Building Moisture

-

Upload

blackknight728 -

Category

Documents

-

view

221 -

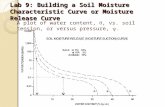

download

0

Transcript of Building Moisture

-

8/14/2019 Building Moisture

1/83

% RH

C td

C

With practicaladvice, tipsand tricks

Field guide

Building moisture

-

8/14/2019 Building Moisture

2/83

2

-

8/14/2019 Building Moisture

3/83

-

8/14/2019 Building Moisture

4/83

Air humidity

Moisture contentequilibrium on/in thebuilding component

Long-term recordingof the room climateand ventilationcharacteristics

Measuring in cavities(insulating course,screed joint)

Recording roomclimate on firstinspection

4

Parameter

Parameter

Design

Design

Wind determination(meteorology)

Air temperature

Long-term recordingof the room climateand ventilationcharacteristics

Comfort analyses(room climate atworkplaces)

Recording roomclimate on firstinspection

Overview

-

8/14/2019 Building Moisture

5/83

-

8/14/2019 Building Moisture

6/83

-

8/14/2019 Building Moisture

7/83

7

3. Typical applications of building practice 47

3.1 Locating leaks in pipes 47

3.2 Locating air leaks in BlowerDoor tests, assessing draughts 50

3.3 Assessing moisture damage 57

3.3.1 The problem 57

3.3.2 The procedure 59

3.4 Assessing mould damage 62

3.4.1 Procedures in an inspection 63

3.4.2 Short-term and long-term measurement 65

3.4.3 Measuring location 65

3.4.4 Recommended programming for loggers used to record room climate 67

3.4.5 Narrowing down the causes 68

3.5 Assessing heat bridges 70

3.5.1 The problem and its importance 703.5.2 Types of heat bridge 70

3.5.3 Recording heat bridges 73

4. Reference to other field guides 75

5. General 78

Contents

-

8/14/2019 Building Moisture

8/83

8

1. Parameters and measuring methods

(See page 4 for an overview).

1.1 Air temperature

The measurement of air temperature is a fundamental measuring task. It is car-

ried out in order to control heating and ventilation, and also to assess the level

of comfort and mould damage.

The measurement of air temperature is straightforward in terms of handling

and technical requirements.

In principle:

It is always the actual temperature of the air that is measured, regard-

less of whether it is stagnant or agitated Stagnant air and agitated air

are feltin different ways.

Agitated air has a cooling effect: a breeze, for instance, makes oppres-

sive summer heat more bearable, even if it has the same temperature.

On the other hand, cold is felt more keenly the stormier it is (this is

known as the wind chill factor).

The subjective perception of cold and draught can be indicated

with the perceived temperature , which is always lower than the

actual temperature. However, empirical anthropological factors (the

sensitivity of a person) extending beyond the purely physical indica-

tion of a temperature also come into play here. Finding the right

definition is crucial when giving weather/climate information, for

sporting events and expeditions and when considering comfort

levels.

It is just as important that radiating elements change both the perceived tem-

perature and the actual temperature!

Everyone knows how the embers of a campfire on a cool autumn evening can

make you feel pleasantly warm - albeit only on one side. Similarly, an ordinary

radiator, tile stove or halogen radiator in an apartment can radiate heat and

raise the perceived temperature.

If this radiated heat meets a thermometer, the thermometer will display a higher

temperature than the ambient air actually has. This radiation component is not

normally measured as well.

Helpful phrase

Parameters and measuring methods

-

8/14/2019 Building Moisture

9/83

9

Air thermometers should in principle be shielded from radiation (meteorological

measurements, for instance, are always performed in the shade).

If the radiation component and its effect on comfort are to be recorded,

though, there are special thermometers (e.g. globe thermometers) for this pur-

pose.

1.1.1 The measuring principle

There are a number of different ways of measuring air temperature.The most common are measurement with a temperature-dependent electrical

resistor (high-impedance NTC or low-impedance PT100) and measurement

with a thermocouple. This thermocouple generates an electric voltage accord-

ing to the temperature.

As in other measuring tasks, there are preferred applications for the one or the

other principle depending on the temperature level to be recorded (e.g. 20 C

or 200 C?) and the requirements with regard to precision, design and speed.

Suitability and precision are indicated by the manufacturer of each device; tem-

perature sensors are often combined with air humidity sensors or an air velocity

sensor in one probe.

The accuracy of TESTO s standard sensors (combination probe) is about

0.4 K, the response times for agitated sensors about 30 sec.1

1.1.2 Correct and incorrect application

Always remember the following:

The instrument only ever records the temperature of the sensor, not the tem-

perature of the medium!

For that reason the temperature of the sensor must come as close as possibleto that of the medium to be measured.

That is why the sensor is normally detached from the handheld instrument and

accommodated in a handheld probe.2

Handheld probes must be specifically designed for measurements in air (or

more generally, in gases). They are markedly different in design from sensors

for the surfaces of solids, for bulk goods and for liquids!

Parameters and measuring methods

1 For more about the response time, see chapter 1.1.2.12 For a definition of the terms sensor and probe , see Fig. 1

-

8/14/2019 Building Moisture

10/83

10

The temperature should only be recorded in that part of the space in which the

sensor is located.

Given that the layers of air that prevail in homes can produce a difference of 4 K

between near the floor and near the ceiling, the question arises as to the best

height for measuring.

If in doubt, it is better to measure at several heights and to note all measure-

ments. Otherwise it is normally sufficient to measure at chest height. This cor-

responds to a height of about 140 cm, which comfort guidelines give as the

mean measurement height.3The middle of the room is taken as representative

of the room. If other locations are to be assessed, e.g. a balcony door that is

thought to have a draught, they must be measured separately.

Fig. 1: Components of a measuring instrument

1.1.2.1 Transport/inertia of the sensor

As already explained, the temperature of the sensor should approach the tem-

perature of the medium as quickly and without hindrance as possible.

After transportation or storage at significantly different temperatures, the sen-

sor must be given a sufficient equalisation time to be able to react to the actual

prevailing temperatures (e.g. do not keep the instrument in the car overnight

during frosty periods if you are going to perform a measurement in a home the

next morning).

Parameters and measuring methods

Handheld unit

Sensor/probe

Sensor

3 cf. DIN 1946: Head height for seated activity 110 cm, head height for standing activity 170 cm

-

8/14/2019 Building Moisture

11/83

11

If the temperature of the handheld instrument is different, this is not as critical

as the temperature of the probe being too low.

If the probe was cooled down (or heated) when brought into the room to be

measured, however, it would need about 10 minutes lying still in order to ad-

just. The actual inert mass here is the sensor housing, not the sensor itself.

If measurement is carried out with a probe that has cooled down too much, the

sensor would fog up. This would result in lower values. If you have not waited

long enough, you can see by excessively high or low values that the reading is

wandering . Only when the reading is stable has the probe reached the equi-

librium and hence correct temperature.

In the typical design, in which the sensor sits in a slotted protective cap well ex-

posed to direct flows, a microclimate forms. With the sensor at rest, an insulat-

ing air cushion can be maintained in the cap (this is particularly true for fully en-

closed sintered caps used in dusty atmospheres). Temperature equalisation

can be accelerated by moving the probe around in the ambient air: the micro-

climate is then broken up.

Even with good flows around it, the response time of the sensor depends on its

design and especially its mass. The response time of commercial air sensors is

a matter of seconds and so has little bearing. In technical language, the re-

sponse time is expressed as a characteristic value known as t99. This is the

time taken for the displayed temperature to approach 99 % of the end value.

Parameters and measuring methods

-

8/14/2019 Building Moisture

12/83

12

1.1.2.2 Performing the measurement

When carrying out a measurement, you must make sure that your own body

heat and especially the air that you exhale do not reach the probe. One solution

is to move the sensor around. This should not be done vigorously, but nor

should it be too gentle.

In summary, measurements should be performed as follows:

Roughly in the centre of the room

At chest height

Shield off strong sources of radiation with your body

Keep your arm stretched away from your body

Use your wrist to swing the instrument. Aim for about 1.5 m/s; this corre-

sponds to about 2 swings per second

Fig. 2: Correct handling when measuring air temperature and air

humidity

1.1.2.3 Special applications

Measurements of comfort are carried out using a globe thermometer. This is

not agitated but is instead fixed immovably in position using a stand at one of

three defined heights that are laid down in DIN 1946-2 and VDI 2080. The

globe thermometer consists of a hollow sphere painted matt black. The actual

sensor is located in the sphere.

Parameters and measuring methods

-

8/14/2019 Building Moisture

13/83

13

Incident heat radiation (e.g. sunlight) has the effect of warming the sphere in a

similar way to how the human body would experience it. The reading approxi-

mates very closely to the average human sensitivity if the readings are calibrat-

ed on the basis of empirical experiments with a large number of test people.

The reading given by the globe thermometer cannot, however, indicate

whether the radiation was uniform all the way round or just on one side of the

sphere. That makes a huge difference with regard to comfort.

Fig. 3: Globe thermometer

Long-term recording is advisable if temperature fluctuations are to be record-

ed. This requires a programmable device with a data memory, known as a data

logger. What was said under 1.1.2.2 applies analogously for the positioning of

a probe in the room. Because the sensor is not moved around, the inertia of theglobe thermometer is theoretically greater. That is irrelevant in practice, howev-

er, as the air temperature in rooms does not vary so quickly that the sensor is

unable to keep track.

Parameters and measuring methods

-

8/14/2019 Building Moisture

14/83

14

1.2 Air humidity

The parameter of air humidity is very important in any assessment of mould

damage. It is also a key indicator in the technical drying of buildings in order to

ascertain when a drying process can be terminated.

There are a large number of characteristic values which can be used to indicate

how much water vapour is in the air.

As regards the applications addressed in this field guide, only

absolute humidity and

relative humidity

are of interest.4

The absolute humiditydescribes the mass of water (vapour) which exists in one

cubic metre of ambient air (including the vapour). Strictly speaking, you would

have to make sure that the standard pressure was maintained. That is irrele-

vant in practice, however, because the instrumentation and the performance ofthe actual measurement lead to greater inaccuracies.

The relative humiditydescribes how much of the maximum possible absorbing

capacity of the air is actually taken up. This depends on the temperature!

Fig. 4: Saturation curve and dew point temperature curve

Parameters and measuring methods

g water

m3gas

gactual water

gmax. possible water

4The terms vapour pressure , enthalpy and water content are preferred in some industries (air-conditioning, production engineering). The units can be transferred using an h-x diagram ( Mollier diagram ) ifthe side parameters are known.

Flowing water

Water vapour

Increasing

saturation

Air temperature in C

Watercontentofairing/m3

Warm, moist airDry, cool air

-

8/14/2019 Building Moisture

15/83

15

Fig. 5: Temperature dependence of relative humidity

Parameters and measuring methods

Room air at

20 C

with an assumed water

content of

9.5 g/m

...would be saturated at...

17 g/m

and consequently has a

relative humidity of...

55 %

So this air only cools down

to...

15 C

It still contains...

9.5 g/m

...but is not saturated until...

13 g/m

This corresponds to a relative

humidity at the wall of:

73 %. This figure is much lower

than the critical value for mould to

form, namely 85 %. => Problem

solved!

...this air cools down to...

10 C

At first it still contains...

9.5 g/m

...but is already saturated

at...

9 g/m

In other words:

About 0.5 g, corresponding to

0.5 ml, excess condensates

out, on the cold surface first=> mould forms!

The condensation begins from

cooling down to 10.7 C. Mould

begins to form before

condensation occurs.

This would be a typical room climate in a lounge, for instance. If this air then gets into a cooled bedroom, in a corner which is

only 10 C on the surface,...

Remedy: Move the furniture out, insulate the top of the ceiling, heat the bedroom better. This would help to increase the

wall temperature up to 15 C, for instance:

Absolute and relative humidity in practice

5 For the sake of simplici ty, constant values were assumed in this scenario. In practice, the room climate will ofcourse vary. However, mean values can be used.

5

75 %RH

55 %RH

Troom

= 20 C

Tsurface

= 15 C

Minimum distance from wall tomeasurement point forrepresentative room climatemeasurements

-

8/14/2019 Building Moisture

16/83

16

Relative humidity is the indicator most commonly used, probably due to mete-

orology and considerations of comfort levels. Relative humidity depends not

only on water content, but also on air temperature. Since different air tempera-

tures may prevail within a room (the temperature at floor level and on ceilings

next to external walls is smaller than in the centre of the room), a room may

have a variety of relative humidities!

That is why absolute humidity is more helpful for considerations relating to the

physics of construction, which often involve condensation and drying. Well-de-

signed instruments indicate both characteristic values and also provide infor-

mation on the dew temperature (often called the dew point temperature ).

This is the temperature at which condensation would begin if this ambient air

were cooled down. This parameter is very important if you want to know where

cool sections of a wall fog up in a given room climate.

1.2.1 The measuring principle

The actual sensor is usually located in a handheld probe along with a tempera-

ture sensor. It consists of an approx. 0.5 cm2-large lamina comprising three

layers and hence forming a capacitor. The middle layer is a moisture-sensitiveplastic. Depending on the ambient humidity, it brings about a different dielectric

constant, so that the capacity changes.

The change in the response of the resonant circuit is analysed electronically.

Sensors are available in different tolerance classes. Dust deposits can be

rinsed off, but mechanical stresses (scratches) or sweat from your hand can

damage the sensor.

While today s sensors are considered to have long-term stability, they are sub-

ject to unavoidable ageing. For our applications, they must be inspected every

2 years and recalibrated if necessary. This is particularly important if the accu-racy of the determined values has a legally binding effect or if several measur-

ing instruments are used at the same time and their values are not allowed to

differ (e.g. when diagnosing heat bridges and mould, see chapter 3.5.3).

If calibration takes place in the factory, the relevant certification is provided (e.g.

a calibration certificate). This helps to allay lack of confidence with regard to the

accuracy of measurement.

The accuracy of TESTO s standard sensors is + 2 % of relative humidity (not a

% of the displayed value). The response time (for agitated combination sen-

sors) is about 30 s.

Parameters and measuring methods

Different relative

humidities within

a room

The dewtemperature

-

8/14/2019 Building Moisture

17/83

17

Fig. 6: Combination sensor

1.2.2 Correct and incorrect application

Before performing any measurement, it is essential to ask yourself this ques-

tion: what do I want to achieve with this measurement?

When it comes to measuring moisture in order to assess mould, it is often

unclear where the probe should be positioned:Do I want to find out the air humidity in the corner that is being attacked

by mould?

Or do I want a representative moisture value for a living space in order to

assess the ventilation requirements?

Here too, the principle is that:

the measurement applies only for the place at which it was taken.

It is always advisable to carry out a measurement in each room, this being

done roughly in the centre of the room, as when measuring temperature. Hu-midity can also then be measured in corners, behind cupboards and the like,

and these must then be noted separately in the report.

The room climate is always influenced by the measurement itself, i.e. by the

presence of the person doing the measuring. You should therefore go into the

room quickly, close the doors and perform the measurement promptly. Even

just opening the door or leaving it ajar, or staying for longer than necessary, will

change the air humidity in the room.

The report must normally show the measuring location, the time, the

weather and the air temperature, as these are indispensable for subse-quent interpretation of the results.

Parameters and measuring methods

-

8/14/2019 Building Moisture

18/83

18

1.2.2.1 Transport/inertia of the sensor

As with temperature sensors, humidity sensors also have a certain equalisation

period. This is because the humidity in the air must first penetrate into the plas-

tic layer of the probe. Although the plastic layer has only an ultra-thin, microp-

orous metal layer as the second pole, the process can still take from a few sec-

onds to several minutes.

Here too, the inertia depends primarily on how exposed the sensor is to flows,

i.e. whether the sensor is moved around in the air. If the probe is hardly moved,

an equalisation period of about 10 minutes should be expected.

More rapid equalisation takes place if the instrument is agitated at approx.

1.5 m/s. To prevent condensation and reduce the response time, the instru-

ment should not have been stored in a cold place beforehand. The measure-

ment can be taken once the reading is stable.

1.2.2.2 Performing the measurement

Everything that applies for temperature measurement must also be observed

when measuring humidity: the sensor must be kept away from the body so that

it is not exposed to exhaled air (which is saturated with moisture!). The sensor

should be agitated using the wrist, at chest height etc.

1.2.2.3 Special applicationsThere are long-term recordingsin humidity measurement as well. These are vi-

tal for assessing mould. The probes and instruments are positioned in the

same way as for a one-off measurement.

For measurement in cavitiesor screed insulating layers, particularly thin probe

types which can be pushed into drill holes or edge joints are available. The very

slim protective caps that come with them protect against dust and grains, but

prolong the response time.

Sintered metal protective caps which are permeable to gas but impermeable

for particles are available for measurements in dusty atmospheres. Again,these prolong the equalisation period.

Posture during

measurement

Parameters and measuring methods

Waving the

sensor around

reduces the

equalisation

period

-

8/14/2019 Building Moisture

19/83

19

Fig. 7: Measuring in a screed edge joint

With special adapters, air humidity sensors can also be used to determine ma-

terial moisture(see chapter 1.4.1.3).

1.3 Material temperature

1.3.1 The principle of contact measurement

Here measurement is performed according to the tried and tested principle

that the sensor has to take on the temperature of the medium to be measured.

The accuracy of measurement depends on how well that succeeds.

Principle: every measuring instrument only measures the temperature of its

own sensor.

Since with solid bodies the sensor is normally placed only on the surface, it is

important that a vital intimate contact of the sensor is achieved, e.g. by having

a sufficiently large contact area. This contact area should adapt as fully as pos-

sible to the contours of the surface. The part to be placed on the surface

should also have little mass so that it equalises quickly. The measured temper-

ature is always a mixed temperature, as the air temperature is unavoidably

measured as well.

Parameters and measuring methods

-

8/14/2019 Building Moisture

20/83

-

8/14/2019 Building Moisture

21/83

21

The standard accuracy of spring band sensors for usual room temperatures,

for instance, is 2.5 K. More precise measurements, however, are required for

applications demanding a high level of accuracy.

Calibration is possible and recommended if greater accuracy is desired in the

temperature range of 10 C (the typical heat bridge temperature). Penetration

probes which could be pushed behind a wallpaper are sometimes more accu-

rate, but also more inert; the transmission of heat is also more undefined. A

more accurate type of sensor is described in the next chapter.

1.3.1.2 Special applications

There is a need for long-term recording even when measuring surface temper-

ature. Expert assessors require them primarily when assessing mould or in re-

search in the determination of heating response. The equalisation period is vir-

tually irrelevant here. It is much more important that a sensor can be anchored

in position. Lamina sensors 1.5 x 4 cm in size which - with thermal conductive

paste - can be fixed to the wall using two small nails are available to this end.

The rear should be shielded from heat radiation and the air flows in the room by

means of a small piece of polystyrene.

Fig. 9: Lamina sensor

The achievable accuracy here is much greater than for a sensor simply placed

onto a surface. It is about 0.5 K for the lamina itself, which is fitted with a

PT100 sensor, and is sufficient for assessing dew. Intimate contact with the

surface is essential, which is why an air gap must be avoided and thermal con-

ductive paste must be used.

The location of measuring/mounting depends on the particular task. It is often

useful to measure at two different locations simultaneously.

For more about the procedure for mould damage, please refer to chapter3.4. Aspects to do with assessing heat bridges can be found in chapter

3.5.3.

Parameters and measuring methods

-

8/14/2019 Building Moisture

22/83

22

1.3.2. The principle of non-contact measurement

All bodies which are warmer than absolute zero (-273 C = 0 Kelvin) radiate

heat (also known as infrared radiation).

Infrared radiation has a long wavelength (>770 nm) and is thus in a spectral

range that the human eye cannot see. The higher the frequency, i.e. the shorter

the wavelength, the more energy-rich the radiation. It can be picked up by sen-

sors. The intensity (output) of the heat radiation is a measure of the tempera-

ture of the radiating body.

Most substances have a clean radiation behaviour that is utilised by the stan-dard measuring instruments in the range from 8 to 14 nm.6 7

What is critical is whether the body really only gives off its own energy at the

surface or whether it reflects a considerable proportion of the ambient heat ra-

diation (rather like a polished surface does with visible light).

The proportion made up of reflected radiation is described as the emissivity co-

efficient .

It must be remembered that the reflective or transparent property of a body

may behave differently in response to radiated heat than in the case of visible

light!What is transparent glass to the eye, for instance, may be a matt pane for a

measuring instrument. As a rule, however, surfaces which appear to be reflec-

tive are also critical for infrared measurement.

The colour that we perceive an object to have (white, black, blue etc.) is irrele-

vant for the purposes of measurement.

In principle:

Only the temperature of the surface of the solid is measured. The core

temperature and the air temperature in front of it are not displayed.8

Parameters and measuring methods

6 Some infrared cameras also work in ranges of 3 to 5 mm7

There are some materials (e.g. metal oxides and plastics) that give off radiation in several spectral ranges andchange their wavelength erratically when the temperature changes; they are known as coloured emitters .These are technically more difficult to measure. However, this is not relevant for typical building applications.

8 Of course, the temperature that arises on the surface also depends on the core and air temperatures. Cold airthat flows in and along the wall, for instance, leads to smear-like cooling zones on the surface. The cold airitself is not recognised , but it can be seen by the effect it achieves on the surface.

-

8/14/2019 Building Moisture

23/83

23

1.3.2.1 Application and performance

The correct emissivity coefficient is crucial for the accuracy of the measure-

ment. For the majority of matt building materials it is 0.93 ... 0.95. Lower-priced

devices have a fixed value. With more variable devices, the emissivity coeffi-

cient can be adjusted to requirements. The measurement of reflective surfaces

(e.g. polished stainless steel rails, anodised surfaces) can be very inaccurate

because there is very little characteristic radiation.

Glass is not always as reflective or transparent as it may appear. Whether or

not glass surfaces act like matt surfaces of building materials depends on the

wavelength range in which the instrument is operating.

Window panes can be opaque for many thermographic cameras and instead

act like a mirror for cosmic radiation. The panes then appear unnaturally cold in

the readings.

If there are no recommendations from the manufacturer or previous experi-

ence, help can be found by covering the surface in question with a matt-effect

adhesive tape (heat-resistant adhesive tape for high temperatures is available

to this end). Aluminised adhesive tapes are of course out of question. However,

the Gaffa tape used by sound engineers, or even masking tape, are also very

suitable. These allow glazed tiles, panes, mirrors, radiators, metal railings, gal-

vanised surfaces etc. to be measured more reliably.

Consideration must be given to the size of the measuring spot. With thermo-

graphic cameras the subject area that goes into the measurement is known

because the area is continuously scanned.

Handheld devices, however, make only 1-point measurements, and this is nor-

mally over a circular spot rather than on one single point. This is due to the lens

arrangement (cf. principle of a photo camera). A mean temperature value is ob-

tained for the surface to be measured.

To let you know where you are measuring, the instruments have a laser beam

that picks out the positionof the measuring spot. The sizeof the measuring

spot is also significant, however, e.g. in corners, near water pipes or on the ad-

hesive tapes mentioned above. That is why the more convenient instruments

have additional laser beams that highlight the contours of the measuring spot.

Otherwise the size of the measuring spot must be derived from the distance to

the object as detailed in the operating instructions.

Parameters and measuring methods

The reflection

The measuring

-

8/14/2019 Building Moisture

24/83

24

The surface to be measured should be viewed as far as possible at right an-

gles. Deviations of up to 30 from the vertical are irrelevant. The measuring in-

strument should be held away from the side of the body so that the reflected

radiation of body heat cannot reach the instrument. Very flat angles of observa-

tion not only impair accuracy, but also lead to a distorted, oval-shaped measur-

ing spot.

Non-contact measurement is not necessarily more accurate than contact

measurement. A direct comparison between the two methods at one and the

same location can show up differences.

The accuracy is determined not only by the resolution of the digital display, but

also by the accuracy of the emission factor, the compensation capability of the

electronics with regard to the ambient air temperature and the exactness of the

lens.

A comparison between both methods on the building site is useful in delivering

an impression of the accuracy. 9

Parameters and measuring methods

9 Even if results coincide, this does not mean that the measurement was accurate. The deviation might be inthe same direction for both measurements. Nevertheless, it is vital to always employ several methods forcritical applications!

-

8/14/2019 Building Moisture

25/83

25

Table 1: Important criteria for the accuracy of measurement in infrared

and contact measurements

An accurate measurement also depends to a large extent on having a measur-

ing instrument that is at room temperature, particularly when measuring ob-

jects with a low emission factor.

The great advantage of infrared measuring instruments is their ease of use.

Building components which cannot be reached by hand, e.g. ceilings in sports

Parameters and measuring methods

Infrared measurement

Emission factor estimated

correctly?

Reliable surface?

Strong background radiation

(incandescent bulb, smelting

furnace, clear winter sky)?

Lens foggy?

Device at room temperature?

Measuring spot larger than

measuring object?

Size of measuring spotknown?

Dust or other non-

homogeneous film on

measuring object?

Measuring object foggy?

No reproducibility?

Sharp deviations between

measuring locations close

together?

Find correct value from

handbook and adjust

Apply matt adhesive tape on

metals, anodised surfaces

and reflective surfaces

Shield with own body,

cardboard cover or umbrella

Wait

Determine size from

operating instructions or use

device with laser display

Clean

Surface property not

homogeneous! Apply

adhesive tape

Uneven surface?

Does the sensor have a

sufficient contact surface?

Rough surface? Enclosed

layer of air?

Sensor type generally too

inaccurate?

Sensor and handheld device

at room temperature?

Probe heated up at wrong

place?

Reading stable?

No reproducibility?

Sharp deviations between

measuring locations close

together?

Select suitable sensor

Use thermal conductive

paste

Select different principle for

recording measurements;

select different accuracy

class; individual calibration

Wait

Hold probe only by the

handle, not by the connector

and not by the shaft;insulate leaf sensor on

room side

Wait until room temperature

is reached; find more reliable

contact surface; avoid tilting

when positioning; check

device

Surface property or contact

surface not homogeneous!

Use conductive paste

Criterion Possible remedy Criterion Possible remedy

Contact measurement

-

8/14/2019 Building Moisture

26/83

26

halls, coving above bedroom wardrobes and corners of rooms can be meas-

ured quickly and with sufficient accuracy. Temperature differencescan be

measured with much greater accuracy than the absolute temperature, provid-

ed that the surface is identical. Joins in brickwork, piping, concrete lintels etc.

are identified by their temperature. If the current dew temperature of the room

climate is known, it is easy to find zones in which condensation is taking place

at the moment.

It is even more convenient if the dew temperature can be entered into the in-

strument as a lower threshold value so that an optical and acoustic signal is

given if this lower value is not reached.

Infrared measurement measures rough surfaces as well as inaccessible sur-

faces, something that is critical for building applications.

1.4 Material moisture

There are about a dozen different ways of determining the water content in

mineral building materials. Some of these methods are destructive, require

time-consuming calibration work, a great deal of time, a lot of electricity or ra-

dioactive substances. Not all methods are transportable and economically vi-

able for smaller firms.

All procedures must be based around a reference procedure, the Darr-W ge

(dry-and-weigh) method.

For this method a sample is taken (chiselled out), packed in an airtight and

steam-tight container and sent to a laboratory. The sample is weighed precise-

ly before all the water is expelled from the sample in a drying oven (the drying

temperature for cement building materials is 105 C). The sample is weighed

again when a constant weight is reached. The difference in weight corre-

sponds to the quantity of water contained.

The mass of this water is then compared with the dry mass of the sample:

U =

It is normally indicated as a %.

The indication U of the water content that is obtained in this way, however, re-

veals nothing about the actual saturation of a substance, i.e. whether or not it isalready saturated.

Parameters and measuring methods

mmoist

- mdried

mdried

-

8/14/2019 Building Moisture

27/83

27

To draw a conclusion about that, a further step is required:

the fully dried sample is immersed in a water bath. It is left there until no further

increase in weight can be ascertained (complete saturation = maximum possi-

ble water absorption).

The quantity of water that is contained is then compared with the maximum

possible quantity (there are parallels here with the definition of relative air hu-

midity):

Moisture penetration =

Please note:

Some people compare the water volume with the moistsample (in some

industries and in the English-speaking world).

There is a volume density indication (vol. %) which must not be confused

with the mass density figure (m %).

All the water is driven out of the dried sample and so it reaches a level of

dryness that would never occur under normal circumstances. A level of

dryness that is assumed in our home or ambient climate is called the

moisture content equilibrium 10. This depends on the ambient air humidi-

ty.

The Darr-W ge method takes several days due to the drying and saturation

processes, assumes air-conditioned drying ovens and precision scales and ul-

timately supplies values which are primarily of interest for research purposes

(materials science, fundamental research, calibration values for other process-

es etc.).

Other methods for determining material moisture which are primarily suited for

day-to-day use in terms of financial and practical aspects will be addressed

below. However, these methods cannot provide the moisture content U oreven the moisture penetration for unknown materials without further calibration

with the Darr-W ge method.

Parameters and measuring methods

mcontained water

mmaximum absorbable water

10The terms moisture content equilibrium and moisture ratio at equilibrium are not differentiated properlyand consistently in the literature and are used as synonyms. For a definition in this guide, see chapter 1.4.1.3.

-

8/14/2019 Building Moisture

28/83

28

1.4.1 The different measuring processes: Possibilities and limits

1.4.1.1 The scatter field method

An electrode with coil is placed on a building component. An applied alternat-

ing low voltage generates an electrical field that - depending on the design -

penetrates the component to a greater or lesser depth. The standard forms are

a spherical head and a loop head. The depth of penetration is between 2 and

5 cm. This depends on the geometry of the component and the layer structure.

Water contained in the building material has a significant effect on the electrical

field. Field changes are therefore a measure of the water content.

The type of building material has a considerable influence on the readings.

Metals in the substrate (e.g. reinforcing iron and water pipes) lead to sharp

changes (cf. functional principle of cable search devices). Different densities

can lead to varying readings even in identical types of building material, e.g.

bricks.

In addition, lack of homogeneity (cavities, mortar in joints, mixed masonry) re-

sults in fluctuations and mixed values . It is understandable, then, that the

measuring instruments do not supply the water content directly, but instead

measure only an output voltage. This is usually converted into dimensionlessunits or digits or indicates that conditions are dry , moist or wet using

LEDs.

High-end devices enable individual scaling by the user.

Although it is possible to determine the moisture content U from the value dis-

played, this presupposes prior laboratory calibration for the material used, with

its own specific density, according to the Darr-W ge method.

In practice, these instruments are often used to locate leaks, as they can pene-

trate tiles, for instance. Water in the substrate can be narrowed down to a par-

ticular area, even under (thin) screeds, rubber floorcoverings or laminate floors.The second advantage, the absence of destruction, is useful in the case of very

hard, dense or valuable surfaces (mosaic, frescoes, paving stones).

The instruments also enable conclusions about the development of damage to

be drawn, e.g. whether building components are tending to dry out, remain

just as moist or become increasingly moist. Two or three measurements taken

several weeks apart are performed to this end. The location of the measure-

ment points and the readings must be recorded very precisely.

A grid is drawn on the building component so that the repeat measurements

are performed at exactly the same spots.

Parameters and measuring methods

-

8/14/2019 Building Moisture

29/83

29

Caution: Depending on the shape, the position of the probe (tilted or straight,

pressed on firmly or just placed on lightly) also has an effect on the reading!

Placing the probe on one location several times givens an indication of whether

the measurement was correct. Ideally, identical values will be obtained. Repro-

ducibility can be improved by having a strictly defined probe position. The

probe can be laid flat on the surface, for instance, in order to exclude a variety

of angles when applying the probe from above.

Fig. 10: How to hold a loop head probe

Parameters and measuring methods

-

8/14/2019 Building Moisture

30/83

30

Fig. 11: Marking enables repeat measurements

Since, as already indicated, the slightest movements (or changes of angle) of

the probe have a considerable influence on the reading, corners, coving and

rough/uneven surfaces are very difficult to measure precisely. Because of the

concentration of masses, corners tend to produce higher readings that usually

only simulate an increased water content.

Any consideration of accuracy is superfluous with this measuring method be-

cause the handling differences outlined above and the lack of homogeneity of

the substrate yields far greater fluctuations than the equipment itself. That is

why many manufacturers dispense with indicating the accuracy.

Parameters and measuring methods

-

8/14/2019 Building Moisture

31/83

31

1.4.1.2 Conductivity

Water conducts electricity and, through its resistance, influences the electrical

conductivity of a building material that contains water. This fact can be utilised

in measuring the water content.

Two electrodes must be introduced into the building component, or at least

placed on top. This can be done using

brush probes inserted into previously drilled holes (in concrete and brick-

work)

drive-in probes that are driven in with blows of a hammer (primarily for

analyses in wood)

needle points that are pushed in (plasters and screeds).

Fig. 12: Probe types for measuring conductivity

The reading is slightly affected by temperature, but this can be compensated

through technical means. The penetration depth of the needles or brush

probes and their spacing also have an influence on the reading that can be

compensated. If the spacing of the holes is not already prescribed by the de-

sign, it must be taken from the operating instructions.

In the case of drilled holes, the heat of the drilling process causes a certain

amount of drying that has to be compensated through a sufficiently long wait-ing time. The drill hole must be kept closed for that period. This is easily done

Parameters and measuring methods

-

8/14/2019 Building Moisture

32/83

32

using plastic adhesive tape.

The biggest unknown in the whole measurement is the chemical composition

of the building component. This means that the conductivity - given an identical

water content - differs from one material to another: clinker, concrete, sand-

lime blocks, mortar etc. behave in different ways depending on their density.

If the instruments are being used to diagnose damage, it must also be remem-

bered that moisture that has been in the component for some time may have

released and relocated salts. Salts conduct electricity, i.e. increased salt loads

increase conductivity relative to the standard salt content of the building mate-

rial, in some cases many times over. Salts are always carried with the water

flow to the evaporation surface. Measurement usually takes place on this evap-

oration surface (interior plaster). This can lead to a higher water content being

displayed than actually exists.11

Instruments with contact gauges have proven to enable rapid diagnosis in

practice. The main application here is assessing whether wall stains indicate a

previous but rectified case or acute damage.

If the instrument indicates dry , the wall - at least on the surface - is actually

dry. If the instrument indicates moist , water and/or salts may be present: ei-

ther a lot of water with a few salts or a little water with a lot of salts.

Highly reliable conclusions can be drawn by observation (is the plaster dis-

coloured or fragmented?) and another, separate, method of measurement. If

the instruments indicates complete wetness , it must be assumed that the

building material is actually wet.

When measuring thoroughly moist plaster, the force required to push the in-

strument in often says a lot about the damage: moist plaster which has already

been thoroughly penetrated by moisture for a longer period is fragmented and

offers no resistance to the gauges.If you always get an end-of-scale reading at different locations, you should

check whether an aluminium-backed wallpaper was put up!

Moist wallpapers should be removed for the purposes of measuring anyway,

as their hygroscopicity means that they retain water well and cause high dis-

play readings.

Parameters and measuring methods

11 It is true that salts have a direct influence on the reading, especially in the conductivity measurement method.However, there is a second relationship that applies for all methods: an increased salt concentration causesmoisture to be absorbed from the air (hygroscopicity of the salts). These building materials thus have a highermoisture content equilibrium and are never as dry as uncontaminated material under a particular ambient

climate. See also chapter 1.4.1.3.

-

8/14/2019 Building Moisture

33/83

33

The conductivity response can - in conjunction with the approx. 30 cm long

brush probes - also be used to determine moisture profiles, for instance

at various heights (with constant depth) or

at various depths in the brickwork (in only one drill hole pair).

This allows a conclusion to be drawn e.g. about whether the moisture is com-

ing from outside or is rising moisture. In the ideal scenario, mathematically

clean curves would be produced. In practice, however, lack of homogeneity

(different types of brick used in wall, joins in the brickwork, cavities) lead to very

different curves from which only trends can be ascertained. Inhomogeneity can

be identified in advance by the resistance felt when drilling and the colour of the

boring dust that is produced.

The procedure can also be used to assess readiness for a floorcovering, sub-

ject to three conditions:

1. It must be possible to define the recipe of the building material to be as-

sessed (e.g. screed ZE 20)

2. Set or limit values must have been elaborated for this recipe (i.e. this re-

quires one-off calibration in the laboratory using the Darr-W ge method)

3. The immersion path of the brush probes must be defined by a limit stop

or similar

If the above requirements for calibration are not met, the conductivity method

will not supply any direct moisture figures either, merely indicators for classifica-

tion. This dry-moist-wet statement applies for mineral and industrial building

materials.

With wood, the situation is different: this is because although the types of wood

differ, there is very little deviation among woods of one particular type, so good

reference values exist and can be used to determine the moisture content

more accurately.

Example: Fir has a different conductivity to beech. However, fir that comes

from Scandinavia does not differ to any meaningful extent from fir that comes

from the Black Forest.12

Parameters and measuring methods

12 It is not proposed to go into more detail with regard to measuring wood moisture since the method can betaken from the manufacturers operating instructions.

Inconsistencies

in terms

-

8/14/2019 Building Moisture

34/83

34

1.4.1.3 Moisture ratio at equilibrium

This method is a special case because, instead of being measured directly, the

moisture of the material is measured indirectly via the air humidity.

The air humidity is that which occurs on contact with the building component

to be examined. The reason is clear from the above explanation of the other

methods: in terms of technology, measuring air humidity is very reliable and can

be achieved at little expense!

Definitions and terms...

Although the term equilibrium is used in both MOISTURE RATIO AT EQUI-

LIBRIUM and MOISTURE CONTENT EQUILIBRIUM, for the purposes of

this guide a distinction should be made:

The moisture ratio at equilibriumis the air humiditythat corresponds to any

particular water content of the building material, i.e. forms a stable equilibrium

with it (see below). The unit is % RH or g/m .

The moisture content equilibriumis the material moisturethat occurs in contact

with a normal average room or indoor climate. The unit is usually M %.

It must be remembered that these terms are used in different ways in the litera-

ture.

Other common terms related to these physical phenomena are:

moisture equalisation method, hydrometer method, water activity, hygroscopic

moisture.

A closed system in miniature must be created if this air humidity (known as themoisture ratio at equilibrium) is to be determined.

Either a sealed volume on the surface of the building component. Such a

test chamber can be created, for instance, by using film that is glued

down all the way round or a funnel that is applied tightly.

Or a chamber can be created in the building component itself by drilling a

hole which is then sealed up.

There are handy aids for both variations.

Parameters and measuring methods

-

8/14/2019 Building Moisture

35/83

-

8/14/2019 Building Moisture

36/83

-

8/14/2019 Building Moisture

37/83

37

Salinisation will lead to an increase in the moisture content equilibrium!

In the diagram the line of a sorption isotherm influenced by salt goes higher

than a comparable isotherm for unsalinised material.

What this means in reverse is that theoretically much drier ambient air is need-

ed in order to dry salinised components. Salinised brickwork causes problems

for painting and conventional plastering. Stains become evident within a very

short space of time.

Salts can be determined qualitatively and semi-quantitatively on site, and in the

laboratory fully quantitatively as well. This is only important for complex cases,

e.g. the restoration of historical building fabric with special plasters.

Measuring the moisture ratio at equilibrium is straightforward in terms of equip-

ment and does not depend on the make. The disadvantage, however, is the

relatively long equalisation period, which is about 1 minute in practice with

small funnels on the surface. The air cushion first has to be enriched with dif-

fused moisture. The larger the cushion of air, the longer this process takes. In

the case of larger air cushions, e.g. under films or in drill holes (which must be

allowed to cool down first), the additional waiting time is at least 30 minutes.

Because of this equalisation period and the longer waiting time that may be re-

quired, this method is not practical for leak location. The long time taken to

scan many points makes the solution unprofitable. On the other hand, the

method is very suitable for:

Diagnosing mould, addressing the question of: is the air moistening the

wall, or is the wall moistening the air?

Verifying a different method (where resistance is measured first, for in-

stance, and if the result is not clear the moisture content equilibrium is

then measured)

Monitoring checks of technical building drying under screeds as well ason plaster

Examining readiness for floorcoverings. Only measurement on the surface

of the screed is non-destructive, but drilling a hole is more conclusive. The

recipe of the material being investigated must be based on a sorption

isotherm (determined in the laboratory with the Darr-W ge method) or on

own field experience. Complete drying out is identified in residential build-

ings even without sorption curves, but residual moisture can only be as-

sessed with a sorption curve.

Parameters and measuring methods

-

8/14/2019 Building Moisture

38/83

38

Always remember the following:

For funnel measurements:

The funnel must offer tight, all-round contact. Tilting or raising it leads to a

partial exchange of air, which can prolong the equalisation period. Rough

and uneven surfaces cannot normally be measured using a funnel.

The funnel must not be warmed up with the hand. However, the effect of

the temperature can be negated if the air humidity sensor is used to de-

termine the absolute air humidity rather than the relative air humidity.

For drill holes:

The heating and drying caused by the drilling process must have abated

completely. A waiting period of 1 to 2 hours is recommended. Unless seri-

al drilling/measurements are being carried out on a lot of holes one after

the other, a further visit will normally be required.

The sealing dowel must have a tight fit.

In general:

It is normally advisable to note the absolute and relative humidity along

with the relevant temperature. The humidity of the room air should also be

recorded.

If jointing compounds are used to hermetically seal the measuring cham-

ber, these must not give off any water (e.g. chewing gum or water-based

jointing compounds are not suitable). Permanently flexible mastic (e.g. as

used by the sanitary trade) is very suitable.

Parameters and measuring methods

-

8/14/2019 Building Moisture

39/83

-

8/14/2019 Building Moisture

40/83

40

The best prospects are offered by the moisture content equilibrium method,

since this is cost-efficient, does not depend on designs and shows little side

sensitivities. As experience grows, the necessary calibration curves are being

produced (such as the CM limit values we know today).

The microwave method is similar to the scatter field method in its effect, but

works with different frequencies and produces greater penetration depths. The

probes are roughly the size and shape of a large flashlight and, depending on

design, give different penetration depths ranging from 5 to 30 cm. This method

too reacts to the properties of the building material (recipe, density) as well as

the water content. Metals and the interfaces between building material and air

distort the measurement. This means that vertically perforated bricks, with the

numerous chambers they contain, cannot be measured. Reinforcing rods can

be identified by the higher readings that keep occurring at certain intervals.

A microwave measuring instrument has roughly the same dimensions as other

handheld units, but is more expensive.

Finally, the very cost-intensive neutron probe (Troxler probe) should also be

mentioned in passing. It is used with weakly radioactive material and the corre-

sponding handling and transport authorisation documents and is very compli-

cated. Because of the high penetration depth and its shape (similar to an up-

right vacuum cleaner), it is very suitable for revealing water distribution on flat

roofs.

Parameters and measuring methods

-

8/14/2019 Building Moisture

41/83

41

The basics of measurement

2. The basics of measurement

2.1 The authority advantage

A convincing representation and interpretation of important facts requires a

solid basis of data. This solid basis of data is provided by verifiable

measurements properly carried out by an expert.

Only if the exact and verifiable data and measurements that are obtained are

combined with professional presentation and communication of the results,however, will they find broad acceptance across all sections of the population.

This acceptance signifies an advantage in authority which can nevertheless

only be maintained if the conclusions that are given are actually underpinned by

the technology, i.e. there are no gaps in the arguments or data.

It is therefore essential

to perform the measurements properly in terms of the systems used,

to handle the measuring instruments expertly,

to document the results clearly and comprehensibly,and to interpret them with the required degree of caution.

2.2 Blind faith in digital technology

Even an expert runs the risk of believing what his measuring instruments tell

him without reservation. This is even more marked where instruments have

digital displays than with traditional pointer devices, because readings given to

decimal places give an impression of exactness that does not actually exist. In

addition, fluctuations are harder for the eye to pick up than a needle that isswinging back and forth.

When performing a measurement, you must always ask yourself:

Is the reading obtained at all plausible?

Is there a clear explanation for the value?

Was it expected to be at that level?

Is this value at all physically possible?

Am I making a glaring error in how I am conducting the measurement?

Can the measurement be reproduced in the event of doubt?

-

8/14/2019 Building Moisture

42/83

42

If different readings are obtained when a material moisture sensor, for instance,

is repeatedly applied to the same part of the wall, the individual measurement

cannot be used.

The probable reason is that the position of the sensor is not exactly the same,

the surface is too rough, the sensor is not held still, etc. If these chances are to

be excluded statistically, a lot of repeat measurements would have to be

performed and the mean and standard deviation then calculated.

What tolerances can be expected?

Inaccuracies can be traced back to several sources:

- the sensor

- the handheld device

- side influences (temperature, salts)

- handling differences.

- How does the accuracy of measurement compare with the accuracy of

the display?

Example: If a moisture indication of 21 %RH has an error of 5 %RH, it makes

little sense to give a decimal place, especially not if this measurement is carried

out on a random basis which could deliver very different readings one hour

later. No expert should on any account offer a conclusion based on such a

value.

What tolerances

can be

expected?

The basics of measurement

-

8/14/2019 Building Moisture

43/83

43

The basics of measurement

2.3 The four basic elements of measurement

There is more to diagnosis of a building structure than simply measurements.

There are four basic elements to it:

Fig. 16: A jigsaw puzzle comprising observation, interview, measurement,combination

Observation

Experienced inspectors can often deduce the cause of damage from its

appearance (observation). Of course, the recognition effect means there is also

a risk of coming to a premature conclusion without having examined and then

ruled out other possible causes.

Measuring technology can offer the critical assistance here that enables a

suspicion to be confirmed and other causes to be rejected.

Interview

The answers provided by the developers are also of great psychological

importance. It is better if those concerned feel included. In addition,

establishing the timescale over which the damage occurred can often provide

valuable information. If interviewees say, for instance, that a damp patch

occurred after a very cold period, the possibility of frost damage to the pipes

will be investigated and analysed more closely.

Observation

Interview Measurement

Combination

-

8/14/2019 Building Moisture

44/83

44

Typical questions might be:

When did the damage occur?

Under what external influences and weather conditions did the damage

occur?

If there are several symptoms: in what order did they occur?

Is the phenomenon continuous or repetitive?

If the phenomena reoccur: at what intervals of time or on what occasions?

If this interview is carried out, it will often give initial approaches for the best way

to carry out the measurements.

Combination

If the findings are combined together, an all-round picture should finally be

obtained. It is not always possible to put the jigsaw puzzle of findings together

on site; it often takes several days of intensive consideration for thinking to

ripen . In many cases this will also lead to a decision as to how the problem

can ultimately be clarified and a solution found during a second visit to the

location.

Measurement

Before measurement begins, it must be clear what the actual problem is. This

is often determined intuitively.

It is highly advantageous if you are clear in advance as to the readings that your

experience tells you to expect and what measurements would prove or

contradict a theory.

For most cases, it is highly recommended that the readings are recorded

exactly. This can be done using a handwritten report, a log produced on a

laptop or a paper printout from the measuring instrument.

The important details are:date, apartment/room/building component,

parameter and ambient climate.Preprinted log forms are very useful. These ensure that nothing is forgotten and

mean that the facts are always set down in the same format. You can design

these forms yourself, or ready-made forms can be obtained (from the author).

The basics of measurement

-

8/14/2019 Building Moisture

45/83

45

The basics of measurement

Fig. 17: Excerpt from a preprinted moisture measurement log form

-

8/14/2019 Building Moisture

46/83

46

Supplementary photographs help to recall the process even after a few months

and enable further expert processing (this also gives legal certainty in critical

legal scenarios). Sufficient experience is essential for many readings to be

interpreted. Premature conclusions given to those involved in the process

should be avoided.

Fig. 18: Process chain : problem, limit value definition, performance,

recording, interpretation

The basics of measurement

5544

33

22

1

INTERPRETATION

RECORDING

PERFORMANCE

LIMIT VALUES

PROBLEM

-

8/14/2019 Building Moisture

47/83

47

Typical applications of building practice

3. Typical applications of building practice

3.1 Locating leaks in pipes

If large quantities of water escape from pipes, these are normally quickly

identified: the water soaks through the wall or floor within a matter of days.

If only a little water escapes, it can take several weeks for the moisture to

spread. Such small quantities of water can escape if pipes drip water due to

corrosion or soldered joints that have since become detached. Drinking water

pipes that are under several bars of pressure often show an ultra-thin, barelyvisible jet on exposure (the diameter is thinner than that of a pin).

Nevertheless, it is not unusual for walls to be completely saturated up to 2 m in

height and across the entire cross-section. Once the whole wall is moist, it is

very difficult to narrow down the leakage area by measurement. The measuring

instrument simply indicates completely moist at every measurement point.

If the damaged pipe is located inside a wall, the moisture zone will spread

roughly concentrically around the actual leak. If the pipe is in the floor, moisture

will penetrate the insulating layer or separating layer from the screed. The water

will consequently rise in the walls with a fundamentally horizontal moisture linethat can be observed on interior and exterior walls.

Leaks in hot water pipes can be easily located using infrared technology. Here

the infrared camera is the instrument of choice so that a lot of time does not

have to be spent scanning all the surfaces.

The coloured printouts (known as thermograms) also illustrate the distribution

of the water in a very vivid way (see Fig. 19). The heated zones normally show

up clearly. This presupposes, of course, that hot water leaked out.

In the case of underfloor heating, it is best to let the screed cool down

overnight and start the heating up again about 1 hour before visiting the site.

The location of the leaks can then be more easily seen against the cold surface

of the floor than if the screed were already uniformly warmed through.

-

8/14/2019 Building Moisture

48/83

48

Fig. 19: Thermogram for hot water leaks

For cold water pipes, the location of the leak is best narrowed down by using a

compact conductivity measuring instrument (e.g. testo 606). There is little need

to worry about salt distorting the result in this type of measurement because

the period of moisture penetration following a pipe burst is no more than a few

weeks.

If a moisture pattern on walls indicates moisture under the screed, this can be

confirmed by measuring the air humidity in the edge joint. If there is free water

below the screed the readings will be in excess of 95 %. Further localisation is

impossible using this method as water and water vapour spread in roughly the

same way under the screed.

Typical applications of building practice

-

8/14/2019 Building Moisture

49/83

49

Typical applications of building practice

Fig. 20: Measurement in a test hole of a tiled floor

If no further localisation is possible (perhaps because a measuring instrument

gives an end-of-scale reading everywhere), it is best to trust to instinct and

understanding of structural engineering. Now and then there are surprises,

especially in old buildings, because pipes run at places no one would ever have

suspected. Drawings of the building can be helpful in searching for particular

piping in this case.

With a drinking water pipe, initial localisation can be carried out by observingthe water meter. The loss may of course be slight, e.g. only a few litres per

week. That is why it is only possible to establish whether a loss is being caused

by a damaged pipe or the like if the building is not occupied for several days

and the consumers are switched off. It is important to read the water meter

carefully, right down to the last decimal place. If only a slight loss is found,

dripping water taps and leaky sink inlets must be ruled out as a cause of the

loss (it would be sensible to shut off the corner valves at the start of the

observation period).

-

8/14/2019 Building Moisture

50/83

50

If the water meter does not show any consumption, but the heating system

suffers a constant loss of pressure and needs to keep being topped up, further

investigation is required. However, low water quantities being lost can also be

an indication of leaky pumps or cracked boilers!

Caution: In the case of basement flats, moisture under the screed is not always

caused by a leaking pipe! It may be that water is also being forced up from the

ground, e.g. through the joint between the wall and the floor, the sole plate or

even leaking sewage pipes (floor outlets from laundry rooms or the like).

All in all, leaks in pipes that are subject to pressure are relatively easy to locate.

The plumbing industry offers some special processes such as sound

localisation and trace gas snifting devices for the very tough nuts .

3.2 Locating air leaks in BlowerDoor tests, assessing draughts

This chapter is concerned with the medium of air. The issues of ventilation heat

losses, heatability, draughts, cold air fogging and comfort frequently have to be

clarified, particularly where lofts have been converted. Loft conversions have

been practically always permeable to air over the last few decades because noattention was paid to the airtight laying of foil.

If proper measurement evidence is to be collected in every single case, the

problem must be defined precisely beforehand. This depends primarily on the

legal position which the customer finds himself in (e.g. buyer, tenant, landlord,

developer, planner). It also hinges on whether claims under private law are to

be clarified (warranty periods, deficiencies in construction) or infringements

under public law (building regulations, German energy conservation laws).

In practice, three questions in particular arise:

a) Does the shell of the building conform to the generally recognised rules

of structural engineering and rules on energy conservation in terms of

airtightness? (This question is often asked in an acceptance inspection

focusing on quality assurance).

Typical applications of building practice

-

8/14/2019 Building Moisture

51/83

51

Typical applications of building practice

b) Are the draughts or coldness which the occupant is complaining

about verifiable and reproducible?

In other words, is there a technical reason for them, or is it a matter of

oversensitivity? (This question usually arises in disputes between

landlord and tenant).

c) If apartments cannot be heated properly:

- Does the cause lie in the heating system (radiators too small)?

- in the building shell (workmanship of air membrane, windows etc.)?

- or in the design (arrangement of concrete columns, wide areas of

glazing, open-plan floors etc.)?

The subsidiary questions under c) often refer back to b) and are aimed at

finding those who are responsible (planners, craftsmen etc.).

This subject area is actually very complex. For that reason only the basic

principles and the application of flow measuring techniques will be explained

here.

The requirement: the entire shell must be made airtight. This is taken to mean

that, assuming the usual differences in pressure between the inside and theoutside, no significant air flows will penetrate or escape through walls, ceilings,

windows and doors. Air that escapes while the building is being heated results

in loss of energy and condensation damage. Air that penetrates brings a

perceptible draught and a layer of cold air on the floor (the trend towards

airtight structures arose out of energy considerations).

The fresh air required for hygiene should be provided through conscientious

shock ventilation or even a ventilation system.

Airtightness can only be determined for the building as a whole. The only

measuring device suitable for the purpose is what is known as a BlowerDoor. Itdetermines the leakage flow quantitatively at an artificially high pressure

difference so that natural weather conditions have less of an effect on the

reproducibility of the measurement. A certain level of leakage must of course

be allowed for given the tolerances used in construction work. The question

asked under a) above can normally be answered with the help of a BlowerDoor.

The limit values required for such assessments have been laid down in law.

-

8/14/2019 Building Moisture

52/83

52

Fig. 21: Fitted BlowerDoor

If question b) is to be answered, the places where the air comes in must be

known. Here too, a BlowerDoor (see Fig. 21) is useful. It generates the vacuum

required for a forced draught (something that only naturally occurs in very

strong winds). The inlet points of the air can usually be localised fairly easily by

hand: at sockets, underneath sills, flaps in the dividing wall, built-in radiators,

roof windows, screed edge joints.

Fig. 22: Smoke pipe/air flow at a socket

Typical applications of building practice

-

8/14/2019 Building Moisture

53/83

53

Typical applications of building practice

Once the inlets have been found, it needs to be assessed whether the draught

can have an actual impact on the level of comfort. A superficial assessment

can have massive financial consequences ( just think of the court cases

concerning very high renovation costs).

Several factors must be taken into consideration:

The temperature of the incoming air

The position of the leakage point (hall or corner of the lounge, by the bed

or in the shower, height, distance from people)

The geometry of the leakage point (slit, nozzle, perforation)

The size/distribution of the leakage point(s)

The amount of leakage, i.e. the volume flow.

As yet there are not practicable means of determining the volume flow of a

leak. The form of a leak in window frames or similar locations usually prevents

measurement with flow funnels such as can be carried out at geometrically

properly defined places (e.g. room air outlets of air-conditioning systems). In

addition, the volume flows are too small to be identified as differences in a

BlowerDoor measurement.

All that can be done, then, is to measure the temperature and the flow velocity.

Although these measurements supply an inadequate description, given the

lack of alternatives they are applied in the majority of cases.

Rule:

Air flows have a negative effect on comfort when

people are standing still nearby, or even unclothed (the draught from the

push knob of the WC cistern is a classic example); critical distance from

the throw is approx. 0.5 m

the air comes in unbraked from the outside

the draught exceeds a flow velocity of 2 .. 3 m/s (assuming a significantvolume flow and a differential pressure of 50 pascal)

the incoming air is cold and is not heated up as it passes through that part

of the building (temperature on entry more than 10 K below the room

temperature)

a leakage place, if only isolated or even in nozzle form, is of a significant

size (about the size of a thumb)

a leakage place in the shape of a slit is of significant length (e.g. length of a

window casement)

-

8/14/2019 Building Moisture

54/83

54

the leakage place lets in large quantities of air, albeit it braked, spread out

and warmed up (e.g. unplastered floating brick)

the incoming air cools down large areas through flushing (e.g. panels in

front of sanitary installations, bathtubs or ceiling lining)

the air comes in at an outside wall exposed to the wind.

The more these assessment criteria accumulate, the more critical the draught

is for the comfort level. It does not generally matter whether the actual

occupant feels uncomfortable! What does matter is whether an impairment of

comfort is felt by the average occupant as described by the guidelines on

comfort!14

Even if all the limit values are observed, there will always be some people who

tend to complain, whether through greater sensitivity or simply attitude.

Fig. 23: Hot-ball and hot-wire designs