Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

Transcript of Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

1/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page i

Exhibit 2-13-A

GERALD DESMOND BRIDGE

REPLACEMENT PROJECT

STRUCTURAL DESIGN CRITERIA

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

2/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page ii

TABLE OF CONTENTS

TABLE OF CONTENTS .................................................................................................................................... ii

REVISION RECORD ........................................................................................................................................ iii

1. GENERAL PROVISIONS ............................................................................................................................. 1

1.1

OBJECTIVES

&S

COPE............................................................................................................................... 1

1.2

LIMITS OF APPLICABILITY ......................................................................................................................... 1

1.3 GOVERNING SPECIFICATIONS .................................................................................................................... 1

1.4 UNITS ........................................................................................................................................................ 1

1.5 DESIGN APPROACH ................................................................................................................................... 1

1.6 BRIDGE LAYOUT ....................................................................................................................................... 1

1.7

DESIGN SERVICE LIFE ............................................................................................................................... 1

2. DESIGN LOADING ....................................................................................................................................... 2

2.1 STRUCTURAL DEAD LOADS ...................................................................................................................... 2

2.2 SUPERIMPOSED DEAD LOADS ................................................................................................................... 2

2.3 LIVE LOADS .............................................................................................................................................. 2

2.3.1Design Truck, Design Tandem and Design Lane Loads ................. ........... .......... ........... .......... ...... 3

2.3.2Permit Vehicle Loads .................. ........... .......... ........... .......... .......... ........... .......... ........... .......... ...... 3

2.3.3

Dynamic Load Allowance ............. .......... ........... .......... ........... .......... ........... .......... .......... ........... .... 3

2.3.4

Pedestrian Loads ........... ........... .......... ........... .......... ........... .......... .......... ........... .......... ........... ......... 4

2.3.5

Deflection and Vibrations Limitations .......... .......... ........... .......... .......... ........... .......... ........... ......... 4

2.3.6

Live Load Contribution under Seismic Conditions ........... ........... .......... ........... .......... ........... ......... 4

2.4

FATIGUE LOADING .................................................................................................................................... 4

2.5

WIND LOADS ............................................................................................................................................ 4

2.5.1

Serviceability Wind Event ............................................................................................................... 5

2.5.2

Aerodynamic Stability Wind Event .......... ........... .......... ........... .......... ........... .......... ........... .......... .... 5

2.6

SEISMIC LOADS ......................................................................................................................................... 5

2.7 THERMAL LOADS ...................................................................................................................................... 5

2.8 DIFFERENTIAL SUPPORT MOVEMENT........................................................................................................ 5

2.9 LIMIT STATES COMBINATIONS .................................................................................................................. 5

3.

CONCRETE DESIGN .................................................................................................................................... 6

3.1

MATERIALS ............................................................................................................................................... 6

3.1.1

Concrete .......................................................................................................................................... 6

3.1.2Mild Steel Reinforcement .............. .......... ........... .......... ........... .......... ........... .......... .......... ........... .... 6

3.1.3Prestressing Steel .......... ........... .......... ........... .......... ........... .......... .......... ........... .......... ........... ......... 7

3.2 DESIGN ..................................................................................................................................................... 7

3.2.1Stress Limits in Prestressed Concrete Members .......... ........... .......... ........... .......... ........... .......... .... 7

3.2.2

ConcreteCast-in-Place Superstructure and Substructure ........................................................... 8

3.2.3

Corrosion Protection....................................................................................................................... 8

3.2.4

Stirrups Design in Segmental Box Girders .......... .......... ........... .......... .......... ........... .......... ........... .. 8

4.

STEEL DESIGN ............................................................................................................................................. 9

4.1 MATERIALS ............................................................................................................................................... 9

4.1.1

Structural Steel ................................................................................................................................ 94.1.2Miscellaneous Steel ........... .......... ........... .......... ........... .......... .......... ........... .......... ........... .......... ...... 9

4.1.3Stay Cables ...................................................................................................................................... 9

4.2

DESIGN ................................................................................................................................................... 10

4.2.1

Stay Cables .................................................................................................................................... 10

4.2.2

Miscellaneous ......... ........... .......... ........... .......... ........... .......... .......... ........... .......... ........... .......... .... 10

5.

SEISMIC DESIGN ....................................................................................................................................... 11

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

3/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page iii

5.1 GENERAL PERFORMANCE REQUIREMENTS .............................................................................................. 11

5.1.1Safety Evaluation Structural Components.................................................................................. 11

5.1.2Safety EvaluationGeotechnical Considerations ........................................................................ 12

5.1.3Functional Evaluation .......... ........... .......... ........... .......... ........... .......... .......... ........... .......... ........... 12

5.1.4Performance Assessment .......... .......... ........... .......... ........... .......... .......... ........... .......... ........... ....... 12

5.1.5Seismic Loading during Construction ........................................................................................... 13

5.2

DEFINITION OF GROUND MOTIONS ......................................................................................................... 13

5.3

ANALYSES FOR DETERMINATION OF DEMANDS ...................................................................................... 135.3.1

Service Load Demands and Combination with Seismic Demands ......... ........... .......... ........... ....... 13

5.3.2

Seismic Demands .......................................................................................................................... 13

5.3.3

Nonlinear Local Analysis for Evaluating Seismic Demands .......... .......... ........... .......... ........... ..... 15

5.4

ANALYSES FOR DETERMINATION OF CAPACITIES ................................................................................... 15

5.4.1Structural Steel Component Capacities......................................................................................... 15

5.4.2Tower Shafts and Strain Limits ..................................................................................................... 15

5.4.3Tower Connections ........................................................................................................................ 16

5.4.4Reinforced Concrete Component Capacities .............. .......... .......... ........... .......... .......... ........... .... 16

5.4.5Allowable Concrete Strain Values ......... .......... ........... .......... .......... ........... .......... ........... .......... .... 17

5.4.6Allowable Reinforcement Strain Values ......... ........... .......... ........... .......... ........... .......... ........... ..... 17

5.4.7Main Span Bridge Tower and End Bent Shaft Energy Dissipating Shear Link (If Energy

Dissipating Shear Link Are Used) .......... .......... ........... .......... .......... ........... .......... ........... .......... .... 18

5.4.8

Energy Dissipating Shear Link Testing (If Energy Dissipating Shear Links Are Used) ......... ...... 18

5.4.9

Concrete Pile Caps ....................................................................................................................... 20

5.4.10

Allowable CISS Pile Shell Strain Values ............. ........... .......... .......... ........... .......... ........... ....... 20

5.4.11

Shear Design of Ductile Concrete Members .................. .......... .......... ........... .......... ........... ....... 21

5.4.12

Plastic Hinge Length ............... ........... .......... ........... .......... .......... ........... .......... .......... ........... .... 21

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

4/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 1

1. GENERAL PROVISIONS

1.1 Objectives & Scope

The purpose of these criteria is to document the specifications used for the final analysis and design of the

Project. The Design-Builder shall meet the requirements of these criteria in the completion of the Project.

1.2 Limits of Applicability

These criteria apply to elements of the Main Span Bridge and Approach Bridges between SR 47and SR 710.

1.3 Governing Specifications

Standards are listed in the beginning of the structures section.

1.4 Units

1. The bridges shall be designed using English Units.

2. The units shown in the final plans shall be English Units.

1.5 Design Approach

The Load Resistance Factor Design (LRFD) method as defined in AASHTO LRFD Bridge Design Specifica-tions, 4thEdition,and as modified by the Caltrans California Amendments to the AASHTO LRFD Bridge Design

Specificationsshall be used for the design of all structural members. Exceptions and additions to the AASHTO

LRFD Bridge Design Specifications, 4thEdition,are defined in these project-specific Design Criteria.

Design for seismic loads shall be in accordance with Caltrans Seismic Design Criteria, Caltrans Guide Specifi-

cations for Seismic Design of Steel Bridges, AASHTO Guide Specifications for LRFD Seismic Bridge Design,

NCHRP 12-49, ATC-32, and the specific requirements of these project-specific Design Criteria.

The design requirements may differ for the Main Span Bridge and Approach Bridges as defined by these crite-

ria.

1.6 Bridge Layout

Bridge layouts shall use the vertical and horizontal datums identified elsewhere in the Contract Documents.

1.7 Design Service Life

The structure design service life is 100 years.

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

5/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 2

2. DESIGN LOADING

2.1 Structural Dead Loads

Structural dead loads shall be based on unit weights of materials and the computed volumes of the structural

elements. The following unit weights shall be usedunless the Design-Builder demonstrates different loadingsare appropriate:

Concrete, Reinforced or Prestressed (Including Reinforcing)

Normal Weight Concrete, fc 5000 psi 150 pcf

Normal Weight Concrete, fc > 5000 psi 160 pcf

Lightweight Concrete 120 pcf

Steel

Fabricated Plate Steel 490 pcf

Rolled Shapes 490 pcf

Cable Stays 490 pcf

2.2 Superimposed Dead Loads

Superimposed dead loads shall be as follows unless the Design-Builder demonstrates different loadings are

appropriate:

Steel Railings 490 pcf

Concrete Barriers 150 pcf

Initial Polyester Concrete Overlay

Main Span Bridge 150 pcf

Approach Bridges 150 pcf

Future Wearing Surface 6.25 psf

Maintenance facilities and Utilities Actual Weight

Provision for future Utilities shall be considered as follows:

Future Utilities 5 psf placed in a 10 ft wide strip and located longitudinally

along a bridge and transversely between the outside edges of a

deck to create the worst case loading condition.

Loading for future Utilities is in addition to the calculated weight for specific Utilities accounted for in the

design of the bridges, and includes allowance for Utilities, Utility supports, service platforms, service platform

supports and associated miscellaneous metal.

2.3 Live Loads

Live loads on the Main Span Bridge and the Approach Bridges shall be as defined by AASHTO LRFD Bridge

Design Specifications, 4th Edition,with California Amendments,Section 3.6.1.1.1 for traffic lane width of 12

feet. Multiple presence factors shall be used in accordance with AASHTO LRFD Bridge Design Specifica-

tions, 4th Edition, with California Amendments, Section 3.6.1.1.2. Pedestrian loads shall be in accordance

with AASHTOLRFD Bridge Design Specifications, 4th Edition,with California Amendments,Section 2.3.4.

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

6/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 3

2.3.1 Design Truck, Design Tandem and Design Lane Loads

The single-lane average daily truck traffic (ADTT SL) shall be taken as 7,000 (year 2056). Average daily traffic

(ADT) shall be taken as 123,000 (year 2056).

Vehicular live load shall be AASHTO LRFD Bridge Design Specifications, 4th Edition, with California

Amendments,HL-93 with an increase of 10% for AASHTOLRFD Bridge Design Specifications, 4th Edition,

with California Amendments,Strength I and Service I, II, and III limit states in designing following structural

members:

All members in the Main Span Bridge superstructure including stay cables, edge girders, floor beams,

stringers, bearings, and deck.

All members in the Approach Bridges, including foundations.

Main Span Bridge seismic energy dissipation elements, tension elements between stay cable anchorages

and diaphragms, if the seismic energy dissipation elements and tension elements are used.

Vehicular live load shall be AASHTO LRFD Bridge Design Specifications, 4th Edition, with California

Amendments,HL-93 for Main Span Bridge towers and end bents, including foundations.

A maintenance vehicle load as designated by one H10 truck shall be placed between the two median barriers

on the Main Span Bridge for Strength I Load Combination.

2.3.2 Permit Vehicle Loads

Permit loads (P-15) shall be considered for design of the bridge superstructure as defined in AASHTOLRFD

Bridge Design Specifications, 4th Edition,with California Amendments.

When considering Permit loads (P-15), the bridge shall satisfy AASHTO LRFD Bridge Design Specifications,

4th Edition,with California Amendments, Section3.4.1 Load Combination STRENGTH II.

2.3.3 Dynamic Load Al low ance

Dynamic load allowance shall be applied in accordance with AASHTO LRFD Bridge Design Specifications,

4th Edition, with California Amendments, Section 3.6.2 and PTI Recommendations for Stay Cable Design,

Testing and Installationfor dynamic load allowance from cable stay loss (Article 5.5).

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

7/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 4

2.3.4 Pedestr ian Loads

Pedestrian loads shall be applied to the non-motorized Class I bikeway (bike path) and pedestrian sidewalk in

accordance with AASHTO LRFD Bridge Design Specifications, 4th Edition, with California Amendments,

Section3.6.1.6.

2.3.5 Deflection and Vibrations Limitations

Bridges with a non-motorized Class I bikeway (bike path) and/or pedestrian sidewalk shall be designed to

avoid pedestrian discomfort from affects of vehicular traffic, synchronized pedestrian loading, and wind.When subject to the required vehicular loading and simultaneous occurring winds up to 30mph, the maximum

vertical and horizontal acceleration of the superstructure shall be limited to 5%g and 2.5%g respectively at an

operation speed of 25 mph. When loading two tracks or lanes, the vehicles shall be assumed to be traveling in

opposing directions and placed on the bridge so as to produce the maximum deck accelerations.

The procedure published by the Technical Department for Transport, Roads and Bridges Engineering and

Road Safety (Stra) of the French Ministry of Transport and Infrastructure, entitled Technical Guide, Foot-

bridges, Assessment of vibrational behavior of footbridges under pedestrian loading, shall be used for evaluat-

ing the magnitude of the excitation and limiting frequencies. When evaluating synchronous lateral excitation

(SLE), the following parameters shall be considered:

Accelerations shall be limited to Range 1 for Maximum Comfort (0.00 to 1.64 ft/s2 Vertical, 0.00 to 0.33-

ft/s2 Horizontal)

Pedestrian loading shall be considered for Class I, II, and III traffic.

Analysis of mode shapes coupled in multiple directions shall consider simultaneous pedestrian loading in

those directions.

2.3.6 Live Load Contr ibu tion under Seismic Cond it ions

Live load shall be considered for combination with seismic demands in accordance with AASHTO LRFD

Bridge Design Specifications, 4th Edition,with California Amendments,(EXTREME EVENT - I). The load-

ing factor EQ shall be taken as 0.17 for all structures. EXTREME EVENT I shall apply to either Function-

al Evaluation Earthquake or Safety Evaluation Earthquake events.

2.4 Fatigue Loading

For the Fatigue I limit state, the fatigue load shall be a single design truck, as specified in AASHTO LRFD

Bridge Design Specifications, 4th Edition,with California Amendments, Section3.6.1.4, occupying a single

lane in each traffic direction. The load factor of 2.0 shall be used for infinite fatigue life.

For the Fatigue II limit state, the fatigue load shall be one Permit truck as specified in AASHTO LRFD Bridge

Design Specifications, 4th Edition,with California Amendments, Section 3.6.1.4.1.

2.5 Wind Loads

Wind analysis and design for the Approach Bridges shall be performed in accordance with AASHTOLRFD

Bridge Design Specifications, 4th Edition,with California Amendments.

Wind analysis and design for the Main Span Bridge shall be performed in accordance with AASHTO LRFD

Bridge Design Specifications, 4th Edition,with California Amendments, Section3.8 and ANSI/SEI 7. For theMain Span Bridge, both static and dynamic wind effects shall be considered, utilizing computer models of the

bridge that incorporate the results of wind tunnel tests of section models of the deck. Wind tunnel tests shall

include smooth and turbulent flow, and 0.5% to 1.5% damping. Wind analysis and design shall include both a

high-probability Serviceability Event and a lower-probability Aerodynamic Stability Event.

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

8/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 5

2.5.1 Serviceabi l i ty Wind Event

The Serviceability wind event shall have a probability consistent with a mean return period of 100 years, but

not less than a basic wind speed of 85 mph as defined in ANSI/SEI 7. In this event, the nominal stresses and/or

loads and resistance factors of AASHTO LRFD Bridge Design Specifications, 4th Edition, with California

Amendments,shall be met by all components in the completed bridge.

2.5.2 Aerody namic Stabi l i ty Wind Event

Vertical deck accelerations shall not exceed 0.03g for winds up to 30 mph and 0.10g for winds above 30 mphup to 45 mph. Furthermore, the bridge shall show no sign of flutter instability up to a wind velocity of 1.4

times the one-hour mean 100-year wind. If the bridge shows any sign of aerodynamic instability within these

limiting wind velocities, the cross section and other bridge design features shall be revised until the require-

ments are met.

Bridge responses to wind during construction (free standing tower, partially erected bridge, etc.) shall be eva-

luated from wind tunnel tests for 20-year wind. The Design-Builder shall identify temporary remedial meas-

ures to counteract any distress.

2.6 Seismic Loads

Seismic design issues are covered in Section 5 of this document.

2.7 Thermal Loads

Design temperature range shall correspond to requirements for a moderate climate.

A temperature gradient between the top and bottom of the superstructure shall be considered in accordance

with AASHTOLRFD Bridge Design Specifications, 4th Edition,with California Amendments, Section3.12.3.

2.8 Differential Support Movement

Differential support shall be considered as follows:

1. Support movements during construction, as the loads from the structure applied to the foundations shall beconsidered in design.

2. Support movements during the service life of the bridge, due to the time dependent strains in the subsur-

face materials, shall be considered in design.

3. Permanent deformation of the structure due to earthquake shall be acceptable within the strain limits de-fined in Section 5 of this Design Criteria.

2.9 Limit States Combinations

Load factors and load combinations shall be in accordance with AASHTOLRFD Bridge Design Specifica-

tions, 4th Edition,with California Amendments, Tables 3.4.1-1 and 3.4.1-2, except as follows:

The effects of stay cable force adjustments are treated as dead load.

Service load thermal loading combination for the cable-stayed spans shall be in accordance with

AASHTOLRFD Bridge Design Specifications, 4th Edition,with California Amendments,Section 3.12.3.

Secondary effects due to post-tensioning (EL) shall have a load factor, Pof 1.0.

The load modifier for "importance" should be taken as 1.0 for "Typical Bridges".

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

9/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 6

3. CONCRETE DESIGN

3.1 Materials

3.1.1 Concrete

Superstructure deck, precast deck panels and edge girders, f'c = 4000 psi minimum, 8000 psi maximum, where

fc = 28-day compressive strength. Concrete strengths greater than 8000 psi require Port Approval.

Towers and bent columns and bent caps, f'c = 4000 psi minimum, 8000 psi maximum.

Footings and pile caps, fc = 4000 psi minimum,5000 psi maximum.

Cast In Steel Shell (CISS) piles, Cast In Drilled Hole (CIDH) piles, fc = 5000 psi minimum.

Barriers and retaining walls: f'c = 3600 psi minimum.

Prestressed Concrete:

f'c = 8000 psi maximum, 4000 psi minimum.

Prestressed concrete shall meet the requirements of AASHTO LRFD Bridge Design Specifications, 4th Edi-

tion,with California Amendmentsand be limited to the following allowable stresses:

Temporary stresses during construction and before losses:

f'ci = 3500 psi minimum at time of prestressing operations

fci = 0.60 f'ci compression for pretensioned and post-tensioned members

Tensile stress limits shall be in accordance with AASHTO LRFD Bridge Design Specifications, 4th

Edition,with California Amendments,Table 5.9.4.1.2-1

Stresses at service load after losses:

Compressive stress limits shall be in accordance with AASHTO LRFD Bridge Design Specifications,

4th Edition,with California Amendments Table 5.9.4.2.1-1.

Tensile stress limits shall be in accordance with AASHTO LRFD Bridge Design Specifications, 4th

Edition,with California AmendmentsTable 5.9.4.2.2-1.

Transversely Prestressed Bridge Deck Design - Tensile stress limits shall be

A. Top of deck- No tension

B. Bottom of deck-'

3 cf psi

Member section force effects that include seismic loading shall use the expected concrete compressive

strength as defined in Section 5.4.2 of this Design Criteria.

Modulus of Elasticity Ec for concrete elements shall be determined in accordance with AASHTO LRFD

Bridge Design Specifications, 4th Edition,with California Amendments,Section 5.4.2.4, unless more precise

data is available. When performing analysis that includes seismic loading, the modulus of elasticity shall be

based on the expected concrete strength as defined in Section 5.4.2 of this Design Criteria.

See also section 5.4.2 of this Design Criteria for concrete material properties for ductile reinforced concrete

plastic hinge elements.

3.1.2 Mild Steel Reinforcement

All mild steel reinforcement shall be ASTM A706 (Grade 60). The following properties shall be used in the

design:

Specified minimum yield stress: Fy = 60 ksi

Specified maximum yield stress: Fy max = 78 ksi

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

10/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 7

Specified maximum tensile stress: Fu max = 107 ksi

Modulus of elasticity: Es = 29,000 ksi

3.1.3 Prestr essin g Steel

Strand Prestressing Steel shall meet the following requirements:

0.6" or " diameter ASTM A416 low relaxation strand

f's = 270,000 psi ultimate strength

Stress limits shall be in accordance with AASHTO LRFD Bridge Design Specifications, 4th Edition,with

California Amendments,Table 5.9.3-1.

Es = 28,500,000 psi modulus of elasticity

All prestressing steel shall be bonded.

Bar Prestressing Steel ASTM A722 (Type II) shall meet the following requirements:

High strength threaded bars

f's =150,000 psi ultimate strength

Stress limits shall be in accordance with AASHTO LRFD Bridge Design Specifications, 4th Edition,with

California Amendments,Table 5.9.3-1.

Es = 30,000,000 psi modulus of elasticity

Prestressing Losses shall meet the following requirements:

Friction losses based on AASHTO LRFD Bridge Design Specifications, 4th Edition, with California

Amendments,Section 5.9.5.2.2.

Anchor set for strand = "

Anchor set for bar = "

Elastic Shortening losses based on AASHTOLRFD Bridge Design Specifications, 4th Edition,with Cali-

fornia Amendments, Section5.9.5.2.3.

Long-term losses - It is the responsibility of the Design-Builder to select an appropriate creep and shrinkage

code model, which is subject to review and Approval by the Port.3.2 Design

3.2.1 Stress Lim its in Prestressed Conc rete Members

Stress limits for concrete in prestressed and post-tensioned concrete members shall be in accordance with

AASHTOLRFD Bridge Design Specifications, 4th Edition,with California Amendments,Section 5.9.4

Stress limitations for prestressing tendons shall be in accordance with AASHTOLRFD Bridge Design Spe-

cifications, 4th Edition,with California Amendments,Table 5.9.3-1.

Principle tensile stress for web shear in girders during service conditions shall not exceed the following

limits:

Normal weight concrete: 0.0948*fc (ksi)

Lightweight concrete: 0.0800*fc (ksi)

Where: fc = 28-day compressive strength in ksi.

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

11/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 8

3.2.2 Concrete Cast- in-Place Superstruct ure and Subs truct ure

Design of cast-in-place concrete shall conform to AASHTOLRFD Bridge Design Specifications, 4th

Edition,with California Amendments, and these Design Criteria.

For shear design of concrete members that may experience plastic hinging, see Section 5.4.11 of this

Design Criteria.

3.2.3 Corrosio n Protection

Steel Casing Thickness Reduction for CISS Piles: 0.001 in/face/year plus 1/16 in.

Thickness reduced at outer face of the CISS piles only.

Concrete Cover for Reinforcement:

Concrete Cover: Minimum cover per AASHTOLRFD Bridge Design Specifications, 4th Edition,with

California Amendments, Table 5.12.3-1 for marine environment.

Concrete cover for the top mat of deck reinforcement in the Main Span bridge and Approach Bridges shall

be 2.5 inches measured from the bottom of the polyester concrete wearing surface or top of structural

deck. Of the 2.5 inches, the top 0.5 inches is sacrificial and shall not be relied upon for structural capacity.

Concrete Cover within CISS Casings: Minimum cover shall be 2 in.

Concrete Cover within CIDH Concrete Piles: Minimum cover shall be 6 in.

Cathodic Protection: Not allowed.

3.2.4 Stirrups Design in Segmental Box Girders

Stirrups in girder webs shall be designed for the longitudinal shear and torsion (Av) and the out of plane

bending from the transverse box girder analysis (Af). The minimum area of steel should not be less than the

larger of the following combinations of the two effects:

a) Av+ 0.5Afor b) 0.5Av+Af

or c) 0.7(Av+Af)

(Construction and Design of Prestressed Concrete Segmental Bridges, Podolny & Muller, page 203)

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

12/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 9

4. STEEL DESIGN

4.1 Materials

4.1.1 Struc tur al Steel

ASTM A709, Grade 36, HPS50W, or HPS70W as applicable. The equivalent specification, ASTM A36, shall

be used with the ANSI/AWSBridge Welding Code.

ASTM A36-08/ASTM A790 Grade 36-08 (for Energy Dissipating Shear Links only if Energy DissipatingShear Links are used)

Yield Strength, minimum = 38 ksi

Yield Strength, maximum = 42 ksi

All steel shall be painted. Interior of closed steel box sections shall be painted with two coats of primer.

Orthotropic Deck:

The orthotropic deck design details shall be in accordance with AASHTO LRFD Bridge Design Specifica-

tions, 4th Edition,with California Amendments,(Sections 2, 4.6.2.2.4-1, 6 and 9) except that the loading

shall be 3xHS 15.

Deck plate thickness shall be a minimum of 5/8 inch

Rib plate thickness shall be not less than 5/16 inch

The weld between the deck plate and ribs shall be 80% penetration into the rib wall thickness and shall be

made using SAW process.

The weld between the ribs and floor beam web at the cutout shall be a full penetration groove weld, with

runoff tab, for a minimum of 4 inch from the cutout. The run-off tab shall be ground flush to a radius. An

internal rib bulkhead plate is to be provided at floorbeam locations.

Overlay shall be a two-layer system with liquid water proofing membrane overlaid by a total thickness of

1 inch asphalt comprised of inch high density asphalt and 1 inch latex modified asphalt.

Live Load Deflection limitations:

Deflection of deck plate = span length/300

Deflection of ribs = span length/1000

Relative live load deflection between adjacent ribs = 0.1 inch

4.1.2 Misc ellaneou s Steel

Steel Casing for CISS piles ASTM A252, Grade 3

High Strength Bolts ASTM A325, A490

Anchor bolts ASTM A307, F1554, A354 or A449 as deter- mined by design.

ASTM A722 thread- bars may also be used for anchor bolts in

specific applications.

4.1.3 Stay Cables

See Exhibit 2-13-D.

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

13/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 10

4.2 Design

4.2.1 Stay Cables

Stay cables shall be designed in accordance with PTI Recommendations for Stay Cable Design, Testing and

Installation.

The LRFD Group combinations as specified in AASHTO LRFD Bridge Design Specifications, 4th Edition,

with California Amendments, Section 3.4.1 for the Strength, Service, Extreme Event, and Fatigue limit

states, and these Design Criteria, shall be used to supplement the PTI Recommendations for Stay CableDesign, Testing and Installation.

A minimum tension force of 10% of the dead load a stay cable experiences shall be provided in the stay-

cables during all extreme events.

Provision shall be made for the replacement of any individual cable as required by the PTI

Recommendations for Stay Cable Design, Testing and Installation.

Details shall be provided for the replacement of any individual stay cable by detensioning at the live end

anchors.

After final adjustment, the polyethylene pipe sheathing shall not be filled with grout.

Provision shall be made for the adjustment of any individual cable during and after completion ofconstruction.

4.2.2 Miscel laneous

Expansion joints and bearings shall be designed to provide the movement range required to allow free move-

ment under the temperature changes given in Section 2.7 of this document, as well as for seismic movements

under the Functional Evaluation Earthquake (Section 5.1). Expansion joints and bearings shall also be de-

signed to prevent collapse of the joint or bearing when subjected to the maximum anticipated movement under

the Safety Evaluation Earthquake (see Section 5.1)

Maintenance facilities or accesses, including hatches, stairways, walkways, platforms and ladders shall be de-

signed in accordance with CALOSHA standards.

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

14/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 11

5. SEISMIC DESIGN

Seismic design of the Project shall be performed in accordance with Caltrans Seismic Design Criteriaand Cal-

trans Guide Specifications for Seismic Design of Steel Bridges, augmented with pertinent provisions of ATC-

32, NCHRP 12-49, AASHTOLRFD Bridge Design Specifications, 4th Edition,with California Amendments,

AASHTO Guide Specifications for Seismic Isolation Design, PTI Recommendations for Cable Stay Design,

Testing, and Installation,and Project specific criteria as detailed in this document.

5.1 General Performance Requirements

Seismic design of the Project shall consider both the Safety Evaluation Earthquake (SEE) and the lower level

Functional Evaluation Earthquake (FEE).

Seismic performance levels, expressed in terms of damage levels, are defined as follows:

No Damage: Defined for structural members as the nominal capacity as described in AASHTOLRFD

Bridge Design Specifications, 4th Edition,with California Amendments. Nominal, not expected material

properties shall be used and increased member strength due to the effects of confinement steel shall be ig-

nored. No damage is defined as full serviceability without repair or replace ment.

Minimal damage: Although minor inelastic response may occur, post-earthquake damage is limited to

narrow cracking in concrete, and inconsequential yielding of secondary steel members. Damage to non-

structural components of the cable system would be allowed.

Moderate damage: Inelastic response may occur, resulting in concrete cracking, reinforcement yield,

minor spalling of cover concrete and minor yielding of structural steel. The extent of damage shall be suf-

ficiently limited such that the structure can be restored essentially to its pre-earthquake condition without

replacement of reinforcement or replacement of structural members.

Significant damage: Damage consisting of concrete cracking, reinforcement yielding, major spalling of

concrete and deformations in minor bridge components which may require closure of the bridge to repair.

Partial or complete replacement of secondary elements may be required in some cases. Secondary ele-

ments are those that are not a part of the gravity load resisting system.

Meeting the stress and strain limits specified in these criteria form the basis for satisfying the seismic perfor-

mance level goals of the Project.

5.1.1 Safety Evaluati onStructura l Compon ents

The SEE for structural evaluation corresponds to a mean return period of 1,000 years, representing approx-

imately a 10% probability of occurrence in 100 years. In this earthquake, the bridge can be subject to primarily

minimal damage with some moderate damage and some significant damage in secondary components as

described in this section.

The Design-Builder shall design the bridge components to the following behavior levels under the SEE:

Piles/Drilled Shafts: Minimal damage.

Pile Caps: Minimal damage

Approach Bridge columns and abutments (above pile caps): Moderate damage.

Main Span Bridge Towers and End Bents (above pile caps): Minimal damage.

Energy Dissipating Shear Links, if used (at Main Span Bridge Towers and End Bents): Significant dam-

age.

Approach Bridge abutment backwalls: Significant damage.

Superstructure: Minimal damage.

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

15/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 12

Bearings, Hinge Beams and Shear Keys: Moderate damage.

Expansion Joints: Significant damage, without collapse of the joint

Cable Systems (structural elements): No damage.

Cable Systems (non-structural elements): Minimal damage.

Permanent offsets at Main Span Bridge towers and end bents at the deck level relative to pile caps must

be avoided, except at the SEE level permanent offsets not exceeding 6 in any direction are permitted.Such offsets are exclusive of affects from adjoining Approach Bridges. Seismic affects from supported

Approach Bridge spans shall be considered and shall not contribute to the end bents exceeding the 6" re-

sidual displacement. Approach Bridge span residual displacements at the end bents need not comply

with the 6" residual displacement limit. Permanent offsets of the foundations are also permissible if the

strain limits specified in Section 5.4 of this document are not exceeded and the permanent offsets do not

prevent use of the bridge subsequent to the SEE event after repairs are completed.

5.1.2 Safety Evaluati on Geotechnica l Considerat ions

Soil Liquefaction: The SEE event shall be used to assess liquefaction potential and corresponding downdrag

forces, if applicable. If liquefiable soils are determined to be present, and it has been determined that they may

in fact liquefy under the design earthquake for the site, the structure shall be designed to withstand the forces

and moments resulting from the lateral and vertical movements caused by the liquefaction. Soil stabilization

may be used to mitigate liquefaction conditions. Additionally, the design of the foundations shall be evaluated

with the soil in a liquefied state.

Slope Stability: For the SEE event, deformations of the supporting ground mass and displacements of the

slopes shall be considered in the design of the bridge components. If necessary, the soil shall be stabilized to

protect the bridge from damage due to lateral spreading, soil deformation and associated applied forces.

5.1.3 Functio nal Evaluation

The FEE is defined as an earthquake that has a return period of 100 years, representing approximately a 60%

probability of occurrence in 100 years. In this earthquake, Approach Bridges can be subject to damage only if

it can be classified as minimal. The Main Span Bridge, including Main Span Bridge tower, end bents, sup-

porting piles, superstructure, and stay cable system shall meet the requirements of the No Damage perfor-

mance level. Main Span Bridge and Approach Bridge bearings shall meet the requirements of the No Dam-

age performance level. The expansion joint between the Main Span Bridge and Approaches Bridges shall

meet the requirements of the Minimal Damage performance level. For reinforced concrete elements, mi-

nimal damage for the FEE event shall be based on the member strengths determined using the strain limita-

tions given in Section 5.4.

5.1.4 Performanc e Ass essment

The seismic performance of all structures shall be assessed by verifying estimated structural demands on com-

ponents are less than or equal to estimated structural capacities of those components. Methods for determining

demands and capacities are defined in the following sections.

When significant yielding of components is allowed, demand and capacity are defined by strain or rotational

limits. When components are required to remain elastic or experience minor yielding, demand and capacity

are defined by force Demand/Capacity (D/C) ratios.

All capacity-protected components, as defined by Caltrans Seismic Design Criteriaor these criteria, shall have

a force D/C ratio of 1.0 or less when subjected to over-strength forces.

When checking seismic conditions, use the corrosion allowance for pile casings at 50 percent of the 100-year

design life.

The horizontal diaphragms and tension elements that transfer for from one stay to the next between shafts or

elements that make up a tower or end bent column, if used, shall be capacity protected.

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

16/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 13

5.1.5 Seismic Loading dur ing Construct ion

For all bridges, the seismic loading during all phases of construction shall be designed to resist forces as de-

scribed in Caltrans Bridge Memo to Designers 20-2.

5.2 Definition of Ground Motions

Ground motions for use in dynamic seismic analysis of the bridge structures shall be taken from the Project

Seismic Ground Motion Report information provided in Book 2, Section 8, Exhibit 2-8-F which documents

the project-specific ARS design curves and spectrum-compatible ground motion time histories for the SEE andFEE. The Project consists of three soil zones: West Approach, Main Span, and East Approach. For each soil

zone, ARS design curves and earthquake time histories that were spectrally matched to the ARS design curves

were developed using the Probabilistic Seismic Hazard Analyses (PSHA) and considering the site response

characteristics of the subsoils. Revision to the project-specific ARS design curves and earthquake time histo-

ries provided in in Book 2, Section 8, Exhibit 2-8-F will not be allowed.

Non-linear time history and response spectrum analyses shall be used in the evaluation of the bridges, as de-

scribed in Section 5.3.2. For the purpose of non-linear time history analyses, the ground motions shall consist

of three, 3-component time histories consistent with the SEE and one, 3-component time history consistent

with the FEE. Each time history shall consist of 2-horizontal orthogonal components and one vertical compo-

nent. For the SEE, the envelope of the three time-history ground motion analyses results shall be used to de-

sign the bridge.

The Project Site is located in the seismically active southern California area. The principal faults affecting the

seismic hazard of the bridge are the Newport-Inglewood (Cherry Hill Segment) Fault northeast of the bridge

and the Palos Verdes Fault southwest of the bridge. Since the location of the bridge places it in close proximity

to the two active faults, near-fault directivity effects, including velocity pulses, shall be included in the time

history analyses.

5.3 Analyses for Determination of Demands

Demands on structural components of a bridge shall be determined by analysis of global three dimensional

computer models of the bridge that represent its dominant linear and nonlinear behavior and the effects of soil-

foundation-structure interaction. Demands shall be evaluated as load-type quantities (forces and moments) or

as displacement-type quantities (displacements, relative displacements, and rotations) as required by the eval-

uation rules for various components.

5.3.1 Service Load Demand s and Comb ination with Seismic Demands

For combination with seismic demands, component demands due to dead load, traffic load, temperature

changes, and wind shall be determined by static analyses of global models.

5.3.2 Seismic Demands

Seismic demands shall be determined by nonlinear dynamic time history analysis for the Main Span Bridge

and at least one Approach Bridge frame, but not less than 700 feet of Approach Bridge, adjacent to each end of

the Main Span Bridge. The analysis shall be completed for uniform support excitations for all pier locations

within the same soil zone developed for the project.

Appropriate analysis methods as specified in Caltrans Seismic Design Criteriashall be used for all other Ap-

proach Bridge structures.

Non-linear dynamic time-history analysis shall incorporate the following:

Both dead load and seismic load analyses shall be geometrically non-linear to account for the geometric

stiffness of the cable elements.

Boundary condition non-linearities shall be accounted for in the form of gap elements at expansion joints

and foundation impedances.

The structural model shall explicitly consider the geometric nonlinearity, inelastic structural components

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

17/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 14

and other inelastic elements (e.g. dampers). Any reinforced concrete members with a force De-

mand/Capacity (D/C) ratio larger than 0.5 shall be modeled with adjusted material and section properties to

represent the cracked section. Structural steel members with a force D/C ratio less than 1.5 shall be mod-

eled with elastic elements. Any members with a force D/C ratio larger than 1.5 shall be modeled with non-

linear elements.

Rayleigh damping is to be used for non-linear dynamic time-history analysis. Modal damping may be used for

other analytical tools. The range of Rayleigh damping values represents the target maximum and minimum

damping values that apply over the dominant periods of the various element groups.

The maximum upper range of Rayleigh damping for non-linear dynamic time-history analysis shall not ex-

ceed the following:

Reinforced Concrete Columns: 4% - 6%

Reinforced Concrete Towers: 4% - 6%

Steel Towers: 2% - 5%

Steel Superstructure: 2% - 5%

Concrete Superstructure: 3% - 5%

Foundations: 8%

Rayleigh damping shall be incorporated into the model with values for each element group representing the

expected extent of inelastic energy dissipation in that group. The range of dominant periods for the various

bridge components used to select Rayleigh damping shall capture at least 90% of the mass of the bridge com-ponents under consideration. If higher Rayleigh damping is used at a foundation, the higher damping shall be

limited to piling and pile caps that are entirely below grade and shall be established from bridge foundation

only component models. Anchor points used for establishing Rayleigh damping at foundations shall be se-

lected for the range of dominate periods of the foundation elements that capture at a minimum 90% of the

mass of the foundation elements. When the pile cap dominates the foundations response, it is acceptable to

exclude the mass of piles from the bridge foundation only component model. When soil springs or other

foundation elements are represented by hysteretic elements in global models, total foundation damping shall

not exceed an equivalent viscous damping of 8% with respect to the foundation stiffness and mass in defining

the Rayleigh damping parameters.

Modal Damping for Other Analytical Tools:

Reinforced Concrete Columns: 5%

Reinforced Concrete Towers: 5%Steel Towers: 3%

Steel Superstructure: 3%

Concrete Superstructure: 5%

Main Span Bridge tower shafts and end bent column shaft seismic energy dissipation elements, if used, shall

be explicitly modeled to represent the energy dissipation characteristics of each seismic energy dissipation

element.

The global seismic analysis model for the Main Span Bridge shall use explicit foundation modeling for the

Main Span Bridge and at least one Approach Bridge frame, but not less than 700 feet of Approach Bridge,

adjacent to each end of the Main Span Bridge. Explicit foundation modeling in the global model shall usethesame spectrum-compatible motions applied uniformly at all depth at the ground nodes along the full length of

the pile. The explicit foundation modeling shall include a representation of each individual pile, with distri-

buted soil supports over the entire length of the pile. The uniform ground motions documented in Book 2, Sec-

tion 8, Exhibit 2-8-F shall be used to excite the soil-pile structure system.

For all other structures, foundation substructure models may be used to capture significant soil-pile interaction

effects. The foundation substructure should consist of a linear stiffness and mass matrices representing the

entire soil-pile system. The linearized foundation stiffness and mass matrices must be approximated with the

anticipated strain levels during the design earthquake. The project ground motions developed in each soil zone

shall be used to excite the foundation substructure. The same input earthquake ground motions shall be used

for all supports within the same soil zone.

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

18/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 15

When modeling of foundations for seismic demand evaluations, softening effects of local soils shall be consi-

dered including seismic induced large deformations and liquefaction. The ground motions documented in

Book 2, Section 8, Exhibit 2-8-F shall be used for all cases of foundation modeling, with and without soften-

ing effects.

When checking AASHTO LRFD Bridge Design Specifications, 4th Edition, with California Amendments,

Extreme Event I, a permanent load factor , p, of 1.0 shall be used for Load Type DC.

Damping curves shall be submitted with the seismic analysis and design.

5.3.3 Nonl inear Loc al Analys is for Evaluating Seism ic Demands

At a minimum, nonlinear local analyses shall be performed on the following bridge elements or conditions to

supplement the global three dimensional nonlinear multi-support dynamic time- history analysis:

Regions of significant Stress Concentrations (such as seismic energy dissipation elements, tower diaph-

ragms, tower tension ties, mid-span pipe hinges, etc)

Locations of discontinuous load path

Fracture critical elements

Energy dissipating regions and devices

These analyses shall provide independent assessment of controlling seismic demands based on the assumption

of maximum plastic moments and forces developed by potential plastic hinges or other inelastic behavior.

These analyses shall be used to confirm adequate structural performance in the event that the SEE demands

obtained from the global time-history analysis are exceeded.

5.4 Analyses for Determination of Capacities

Capacities of structural components of a bridge shall be determined by analysis of local elastic and inelastic

computer models of the components. Capacities shall be evaluated as load-type quantities (forces and mo-

ments) or as displacement-type quantities (displacements, relative displacements, rotations, and curvatures) as

required by the evaluation rules for various components.

5.4.1 Structu ral Steel Comp onent Capacit ies

Cable Stays: The load capacity of cable stays shall in accordance with PTI Recommendations for Cable Stay

Design, Testing, and Installation.

5.4.2 Tower Shafts and Strain Limit s

The towers shall be designed in accordance with ATC-32 Improved Seismic Design Criteria for California

Bridges: Provisional Recommendationsaugmented by the following requirements:

l/ lreq> 2.0

b/t 2l

Pmax/Area 0.6Fy

Where:

l = the relative stiffness of the longitudinal stiffener to the tower skin wall

b/t = the width to thickness ratio of the skin wall

Pmax/Area= the maximum axial stress

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

19/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 16

Main Span Bridge steel tower allowable strain limit value at the SEE Event shall meet the following require-

ments:

Tower without seismic energy dissipation elements: 4* y where yis the yield strain of the steel

Tower with seismic energy dissipation elements: The tower shall be designed to remain essentially elastic.

Main Span Bridge steel tower allowable strain limit value at the FEE Event shall not exceed y.

5.4.3 Tower Connectio ns

Tower splices shall be designed for the expected yield strength capacity of the component in accordance with

AASHTOLRFD Bridge Design Specifications, 4th Edition,with California Amendments.

Tower anchorage to the foundation shall be designed based on global push-over of the tower. The capacity of

the tower anchorage shall be larger than the over strength demands associated with plastic hinging of the tower

shaft. The capacity shall be evaluated in accordance with AASHTOLRFD Bridge Design Specifications, 4th

Edition,with California Amendments.

5.4.4 Reinforced Concr ete Compon ent Capacit ies

The expected nominal moment capacity Mneof ductile reinforced concrete members and capacity protected

members as defined in Caltrans Seismic Design Criteria Section 3.4 shall be based on expected material

strengths:

fce= 1.3 * f'c (expected concrete compressive strength)

fye=68 ksi (ASTM A706, Grade 60) (expected reinforcement yield)

Maximum concrete strains at the nominal moment capacity Mne shall not exceed 0.003, and the reinforcing

steel strains shall be limited to the allowable reinforcement strain values defined in Section 5.4.6 of this docu-

ment.

Capacity protected members shall be designed for forces derived from design overstrength moments (M o) of

the members framing into the capacity protected member. The design overstrength moment Moshall be based

on expected material strengths.

Plastic moments shall be determined from moment-curvature analysis that considers the effects of concrete

confinement and strain hardening of the reinforcement. The overstrength moment shall be taken as 1.20 timesthe calculated plastic moment at the design deformation of the element.

The horizontal diaphragms between shafts or elements that make up a tower or end bent column, if used, shall

be capacity protected.

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

20/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 17

5.4.5 Al low able Conc rete Strain Values

The allowable concrete strain values for each earthquake level and components shall be according to the table

below. The stress-strain relationships developed by Mander for confined concrete shall be used to calculate the

values as a percentage of cu. When the no damage performance level is required, concrete strain limit of

0.003 pursuant to AASHTOLRFD Bridge Design Specifications, 4th Edition,with California Amendments,

Section 5.7.2.1 shall be taken at the extreme face of the concrete component and not the confined core.

ALLOWABLE CONCRETE STRAIN VALUES

Location

SEE FEE

Dam-

ageStrain

Dam-

ageStrain

Main Span Bridge Towers Minimal 0.004

0.4 cuNo 0.003

Main Span Bridge End Bents Minimal 0.004

0.4 cuNo 0.003

Main Span Bridge CISS/CIDH Piles Minimal 0.004

0.4 cuNo

0.003

Approach Bridge Columns Mod-erate

0.015 0.75 cu

Minimal 0.004

Approach Bridge CISS/CIDH Piles Minimal 0.01

0.5 cuMinimal

0.004

All other ElementsMod-

erate

0.015

0.75 cuMinimal

0.004

cudefinition shall be per Caltrans Seismic Design Criteria.

5.4.6 Al low able Reinforcement Strain Values

To achieve the performance goals for the SEE and FEE event, the strains in reinforced concrete members,

shall be limited to the values in the table below. The design level of peak steel strain values given in this table

are to be used for evaluating the moment-curvature relationship for all potential plastic hinge areas.

ALLOWABLE REINFORCEMENT STRAIN VALUES

Location

SEE FEE

Damage StrainDam-

ageStrain

Main Span Bridge Towers Minimal 0.015 No -

Main Span Bridge End Bents Minimal 0.015 No -

Main Span Bridge Tower + End Bents Lateral Rein-

forcement (Bars #8 and Smaller)Minimal 0.05 No -

Main Span Bridge CISS/CIDH Piles Minimal 0.015 No -

Approach Bridge Columns (Bars #11, #14 & #18) Moderate 0.05 Minimal 0.015Approach Bridge Columns (Bars #10 and Smaller) Moderate 0.06 Minimal 0.015

Approach Bridge CISS/CIDH Piles Minimal 0.02 Minimal 0.015

All other Elements Moderate 0.06 Minimal 0.015

u,R

su, sh fu, fue, y, ye, definitions shall be per Caltrans Seismic Design Criteria.

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

21/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 18

5.4.7 Main Span Bridge Tower and End Bent Shaft Energy Dissipating Shear Link (If Energy

Dissipating Shear Link A re Used)

Except for base fixity resistance from the dual columns, frame lateral resistance shall only be from the interac-

tion of the twin columns and Energy Dissipating Shear Links or Seismic Energy Fuses. All loading combina-

tions not including seismic loads shall not exceed the nominal yield strength of the Energy Dissipating Shear

Links or Seismic Energy Fuses.

All components of Energy Dissipating Shear Link or Seismic Energy Fuse connections to Main Span Bridge

tower shafts and end bent column shafts shall be designed as capacity-protected elements and shall be detailed

to permit their removal and replacement after a seismic event.

The rotation demand on Energy Dissipating Shear Links or Seismic Energy Fuses shall be limited to a maxi-

mum value of 0.01 radians at the SEE level and 0.003 radians at the FEE level.

5.4.8 Energy Dissipating Shear Link Testing (If Energy Dissipating Shear Link s Are Used)

Full scale proto-type laboratory cyclic load testing of the Energy Dissipating Shear Links shall be performed

to verify the required ductility and strength of the link is achieved; to confirm the adequacy of the connection

to towers; and to demonstrate that the Energy Dissipating Shear Links can be readily removed and replaced

after it has reached the required maximum ductility demand as shown by analysis. The over-strength factor to

be used when designing Energy Dissipating Shear Link capacity protected components shall be established by

the full-scale testing.

The quasi-static loading protocol for testing the Energy Dissipating Shear Links shall consist of three distinc-

tive phases as summarized in Tables 1 to 3 and illustrated in Figure 1.

The first and the second phase of the loading history reflect the actual cumulative link rotation demands under

design earthquake loadings. Each of them representing a complete deformation history resulted from design

SEE event in terms of the maximum link rotation and the total number of inelastic cycles. In Phase I the de-

formation sequence closely follows the response time history which contains large velocity pulses; whereas in

Phase II the deformation sequence is arranged in the order of increasing rotation amplitude.

Table 1: Energy Dissipating Shear Link Test Loading Sequence Phase I

Load Step Link Rotation Amplitude (Radians) Number of Cycles

1 0.00375 1

2 0.03000 1

3 0.01000 1

4 0.00750 1

5 0.00500 2

6 0.00375 1

7 0.01500 1

8 0.01000 1

9 0.00500 1

10 0.00375 2

Table 2: Energy Dissipating Shear Link Test Loading Sequence Phase

Load Step Link Rotation Amplitude (Radians) Number of Cycles

11 0.00375 4

12 0.00500 3

13 0.00750 3

14 0.01000 4

15 0.01500 3

16 0.02000 1

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

22/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 19

17 0.03000 1

Table 3: Energy Dissipating Shear Link Test Loading Sequence Phase

Load Step Link Rotation Amplitude (Radians) Number of Cycles

18 0.04000 1

19 0.06000 1

20 0.08000 1

21 0.10000 122 0.12000 1

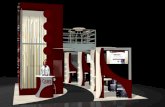

FIGURE 1Loading History for Energy Dissipating Shear Link Test

In Phase III the loading cycle continues at increments of 0.02 radians, with one cycle at each increment until

link failure occurs. The link is considered as failed when significant loss of strength occurs. If in case the linkfailure does not occur when the actuator has reached its maximum capacity (of either force or stroke), the load-

ing cycle shall be kept at the constant rotation amplitude that corresponding to the maximum capacity of the

actuator and repeated until link failure occurs.

The acceptance criterion is set forth as follows: For the given loading protocol, the test specimen must sustain

the required shear link rotation angle for at least one full cycle prior to the link shear strength dropping below

the nominal link shear strength.

The Design-Builder shall provide a Energy Dissipating Shear Link Testing Protocol to the Port that includes

the following:

- Structural laboratory location and name of facility to test the specimen. - Step by step process for how testing is to be completed

- Test goals and requirements- Evaluation of test acceptance criteria provided in the Contract Documents as well as additional test-

ing requirements the Design-Builder may want to add- Explanation of design method with expected theoretical testing results- Roles and responsibilities of testing laboratory and the Design-Builder- Schedule- Test report table of contents- Post testing evaluation procedures- Mitigation procedures and strategies to limit impact to the Project if a test were to not meet accep-

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

23/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 20

tance criteria.

The minimum requirements for structural laboratory are, at a minimum:

- The structural laboratory shall be capable of conducting the required full scale Energy DissipatingShear Link test including: provision of loading mechanism, specimen setup, instrumentation installa-

tion, testing of the instrumentation, acquisition and interpretation of the data;

- Principal-in-charge and staff members shall have applicable experiences on similar tests;- The structural laboratory shall be able to finish the test within the time frame required.

The Design-Builder shall submit a Energy Dissipating Shear Link Test Report showing the specimen(s) have

met the test acceptance criterion provided in the Approved Energy Dissipating Shear Link Testing Protocol.

Data shall be provided and certified by the testers and testing agency.

5.4.9 Con crete Pile Caps

All concrete pile caps shall be designed as capacity protected members for over-strength forces generated from

bent columns, towers, and piles.

5.4.10 Allo wab le CISS Pile Shell Strain Values

Permanent steel shells for CISS concrete piles (hereinafter called casings) shall supplement the pile strength

and ductility provided that the effective casing thickness after full allowance for corrosion is at least 1/16 inch.

For all non-seismic loading conditions, the effective casing shall consider full allowance for corrosion as de-fined in Section 3.2.3. For all seismic evaluations, the effective casing shall consider one-half the allowance

for corrosion as defined in Section 3.2.3.

Steel pile casings may be assumed to act compositely with the interior reinforced concrete section provided

that an adequate shear transfer mechanism is included at the casing/concrete interface. Shear transfer may be

augmented by the addition of welded shear rings or other mechanical devices at the casing/concrete interface.

Shear transfer shall be assessed as described in American Petroleum Institute (API) RP-2A/LRFD - Section

H.4, Grouted Pile to Structure Connection.

At the pile casing tip and casing cut-off elevations, the casing shall be assumed to contribute only lateral con-

finement for a distance of 2 times the pile diameter. With the allowance for corrosion considered, the casing in

these regions may be assumed to contribute 100 percent of its net area for confinement. In any case, piles shall

have minimum spiral or hoop confinement reinforcing equal to #6 @ 6 inch spacing.

With the allowance for corrosion considered, the casing may be assumed to contribute up to 80 percent of its

net area to flexural capacity of a section and up to 20 percent of its net area to confinement of the pile interior.

In any case, piles shall have minimum spiral or hoop confinement reinforcing equal to #6 @ 6 inch spacing.

Also, the pile longitudinal reinforcing bars within the casing should contribute to at least 50 percent of the pile

flexural capacity.

The casing contribution to foundation stiffness shall be based on the net casing thickness after allowance for

corrosion. A sensitivity study shall be performed to assess the structural seismic response with no allowance

for corrosion in pile casings.

The maximum allowable casing strains are as follows:

Longitudinal Tension (along pile axis) 0.02

Longitudinal Compression (along pile axis) 0.01

Where steel casing acts compositely with the concrete pile interior:

Hoop Tension (on net casing with 0.040

corrosion allowance)

Where details are provided such that the steel casing does not act compositely with the concrete pile interior

and longitudinal compression strains in the casing are negligible:

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

24/25

Gerald Desmond Bridge ReplacementExhibit 2-13-A - Design Criteria Page 21

Hoop Tension (on net casing with 0.060

corrosion allowance)

5.4.11 Shear Design of Ducti le Concr ete Members

The shear design of reinforced concrete members that are detailed as ductile members that may experience

yielding shall conform to Caltrans Seismic Design Criteria,Section 3.6.

In addition, for any hollow sections as described in Section 5.4.12 and shown in Figure 2, the concrete shear

capacity component, Vc, shall be based on the web sections only, where the web section is defined as thelonger slender section parallel to the direction of the demand shear force.

Similarly, the reinforcement shear capacity component, Vs, shall be based on the rebar in and extending along

the full length of the web section, and parallel to the direction of the demand shear force only. No other rein-

forcements (long bars, cross ties, rebars in flange sections) shall be allowed to contribute to the shear capacity,

Vs. The web shear reinforcement shall be fully developed into the web/flange joints.

For cross ties, lap splices shall be the full length of the bars, if lap splices are used.

5.4.12 Plastic Hinge Length

The maximum length of plastic hinges (Lp) in a solid section shall be as specified by Seismic Design Criteria

Equation 7.25

The length of plastic hinges at CISS pile connection to pile cap shall be as follows:

Lp= G + 0.3fyedbl 0.08L + 0.15fyedbl

Where fye, dbl, and Lare defined by Seismic Design CriteriaEquations 7.25 and 7.26

G= The gap, if any, between the top of the CISS pile steel shell and the bottom of the pile cap.

The required shape of hollow Approach Bridge bent columns is shown in Figure 2, have been reviewed by the

Department, and have been determined to provide acceptable seismic performance characteristics up to a duc-

tility demand of 3, if the following criteria are met:

Section Geometry: The hollow section walls with curved faces shall be configured with a flat inside

face as shown in Figure 2.Cross Ties in curved walls: 180 degree hooks shall be used for all cross ties in curved walls.

Cross Ties in flat walls: Cross ties shall have alternating 180 degree and 90 degree hooks. In lieu of

90 degree hooks, T-head bar ends may be used.

The Design-Builder shall evaluate the performance of hollow Approach Bridge bent columns using the plastic

hinge length (Lp) given in the CaltransSeismic Design Criteria.

The shear capacity of hollow Approach Bridge bent column sections shall not rely on lap spliced lateral ties.

If the Design-Builder changes the hollow shape from that shown in Figure 2, full scale testing shall be pro-

vided and the Design-Builder shall submit a testing protocol for Approval.

-

7/24/2019 Bridge Replacement Project -Structural Design Criteria Exhibit 2-13-A Design Criteria

25/25

Gerald Desmond Bridge Replacement

FIGURE 2Approach Bridge Column Details