Brokk Product Catalogue 2016-2017 English

-

Upload

tr-kommunikation -

Category

Documents

-

view

231 -

download

3

description

Transcript of Brokk Product Catalogue 2016-2017 English

-

YEARS

ORIG

INAL D E M O L I T I O N P O

W ER

S INCE I976

C E LE BRAT I NG

40 years of innovation

YEARS

ORIG

INAL D E M O L I T I O N P O

W ER

S INCE I976

C E LE BRAT I NG

-

TABLE OF CONTENT40 Years of Innovation ........................................... 4-5A Success Story Thats Just Begun .................. 6-7Unparalleled Technology ............................................ 8Construction ............................................................. 10-11Tunneling ................................................................... 12-13Mining ......................................................................... 14-15Metal Processing ................................................... 16-17Cement ......................................................................... 18-19Nuclear ....................................................................... 20-21Rescue ........................................................................ 22-23Unique Features of Brokk machines ........ 28-29Brokk 60II ................................................................. 30-31Brokk 100 ................................................................ 32-33Brokk 120 Diesel .................................................. 34-35

Brokk 160 ................................................................ 36-37Brokk 280 ................................................................ 38-39 Brokk 400 ................................................................ 40-41Brokk 400 Diesel .................................................. 42-43Brokk 800 Process .............................................. 44-45Brokk 800 Standard .......................................... 46-47Brokk Ex ............................................................................ 48Options ............................................................................... 49Original Attachments ......................................... 52-57Training and Brokk Academy ...................... 60-61Service and Support ............................................ 62-63Contacts World-wide .......................................... 64-65Machine Comparison Chart ................................... 67

-

The Result of 40 Years of Innovation in Demolition.

When we began our journey, we made a promise to improve the safety and productivity of some of the hardest working people on earth. Four decades later, weve not only kept that promise, but weve also come farther and accomplished more than we ever imagined.

Today, there are 7 000 Brokk machines in more than 100 countries around the world. Theyre all busy improving the safety, efficiency and profitability of demolition work in a vast array of businesses. Weve come this far because of our persistent passion for our work and our customers.

Through our global service and sales network, we learn by meeting our customers face to face. We listen, learn and get inspired to improve our products in new ways.

This hands-on process has helped us build an unparal-leled range of machines with a wide range of attach-ments to meet the needs of nearly every workplace. When it comes to getting the job done, our customers are safer and more successful than ever before.

Todays Brokk machines were inconceivable 40 years ago, and we spend every day imagining and designing machines that will be doing the work of the future. But it's not just about the machine. It's much more. It's about having the right tool on the machine for the job, knowing there is knowledgeable support when needed, and every-thing else that brings confidence to the job. All that is now taken for granted when having a Brokk machine.

4

-

40 YEARS OF EVOLUTION

FOCUSThe business of Brokk is the business of demolition robots. That is 100% of our focus. Period. Our knowledge, ex-pertise and energy are entirely devoted to innovating and improving our demolition machines.

Were constantly seeking out new challenges to push the boundaries for what a Brokk machine can do. The result is a remarkably dependable machine that never gives up or gives in. A machine whose sole focus is making your job easier, safer and more profitable.

4 5

-

HISTORYIt's 1976. The demolition business has long been struggling with dangerous work environments and inaccessible demolition sites. There is a need for a safer, more productive way of getting the job done in places where hand-held tools are too weak and big machines wont fit. From that challenge, a dream was born of higher efficiency and safer conditions.

Visionaries and engineers from founding companies PE Holmgren and Rivteknik joined forces and started working on a solution. For months they worked to conceive, build and test a device that would change the demolition business forever: the worlds first remote controlled demolition machine.

Every year since 1976, Brokk has listened to customers, learned from their work and improved the machines. And what a difference we have made. Our demolition machines have changed the working conditions for thousands of people around the world, and they provided critical service when it was needed most. Brokk machines helped to clear Ground Zero after 9/11. They assisted in containing the nuclear disaster at Fukushima NPP after the devastating tsunami. And every day, they work at thousands of jobsites, keeping people safe while making

A Success StoryThats Just Begun.

The companies, PE & Rivteknik develop the world's first demolition robot in Skellefte, Sweden.

The first mass-produced remote-controlled demolition machine, the Brokk 250, hits the market.

Fred R. Conrad / NY Times / TT

1 000 Brokk machines delivered.

First international subsidiaries established in the USA and UK.

6

-

Brokk acquires Darda in Germany, the world's leading manufacturer of compact crusher attachments and other tools.

Brokk acquires Ahlberg Cameras, the worlds leading supplier of camera equipment for the nuclear industry.

Brokk celebrates 40 years of relentless innovation -- and it's just the beginning.

40 YEARS OF EVOLUTION

them more efficient. Our goal has always been to make a difference and were doing it, every day.

The Brokk difference begins with getting to know our customers, the environments they operate in and the challenges they face. It's the task of our worldwide sales and service network to listen and learn what businesses, operators and projects require for a safer, more powerful, more effective demolition solution.

THE FUTUREHumans have always been explorers. We discover new frontiers, build bridges to connect people and places, and seek new ways to understand our world. Electricity, the automobile, the Internet they were all created by people who dared to go where no one had gone before. Thats the spirit that drove Brokks founders to imagine and create the first remote-controlled demolition machine. And it's the spirit that continues to drive us as we improve our products and grow our business.

Research and development plays a big role in our quest to constantly improve. By applying new technologies, experimenting and testing new solutions, we discover new possibilities for making better, more durable, more

capable machines. Brokk is forever asking questions. Can we improve the machine operation by changing the human-machine interface? What would it take for the machine to do more of the work by itself? Were on an endless search for answers. It's how we improve.

So this is where we are today - constantly with one foot in the unknown. And thats where our experience makes all the difference. After 40 years of designing, building, test-ing and improving machines, weve learned what works, what doesnt and how to arrive at the best solution. It's this expertise that makes us an invaluable partner to our customers. Together, we anticipate problems and find innovative answers to meet the challenges that inevitably arise on new projects.

The world is changing faster every day. Demolition projects get bigger and more complex while schedules become more compressed. Brokk is constantly striving to stay one step ahead with state-of-the-art solutions that allow contractors to improve their performance. For 40 years weve been transforming the demolition business, and 40 years from now well still be transforming it.

Brokk's owner, Lifco, is listed on the stock market.

6 7

-

Brokk machines are specifically designed for high per-formance demolition. Whether the work environment is construction, metal processing, nuclear or underground, the compact profile allows access to places too small, too difficult or too dangerous for people or traditional machinery.

Once in position, a Brokk machine wields the power to outperform excavators up to five times its size, making the process significantly more efficient than traditional methods. The safe, ergonomic remote control removes the operator from the risks of the site, eliminates harmful vibrations and allows the operator a better view of the work. With a powerful electric motor, fumes are eliminated, making Brokk machines ideal for both indoor and outdoor jobs.

These qualities combine to put Brokk machines in a league of their own when compared to traditional demolition methods. But theres one more feature that makes these small giants so unique: unparalleled reliability. We know that every stop, every breakdown and every delay means time and money lost, so every part, detail and function is engineered to take the pounding of hard work and keep on delivering day after day, year after year and job after job.

When you choose a Brokk, you choose much more than a machine. You choose the original demolition robot, and you choose to work with the people whove spent 40 years designing, building, servicing and perfecting over 7 000 demolition robots. And you choose a partner who brings all that product, application and industry knowl-edge to your job site when you need it the most.

Unparalleled Technology.For Safe and Efficient Work.

40 years of expe-rience in designing and manufacturing demolition robots.

1Focus: Brokk is demolition robots. Since inventing the first machine, weve been the leader in robotic demolition technology.

2A full range of machi-nes and attachments means you get preci-sely the right tool for the job.

3Solution provider. We dont sell a product, we deliver a solution. We know the applica-tions for Brokk machi-nes and understand your needs.

4 5WHY CHOOSE BROKK?

After Sales. We provide a global service network with local presence and experienced and knowledgeable staff.

8

-

CONSTRUCTIONTUNNELING

MININGMETAL PROCESSING

CEMENTNUCLEAR

RESCUE

APPLICATIONS

The following pages reveal the wide range of Brokk applications, from precision maintenance work to demanding power demolition. Each case illustrates how a Brokk machine brings power, safety and flexibility to almost any space.

98

-

Fast and Agile. Safe and Ergonomic. Brokk Gives You More Power in a Smaller Package.

Construction demolition involves a wide range of jobs, from bathroom renovation to tearing down thick, reinforced concrete walls. The Brokk machine easily outperforms traditional demolition methods like concrete sawing, handheld tools and excavators. Not only due to the raw demolition power of the Brokk, but also because the compact size provides easy access to the core of the worksite. Once in place, the Brokk robot can finish the job in a fraction of the time of other methods.

Brokk machines are specially designed for confined spaces. The three-part arm system provides extraordinary flexibility and reach, and can be equipped with a variety of powerful attachments. When equipped with a crusher, the quiet, electric-powered hydraulics allow you to work during business hours or in areas with noise restrictions. Whats more, there are no exhaust fumes and less dust and vibration than with traditional methods. Cutting and coring usually requires water which needs to be disposed. With the Brokk method, this is not a problem.

Due to the fact the Brokk is so light and agile, it works in places where most other machines wont fit. The Brokk will easily climb over debris or up a staircase. Or if you don t like walking up stairs, you can take the compact and light-weight Brokk machine floor-to floor in an elevator.

APPLICATION

CONS

TRUC

TION

10

-

Demolishing ceiling with Brokk 90 and CC320, Norway.

Brokk 400 with concrete crusher CC700 demolishing reinforced concrete.

Concrete crushing with Brokk 100 and CC320 in Johannesburg, South Africa.

Brokk 60II with CC260 demolishing reinforced concrete pillar.

Brokk applications at a construction site.

Everything is possible.

Brokk 260 and SB302 in Poland.

REASONS TO CHOOSE BROKK IN THE CONSTRUCTION INDUSTRY- FASTER AND CHEAPER THAN JACKHAMMERS AND CUTTING & CORING- MORE POWERFUL AND FLEXIBLE THAN EXCAVATORS- SAFE REMOTE CONTROLLED DEMOLITION- ENABLES SILENT DEMOLITION- MANY DIFFERENT TOOLS MEANS THE BROKK WILL ALWAYS FIND JOBS

Brokk 160 and Brokk 100 working at a

large construction site in Stockholm, Sweden.

Brokk 100 with TE-160-100, construction

basement.

1110

-

The Preferred Tunneling Tool from Ground Zero, via the Swiss Alps to Down Under.

Tunneling applications present a wide range of opportunities for the high power and compact profile of a Brokk machine. Brokk robots are the ideal work method for utility tunnels, such as cable and water tunnels, and for tunnel enlargements. And in larger tunnels, Brokk machines are the preferred tool for cross passages, substations, safety niches, lining renovation. Thats why you see them on road, rail and subway tunnel projects across the world.

A Brokk machine brings the perfect combination of power and accessibility to areas where space limitations make it impossible or impractical to use a larger machine. Remote-controlled operation, small size and extraordinary flexibility and reach provide incredible access and capability in confined spaces without sacrificing power.

The ability to use heavy duty attachments that normally are recommended for much heavier excavators makes the Brokk perfect for the tunneling industry. For example, a Brokk 400 (weighing just 5 tons) with a half-ton breaker gives you an unparalleled size-to-power ratio, outperforming excavators up to five times as big. And if that still isnt enough, there is always the Brokk 800 with its 1,2 tons breaker to do the job.

With a wide range of attachments, the Brokk machine easily handles a full range of tasks such as drilling, rock breaking, excavating, scaling, rock splitting, removal of debris, and even shot-creting. The Brokk robot is really one machine for all tasks, which will save on both machine investment costs and set up times at the work site. Whether the job is below the sea, on the ground or at thousands of feet in altitude, a Brokk delivers where other machines cannot.

APPLICATION

TUNN

ELIN

G

12

-

Brokk 800 with MB1200 working in the metro of Hong Kong.

Brokk 800 with MB1200 working with safety nisches in Italy.

Brokk 800 with MB 1200 developing cross passges in Australia.

Brokk 400 with TE-260-180.

Brokk 800 with MB 1200 developing safety nisches in

Switzerland.

Excavating safety niches. Brokk 330 with concrete

cutter in Paris, France.

Enlarging existing tunnel in Stockholm City. Brokk 260

with SB302.

REASONS TO CHOOSE BROKK IN THE TUNNELING INDUSTRY- POWERFUL WHILE EXTREMELY COMPACT FOR TIGHT UNDERGROUND SPACES- MULTI TOOL CARRIER MEANS MANY JOBS WITH ONE MACHINE- ELECTRIC POWERED WITH NO FUMES- REMOTE CONTROLLED FOR SAFE OPERATION- ROBUST FOR UNDERGROUND WORK

Brokk 400 with SB552 developing cross passages on the Sydney Metro Northwest project in Australia.

1312

-

Power, Increased Safety and a Wide Range of Tools Takes Mining to aNew Level.

Below ground, the advantage of a compact machine becomes abundantly clear. And the small Brokk machines provide the same breaking capacity as larger traditional mining machines. In addition, one Brokk machine can perform a variety of tasks, such as scaling, breaking, digging, drilling, secondary breaking, bottom shaft cleaningetc.

Thanks to remote, radio-controlled handling, the operator can overlook the job from a safe, comfortable position with no risk of injury from falling debris. The electric mo-tor provides strong, quiet power with no exhaust fumes or other hazardous pollutants or vibration. Load-balanced outriggers provide excellent machine stability in all working directions while the sturdy track system and well-protected cylinders make the Brokk extremely durable and easy to maintain.

Above ground, the Brokk machine proves its value in the processing of material, when used in the maintenance of kilns, crushers etc. Typical applications include refrac-tory removal and oversize breaking. So above ground or below ground, Brokk is the preferred choice for manymines.

APPLICATION

MIN

ING

14

-

Brokk 260 with SB302 in a talc mine in Italy.

Brokk 400 with SB 552 working in a shaft.

Brokk 800 with drillling attachment working in Sweden.

Brokk 400 S working in a platinum mine in South Africa.

Drilling in narrow space. Brokk 90 with

BSD-80 hydraulic drill in South Africa.

Brokk 160 and SB 202 working in a narrow mine in South Africa.

REASONS TO CHOOSE BROKK IN THE MINING INDUSTRY- POWERFUL WHILE EXTREMELY COMPACT FOR TIGHT UNDERGROUND SPACES- MULTI-TOOL CARRIER MEANS MANY JOBS WITH ONE MACHINE- ELECTRIC POWERED WITH NO FUMES- REMOTE CONTROLLED FOR SAFE OPERATION- ROBUST FOR UNDERGROUND WORK- IDEAL FOR NARROW MINING

1514

-

Controlled Tough Debricking and Slag Removal. True Maintenance Power When the Heat is on.

Brokk machines main task in the metal process industry is to reduce the plant shut down time and yet maintain safety for the workers involved. Anywhere there is refrac-tory or slag there is work for Brokk robots. Thanks to the machines flexible design, it can be used for many applications within one plant.

Whether you need more power or precision for cleaning a ladle, EAF, torpedo car, BF runner, converter mouth, tundish, blast furnace, you can trust Brokk to get the job done. Remote-controlled precision and tough durability make these machines the ideal tool for the high quality demolition work required in the process industry. The precise movements of the machines make it no problem to demolish the work lining without damaging the safety lining for example.

The Brokk machine combines compact design with optimum power to provide easy access and fast, efficient performance. The small size makes it possible to enter areas where no other machine could enter and replace work that otherwise is done manually. The heat resistance options enable you to start the job earlier while minimiz-ing risks for any breakdown. Since the operator controls the Brokk remotely, he can choose a working position thats safe, comfortable and allows for the best possible view of the job.

The strong, three-arm system handles a wide range of powerful tools and allows for exceptional reach and power in all directions. And all this flexibility comes with the Brokk machines proven performance record, ensuring that you can break and remove material without fear of damaging the machine.

APPLICATION

MET

AL P

ROCE

SSIN

G

16

-

Copper converter mouth cleaning with Brokk 800 and a special designed heat-protected breaker in Sweden.

Ladle cleaning. Brokk 180 with SB 202 in ferroalloy plant.

Ladle cleaning with Brokk260 and a SB302.

Brokk 100 easily enters the torpedo car.

Brokk 100 with SB152 working in a torpedo car.

Furnace mouth cleaning with

Brokk160 and SB202.

REASONS TO CHOOSE BROKK IN THE METAL INDUSTRY- REDUCE PLANT SHUT DOWN TIME- EFFICIENT AND SAFE WAY TO REMOVE SLAG AND REFRACTORY- REMOTE CONTROLLED FOR SAFETY AND OPTIMAL VIEW- ACCESS TO AREAS NO OTHER MACHINE CAN ENTER- HEAT RESISTANT- MULTIPLE APPLICATIONS MEANS MANY USES IN ONE PLANT

1716

-

BRICKINGSOLUTIONSA D I V S I O N O F

Easy Access, Maximum Efficiency and Operator Safety. Concrete Brokk Advantages.

Demolishing coating and brick linings is a job the Brokk machine was born to do. Theres simply no faster or safer method. The compact design makes access easy, while the remote control makes the work safe and quick. The operator can choose the best position for viewing the work, and since hes not bothered by vibrations, fumes or the risk of collapsing material or hot coating, hes much more efficient.

With excellent stability in all directions and easily adjust-able breaker frequency, the Brokk ensures precise opera-tion without shell or lining damage. The three-part arm system provides flexibility and reach and allows for less repositioning of the machine compared to conventional excavators.

In an industry where every hour a kiln is down means a loss of profitable production, investing in a Brokk can pay for itself with the very first refractory tear-out. Since the Brokk is heat resistant with well-protected cylinders and components, you can start the job earlier without risking breakdown due to heat. This reduces plant downtime and increases the plant profit.

APPLICATION

CEM

ENT

BRICKINGSOLUTIONSA D I V S I O N O F

18

-

Breaking out brick lining. Brokk 330 with SB 300 in Gotland, Sweden.

Breaking out coating. Brokk 90 with SB 152.

Brokk 400 with a SB552 tearing out bricks in the Middle East.

Entering a kiln inlet section with Brokk 50.

Brokk 160 with SB 202 tearing down coating in

Turkey.

REASONS TO CHOOSE BROKK IN THE CEMENT INDUSTRY- REDUCE PLANT SHUT DOWN TIME- EFFICIENT AND SAFE WAY TO REMOVE COATING AND REFRACTORY- REMOTE CONTROLLED FOR SAFETY AND OPTIMAL VIEW - HEAT RESISTANT- RELIABILITY FOR TOUGH ENVIRONMENTSEMENT

1918

-

Extraordinary Power and Reliability for Extraordinary Jobs.

Some projects call for a special solution. At Brokk, we offer a proven combination of design, engineering and service that can tackle almost any undertaking. From consulting to mock-ups; from operator training to maintenance; from start-up to final testing, we leave nothing to chance when it comes to perfecting the performance of our machines. And since the Brokk is built for adaptability, our engineers can customize the machines to meet your specialized needs.

It's hard to think of an environment where remote control is more critical than at a nuclear site and for nuclear decommissioning work. Here, Brokk technology has reached its highest level, enabling camera operation with remote video monitors. Through the partnership with Ahlberg Cameras, Brokk machines can now be equipped with the markets leading radiation tolerant camera systems. In this extraordinary environment, dangerous tasks like demolishing, removing, sorting and containerizing radioactive waste are all in a days work for a specially equipped Brokk. We have close to 30 years of experience in nuclear projects, and a large number of machines delivered to the nuclear industry in the US, UK, France, Germany, Belgium, Sweden, Japan, China and more.

All Brokk machines come with unique features you wont find in typical demolition tools: remote-controlled handling, heat resistant design, flexible three-arm system with exceptional reach and strength, and an electric motor for powerful, quiet, fumeless operation. And it gets into places where people or other machines cant go. All this comes together with the reliability built into the machines after having 7 000 machines operate in harsh and abusive environments for the last 40 years.

APPLICATION

NUCL

EAR

20

-

Brokk 100 with cameras and other accessories.

Brokk 330M with a SC600 steel shear cutting and sorting radioactive waste.

Demolishing a hot cell behind acrylic glass. Brokk330 with SB 450.

Brokk 330M with a SC600 steel shear cutting and sorting radioactive waste (after more than 10,000 hours) in USA.

Dismantling nuclear equipment. Brokk 330

with cut off saw.

Brokk 100 with a manipulator arm.

REASONS TO CHOOSE BROKK IN THE NUCLEAR INDUSTRY- REMOTE CONTROLLED - POSSIBILITY TO OPERATE VIA CAMERAS- MULTI TOOL CARRIER- RADIATION TOLERANT- CUSTOMIZABLE FOR THE SPECIFIC TASK- PROVEN RELIABILITY FROM TOUGH ENVIRONMENTS

2120

-

APPLICATION

RESC

UE

Independent, Powerful and Flexible. Reliability Where It's Needed.

Hazardous environments come in many forms - explosive items, gas leaks and large fires are just a few examples. In these situations, the inherent dangers of the location and the work put humans at risk. Thats where a Brokk ensures safety and saves lives. A flexible, independent machine (whether electric or diesel) is the perfect solution for firefighting, mine clearance, nuclear applications, explosive ordnance disposal, or the aftermath of an earthquake in short; any work where safety and reliability are the highest priority.

Unlike typical EOD robots, even the smallest Brokk robot can perform heavy tasks, carry powerful tools and lift heavy items. Thats why Brokk machines were brought into Fukushima Daiichi NPP after the accident real work needed to get done.

Brokk offers reinforced, highly customizable machines to meet the punishing demands and harsh conditions of rescue applications. These machines are built for the most challenging environments. With the right Brokk, unsafe conditions become safe work environments.

22

-

REASONS TO CHOOSE BROKK FOR RESCUE TASKS- REMOTE-CONTROLLED - POSSIBILITY TO OPERATE VIA CAMERAS- PERFORMS HEAVY TASKS AMD CARRIES HEAVY ITEMS- MULTI-PURPOSE MACHINE WITH MANY TOOLS- PROVEN RELIABILITY FROM TOUGH ENVIRONMENTS- EXCELLENT MANERUVERABILITY AND MOBILITY

Brokk 330 and a bucket working with an operational field test.

Brokk 100, easy to transport to the rescue area.

Brokk 100 with a cut off saw in China.

Brokk 100 with sorting grapple handling hazardous material.

Brokk 100 with steel shear and camera.

Brokk 100 with SB 152 in black if you have

a need for a discretely appearing machine.

Fire fighting with Brokk.

2322

-

STOCKHOLM8.45AM

-

PROD

UCTS

-

OUR

CONC

EPT

The Brokk Credo:Strength is in the Details.The Brokk robots are built to last. The key quality engineered into every part and every detail is the ability to withstand countless hours of tough work. To guarantee the highest quality and performance, over 80% of the machines components are custom made specifically for Brokk. It means more time and expense in building the machine, but the results speak for themselves: Brokk robots last over time.

WIDE RANGE OF TOOLS

A whole range of tools, many specifically designed for Brokk. Patented quick-hitch for fast and easy tool changing.

THREE-ARM SYSTEM

A strong and flexible solution that allows for extraordinary reach and power in all directions, providing maximum precision and accuracy.

REMOTE CONTROLLED OPERATION

Maximizes efficiency while keeping the operator safe from harmful vibrations and dangerous areas.

DEMOLITION POWER

Despite its compact size, Brokk machines can outperform excavators five times as big.

NO EXHAUST FUMES

Less noise and less maintenance.

COMPACT AND MANEUVERABLE

Easy to maneuver and easy to transport. Can get access through narrow spaces and climbs stairs.

OUTRIGGERS FOR STABILITY

When working with heavy tools.

HEAT RESISTANT

From covers to cylinders and components, everything is heat and impact protected.

PATENTED QUICK HITCH

Saves weight and enables fast and safe tool changes.

28

-

TECHNICAL ADVANTAGES

OUR

EDGE

WIDE RANGE OF MACHINE MODELS

A wide range of machine models, with unique characteristics and countless options.

MAXIMUM OUTPUT MINIMUM INPUT

Maximum power using minimum energy input. Run on small electrical fuses. Built to optimize tool performance.

ERGONOMIC FOR OPERATOR

Belt, harness and hand support for control levers for optimal real-life ergonomics.

HARDENED ELECTRICAL SYSTEM

Designed with special components for tough environments.

SUPERIOR STABILITY

Track design and load balancing outriggers that maximize stability and safety.

UNIQUE CONTROL SYSTEM

Superior radio technology with an easy to read display. Proven reliability with up to 300 m reach with no delay.

RELIABILITY

Built to last in tough and hot conditions, based on 40 years of engineering.

UNBEATABLE COOLING CAPACITY

Designed for hard work in hot conditions.

SERVICEABILITY

Everything is designed for quick and easy service, even when at the job site.

RIGHT CONFIGURATION FOR THE APPLICATION

Wide range of options and accessories for different applications.

2928

-

More Power in Minimal Spaces The BROKK 60II is the perfect solution for safe, effective demolition in very confined spaces. It's combination of small size and lightweight po-wer works wonders in places where it was previously impossible to do mechanized demolition work. Compared to its older brother, the Brokk 50, the 60II boosts productivity by 25% with a stronger breaker, faster movement, new control system and smaller profile. The low weight ma-kes it ideal for indoor work on weak floors, and it can be transported in an ordinary passenger elevator.

The smallest remote-controlled demolition robot in the world

More efficient than 5-10 people with jackhammers

Safe and ergonomic for operators Operates on just 16 amp electricity Access through even the smallest of doorways

BROK

KUPGR

ADED!

30

-

Hydraulic breaker in illustrations SB 52Load and stability diagram can be ordered from Brokk ABPerformanceSlewing speed 6,5 sec/245Transport speed, max. 2,5 km/h; 0,7 m/s; 1.6 mphIncline angle, max. 30Hydraulic systemHydraulic system capacity 27 l; 7.1 US galPump type Gear pump with fixed displacement System pressure 18 MPa; 2,610 psi Pump flow max 50 Hz and 60 Hz 22 l/min; 5.8 US gal/minElectric motorType ABBMotor rating* 5,5 kWRated current* 14 APower consumption* 0-6 kWStarting device Direct startControl systemControl type Portable control boxSignal code DigitalTransfer Cable/RadioWeightWeight of basic machine excl attachment and extra equipment 500 kg; 1 102 lbRecommend attachment weight 80 kg; 175 lbNoise levelSound power level Lwa, measured according to directive 2000/14/EC 90 dB(A)

*Valid for 400 V/50 Hz

RANG

ETE

CHNI

CAL

DATA

SIZE

TOOL

S

Arm SystemImpact and heat protection for cylinder C2 and C3Under carriageRubber caterpillar tracksOther optionsBrokk coverExtra hydraulic functionForced draft cooling

ACCE

SSOR

IES/

OPTI

ONS

30 31

-

BROK

K

The Next Step in Demolition Versatility BROKK 100 is one of the industrys most popular choices for meeting the ever-increasing demands of confined-space demolition. Compared to it's predecessor, this Brokk brings 30% more hitting power, even better cooling capacity, reduced height and weight. And it keeps the phenomenal versatility in restricted spaces. It's compact design, easy operation, unparalleled stability and powerful tools make it the perfect answer in a wide variety of residential, commercial and industrial environments. In spite of it's reach and power, it folds up into a surpris-ingly compact package that can climb stairs, fit in an elevator and be carried to the site in a small truck or trailer.

Versatile with compact size and low weight Most powerful machine of its size Operates on both 16 and 32 amp electricity

Great balance on both tracks and outriggers

Real 360 degrees slewing Unbeatable cooling capacity Fully covered and protected components

32

-

Hydraulic breaker in illustrations SB 152Load and stability diagram can be ordered from Brokk ABPerformanceSlewing speed 10 sec/360Transport speed, max. 2,5 km/h; 0,7 m/s; 1.6 mphIncline angle, max. 30Hydraulic systemHydraulic system capacity 45 l; 11.8 US galPump type Variable load-sensing piston pumpSystem pressure 17,5 MPa; 2 538 psiPump flow max 50 Hz/60 Hz 50 l/min; 13.3 US gal/minElectric motorType ABBMotor rating* 15 kWRated current* 31 ARated current reduced power* 16 APower consumption* 0-15 kWStarting device Soft start/Direct startControl systemControl type Portable control boxSignal code DigitalTransfer RadioWeightWeight of basic machine excl attachment & extra equipment 990 kg; 2 183 lbsRecommended attachment weight 160 kg; 352 lbsNoise levelSound power level Lwa, measured according todirective 2000/14/EC 91 dB(A)

*Valid for 400V/50Hz

Arm SystemImpact and heat protection for cylinder C2 and C3Under carriageRubber caterpillar tracksSteel caterpillar tracksHeat resistanceHeat resistant hoses for hydraulic breakerForced draft cooling of machineForced draft cooling of breakerOther optionsAir flushing through breaker to protect from dustWater spray through breaker to bind dustBrokk coverExtra hydraulic functionDrainage hoseCAN cable connection for tools

RANG

ETE

CHNI

CAL

DATA

ACCE

SSOR

IES/

OPTI

ONS

SIZE

TOOL

S

32 33

-

BROK

KNEW

2016!

NEW 2015

!NEW

2016!

Cordless, Fearless, RelentlessThe BROKK 120D is flexibility without compromise. It's the worlds smallest diesel-driven demolition machine. It's small size enables it to enter through any standard door opening and makes it easy to maneuver in tight spaces. Running cordless, it's driven by a powerful diesel engine that can operate for a minimum of eight hours without refueling. And all this flexibility comes without sacrificing any of the power or performance of its electrical sibling, the Brokk 100. Add the new hardened Brokk SmartPowerTM electrical system, and you have a cordless, fearless and relentless work horse at your service.

Worlds smallest diesel-driven demolition machine

Ideal for sites that lack a reliable power supply

Tool compatibility with the Brokk 100 Swift tracking speed for high mobility New rugged electrical system Brokk SmartPowerTM, a new intelligent and hardened electrical system

34

-

RANG

E

SIZE

Hydraulic breaker in illustration SB 152 Load and stability diagram can be ordered from Brokk ABPerformanceSlewing speed 10 sec/360Transport speed, max. 3,0 km/h; 0,8 m/s; 1.9 mphIncline angle, max. 30Hydraulic systemHydraulic system capacity 45 l; 11.8 US galPump type Gear pump with fixed displacementSystem pressure* 18 MPa; 2 610 psiPump flow max 50 Hz/60 Hz 50 l/min; 13.3 US gal/minDiesel performanceType Three-cylinder, water-cooled, 4-stroke engineMotor 18,5 kW; 24.8 hp diesel (EPA Tier 4)Fuel tank capacity 30 l; 7.9 US galEngine oil volume with and without filter change 5,1 l; 1.35 US galOilflow 50 l/min; 13.2 US gal/minFreezing point -40C; -40FControl systemControl type Portable control boxSignal code DigitalTransfer RadioWeightWeight of basic machine excl attachment &extra equipment 1 230 kg; 2 711 lbsRecommended attachment weight 160 kg; 352 lbsNoise levelSound power level Lwa, measured according todirective 2000/14/EC 101 dB(A)

*Hydraulic pressure can be increased depending on the attachment.

Arm SystemImpact and heat protection for cylinder C2 and C3Under carriageRubber caterpillar tracksSteel caterpillar tracksHeat resistanceHeat resistant hoses for hydraulic breakerForced draft cooling of machineForced draft cooling of breakerOther optionsAir flushing through breaker to protect from dustWater spray through breaker to bind dustBrokk coverExtra hydraulic functionDrainage hoseCAN cable connection for tools

TECH

NICA

L DA

TA

ACCE

SSOR

IES/

OPTI

ONS

TOOL

S

34 35

-

BROK

K

Cutting-edge Demolition Unleashed Dont let the size fool you. The BROKK 160 is a giant step forward when it comes to strength in small packages. This lightweight machine and it's mighty electric motor pack a mean wallop with the breaker (over 406 joules at the tip). Still, it's narrow enough to get through standard door openings. Like all our demolition models, the Brokk 160 is designed with safety as the first priority. The state-of-the-art digital remote control removes danger from the demolition equation by giving the operator incredible control and accuracy from a safe distance.

Operates on only 32 amp electricity Maximizes SB 202 breaker performance Superb balance in all directions Unbeatable cooling capacity Service-friendly for onsite maintenance Many options and configurations

36

-

Hydraulic breaker in illustrations SB 202Load and stability diagram can be ordered from Brokk ABPerformanceSlewing speed 10 sec/360Transport speed, max. 2,1 km/h; 0,6 m/s; 1.3 mphIncline angle, max. 30Hydraulic systemHydraulic system capacity 85 l; 22.5 US gal Pump type Variable load-sensing piston pumpSystem pressure** 17,5 MPa; 2 538 psiPump flow max 50 Hz 62 l/min; 16.4 US gal/min 60 Hz 74 l/min; 19.7 US gal/minElectric motorType ABBMotor rating* 18.5 kWRated current* 36 APower consumption* 0-22 kWStarting device Soft start/Direct startControl systemControl type Portable control boxSignal code DigitalTransfer Cable/RadioWeightWeight of basic machine excl attachment & extra equipment 1 600 kg; 3 527 lbsRecommended attachment weight 270 kg; 595 lbsNoise levelSound power level Lwa, measured according to directive 2000/14/EC 87 dB(A) *Valid for 400V/50Hz **Hydraulic pressure can be increased depending on the attachment.

RANG

ETE

CHNI

CAL

DATA

SIZE

TOOL

S

Arm SystemImpact and heat protection for cylinder C2 and C3 Long arm 2Under carriageRubber caterpillar tracksSteel caterpillar tracks Dozer bladesHeat resistanceHeat resistant hoses for hydraulic breakerForced draft cooling of machineForced draft cooling of breaker Steel pads for kiln demoliton or furnanceOther optionsAir flushing through breaker to protect from dustWater spray through breaker to bind dust Counter weightBrokk coverExtra hydraulic functionDrainage hoseCAN cable connection for tools

ACCE

SSOR

IES/

OPTI

ONS

36 37

-

BROK

K

Outperforming All Opponents.The new BROKK 280 enters the market of the original Brokk machine size segment. Evolved from the successful Brokk 260, the Brokk 280 just gets better, built to cope with the ever-increasing demands of the demolition industry. With 20% increased breaking performance, the new intelligent and hardened Brokk SmartPowerTM electrical system and a more robust design, this model is destined to become a huge success. Like its predecessor, it will outperform much heavier excavators. It's just that the gap has now been increased.

Outstanding all-around demolition versatility

20% more hitting power maximizes the power of SB 302

Brokk SmartPowerTM, a new intelligent and hardened electrical system

Outstanding cooling system Rugged and robust

NEW 2016

!

NEW 2015

!NEW

2016!

38

-

Hydraulic breaker in illustrations SB 302Load and stability diagram can be ordered from Brokk ABPerformanceSlewing speed 18 sec/360Transport speed, max. 2,7 km/h; 0,75 m/s; 1.7 mphIncline angle, max. 30Hydraulic systemHydraulic system capacity 90 l; 23.8 US galPump type Variable load-sensing piston pumpSystem pressure to cylinders, attatchment and motors, max. 17,0 MPa; 2 466 psiSystem pressure, increased to attachment, max 20,0 MPa; 2 901 psiPump flow max 50 Hz 100 l/min; 26.5 US gal/min 60 Hz 120 l/min; 31.7 US gal/minElectric motorType ABBMotor rating* 22 kWRated current* 41 APower consumption* 0-27 kWStarting device Soft start/Direct startControl systemControl type Portable control boxSignal code DigitalTransfer Cable/RadioWeightWeight of basic machine excl attachment & extra equipment 3 150 kg; 6 944 lbsRecommended attachment weight 420 kg; 924 lbsNoise levelSound power level Lwa, measured according to directive 2000/14/EC 93 dB(A) *Valid for 400V/50Hz

SIZE

TOOL

S

Arm SystemImpact and heat protection for cylinder C2 and C3Under carriageRubber caterpillar tracksSteel caterpillar tracksHeat resistanceHeat resistant hoses for hydraulic breakerForced draft cooling of machineForced draft cooling of breaker Steel pads for kiln demoliton or furnanceOther optionsAir flushing through breaker to protect from dustWater spray through breaker to bind dust Counter weight Cable reel with 63 m cableBrokk coverExtra hydraulic functionDrainage hoseCAN cable connection for tools

ACCE

SSOR

IES/

OPTI

ONS

RANG

ETE

CHNI

CAL

DATA

38 39

-

BROK

K

Heavy-duty Power DeliveryThe BROKK 400 combines the renowned mobility and versatility of a Brokk with heavy-duty power and performance. Now designed with a larger, stronger undercarriage, the Brokk 400 is the perfect machine for applications in tough environments. The upgraded hydraulics and improved stability produces unparalleled tool performance even with the most demanding attachments. With a near 7-meter reach (23.1 feet) and the flexibility of the signature three-arm-system, the Brokk 400 has an excellent work area without the need for time-consuming repositioning.

A heavy-duty demolition workhorse Demolition capacity comparable to a 15-20ton excavator

Maximizes the power of the SB 552 breaker

Impressive cooling Compact size with exceptional reach

40

-

Hydraulic breaker in illustrations SB 552Load and stability diagram can be ordered from Brokk ABPerformanceSlewing speed 20 sec/360Transport speed, max. 2,5 km/h; 0,7 m/s; 1.6 mphIncline angle, max. 30Hydraulic systemHydraulic system capacity 160 l; 42.3 US galPump type Variable load-sensing piston pumpSystem pressure to cylinders, attatchment and motors, max. 17,0 MPa; 2 466 psiSystem pressure, increased to attachment, max 23,0 MPa; 3 336 psiPump flow max 50 Hz 115 l/min; 30.4 US gal/min 60 Hz 130 l/min; 34.3 US gal/minElectric motorType ABBMotor rating* 30 kWRated current* 55 APower consumption* 0-36 kWStarting device Soft start/Direct startControl systemControl type Portable control boxSignal code DigitalTransfer Cable/RadioWeightWeight of basic machine excl. attachment & extra equipment 5 100 kg; 11 240 lbsRecommended attachment weight 600 kg; 1 323 lbsNoise levelSound power level Lwa, measured according to directive 2000/14/EC 100 dB(A) *Valid for 400V/50Hz

RANG

ETE

CHNI

CAL

DATA

SIZE

TOOL

S

Arm SystemImpact and heat protection for cylinder C2 and C3 Heavy duty arm 3 (with direct connected breaker)Under carriageRubber caterpillar tracksSteel caterpillar tracksHeat resistanceHeat resistant hoses for hydraulic breakerForced draft cooling of machineForced draft cooling of breaker Steel pads for kiln demoliton or furnanceOther optionsAir flushing through breaker to protect from dustWater spray through breaker to bind dust Counter weight Cable reel with 63 m cableBrokk coverExtra hydraulic functionDrainage hoseCAN cable connection for tools

ACCE

SSOR

IES/

OPTI

ONS

40 41

-

BROK

K

The Advantage of Diesel DemolitionThe bigger, stronger, faster BROKK 400D is an impressive step up for diesel-driven demolition. When the job site lacks a power supply, the 400D is the perfect tool for delivering heavy-duty power where you need it most. It outperforms conventional excavators several times heavier with both its breaking capacity and its ability to squeeze into confined spaces. As the fastest Brokk model ever, it moves quickly and easily over longer distances between worksites, delivering a mighty punch with its large hydraulic breaker wherever it goes.

A heavy-duty demolition workhorse Demolition capacity comparable to a 15-20 ton excavator

Maximizes the power of the SB 552 breaker

Impressive cooling Compact size with exceptional reach Ideal for sites that lack a reliable power supply

42

-

Hydraulic breaker in illustrations SB 552Load and stability diagram can be ordered from Brokk ABPerformanceSlewing speed 20 sec/360Transport speed, max. 3,4 km/tim; 0,95 m/s; 2.1 mphIncline angle, max. 30Hydraulic systemHydraulic system capacity 130 l; 34.3 US galPump type Variable load-sensing piston pumpSystem pressure to cylinders, attatchment and motors, max. 17,0 MPa; 2 465 psiSystem pressure, increased to attachment, max. 23,0 MPa; 3 336 psiPump flow max. 130 l/min; 34.3 US gal/minDiesel performanceType Four-cylinder, water-cooled, 4-stroke engineOutput at 2 600 rpm (SAE J1995) 74 kW; 99.2 hpFuel tank capacity 80 l; 21.1 US galEngine oil volume with and without filter change 13,2 l; 3.49 US galCoolant volume 10 l; 2.67 US galFreezing point -40C; -40FControl systemControl type Portable control boxSignal code DigitalTransfer Cable/RadioWeightWeight of basic machine excl attachment and extra equipment 5 500 kg; 12 125 lbsRecommended attachment weight 600 kg; 1 323 lbsNoise levelSound power level Lwa, measured acc. to directive 2000/14/EC 101 dB(A)

RANG

ETE

CHNI

CAL

DATA

SIZE

TOOL

S

Arm SystemImpact and heat protection for cylinder C2 and C3 Heavy duty arm 3 (with direct connected breaker)Under carriageRubber caterpillar tracksSteel caterpillar tracksHeat resistanceHeat resistant hoses for hydraulic breakerForced draft cooling of machineForced draft cooling of breaker Steel pads for kiln demoliton or furnanceOther optionsAir flushing through breaker to protect from dustWater spray through breaker to bind dust Counter weight Particulate filter Brokk coverExtra hydraulic functionDrainage hoseCAN cable connection for tools

ACCE

SSOR

IES/

OPTI

ONS

42 43

-

BROK

K

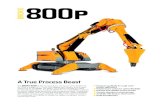

A True Process BeastThe BROKK 800P is considerably bigger than the other machines in the Brokk family. With a weight of 11 300 kg (without attachment), 360 degrees of arm rotation and a reach measuring an incredible 10 meters, it's a game changer for metal processing applications. The Brokk 800P has an unparalleled capacity for heavy, demanding demolition and maintenance work. It's precision operation makes sure no unwanted damage occurs. When equipped with the new process breaker featuring hydraulics heat protection, it's unmatched in its ability to handle hot ladles, converters, runners and furnace work.

Designed specifically for tough metal process applications

Rotation boom system for optimal work angles

Patented heat-shielded process breaker Unparalleled reach for its size Precision operation to avoid damage Available with diesel or electric power

44

-

RANG

ETE

CHNI

CAL

DATA

SIZE

TOOL

S

Hydraulic breaker in illustrations SB452Load and stability diagram can be ordered from Brokk ABPerformanceSlewing speed 28 sec/360Transport speed, max. 3,3 km/h; 0,9 m/s; 2 mphIncline angle, max. 30Hydraulic systemHydraulic system capacity 165 l; 44 US galPump type Variable load-sensing piston pumpSystem pressure to cylinders and motors, max. 18,5 MPa; 2 683 psiSystem pressure, increased to attachment, max 25,0 MPa; 3 626 psiFlow max Diesel/ 50 Hz el. motor 140 l/min; 37 US gal/min 60 Hz el. motor 168 l/min; 44 US gal/minDiesel performanceType Four-cylinder, water-cooled, 4-stroke engineOutput at 2 600 rpm (SAE J1995) 74 kW; 99.2 hpFuel tank capacity 80 l; 21 US galEngine oil volume with and without filter change 13,2 l; 3.49 US galCoolant volume 9 l; 2.38 US galFreezing point -40C; -40FControl systemControl type Portable control boxSignal code DigitalTransfer Cable/RadioWeightWeight of basic machine excl attachment & extra equipment (diesel) 11 300 kg; 24 910 lbsRecommended attachment weight 600 kg; 1 323 lbsElectric motor**Type ABBMotor rating* 45 kW; 60 hpRated current* 81 APower consumption* 0-45 kWStarting device Direct startNoise levelSound power level Lwa, measured acc. to directive 2000/14/EC El: 99 dB(A) Diesel:103 dB(A) *Valid for 400V/50Hz **Option: Electric motor

Arm SystemImpact and heat protection for cylinder C2 and C3Under carriageSteel caterpillar tracksHeat resistanceHeat resistant hoses for hydraulic breakerForced draft cooling of machineForced draft cooling of breakerOther optionsParticulate filterAC

CESS

ORIE

S/OP

TION

S

44 45

-

BROK

K

A New Dimension in Heavy DemolitionWith the BROKK 800S, a whole new realm of application opens up in the field of tunneling and heavy demolition. Large size and unmatched capacity make the Brokk 800S ideal for the heavy, demanding work typical of tunnel projects. It weighs in at a hefty 11 050 kg (without attachment) with an arm that extends a whopping 10 meters. All this bulk and reach is coupled with equally impressive power. Equipped with the MB 1200 breaker, the Brokk 800S delivers more than twice the punch of the Brokk 400.

Worlds largest remote-controlled demolition machine

Powerful 1 200 kg breaker The ultimate machine for tough tunneling or construction works

Unparalleled reach for its size Available with diesel or electric power

46

-

Hydraulic breaker in illustrations MB1200Load and stability diagram can be ordered from Brokk ABPerformanceSlewing speed 28 sec/360Transport speed, max. 3,3 km/h; 0,9 m/s; 2 mphIncline angle, max. 30Hydraulic systemHydraulic system capacity 165 l; 44 US galPump type Variable load-sensing piston pumpSystem pressure to cylinders and motors, max. 18,5 MPa; 2 683 psiSystem pressure, increased to attachment, max 25,0 MPa; 3 626 psiFlow max Diesel/50 Hz el. motor 140 l/min; 37 US gal/min 60 Hz el. motor 168 l/min; 44 US gal/minElectric motorType ABBMotor rating* 45 kW; 60 hpRated current* 81 APower consumption* 0-45 kWStarting device Direct startDiesel performance, option**Type Four-cylinder, water-cooled, 4-stroke engineOutput at 2 600 rpm (SAE J1995) 74 kW; 99.2 hpFuel tank capacity 80 l; 21 US galEngine oil volume with and without filter change 13,2 l; 3.49 US galCoolant volume 9 l; 2.38 US galFreezing point -40C; -40FControl systemControl type Portable control boxSignal code DigitalTransfer Cable/RadioWeightWeight of basic machine excl attachment & extra equipment (diesel) 11 050 kg; 24 361 lbsRecommended attachment weight 1 200 kg; 2 645 lbsNoise levelSound power level Lwa, measured acc. to directive 2000/14/EC El: 99 dB(A) Diesel:103 dB(A)

*Valid for 400V/50Hz **Option: Diesel motor

RANG

ETE

CHNI

CAL

DATA

SIZE

TOOL

S

Arm SystemImpact and heat protection for cylinder C2 and C3 Heavy duty arm 3Under carriageSteel caterpillar tracksHeat resistanceForced draft cooling of machineOther optionsAir flushing through breaker to protect from dustParticulate filterExtra hydraulic functionDrainage hoseCAN cable connection for tools

ACCE

SSOR

IES/

OPTI

ONS

46 47

-

BROK

K

Introducing the Brokk Ex SeriesBehold the newest members of the Brokk family: The Brokk Ex Series. This new product lineup consists of six models designed specifically for use in potentially explosive environments. With specialized modifications and equipment, such as explosion-proof electrical cabinets, gas detectors and more, these machines provide a new level of safety and durability in work areas with explosive gas hazards.

All Ex machines comply with the ATEX 1994/9/EC directive, classified up to Equipment Class 3G IIA T3. They can be used in what the ATEX directive calls Zone 2, where explosive gas, vapor or mist may occur. This new capabi-lity is especially important for customers working in mining, petroleum and other potentially dangerous industries. The Ex Series brings an even higher margin of Brokk safety to all these environments.

Explosion proof according to ATEX directive

Ideal for potentially explosive environments

Same outstanding capabilities as standard Brokk machines

EXBROKK 60 EXBROKK 100 EXBROKK 160 EXBROKK 280 EXBROKK 400 EXBROKK 800 EX

NEW 2016

!

NEW 2015

!NEW

2016!

48

-

OPTIONS

BROK

K

Build Your Own Brokk. For Your Own Specific Needs.AT A FIRST GLANCE, the Brokk family seems to consist of 8 members; from the small but surprisingly powerful Brokk 60II to the monster of power, Brokk 800. But since you are able to customize your machine with different types of options long arms, dozer blades etc you can literally create your own Brokk model.

Here you can see some available options making your Brokk machine even more effective and versatile, year after year. Different options are applicable on different machiens, please see specific data sheet for each machine model.

Long arm 2

Forced draft cooling of breaker

Air flushing through breaker to protect from dust

Waterspray through breaker to bind dust

Dozer bladesSteel or rubber caterpillar tracks

Heat resistant hoses

Counter weight

Forced draft cooling of machine

Steel pads

Impact and heat protection for C2 and C3

Heavy duty arm 3

Cable reel with 63 m cable

Particulate filter (for diesel machines only)

48 49

-

PARIS1.16 PM

-

ATTA

CHM

ENTS

-

BREAKERS

SIDE ANGLING DEVICE**

Equipped with additional tools, a Brokk becomes even more profitable for your business. Grapples, scabblers, buckets, drills and other devices greatly expand the machines efficiency and versatility. Heres our wide and ever-expanding range of original Brokk attachments:

Hitting power*

Blows/min Weight Made for

SB 52 101 J/Nm 960 1 700 55 kg/121 lbs Brokk 60SB 152 254 J/Nm 840 1 900 140 kg/309 lbs Brokk 100, 120D, 160SB 202 406 J/Nm 850 1 800 200 kg/441 lbs Brokk 160SB 302 610 J/Nm 600 1 400 310 kg/683 lbs Brokk 280 SB 452 855 J/Nm 550 1 250 441 kg/972 lbs Brokk 400, 800SB 552 1 048 J/Nm 650 1 150 520 kg/1 146 lbs Brokk 400MB 1200 2 709 J/Nm 340 680 1 200 kg/2 646 lbs Brokk 800

Angle Weight* Made forPTA-04,5 60 140 kg/309 lbs SB 102/Brokk 100, 120DPTA-06 70 215 kg/474 lbs SB 152/Brokk 160PTA-07 70 330 kg/728 lbs SB 202/Brokk 280PTA-09 55 555 kg/1 224 lbs SB 302/Brokk 400

*Actual output, impact energy class (Joule/Nm) A variety of chisels and tools can be fitted to the breakers. Other breaker brands can also be used on Brokk machines. Contact your local Brokk dealer or Brokk AB for information.

*With breaker ** Requires one extra hydraulic function

SB302

PTA-09

53

-

Cutting force Jaw opening Weight Made forHCS6 214 kN/22 t/48 Klbf 267 mm/10.5 in 56 kg/123 lbs Brokk 60, 100, 120DHCS7 312 kN/32 t/70 Klbf 357 mm/14.1 in 158 kg/348 lbs Brokk 100, 120D, 160CC420S 740 kN/75 t/166 Klbf 145 mm/6 in 300 kg/661 lbs Brokk 160, 280CC700S 1 840 kN/188 t/414 Klbf 268 mm/11 in 695 kg/1 532 lbs Brokk 400, 800BMS 100 647 kN/66 t/145 Klbf 195 mm/7.7 in 380 kg/838 lbs Brokk 160, 280BMS 140 863 kN/88 t/194 Klbf 290 mm/11.4 in 645 kg/1 422 lbs Brokk 400BMS 250-H 1 353 kN/138 t/304 Klbf 375 mm/14.8 in 1 360 kg/2 998 lbs Brokk 800MC 200 490 kN/50 t/110 Klbf 200 mm/7.9 in 120 kg/265 lbs Brokk 100, 160, 120DTC 120 662 kN/68 t/149 Klbf 120 mm/5 in 305 kg/672 lbs Brokk 160, 280

METAL SHEARS*

* Requires one extra hydraulic function Rotator with continuous rotation

*See load diagram for each Brokk machine

*Option pulverizing pads **Free rotation

CONCRETE CRUSHERS**Jaw opening

Rebars Crushing force

Weight Made for

CC260 250 mm/9.8 in 16 mm/0.6 in 220 kN/22 t/ 49 Klbf

82 kg/ 181 lbs

Brokk 60

CC340 343 mm/14 in 30 mm/1.2 in 360 kN /37 t/ 81 Klbf

160 kg/ 353 lbs

Brokk 100, 120D

CC430* 431 mm/17 in 30 mm/1.2 in 382 kN/39 t/ 86 KIbf

265 kg/ 584 lbs

Brokk 160

CC520* 540 mm/21 in 30 mm/1.2 in 466 kN/48 t/ 105 Klbf

407 kg/ 897 lbs

Brokk 280

CC700* 650 mm/26 in 30 mm/1.2 in 680 kN/69 t/ 153 Klbf

610 kg/ 1 345 lbs

Brokk 400, 800CC520

BUCKETS*Volume Width Weight Made for20 l/0.7 cu ft 330 mm/13 in 20 kg/44 lbs Brokk 60

60 l/2.1 cu ft 520 mm/20.5 in 61 kg/134 lbs Brokk 100, 120D

80 l/2.8 cu ft 690 mm/27.2 in 76 kg/168 lbs Brokk 160

250 l/8.8 cu ft 930 mm/36.6 in 195 kg/430 lbs Brokk 280, 400, 800

700 l/24.7 cu ft 1 050 mm/41.3 in 650 kg/1 433 lbs Brokk 800

BMS 250-H

250 l

54

-

Jaw opening Weight Made forG30 300 mm/11.8 in 42 kg/93 lbs Brokk 60G50 400 mm/15.7 in 140 kg/309 lbs Brokk 100, 120D, 160D02H-30 790 mm/31.1 in 133 kg/293 lbs Brokk 100, 120D, 160D03HPX-40 975 mm/38.4 in 310 kg/683 lbs Brokk 280D05HPX-50 1 135 mm/44.7 in 400 kg/882 lbs Brokk 400D09HPX-60 1 400 mm/55.1 in 595 kg/1 312 lbs Brokk 800

SORTING & DEMOLITION GRAPPLES*G30

D02H

* See load diagram for each Brokk machine Requires one extra hydraulic function Rotator with continuous rotation

CLAMSHELL BUCKETS*Volume Opening

rangeWidth Weight Made for

C02H-25 25 l/0.9 cu ft 725 mm/28.5 in 250 mm/9.8 in 110 kg/243 lbs Brokk 100, 120D

C03H-35 65 l/2.3 cu ft 880 mm/34.6 in 350 mm/13.8 in 175 kg/386 lbs Brokk 160

C05H-40 115 l/4.1 cu ft 1 090 mm/42.9 in 400 mm/15.7 in 210 kg/463 lbs Brokk 280

C05HPX-60 170 l/6.0 cu ft 1 110 mm/43.7 in 600 mm/23.6 in 375 kg/827 lbs Brokk 400

C08HPX-80 300 l/10.6 cu ft 1 250 mm/49.2 in 800 mm/31.5 in 580 kg/1 279 lbs Brokk 800C05HPX

MULTI PURPOSE GRAPPLES*Volume Opening

rangeWidth Weight Made

forA02H-30 35 l/1.2 cu ft 835 mm/32.9 in 300 mm/11.8 in 152 kg/335 lbs Brokk 100,

120D, 160

A03H-40 70 l/2.5 cu ft 1 475 mm/58.1 in 390 mm/15.4 in 285 kg/628 lbs Brokk 280

A05HPX-40 100 l/3.5 cu ft 1 400 mm/55.1 in 400 mm/15.7 in 410 kg/904 lbs Brokk 400

A09HPX-50 200 l/7.1 cu ft 1 650 mm/65 in 500 mm/19.7 in 675 kg/1 488 lbs Brokk 800

KM651-4 180 180 l/6.4 cu ft 1 450 mm/57.1 in 1 070 mm/42.1 in 520 kg/1 146 lbs Brokk 400

KM651-4 250 250 l/8.8 cu ft 1 550 mm/61 in 1 285 mm/50.6 in 870 kg/1 918 lbs Brokk 800

A05HPX-40

* See load diagram for each Brokk machine Requires one extra hydraulic function Rotator with continuous rotation

* See load diagram for each Brokk machine Rotator with continuous rotation Requires one extra hydraulic function

Orange Peel Grapple

KM651-4

54 55

-

DRILLING EQUIPMENT***

*Extension rod drilling**Per stroke with open centerlizer ***Requires drainage hose, cable kit, counter weight in some occations, water or airflushing

Length Drill diameters

Dril steel size

Max. stroke length**

Weight Made for

TE 160-100 1 910 mm/ 75.2 in

33 42mm 1.3 1.7 in

R25 1 000 mm/ 3.3 ft

225 kg/ 496 lbs

Brokk 100, 120D, 160

TE 260-180* 2 900 mm/ 114.2 in

33 52 mm 1.3 2 in

R32 1 830 mm/ 6 ft

415 kg/ 915 lbs

Brokk 160, 280, 400

TE 260-240* 3 500 mm/ 137.8 in

33 52 mm 1.3 2 in

R32 2 435 mm/ 8 ft

432 kg/ 952 lbs

Brokk 280, 400

TE 360-240* 3 590 mm/ 141.3 in

42 76 mm 1.7 3 in

R32 2 435 mm/ 8 ft

644 kg/ 1 420 Ibs

Brokk 400, 800

TE 160-100

Cutting depth** Width Weight Made forRT 15-40 0-5 mm/0-0.2 in 120 mm/4.7 in 66 kg/146 lbs Brokk 60RT 15-90* 0-5 mm/0-0.2 in 203 mm/8 in 102 kg/225 lbs Brokk 100, 120D, 160ER 50**** 0-30 mm/0-1.2 in 480 mm/18.9 in 160 kg/353 lbs Brokk 100, 120D, 160ER 100**** 0-65 mm/0-2.6 in 610 mm/24 in 345 kg/761 lbs Brokk 160, 280, 400, 800ER 250**** 0-80 mm/0-3.1 in 680 mm/26.8 in 545 kg/1 202 lbs Brokk 400***

Cutting depth Width Weight Made forBCP 215* ** 0-5 mm/0-0.2 in 215 mm/8.5 in 230 kg/507 lbs Brokk 100, 120DBCP 250* ** 0-5 mm/0-0.2 in 265 mm/10.4 in 345 kg/761 lbs Brokk 160BCP 350* ** 0-5 mm/0-0.2 in 335 mm/13.2 in 600 kg/1 323 lbs Brokk 280, 400PLB 300* 0-50 mm/0-2 in 300 mm/11.8 in 452 kg/996 lbs Brokk 280, 400

SCABBLERS

PLANERS

*Cover and suction on request **Data depending on concrete quality ***B800 on request depending on requirement ****Requires drainage hose

*Available with cover and suction ** Requires extra hydraulic function, drainage hose, cable kit, counter weight in some occations

Requires load holding. On request

ER 100

PLB 300

BCP250

56

-

Jaw opening Beam weight Weight Made forBrokk Beam Grapple

250 mm/9.8 in B280: 90 kg/198 lbs B400: 500 kg/1 102 lbs B800: 500 kg/1 102 lbs

320 kg/705 lbs Brokk 280, 400, 800

Concrete hose (di)

Gunning pressure

Air pressure

Weight Made for**

Brokk Shot Crete

45 mm/ 1.8 in

Depend on concrete pump

Depend on concrete pump

180 kg/397 lbs Brokk 280, 400, 800

BEAM GRAPPLE*

SHOT CRETE*

* Requires two extra hydraulic functions**Other models on request

* Requires load holding valves with hose burst function Requires two extra hydraulic functions

Brokk Shot Crete

Saw disk diameter**

Cutting depth***

Weight Made for

BCS 8 400 mm/16 in 170 mm/7 in 62 kg/137 lbs Brokk 60

BCS 10 400 mm/16 in 170 mm/7 in 65 kg/143 lbs Brokk 100, 120D, 160

BCS 25**** 800 mm/31 in 260 mm/10 in 192 kg/423 lbs Brokk 160

BCS 35**** 800 mm/31 in 260 mm/10 in 195 kg/430 lbs Brokk 280, 400, 800

Length**** Drill hole diameter

Splitting force theoretical

Total weight*****

Made for

C20 V** 1 833 mm/72 in 76 mm/3 in 14 760 kN-17 660 kN/ 1 500 t-1 800 t

455 kg/ 1 003 lbs

Brokk 280* 400

C20 H*** 1 790 mm/70 in 76 mm/3 in 14 760 kN-17 660 kN/ 1 500 t-1 800 t

460 kg/ 1 014 lbs

Brokk 280* 400

C20 J** 2 110 mm/83 in 76 mm/3 in 14 760 kN-17 660 kN/ 1 500 t-1 800 t

440 kg/ 970 lbs

Brokk 280* 400

CUT OFF SAW*

SPLITTERS

*Requires one extra hydraulic function **Different saw disks available depending on material ***With new saw disk ****Requires drainage hose

*Require counter weight **Requires one extra hydraulic function ***Requires two extra hydraulic functions ****Value without wedge set. Value without mounting kit *****With mounting kit and wedge set

Brokk Beam Grapple

C20

BCS10

56 57

-

STOCKHOLM2.30 PM

-

BROKK

TRAI

NING

Maximizing Safety and Productivity. Welcome to Brokk Academy.

Operating a Brokk machine is easy to learn, but practice and experience make a world of difference. To maximize your productivity, we provide specialized training courses for Brokk operators and service personnel. Learning the safe, smart way to work with your machine will make each job more profitable while maximizing your return on your Brokk investment.

Our training program, Brokk Academy, equips you with all the knowledge needed to safely operate and master your Brokk machine. It's also an effective guide for expanding the variety of work youre capable of doing with a Brokk. Although demolition is the primary job of every Brokk, the machines can be used for a wide range of tasks by simply adding a new attachment and the right training.

60

-

Our newly developed simulator is an inva-luable part of the Brokk Academy.

Safety comes first. Brokk training can be adapted to your specific work situation. This personalized training combined with the unique features built into every Brokk machine, will maximize your efficiency and safety.

With more than 7,000 machines in use world-wide, Brokk knows the importance of conveying knowledge.

Direct contact with the Brokk experts makes commissioning effective and project specific.

Our unique training program, the Brokk Academy, gets you off to the best possible start with hands-on education by experienced Brokk experts.

60 61

-

BROKK

SERV

ICE

Help You Can Count On. Whenever and Wherever You Need It.

With 40 years of demolition experience, Brokk has the capabilities and know-how to provide you with the best possible service solution. We take great pride in our dedicated, well-trained service personnel, many of whom have been helping Brokk owners for 10 years or more. The same goes for our parts service. Our efficient distribution center combined with a well-equipped service network ensures effective troubleshooting and swift parts deliverytwo essential factors in getting tough demolition jobs completed safely and on time.

Original Brokk parts are designed and dimensioned for optimal performance to ensure longer life and maximum reliability. In addition, all of our distributors participate in continuous, comprehensive training programs, guarantee-ing the same high-quality Brokk service throughout the world.

To simplify troubleshooting, we provide a detailed user-friendly manual with each Brokk machine, and our vast pool of service knowledge is just a phone call away. We can also assemble spare parts packages that are tailor-made for your new machine upon request.

62

-

Thanks to our global service network, assistance is always just around the corner.

40 years of experience in construction and demolition projects worldwide are just a phone call away. Our spare parts distribution center and our well-equipped service network ensure quick access to parts and lubricants.

Brokk machines are built to last. Their unique quality coupled with regular maintenance ensures that every Brokk will continue to work long after competitors machines have quit.

62 63

-

SWEDEN Brokk ABBox 730 931 27 SkellefteSwedenPhone: +46(0) 910 711 [email protected]

Our SubsidiariesAUSTRALIABrokk Australia Pty Ldt9 Colorado CourtMorphett ValeSouth Australia 5162 AustraliaPhone: +61(0) 8 8387 [email protected]

BELGIUM Brokk BelgiumPart of Brokk France SASZI Inova 3000BP n20033F-88151 Thaon les Vosges [email protected]

CHINABrokk (Beijing) Machines Co. Ltd.A1208 ChengJian Plaza,No. 18 Beitaipingzhuang Road,Haidian, Beijing 100088P.R. ChinaPhone: +86(0) 10 8225 5331 [email protected]

FRANCEBrokk FranceZI Inova 3000, BP 2003388151 THAON-LES-VOSGES CEDEXFrancePhone: +33(0) 329 390 [email protected]

GERMANYDarda GmbHIm Tal 1D-78176 BlumbergGermanyPhone: +49 (0) 770 243 910 [email protected]

ITALYBrokk Italia srlVia Regina Teodolinda, 1722100 ComoItalyPhone: +39 031 273 691Mobile: +39 331 854 [email protected]/it

NORWAYBrokk Norge ASIndustriveien 241400 SkiNorwayPhone: +47(0) 94 83 95 [email protected]/no

SINGAPOREBrokk Asia-Pacific Pte Ltd51 Bukit Batok CrescentUnity Centre # 04-26Singapore 658077SingaporePhone: +65 6316 [email protected]/sgp

SWEDENAhlberg Cameras ABGsvgen 22761 41 NorrtljeSwedenPhone: +46 176 20 55 [email protected] www.ahlbergcameras.com

SWITZERLANDBrokk Switzerland GmbHVorderschlundstrasse 5CH-6010 KriensSwitzerland Phone: +41 41 755 39 [email protected]/ch

UNITED ARAB EMIRATESBrokk Middle Eastco Business SwedenP.O. Box 25906/Concord Tower Office 26076, Media City, DubaiUAEPhone: [email protected] [email protected]

UNITED KINGDOMBrokk UK Ltd.Unit 2 A Moss End Business VillageCrooklands, MilnthorpeCumbria, LA7 7NUEnglandPhone: +44(0) 153 95 [email protected]/uk

USABrokk Inc.1144 Village WayMonroe WA 98272USAPhone: +1 360 794 [email protected]/us

USABrokk Bricking Solutions Inc.1144 Village WayMonroe, WA 98272USAPhone: +1 360 794 [email protected]

Headquarters

64

-

YOUR WORLDWIDE CONTACT

With 7 000 machines working on exciting projects around the world, Brokk has become synonymous with safety, quality and efficiency. A critical part of our product and support offering is the comprehensive ownership expe-rience our customers have come to expectfrom purchase to training to service. It's about staying as close as possible

to our markets and our customers. Thats why weve deve-loped our worldwide sales and service network, so you have reliable access to Brokk resources, support and offers wherever and whenever you need them. For more informa-tion, please contact your local Brokk representative.

The World of Brokk. Always Within Reach.

64 65

-

THE NAME BROKK COMES FROM THE DWARF BLACKSMITH IN NORDIC MYTHOLOGY.THE EXCEPTIONALLY STRONG DWARF BROKK FORGED THE GOD THORS HAMMER MJLNIR. BROKK WAS SMALL, POWERFUL AND UNBEATABLE.

JUST LIKE OUR MACHINES.

-

COM

PARI

SON

CHAR

T

60 500 (1 102)

590 (23.2)

874 (34.4) 0-6

22 (5.8)

80 (175)

3 100 (122)

2 500 (98)

100990

(2 183)780

(30.7)1 147

(45.1) 0-15 50

(13.3)160 (353)

4 300 (169)

3 700 (146)

120D1 230 (2 711)

780 (30.7)

1 250 (49.2) 18.5 D

50 (13.3)

160 (353)

4 300 (169)

3 700 (146)

1601 600 (3 527)

780 (30.7)

1 254 (49.3) 0-22

62 (16.4)

270 (595)

4 800 (189)

4 400 (173)

2803 150 (6 944)

1 200 (47.2)

1 530 (60.2) 0-27

100 (26.5)

420 (924)

6 200 (244)

5 800 (228)

4005 100

(11 244)1 600

(63)1 792

(71) 0-36115

(30.4 )600

(1 323)7 100

(280)6 700

(264)

400d5 500 (12 125)

1 600 (63)

1 975 (78) 74 D

130 (34.3)

600 (1 323)

7 100 (280)

6 700 (264)

800s

11 050 (24 360)

2 200 (86.6)

2 647 (104.2)

74 D 0-45 E

140 (37)

1 200 (2 645)

10 100 (398)

9 400 (370)

800p

11 300 (24 900)

2 200 (86.6)

2 647 (104.2)

74 D 0-45 E

140 (37)

600 (1 322)

10 100 (398)

9 600 (378)

EX Brokk 60 EX Brokk 800 EX

Wei

ght,

kg (l

bs)

Wid

th m

in. m

m (i

n)

Hei

ght m

in. m

m (i

n)

Pow

er c

onsu

mpt

ion,

kW

Pum

p flo

w, 5

0 hZ

, l/m

in(U

S ga

l/m

in)

Reco

mm

end.

/wei

ght

atta

chm

ent,

kg (l

bs)

Vert

ical

rea

ch

(inc.

bre

aker

) mm

(in)

Hor

izon

tal r

each

(in

cl. b

reak

er) m

m (i

n)

67

-

Brokk AB | P.O. Box 730SE-931 27 Skellefte | SwedenTel +46 910 711 [email protected] | www.brokk.com

Item

No.

: 313

6 71

10 8

4-D