Bp Dm v1604 Overview en In

-

Upload

aliasger-bharmal -

Category

Documents

-

view

218 -

download

0

Transcript of Bp Dm v1604 Overview en In

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 1/29

SAP Best Pract ices forDiscrete Manufactur ing

V1.604(India)

SAP Best Practices

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 2/29

Genera l In format ion

SAP Best Practices for Discrete Manufacturing was developed for small andmidsize manufacturers to implement a solution quickly and easily.

By means of an entry-level offering for manufacturing companies, you gainbuilt-in support for the best business practices in the industry.

Funct iona l i t ies

The SAP Best Practices for Discrete Manufacturing V1.604 solution supportsyour business in the following areas :

Materials management

Production planning and control

Sales and distribution

Logistics, product life-cycle management, and quality management

Accounting

Controlling

Forms and reporting

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 3/29

SAP BP for Disc ret e Manufac t ur ing V1.604Solut ion Sco pe (1 of 2)

Manufac tur ing Sales Mat er ials Management Financ ial Acc ount ing

Analy t i cs

Cross Funct ions

Make-to-Stock Production –

Discrete Industry

Make-to-Order Production withVariant Configuration

Make-to Order Production withoutVariant Configuration

Repetitive Manufacturing

Production Subcontracting (External

Processing)

Rework Processing for Stock-

Manufactured Material

Rework Processing for Work-in-

Process

Quality Management (QM) in

Discrete Manufacturing

Repetitive Manufacturing with

Kanban Supply in Production

Planning and Processing of

Semifinished Goods

Co-Product Manufacturing

Tool Production

Engineer-to-Order (ETO) – ProjectAssembly

Make-to-Stock (MTS) Productionwith Order Split

Records Management

Sales Processing Using 3rd Party (w. Ship.Not.)

Credit Management

Sales Order Processing – Sale from Stock

Free of Charge Delivery

Returns and Complaints

Sales Quotation

Sales Order Processing for Prospect

Sales Processing using Third Party (without

Shipping Notification)

Sales of Nonstock Item with Order SpecificProcurement

Debit Memo Processing

Foreign Trade Export Processing

Customer Consignment Processing

Returnables Processing

Batch Recall

Lean Warehouse Management

Sales Order Processing with Customer Down

Payment

Sales: Period End Closing Operations

Credit Memo Processing

Handling Unit Management (HUM) for Production

Order

Sales with Scheduling Agreements

Engineer-to-Order ( ETO) – Quotation Processing

Sales Returns with Quality Management (QM)

Advanced Customer Returns Management

Cash Sales Orders

Shipping and Receiving with WM

Batch Management

Serial Number Management

Quality Management for Procurement with

Vendor Evaluation

Quotation for Procurement

Consumable Purchasing

Procurement without QM

Stock Handling: Scrap and Blocked Stock

Procurement Contract

Stock Transfer with DeliveryStock Transfer without Delivery

Return to Vendor

Physical Inventory/ Inventory Count and

Adjustment

Subcontracting

Procurement & Consumption of Consigned

Inventory

Purchasing with JIT Delivery Schedules

Advanced Batch Management

Outsourced Manufacturing

General Ledger

Accounts Receivable

Accounts Payable

Cash Management

Asset Accounting

Asset Acquisition through DirectCapitalization

Asset Acquisition for Constructed Assets(Investment Orders)

Activate Document Splitting

Cost of Sales Accounting

Segment Reporting

Internal Order R&D Actual

Overhead Cost Accounting – Actual

Period End Closing Financial Accounting

Period End Closing Projects

Internal Order for Marketing and Other

Overhead Actual

Activate Document Splitting for Discrete

Manufacturing

SAP ERP Reports for Accounting

SAP ERP Reports for Logistics

Period End Closing Activities

Period End Closing “General” Plant

Inventory Valuation for Year End Closing

Time Recording

Travel Management

Control l ing

Purchased Material Price Planning

General Cost Center Planning

Manufacturing Cost Center Planning

Internal Order R&D Planning

Internal Order for Marketing and Other

Overhead Planning

Standard Cost Calculation

Research and Dev.

Internal Product Development

New Scenarios

Enhanced Scenarios

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 4/29

Services

Spot Consulting with Fix Priced Billing

Internal Project

Internal Maintenance

Service with Time & Material Based Billing

Service with Fixed Price Billing

Procurement of Third-party Resources

External Procurement Services

Depot Repair

Period End Closing Service Orders

Maintenance and Warranty Processing

Easy Depot Repair

SAP BP for Disc ret e Manufac t ur ing V1.604Solut ion Sco pe (2 of 2)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 5/29

© SAP 2007 / Page 5

Indust ry-Spec i f ic Scenar i os (1 of 2)

SAP Best Practices for Discrete Manufacturing V1.604 provides thefollowing industry-specific scenarios:

226: Handling Unit Management (HUM) for Production Order

227: Quality Management in Discrete Manufacturing

229: Advanced Batch Management

230: Purchasing with JIT Delivery Schedules

231: Sales with Scheduling Agreements

232: Engineer-to-Order (ETO) – Quotation Processing

240: Engineer-to-Order (ETO) – Project Assembly

233: Repetitive Processing with KANBAN Supply into Production

234: Planning and Processing of Semifinished Goods

235: Co-Product Manufacturing

236: Tool Production

E h P 4

E h P 4

New Scenarios

Enhanced Scenarios

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 6/29

© SAP 2007 / Page 6

Indust ry-Spec i f ic Scenar i os (2 of 2)

SAP Best Practices for Discrete Manufacturing V1.604 provides thefollowing industry-specific scenarios:

237: Sales Returns with Quality Management (QM)

238: Cash Sales Order

239: Shipping and Receiving with Warehouse Management

248: Make-to-Stock (MTS) Production with Production Order Split

249: Outsourced Manufacturing

250: Advanced Customer Returns Management

661: Records Management

245: Activate Document Splitting for Discrete Manufacturing

274: Maintenance and Warranty Processing

275: Easy Depot Repair

E h P 4

E h P 4

E h P 4

E h P 4

E h P 4

E h P 4

New Scenarios

Enhanced Scenarios

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 7/29

Purpose Handling Unit Management (HUM) is used to control logistical processes.

A handling unit represents a physical object in the SAP system. It consists of a loadcarrier, one or more packed products and an unlimited quantity of packaging materials.Each handling unit has a unique identification number, which is typically printed as abarcode on a material tag.

You can specify the material and the quantity that is to be packed in certain packaging,that is, in one handling unit. These requirements are reproduced in a packing

instruction. This packing instruction can be used to create handling units automatically.

Benef i t s Automatic packaging according to packing instructions

Track movements of groups of individual materials by tracking the handling units thatcontain them

Full integration into the logistic chain

The scenario offers you the possibility to demonstrate HUM with or without warehouse

management

Key process f lows c overed Creation and release of production order for handling unit (HU) production

HU packaging in production order

Goods receipt for produced HU

Monitoring of HU

Confirming production of HU

HU handling with WM or HU handling without WM

Purpose and Benef i t s :

Handl ing Uni t M anagement (HUM) forProduc t ion (226)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 8/29

Purpose

This scenario deals with quality inspection activities during the productionprocess.Quality activities are required both when a product is manufactured in-house andwhen the production involves external processing where parts of the productionprocess are done by a subcontractor.

Benef i t s

Two sub-scenarios to cover both goods acceptance and goods rejection oracceptance and rejection of the external processing respectively.

Quality Notification to track quality issues, and trigger further actions, such as re-work or scrapping

Key process f lows c overed

QM for goods receipt of production order

QM for goods receipt of external processing

Acceptance and rejection of goods/ external processing work are both covered

Purpose and Benef i t s :

Qual i t y Managem ent (QM) in Disc ret eManufact ur ing (227)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 9/29

Purpose

You get the complete batch history data including the evolution of a batch, byconsidering all relevant batch-related object types (BRO types) maintained indifferent SAP and external systems.

Benef i t s

To track the transactional data related to batches

To find out where a batch was used, e.g. to perform a batch recall or forevaluation purposes

To find out where a batch is used, e.g. in which stocks or inspection lots ormaterial documents

To have a single point of batch maintenance

Key process f lows c overed Batch information cockpit with Batch History

Purpose and Benef i t s :

Advanced Batc h Management (229)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 10/29

Purpose

This scenario focuses on JIT procurement.

It describes an inbound process in a typical repetitive manufacturingenvironment.

Benef i t s

Streamlined demand flow from customer to supplier High integration of customer’s and supplier’s supply chain managed by

cumulative quantities

Shorter process times

Reduction of inventories to a minimum

Key process f lows c overed

Create scheduling agreement for vendor material

Update scheduling agreement with forecast and JIT delivery schedules

Enable traceability via batch or serial number assignment

Create Scheduling Agreement Release

Print and Transmit Scheduling Agreement to vendor

Goods receipt posting with reference to scheduling agreement

Billing

Purpose and Benef i t s :

Purchas ing w i t h J IT Del ivery Sc hedules (230)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 11/29

Purpose

Scheduling agreements are widely used in Discrete Industries.

This scenario focuses on a order-to-invoice cycle.

It describes an outbound process in a typical series business environment.

Benef i t s

Streamlined demand flow from customer to supplier

High integration of customer’s and supplier’s supply chain managed bycumulative quantities

Shorter process times

Print out forms support the basic requirements of discrete industries

Key process f lows c overed

Create basic customer contract called scheduling agreement

Update scheduling agreement with forecast and JIT delivery schedules

Display item due for delivery and create outbound delivery for available parts

Enable traceability via batch or serial number assignment

WMS controlled picking; packaging according to customer‘s packing instruction

Invoice items and transfer to accounting

Receive self-billing information from customer

Purpose and Benef i t s :

Sales w i t h Sc hedul ing Agreement s (231)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 12/29

Purpose and Benef i t s :Purpose

This scenario describes the quotation processing in a standard Engineer-to-Order (ETO) environment.

SAP functionalities of Sales & Distribution (SD) and of Project System (PS) are used to control thecomplete process, from customer inquiry to the handover to project assembly (described in thescenario 240, ETO Project Assembly).

In addition to the SAP reporting functionality also the special purchasing functionality “long lead timeprocurement” is part of the process.

Benef i t s Deep integration to the project structuring and calculation allows for a consistent controlling of all stepsand values

Copy functionalities – e.g. from inquiry to quotation – are facilitating compliance with the process rules

All values and parameters for the subsequent process (ETO 240) are available as default parameters

The option for the creation of project versions are allowing a continuous recording of all relevantvalues along the controlling process and a later comparison of the several situations

The long lead time procurement process is an important step to guarantee material availability on time

Cost planning, budgeting and comprehensive reporting functionality allows for a detailed controlling ofthe project

Key process f lows c overed Creation of inquiry with linkage to project

Easy Cost Planning

Creation of quotation with reference to the inquiry

Integration to the project system including calculation and scheduling functionalities

Controlling and reporting along the complete process

Engin eer-t o-Order (ETO) – Quot at ionProc essing (232)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 13/29

Purpose and Benef i t s :Purpose

This scenario describes the order processing in a standard Engineer-to-Order (ETO)environment.

SAP Project System is used to control the whole process, from the SD requirement toplanning, purchasing, production and delivery.

SAP Project-Oriented Procurement (ProMan) is used as an advanced tool to control theplanning/purchasing steps in the order procedure.

Benef i t s Project structuring/execution via project system is used to control the collaboration between

different departments

Milestone billing is used to control the progressive payment procedure, and track back thestatus of the project

Use of ProMAN to control and monitor the manufacture/procurement procedures centrally

Assignment of personnel resources and technical documents possible

Delivery the semi-finished goods via the project

Handling the final assembly on customer site using network activity in the project

Key process f lows c overed Creation of sales order with reference to the quotation and billing milestones

Use of ProMan for procurement process of components

Assignment of personnel resources and time recording

Assignment of technical documents

Confirmation of project activities

Subassembly for semifinished goods

Delivery to customer

Engineer-t o-Order (ETO) – Projec t Assem bly(240)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 14/29

Purpose

Lean production control method

Production process in a repetitive manufacturing environment

Supply to production is managed by KANBAN processing

Benef i t s

The production process controls itself and manual posting is reduced as far aspossible.

Reduction in lead time and stock.

Components are not procured before they are needed (just in time).

Prevention of overproduction. Reduction of required storage space.

Simple and transparent method of organization.

Key process f lows c overed

Creating Planned Independent Requirements Material Requirements Planning at Plant Level

Production planning and capacity leveling for repetitive manufacturing

Procurement of RAW-Material by external KANBAN with scheduling agreements

In-House Production (subassembly) by internal KANBAN with repetitivemanufacturing

In-House Production (Finished Good) with repetitive manufacturing

KANBAN with stock transfer

Repetitive manufacturing backflush

Purpose and Benef i t s :

Repet i t i ve Manufac tu r ing w i th K anban Supp lyin to Product ion (233)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 15/29

Purpose

Forecasting level is the semifinished product. Planned independentrequirements are generated for the semifinished material.

Semifinished product is manufactured in a Make-to-Stock production (MTS)environment.

Production of the finished product is triggered by customer orders (MTO) havingthe forecasted semifinished product as one component in its bill of material.

Integration of main cost object controlling functions, such as preliminary costingand period-end closing.

Benef i t s

Production triggered by a production plan

Batch management included

Forecast of semifinished products

Make-to-order and Make-to-stock processes in one scenario

Key process f lows c overed

Creating Planned Independent Requirements

Material Requirements Planning at Plant Level

In-House Production (subassembly – Make-to-stock)

In-House final production (assembly – Make-to-order)

Confirming Assembly Activities

Sales Order processing

Purpose and Benef i t s :

Planning and Process ing of Sem i f in ished Goods(234)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 16/29

Purpose

This scenario enables you to produce more than one material within oneproduction order, which is often required in disassembly processes, such as

cutting of tin.

Benef i t s

One or more components are used as input materials in the same productionorder.

Two or more materials are produced simultaneously

All products are posted into storage within the same transaction, so that duringproduction execution value differences do not require different processes.

The main production costs are distributed among the most important products,including production variances

Production orders can be settled during period-end closing

Key process f lows c overed

Creation of production order for co-production

Check of material availability

Production order execution for co-production

Production order settlement

Purpose and Benef i t s :

Co-Produc t Ma nufac t ur ing (235)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 17/29

Purpose

This scenario enables you to produce tools in a MTS (Make-to-stock)environment.The tool product is manufactured anonymously and delivered to storage as a

production resource tool.

Benef i t s

Tool production using MTS (Make-to-stock) production order processing

Material requirements planning for the components

Material staging for tool components

Serial number assignment for tool product

Equipment maintenance for tool product

Key process f lows c overed

Creation of production order for tool production

Check of material availability

Production order execution for tool production

Equipment maintenance for tool product

Purpose and Benef i t s :

Tool Produc t ion (236)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 18/29

Purpose

Sales order returns processing with quality management inspection lots. Thecreation of the return sales order references to the original billing document forthe goods. The goods are shipped back and a return delivery is created withreference to the sales order. After quality inspection the goods are eitherreturned to stock, scrapped, or returned to the vendor. A credit memo is created

from billing, and posted to the customers account.

Benef i t s

Full integration of sales order returns and quality management

Sales order returns are processed according to sales order reference to theoriginal billing document

Credit memo is created and posted to customers account

Key process f lows c overed Creation of return order

Creation of return delivery

Quality inspection

Release returns for billing and billing

Purpose and Benef i t s :

Sales Ret urns w i t h Qual i t y Management (QM)(237)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 19/29

Purpose

This scenario deals with cash only payment transaction for the sales of materialto a customer.

The cash sales process is used when the customer places the sales order andpicks up and pays for the goods at the same time. The system automatically

proposes the current date in the sales order as the date for the delivery andbilling. Once the sales order is saved, the system automatically creates a

delivery.

Benef i t s

Sales and delivery are created in one step

Optional batch management

Key process f lows c overed Creation of sales order and delivery (automatically)

Check batches (optional)

Post goods issue

Billing

Purpose and Benef i t s :

Cash Sale s Order (238)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 20/29

Purpose

This scenario is an example of how warehouse management (WM) can be used.It does not cover all possible warehouse management processes for completeWM implementation (for example inventory counting is not part of this scenario).

WM is used for the storage of raw materials and finished goods.

Internal transfer orders are used for put away, internal transfers and removalfrom storage.

Benef i t s

This scenario shows the integration of WM with inbound logistics, production and

outbound logistics

Key process f lows c overed

Purchasing process with transfer orders

Production order creation and processing of material movements with WM

Sales order processing and WM transfer orders

Purpose and Benef i t s :

Shipp ing and Rec eiv ing w i t hWarehouse Managem ent (239)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 21/29

Purpose

The scenario Make-to-Stock (MTS) Production with order split focuses on optionshow to split an existing production order for which processing may have alreadybegun into two separate production orders. These production orders are thenexecuted separately from a logistics perspective.

Benef i t s

Increased flexibility for the production planner to react to unplanned events on theshop floor, changed customer requirements or repriorization of production orders.

Better cost transparency considering real shop floor-driven plan changes

Reliable batch traceability information also after production order split

Key process f lows c overed

Allows split of already partially confirmed production order

Allows split to put material on stock

Visualization of split history

Supports meaningful comparison of planned vs actual cost on parent & child

Fair split of planned cost between parent & child

Update batch traceability during split

Purpose and Benef i t s :

Mak e-t o-St oc k (MTS) Produc t ion w i t h OrderSpl i t (248)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 22/29

Purpose

Outsourced manufacturing enhances the typical subcontracting and externalprocessing processes with advanced features which are part of EhP 4.

Benef i t s

Serial Numbers Assignment in Procurement

Subcontracting ASN with components

Monitoring of whole process with subcontracting process

Material numbers can be transferred to purchase orders

Usage of subcontracting stock

In-time consumption posting of components

Inventory Reports

Monitoring of Batches

Key process f lows c overed

Subcontracting (MM)

Subcontracting (PP)

Purpose and Benef i t s :

Out sourced Manufac t ur ing (249)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 23/29

Purpose

This scenario describes advanced sales order returns processing with materialinspection. The creation of the return sales order references to the original billingdocument for the goods. The goods are shipped back and a return delivery iscreated with reference to the sales order. After material inspection and decisionon follow-up activities a credit memo is created and posted to the customers

account.

Benef i t s

Manage customer returns with advanced functions that provide end-to-endsupport for the returns process

Sales order returns are processed according to sales order reference to theoriginal billing document

Automatic Creation of follow-up documents after material inspection

Credit memo is created and posted to customers account Monitoring of the whole return process

Key process f lows c overed

Creation of return order and return delivery

Quality Evaluation and automatic creation of follow-up documents

Release returns for billing and billing

Process Monitoring

Purpose and Benef i t s :

Advanced Cust om er Ret urns Managem ent(250)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 24/29

Rec ords Management (661)

Note: Additional license fees may arise when records management is used in a productiveenvironment

Purpose

This scenario focuses on the creation of customer order records and equipmentrecords

It describes records management process in a typical project-orientedmanufacturing environment

Benef i t s Fast access to relevant information leveraging workspace efficiency and

response time to customer inquiries

Non-redundant, reliable information storage with efficient usage of resources

Accelerated implementation of business processes by leaded processautomation and early time-to execution

Decreasing information management costs by using controlled distribution,updates and archiving processes

Usage of records management enables focusing on the core business

Purpose and Benef i t s :

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 25/29

Maintenanc e and Warranty Process ing (274)

Purpose This scenario addresses the processing of a service case from the initial

reporting of the problem by the customer telling about the equipment number ofthe repair good. The process is built on the fact that the repair good has beenproduced at plant once or it is returned for the second time to the plant so thatequipment verification is possible.

Benef i t s

Customer Service and Order Management

Warranty check

Repairs Processing

Inventory Management

Cross-Application Time Sheet

Equipment Handling

Key process f lows c overed: Customer Service and Order Management

Warranty check

Repairs Processing

Inventory Management

Cross-Application Time Sheet

Equipment Handling

Purpose and Benef i t s :

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 26/29

Easy Depot Repair (275)

Purpose This scenario addresses the processing of a service case from the initial

reporting of the problem by the customer up to the point where the customer isbilled, whereat service activities are carried out at plant.

Benef i t s Quotation

Customer Service and Order Management Cross-Application Time Sheet

Resource Related Billing

Key process f lows c overed: Customer Service and Order Management

Repairs Processing

Cross-Application Time Sheet

Billing

Purpose and Benef i t s :

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 27/29

Purpose

The online split is provided with the new General Ledger Accounting.

Documents are enhanced with additional account assignment objects, oradditional postings are done which split the original postings into lines referringto the account assignment objects.

Account assignment objects can be defined according to selected dimensions. InSAP Best Practices the dimensions are profit centers and segments.

Benef i t s

The postings are done in real time (online).

It is possible to draw up complete financial statements for the selecteddimensions at any time (segment reporting).

Key Points The online split is provided with the new General Ledger Accounting.

The online split is based on segments.

The online split must be activated before the start of postings in the client.Postings done before can cause subsequent online split errors (see also note891144).

Purpose and Benef i t s :

Act iva te Docum ent Sp l i t t i ng for Disc re t eManufac tu r ing (245)

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 28/29

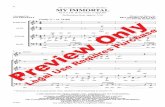

Legend

Symbol Description UsageComments

Band: Identifies a user role, such as Accounts

Payable Clerk or Sales Representative. This bandcan also identify an organization unit or group,rather than a specific role.

The other process flow symbols in this table go intothese rows. You have as many rows as required to

cover all of the roles in the scenario.

Role band

contains taskscommon to thatrole.

External Events: Contains events that start or end thescenario, or influence the course of events in the

scenario.

Flow line (solid): Line indicates the normal sequenceof steps and direction of flow in the scenario.Flow line (dashed): Line indicates flow to infrequently-used or conditional tasks in a scenario. Line can

also lead to documents involved in the process flow.

Connects twotasks in a

scenarioprocess or anon-step event

Business Activity / Event: Identifies an action thateither leads into or out of the scenario, or an outsideProcess that happens during the scenario

Does notcorrespond to atask step in thedocument

Unit Process: Identifies a task that is covered in astep-by-step manner in the scenario

Corresponds toa task step inthe document

Process Reference: If the scenario references anotherscenario in total, put the scenario number and na me

here.

Corresponds toa task step in

the document

Sub-Process Reference: If the scenario referencesanother scenario in part, put the sce nario number,name, and the step numbers from that scenario here

Corresponds toa task step inthe document

Process Decision: Identifies a decision / branchingpoint, signifying a choice to be made by the enduser. Lines represent different choices emergingfrom different parts of the diamond.

Does notusuallycorrespond to atask step in thedocument;Reflects achoice to bemade after stepexecution

Symbol Description Usage Comments

To next / From last Diagram: Leadsto the next / previous page of theDiagram

Flow chart continues on the next /previous page

Hardcopy / Document: Identifies aprinted document, report, or form

Does not correspond to a taskstep in a document; instead, it isused to reflect a documentgenerated by a task step; thisshape does not have any outgoingflow lines

Financial Actuals: Indicates afinancial posting document

Does not correspond to a taskstep in a document; instead, it isused to reflect a document

generated by a task step; thisshape does not have any outgoingflow lines

Budget Planning: Indicates abudget planning document

Does not correspond to a taskstep in a document; instead, it isused to reflect a documentgenerated by a task step; thisshape does not have any outgoingflow lines

Manual Process: Covers a taskthat is manually done

Does not generally correspond toa task step in a document;instead, it is used to reflect a taskthat is manually performed, suchas unloading a truck in thewarehouse, which affects theprocess flow.

Existing Version / Data: This blockcovers data that feeds in from anexternal process

Does not generally correspond toa task step in a document;instead, this shape reflects datacoming from an external source;this step does not have anyincoming flow lines

System Pass / Fail Decision: Thisblock covers an a utomaticdecision made by the software

Does not generally correspond toa task step in the document;instead it is used to reflect anautomatic decision by the systemthat is made after a step has beenexecuted.

< F u n c t i o n >

E x t e r n a l

t o S A P

BusinessActivity /

Event

Unit Process

ProcessReference

Sub-Process

Reference

ProcessDecision

DiagramConnection

Hardcopy /Document

Financial

Actuals

BudgetPlanning

ManualProcess

ExistingVersion /

Data

SystemPass/FailDecision

8/2/2019 Bp Dm v1604 Overview en In

http://slidepdf.com/reader/full/bp-dm-v1604-overview-en-in 29/29

© 2010 SAP AG. Al l r ight s reserved.

No part of this publication may be reproduced or transmitted in any form or for any purpose without the express permission of SAP AG. The information contained herein may be changed

without prior notice.Some software products marketed by SAP AG and its distributors contain proprietary software components of other software vendors.

Microsoft, Windows, Excel, Outlook, and PowerPoint are registered trademarks of Microsoft Corporation.

IBM, DB2, DB2 Universal Database, System i, System i5, System p, System p5, System x, System z, System z10, System z9, z10, z9, iSeries, pSeries, xSeries, zSeries, eServer, z/VM, z/OS,

i5/OS, S/390, OS/390, OS/400, AS/400, S/390 Parallel Enterprise Server, PowerVM, Power Architecture, POWER6+, POWER6, POWER5+, POWER5, POWER, OpenPower, PowerPC,

BatchPipes, BladeCenter, System Storage, GPFS, HACMP, RETAIN, DB2 Connect, RACF, Redbooks, OS/2, Parallel Sysplex, MVS/ESA, AIX, Intelligent Miner, WebSphere, Netfinity, Tivoli and

Informix are trademarks or registered trademarks of IBM Corporation.

Linux is the registered trademark of Linus Torvalds in the U.S. and other countries.

Adobe, the Adobe logo, Acrobat, PostScript, and Reader are either trademarks or registered trademarks of Adobe Systems Incorporated in the United States and/or other countries.

Oracle is a registered trademark of Oracle Corporation.

UNIX, X/Open, OSF/1, and Motif are registered trademarks of the Open Group.

Citrix, ICA, Program Neighborhood, MetaFrame, WinFrame, VideoFrame, and MultiWin are trademarks or registered trademarks of Citrix Systems, Inc.

HTML, XML, XHTML and W3C are trademarks or registered trademarks of W3C®, World Wide Web Consortium, Massachusetts Institute of Technology.

Java is a registered trademark of Sun Microsystems, Inc.

JavaScript is a registered trademark of Sun Microsystems, Inc., used under license for technology invented and implemented by Netscape.

SAP, R/3, SAP NetWeaver, Duet, PartnerEdge, ByDesign, Clear Enterprise, SAP BusinessObjects Explorer, and other SAP products and services mentioned herein as well as their respective

logos are trademarks or registered trademarks of SAP AG in Germany and other countries.

Business Objects and the Business Objects logo, BusinessObjects, Crystal Reports, Crystal Decisions, Web Intelligence, Xcelsius, and other Business Objects products and services mentionedherein as well as their respective logos are trademarks or registered trademarks of SAP France in the United States and in other countries.

All other product and service names mentioned are the trademarks of their respective companies. Data contained in this document serves informational purposes only. National productspecifications may vary.

The information in this document is proprietary to SAP. No part of this document may be reproduced, copied, or transmitted in any form or for any purpose without the express prior written

permission of SAP AG.

This document is a preliminary version and not subject to your license agreement or any other agreement with SAP. This document contains only intended strategies, developments, and

functionalities of the SAP® product and is not intended to be binding upon SAP to any particular course of business, product strategy, and/or development. Please note that this document is

subject to change and may be changed by SAP at any time without notice.

SAP assumes no responsibility for errors or omissions in this document. SAP does not warrant the accuracy or completeness of the information, text, graphics, links, or other items containedwithin this material. This document is provided without a warranty of any kind, either express or implied, including but not limited to the implied warranties of merchantability, fitness for a

particular purpose, or non-infringement.

SAP shall have no liability for damages of any kind including without limitation direct, special, indirect, or consequential damages that may result from the use of these materials. This limitation

shall not apply in cases of intent or gross negligence.

The statutory liability for personal injury and defective products is not affected. SAP has no control over the information that you may access through the use of hot links contained in these

materials and does not endorse your use of third-party Web pages nor provide any warranty whatsoever relating to third-party Web pages.

![7 ZI$ R BP B}qBjB ${sj *$R $AZ $BtR BP yt{jZR %$ qY u stI ...qianj/dn1868.pdf · 7 ZI$ R BP B}qBjB ${sj *$R $AZ $BtR BP yt{jZR %$ qY u stI BZ uF 3 e% t R t$ ]Bjj$R$BtR s $ X ) dM((](https://static.fdocuments.net/doc/165x107/5e871dc3e3be6e54a43ea340/7-zi-r-bp-bqbjb-sj-r-az-btr-bp-ytjzr-qy-u-sti-qianj-7-zi-r.jpg)