcrete

why Silica Fume?

King integrates Social Media into Marketing Mix

Follow Us on Facebook and twitter!

Mixing Strength with Satisfaction

The use of silica fume in cementitious

materials promotes, but is not limited

to, the following benefits:

• Increased compressive and flexural

strength at early and later age

• Reduced permeability to improve

resistance to freeze-thaw cycling,

salt-scaling and sulphate attack

• Reduced permeability to reduce the

ability of carbon dioxide, oxygen,

water and other compounds to

move through the material, which

slows the process of carbonation

and corrosion

• Increased electrical resistivity to

slow the movement of free electrons

and delay corrosion

While the benefits described above

also apply to shotcrete in the

hardened state, silica fume provides

the following benefits to shotcrete in

the plastic state:

• Increased cohesion to allow for

greater build-up thicknesses in both

vertical and overhead application

• Reduced rebound to allow for a

more economical process

• Increased resistance to water

washout

The use of silica fume in King concrete

repair materials also promotes

sustainability, as silica fume is

considered a post-industrial waste

product. Therefore, its use as a

supplementary cementitious material

means that silica fume does not become

waste for a landfill.

William Clements, MASc, EIT Technical Service Representative, Construction Products www.facebook.com/KPMIndustriesLtd www.twitter.com/KPMIndustries

King’s Blainville facility, located just North of Montreal, has been servicing

customers since 1971. In recent years, the quantity of products sold from

the Blainville plant began to outgrow its capacity. So, in the Spring of 2011,

King purchased an existing manufacturing plant in Boisbriand, Quebec, and

enacted plans to turn it into its new production facility.

The new Boisbriand plant opened for business in January, 2013, and is

designed with the most advanced, state-of-the-art production equipment

available. A high capacity, high efficiency, fluid bed dryer will increase

aggregate drying capacity by 600%.

The plant has three production lines controlled by a new, computerized

batching system that is designed to improve accuracy and consistency from

batch to batch.

The new plant is also home to King’s quality control lab and R&D department.

The new lab facility is 500% larger than at the Blainville plant, and houses

the company’s first training facility. All in all, the Boisbriand plant is a

world-class facility that will serve the company well for decades to come.

Mark Lowry,Project Engineer

new boisbriand Plant arrives

Facility will Service Mining and Construction Markets in quebec and the northeast United States.

con

tinu

ed o

n pa

ge 4

KING RE-PUBLISHES

Underground Shotcrete Safety guidelines & Recommendations

There is a key takeaway that applies

to every worksite in every industry;

safety. On most construction sites, the

day cannot begin without a safety

meeting to cover recent events, daily

safety topics, and the notion of taking

safety home. It is important to be

aware of hazards beyond the work-

place and implement safe practices in

our daily lives.

For almost twenty years, King Pack-

aged Materials Company has aided the

shotcrete industry by providing training

and by promoting best practices,

throughout the shotcrete process. To

support this ongoing commitment, King

has developed an Underground Shot-

crete Safety manual to document guide-

lines and recommendations specific to

the shotcrete process. The manual

outlines the topics of proper training,

shotcrete materials, dry and wet-mix

shotcrete operations, as well as the

do’s and don’ts of shotcrete safety.

This manual has already received

positive feedback from site supervisors

and trainers, who have integrated all

or portions of the manual into training

programs. Contact your King Technical

Service Representative, or e-mail

to receive a copy of the Underground

shotcrete safety guidelines &

recommendations.

Craig McDonald, Sales Manager, Mining Markets

It isn’t always easy to write a specifi-

cation for a project from scratch. This

is especially true if the project requires

advanced construction materials such

as shotcrete or self-consolidating con-

crete. The specifier must verify the

applicable standards, as well as codes

and guidelines, and also ensure that he

or she respects the formatting present

in the rest of the document. Finally, the

individual must decide whether or not

they will prescribe a mix design or

performance criterion.

King Packaged Materials Company

is proud to offer shotcrete and self-

consolidating concrete specifications,

based on MasterFormat. The docu-

ments, written in Microsoft Word, can be

easily integrated into project specifica-

tions. This is true, regardless of whether

the specification document was origi-

nally created in Microsoft Word or by

using a specialized, specification-

writing or management software. The

specifications follow state-of-the-art

standards, as well as codes and guide-

lines, including the ACI 506R Guide

to Shotcrete and the ACI 237R Guide

to Self-Consolidating Concrete. The

specifications also take into account

best practices and our company’s

wealth of experience, to ensure project

success and secure a complete under-

standing for all stakeholders.

Of course, the specifications cannot

be used as is, and must be approved

by the project engineer or architect.

Throughout this process, King’s Tech-

nical Service Team is always ready to

help customize and guide your specifi-

cation-writing efforts, Specifications for

the entire King Construction Product

line will be available in the coming

months. So, next time you begin to

write specifications for a project using

a King product, contact one of our

Technical Service Representatives to

aid in the specification-writing process.

Philip Sawoszczuk, Eng. Technical Service Representative,Construction Products

theUnderground Column

the Masonry Corner

technical advances

Macdero Construction, a leading

concrete restoration contractor,

recently completed structural repairs to

the underground parking garage at

111 Gordon Baker Road in Toronto.

The high-rise commercial property is

the Head Office for ING Direct Canada.

A high strength concrete was required

to ensure the structural integrity of the

beams and columns. The congested

reinforcing steel and difficult-to-access

forms meant that the project required

a pumpable, high slump concrete with

flowable properties.

Macdero submitted King’s MS-S6

Self-Consolidating Concrete to the

project consulting engineer, Halsall

Associates, because this product met

both the plastic and hardened

property requirements outlined in the

specification. Surface deterioration of

the concrete was extensive and

resulted in partial depth removal of a

significant portion of the walls,

columns, soffits and overhead

beams, throughout three underground

parking levels. The versatility of King

MS-S6 Self-Consolidating Concrete

allowed Macdero to use one product

for all repair areas throughout the

structure, and resulted in both time

and cost savings.

King supplied technical support on

a number of occasions, and helped

Macdero crews to overcome chal-

lenges related to the placement of

the material.

For almost 30 years, Macdero has been

rehabilitating concrete structures

throughout the GTA. The company has

completed projects this year, using King

MS-S10 Self-Consolidating Concrete,

for deeper formed repairs and King

LM-S10 Concrete for repairs in which

a membrane application is required

24 hours after concrete placement.

Matthew Croutch, Technical Sales Representative, Construction Products

King MS-S6 Self-Consolidating Concrete

Much of the success of our Construc-

tion Products Division can be traced

back to the quality and consistency of

our products. However, before our mix

designs make it into the hands of our

production staff, hundreds of hours are

spent on product development, to en-

sure that the product will perform as

intended and promised.

King Packaged Materials Company has

always recognized the important role

that Research and Development (R&D)

plays in keeping leading companies at

the top of their fields. It can be expensive,

but R&D is a process intended to create

new or improved technology, which

often provides a distinct competitive

advantage. For this reason, we often

find that the higher the Research and

Development budget goes, the more

often we find new and innovative

products in the hands of our customers.

Durable wet and dry shotcrete mixes

that will allow a bridge to be re-

opened hours after placement, high

performance concrete mixes that allow

quicker application of waterproof

membranes, and mortars specially

designed to repair some of North

America’s most cherished heritage

buildings, are just a few examples of

successful products that have resulted

from the efforts of our dedicated

Technical Services team.

Research and Development is often

referred to as an expense. But at

King, we prefer to view it as an invest-

ment, and one that will determine our

future success.

message from Joe Hutter,Vice president of sales

Research & Development Update – an investment in Future Success!

jobsite technical Challenge

the PRODUCt OF ChOiCe FOR the RehabilitatiOn OF ing DiReCt CanaDa’S heaD OFFiCe PaRKing gaRage.

Restoration of quebec City hall

The Quebec City Hall was constructed

in 1896, in the heart of Old Quebec

City. Reflecting the historic character

of the Old Capital, this masonry

building was designated as a “National

Historic Site of Canada” in 1984.

In the Fall of 2010, the architecture

firm, BFH Société d’architecture

(Boudreau, Fortier, & Huot) was

mandated to write a building

specification document that outlined

the restoration of the building, based on

functional integrity. Mainly, the work

consisted of repointing mortar joints,

replacing damaged limestone, and

consolidating voids in the masonry

system. The work was contracted out to

Rainville et Frères, a masonry contractor

that specializes in masonry restoration.

The first phase of construction began in

the Spring of 2011.

To preserve the distinctive character

of the building, different mortar

samples were collected at the

beginning of the project, by a King

Technical Representative. Four colours

of mortar were reproduced in a

laboratory and submitted to the

architectural firm for approval.

A mortar, composed of a combination

of Portland Cement and hydrated

lime, was used on this project. New

masonry elements were installed

using King 1-1-6 Mortar (Type N).

King MasonCare 300 Mortar (Type O)

was used to repoint joints to a depth

of 25 mm (1 inch). The voids in the

walls were gravity-injected using King

HL-5 Grout, a natural hydraulic lime,

injection grout.

The second phase of construction was

completed in November of 2012. The

total budget for the work completed

was approximately $2.4 million.

King’s masonry products division is

proud to have participated in the

restoration of this historic building.

Martin Bissonnette, Technical Sales Representative, Masonry Products

“MS-S6 SELF-CONSOLIDATING CONCRETE HAS GREAT PUMPABILITy, HIGH STRENGTH, AND A SUPERIOR FINISH, WHICH KEPT US ON SCHEDULE THROUGHOUT THE PROJECT. KING REPRESENTATIvES ALWAyS HANDLE PROJECTS IN A vERy PROFESSIONAL MANNER, AND MONITOR ALL CONCRETE PHASES. I APPLAUD ALL OF KING’S STAFF FOR THEIR DILIGENCE.”

-Tony Porciello, Project Manager

Specifying Made easy for Shotcrete & Self-Consolidating ConcreteCONTACT yOUR KING TECHNICAL SERvICE REPRESENTATIvE FOR yOUR SPECIFICATION-WRITING NEEDS

KING RE-PUBLISHES

Underground Shotcrete Safety guidelines & Recommendations

There is a key takeaway that applies

to every worksite in every industry;

safety. On most construction sites, the

day cannot begin without a safety

meeting to cover recent events, daily

safety topics, and the notion of taking

safety home. It is important to be

aware of hazards beyond the work-

place and implement safe practices in

our daily lives.

For almost twenty years, King Pack-

aged Materials Company has aided the

shotcrete industry by providing training

and by promoting best practices,

throughout the shotcrete process. To

support this ongoing commitment, King

has developed an Underground Shot-

crete Safety manual to document guide-

lines and recommendations specific to

the shotcrete process. The manual

outlines the topics of proper training,

shotcrete materials, dry and wet-mix

shotcrete operations, as well as the

do’s and don’ts of shotcrete safety.

This manual has already received

positive feedback from site supervisors

and trainers, who have integrated all

or portions of the manual into training

programs. Contact your King Technical

Service Representative, or e-mail

to receive a copy of the Underground

shotcrete safety guidelines &

recommendations.

Craig McDonald, Sales Manager, Mining Markets

It isn’t always easy to write a specifi-

cation for a project from scratch. This

is especially true if the project requires

advanced construction materials such

as shotcrete or self-consolidating con-

crete. The specifier must verify the

applicable standards, as well as codes

and guidelines, and also ensure that he

or she respects the formatting present

in the rest of the document. Finally, the

individual must decide whether or not

they will prescribe a mix design or

performance criterion.

King Packaged Materials Company

is proud to offer shotcrete and self-

consolidating concrete specifications,

based on MasterFormat. The docu-

ments, written in Microsoft Word, can be

easily integrated into project specifica-

tions. This is true, regardless of whether

the specification document was origi-

nally created in Microsoft Word or by

using a specialized, specification-

writing or management software. The

specifications follow state-of-the-art

standards, as well as codes and guide-

lines, including the ACI 506R Guide

to Shotcrete and the ACI 237R Guide

to Self-Consolidating Concrete. The

specifications also take into account

best practices and our company’s

wealth of experience, to ensure project

success and secure a complete under-

standing for all stakeholders.

Of course, the specifications cannot

be used as is, and must be approved

by the project engineer or architect.

Throughout this process, King’s Tech-

nical Service Team is always ready to

help customize and guide your specifi-

cation-writing efforts, Specifications for

the entire King Construction Product

line will be available in the coming

months. So, next time you begin to

write specifications for a project using

a King product, contact one of our

Technical Service Representatives to

aid in the specification-writing process.

Philip Sawoszczuk, Eng. Technical Service Representative,Construction Products

theUnderground Column

the Masonry Corner

technical advances

Macdero Construction, a leading

concrete restoration contractor,

recently completed structural repairs to

the underground parking garage at

111 Gordon Baker Road in Toronto.

The high-rise commercial property is

the Head Office for ING Direct Canada.

A high strength concrete was required

to ensure the structural integrity of the

beams and columns. The congested

reinforcing steel and difficult-to-access

forms meant that the project required

a pumpable, high slump concrete with

flowable properties.

Macdero submitted King’s MS-S6

Self-Consolidating Concrete to the

project consulting engineer, Halsall

Associates, because this product met

both the plastic and hardened

property requirements outlined in the

specification. Surface deterioration of

the concrete was extensive and

resulted in partial depth removal of a

significant portion of the walls,

columns, soffits and overhead

beams, throughout three underground

parking levels. The versatility of King

MS-S6 Self-Consolidating Concrete

allowed Macdero to use one product

for all repair areas throughout the

structure, and resulted in both time

and cost savings.

King supplied technical support on

a number of occasions, and helped

Macdero crews to overcome chal-

lenges related to the placement of

the material.

For almost 30 years, Macdero has been

rehabilitating concrete structures

throughout the GTA. The company has

completed projects this year, using King

MS-S10 Self-Consolidating Concrete,

for deeper formed repairs and King

LM-S10 Concrete for repairs in which

a membrane application is required

24 hours after concrete placement.

Matthew Croutch, Technical Sales Representative, Construction Products

King MS-S6 Self-Consolidating Concrete

Much of the success of our Construc-

tion Products Division can be traced

back to the quality and consistency of

our products. However, before our mix

designs make it into the hands of our

production staff, hundreds of hours are

spent on product development, to en-

sure that the product will perform as

intended and promised.

King Packaged Materials Company has

always recognized the important role

that Research and Development (R&D)

plays in keeping leading companies at

the top of their fields. It can be expensive,

but R&D is a process intended to create

new or improved technology, which

often provides a distinct competitive

advantage. For this reason, we often

find that the higher the Research and

Development budget goes, the more

often we find new and innovative

products in the hands of our customers.

Durable wet and dry shotcrete mixes

that will allow a bridge to be re-

opened hours after placement, high

performance concrete mixes that allow

quicker application of waterproof

membranes, and mortars specially

designed to repair some of North

America’s most cherished heritage

buildings, are just a few examples of

successful products that have resulted

from the efforts of our dedicated

Technical Services team.

Research and Development is often

referred to as an expense. But at

King, we prefer to view it as an invest-

ment, and one that will determine our

future success.

message from Joe Hutter,Vice president of sales

Research & Development Update – an investment in Future Success!

jobsite technical Challenge

the PRODUCt OF ChOiCe FOR the RehabilitatiOn OF ing DiReCt CanaDa’S heaD OFFiCe PaRKing gaRage.

Restoration of quebec City hall

The Quebec City Hall was constructed

in 1896, in the heart of Old Quebec

City. Reflecting the historic character

of the Old Capital, this masonry

building was designated as a “National

Historic Site of Canada” in 1984.

In the Fall of 2010, the architecture

firm, BFH Société d’architecture

(Boudreau, Fortier, & Huot) was

mandated to write a building

specification document that outlined

the restoration of the building, based on

functional integrity. Mainly, the work

consisted of repointing mortar joints,

replacing damaged limestone, and

consolidating voids in the masonry

system. The work was contracted out to

Rainville et Frères, a masonry contractor

that specializes in masonry restoration.

The first phase of construction began in

the Spring of 2011.

To preserve the distinctive character

of the building, different mortar

samples were collected at the

beginning of the project, by a King

Technical Representative. Four colours

of mortar were reproduced in a

laboratory and submitted to the

architectural firm for approval.

A mortar, composed of a combination

of Portland Cement and hydrated

lime, was used on this project. New

masonry elements were installed

using King 1-1-6 Mortar (Type N).

King MasonCare 300 Mortar (Type O)

was used to repoint joints to a depth

of 25 mm (1 inch). The voids in the

walls were gravity-injected using King

HL-5 Grout, a natural hydraulic lime,

injection grout.

The second phase of construction was

completed in November of 2012. The

total budget for the work completed

was approximately $2.4 million.

King’s masonry products division is

proud to have participated in the

restoration of this historic building.

Martin Bissonnette, Technical Sales Representative, Masonry Products

“MS-S6 SELF-CONSOLIDATING CONCRETE HAS GREAT PUMPABILITy, HIGH STRENGTH, AND A SUPERIOR FINISH, WHICH KEPT US ON SCHEDULE THROUGHOUT THE PROJECT. KING REPRESENTATIvES ALWAyS HANDLE PROJECTS IN A vERy PROFESSIONAL MANNER, AND MONITOR ALL CONCRETE PHASES. I APPLAUD ALL OF KING’S STAFF FOR THEIR DILIGENCE.”

-Tony Porciello, Project Manager

Specifying Made easy for Shotcrete & Self-Consolidating ConcreteCONTACT yOUR KING TECHNICAL SERvICE REPRESENTATIvE FOR yOUR SPECIFICATION-WRITING NEEDS

In 2011, Minnesota’s Ramsey County

Regional Railway Authority approved

plans to purchase the head house of

the St. Paul Union Depot (SPUD), as

part of a $250 million effort to return

trains to the city. While SPUD’s scope

of work included carriageway and

tunnel restoration, the bulk of the

work would be completed in the

Southwest parking structure.

In early 2011, RAM Construction

Services of Livonia, Minnesota, was

awarded the contract to rehabilitate

the structure. RAM used hydro-

demolition methods to remove over

30,000 ft2 of deteriorated concrete

and the company’s proposal to

replace the concrete using King

MS-D1 Shotcrete was accepted by the

project engineers.

Using one nozzleman and two

finishers, RAM showed great respect

for the original formwork of this

historical structure, through the use

of a fabricated form-board to ensure

that the repairs would match the

pattern created 80 years earlier.

“The key to a successful shotcrete

repair,” says Richard Maxwell,

RAM’s Director of Operations, “lies

exclusively with your crew, of which

the most important individual is

your nozzleman”. As such, RAM

takes its shotcrete repair projects

seriously, and utilizes the services of

15 ACI Certified Nozzlemen.

The project was completed in early

2013, and will ease parking conges-

tion in and around the refurbished

head house of the St. Paul Union

Depot. The project recently received

the American Shotcrete Association

award for “Outstanding Rehabilitation

and Repair Project” and supports what

city officials hope will become the

Grand Central Station of the Midwest.

Dave Sawyer,Technical Sales Representative, Construction Products

St. Paul Union Depot (SPUD) in Ramsey County, MinnesotaKing anD RaM awaRDeD “OUtStanDing RePaiR anD RehabilitatiOn” PROjeCt at 2013 aMeRiCan ShOtCRete aSSOCiatiOn banqUet in laS VegaS.

Construction Products group

issue 7 | Spring 2013

R&D Update

Jobsite Technical Challenge

The Masonry Corner

The Underground Column

Technical Advances

technical talk - Shotcrete (Continued)

why Silica Fume?

K i n g pac Kag e d

m at e r i a l s c o m pa n y

1-800-461-0566www.kingshotcrete.com [email protected]

burlington Office3385 Harvester Rd.

Burlington (ON) L7N 3N2

Phone: (905) 639-2993

Fax: (905) 333-3730

boisbriand Office3825 rue Alfred-Laliberté

Boisbriand (QC) J7H 1P7

Phone: (450) 430-4104

Fax: (450) 430-6855

brantford Office541 Oak Park Rd.

Brantford (ON) N3T 5L8

Phone: (519) 756-6177

Fax: (519) 756-7490

Sudbury Office644 Simmons Rd.

Dowling (ON) P0M 1R0

Phone: (705) 855-1155

Fax: (705) 855-1122

Matthew CroutchTechnical SaleS RepReSenTaTive

King Packaged Materials Company is pleased to announce that Matthew Croutch has joined the technical sales staff of our Construction Products Group. Matthew will be responsible for the sales and promotion of our construction products to the GTA (Toronto) and Southern Ontario markets.

Shannon Polk SaleS & MaRkeTing cooRdinaToR

King Packaged Materials Company is pleased to announce that Shannon Polk has been appointed to the position of Sales & Marketing Coordinator for the Construction Products Group. Shannon will be responsible for all aspects of the Construction Products marketing program and will also be taking on sales support roles for the Construction and Masonry Products sales team.

liam ireland Technical SaleS RepReSenTaTive

King Packaged Materials Company is pleased to announce that Liam Ireland has joined the technical sales staff of our Construction Products Group. Liam will be responsible for the sales and promotion of our construction products to Eastern Ontario, Quebec, and the Maritime provinces.

annOUnCeMentS

King has begun a phased approach to include social media services in

its marketing strategy. The integration of social networking sites into the

promotional plan for King Construction Products began in October of

2012 with the introduction of a corporate Facebook page, and continued

in January of 2013 with the launch of a company Twitter page. The

division also released a corporate social media policy, to take a proactive

stance toward social media governance on the web.

Shannon Polk, Sales & Marketing Coordinator, Construction Products

Silica fume, also known as Microsilica, is a fine powder collected as a

by-product of silicon alloy production, and has been used in cementitious

materials for over 30 years. Silica fume is used in many of King’s concrete

repair products, as the benefits to using silica fume as a mineral admixture

improve the performance and durability of shotcrete, concrete, mortar

and grout. The main mechanism behind the improved performance, is

the small silica fume particle size (approximately 150 nm or 100X smaller

than a Portland Cement particle) and the pozzolanic nature of the material.

These properties allow the silica fume particles to fit into the interstitial

spaces that exist between individual cement grains, and to form additional

calcium silicate hydrate, which strengthens the cementitious matrix further.

technical talk - Shotcrete

why Silica Fume?

King integrates Social Media into Marketing Mix

Follow Us on Facebook and twitter!

Mixing Strength with Satisfaction

The use of silica fume in cementitious

materials promotes, but is not limited

to, the following benefits:

• Increased compressive and flexural

strength at early and later age

• Reduced permeability to improve

resistance to freeze-thaw cycling,

salt-scaling and sulphate attack

• Reduced permeability to reduce the

ability of carbon dioxide, oxygen,

water and other compounds to

move through the material, which

slows the process of carbonation

and corrosion

• Increased electrical resistivity to

slow the movement of free electrons

and delay corrosion

While the benefits described above

also apply to shotcrete in the

hardened state, silica fume provides

the following benefits to shotcrete in

the plastic state:

• Increased cohesion to allow for

greater build-up thicknesses in both

vertical and overhead application

• Reduced rebound to allow for a

more economical process

• Increased resistance to water

washout

The use of silica fume in King concrete

repair materials also promotes

sustainability, as silica fume is

considered a post-industrial waste

product. Therefore, its use as a

supplementary cementitious material

means that silica fume does not become

waste for a landfill.

William Clements, MASc, EIT Technical Service Representative, Construction Products www.facebook.com/KPMIndustriesLtd www.twitter.com/KPMIndustries

King’s Blainville facility, located just North of Montreal, has been servicing

customers since 1971. In recent years, the quantity of products sold from

the Blainville plant began to outgrow its capacity. So, in the Spring of 2011,

King purchased an existing manufacturing plant in Boisbriand, Quebec, and

enacted plans to turn it into its new production facility.

The new Boisbriand plant opened for business in January, 2013, and is

designed with the most advanced, state-of-the-art production equipment

available. A high capacity, high efficiency, fluid bed dryer will increase

aggregate drying capacity by 600%.

The plant has three production lines controlled by a new, computerized

batching system that is designed to improve accuracy and consistency from

batch to batch.

The new plant is also home to King’s quality control lab and R&D department.

The new lab facility is 500% larger than at the Blainville plant, and houses

the company’s first training facility. All in all, the Boisbriand plant is a

world-class facility that will serve the company well for decades to come.

Mark Lowry,Project Engineer

new boisbriand Plant arrives

Facility will Service Mining and Construction Markets in quebec and the northeast United States.

con

tinu

ed o

n pa

ge 4