BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLANpassaic.sharepointspace.com/Public...

Transcript of BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLANpassaic.sharepointspace.com/Public...

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN Lower 8.3 Miles of the Lower Passaic River

Operable Unit 2, Diamond Alkali Superfund Site

Essex, Hudson, Bergen, and Passaic

Counties, New Jersey

July 2019

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 BORROW SOURCE SAP_FINAL_REV 2_07-10-19

VERSION CONTROL Issue Revision No Date Issued Page No Description Reviewed by

0 0 11/30/2018 NA Draft version Nancy Gensky

1 1 4/4/2019 NA Revised version Nancy Gensky

2 2 7/10/2019 NA Revised version Nancy Gensky

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 BORROW SOURCE SAP_FINAL_REV 2_07-10-19 i

CONTENTS

Acronyms and Abbreviations ........................................................................................................................ iv

1 Introduction ............................................................................................................................................. 1

1.1 Site Description and Background ................................................................................................... 2

1.2 Remedial Design Considerations ................................................................................................... 3

1.2.1 Backfill ................................................................................................................................. 3

1.2.2 Chemical Isolation ............................................................................................................... 3

1.2.3 Armor ................................................................................................................................... 3

1.2.4 Habitat Restoration .............................................................................................................. 4

1.3 Borrow Site Assessment Objectives and Approach ....................................................................... 4

1.4 Plan Organization ........................................................................................................................... 4

2 Borrow Material Characteristics .............................................................................................................. 5

2.1 Preliminary Material Characteristics ............................................................................................... 5

2.1.1 Engineered Cap and Backfill ............................................................................................... 5

2.1.2 Armor Layer ......................................................................................................................... 5

2.1.3 Habitat Restoration Layer .................................................................................................... 5

2.2 Preliminary Material Quantities ....................................................................................................... 5

3 Borrow Source Identification ................................................................................................................... 7

3.1 Borrow Source Identified Through Previous Work and NJDOT Database ..................................... 7

3.1.1 Potential Borrow Source Identification Process .................................................................. 7

3.1.1.1 Previous Borrow Source Identification....................................................................... 7

3.1.1.2 Phase I and River Mile 10.9 Removal Action ............................................................ 8

3.1.1.3 New Jersey Department of Transportation Materials Database ............................... 8

3.2 Licensed Quarries or Mines Identified as Potential Sources .......................................................... 9

3.3 Other Potential Sources .................................................................................................................. 9

3.3.1 Treatment or Recycling Facilities ...................................................................................... 10

3.3.2 Offshore Sand Mining ........................................................................................................ 10

3.3.3 Large-Scale Dredging Projects ......................................................................................... 10

3.3.4 Confined Disposal Facility Reuse ...................................................................................... 11

3.4 Screening and Ranking Criteria .................................................................................................... 11

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 BORROW SOURCE SAP_FINAL_REV 2_07-10-19 ii

3.4.1 Primary Criteria .................................................................................................................. 12

3.4.1.1 Proximity to Operable Unit 2 .................................................................................... 12

3.4.1.2 Types of Materials Produced ................................................................................... 12

3.4.1.3 Chemical and Environmental Properties ................................................................. 12

3.4.1.4 Production Capability and Available Quantities ....................................................... 12

3.4.1.5 Material Transport and Handling ............................................................................. 13

3.4.2 Secondary Criteria ............................................................................................................. 13

3.4.2.1 Seasonal or Daily Operational Limits ...................................................................... 13

3.4.2.2 Other Contractual Obligations ................................................................................. 14

3.4.2.3 Onsite and Offsite Quality Control Capabilities ....................................................... 14

3.4.2.4 Health and Safety Record ....................................................................................... 14

4 Borrow Source Sampling and Analysis Plan ........................................................................................ 15

4.1 Material Sampling, Testing, and Evaluation Criteria ..................................................................... 15

4.1.1 Sampling Methodology and Frequency ............................................................................. 15

4.1.2 Analytical Testing .............................................................................................................. 16

4.1.2.1 Physical Parameters ................................................................................................ 16

4.1.2.2 Chemical Parameters .............................................................................................. 16

4.1.3 Quality Control and Data Management ............................................................................. 20

4.2 Records Management and Retention ........................................................................................... 21

4.3 Reporting ...................................................................................................................................... 21

5 Health and Safety ................................................................................................................................. 22

6 References ............................................................................................................................................ 23

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 BORROW SOURCE SAP_FINAL_REV 2_07-10-19 iii

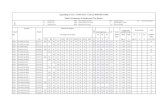

TABLES

Table 2-1 Preliminary Material Quantities

Table 3-1A NJDOT Standard Soil Aggregate Gradations (attached)

Table 3-1B ASTM and AASHTO Standard Soil Aggregate Gradations (attached)

Table 3-2 Initial Screened Potential Borrow Sites (attached)

Table 4-1 Material Acceptance Criteria for Group 1

Table 4-2 Material Acceptance Criteria for Group 2

Table 4-3 Material Acceptance Concentrations

FIGURES

Figure 1-1 Site Location Map

Figure 3-1 Potential Borrow Source Locations

APPENDICES

Appendix A Borrow Material Facility List

Appendix B SOP No. 17 – Soil Stockpile Sampling

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 BORROW SOURCE SAP_FINAL_REV 2_07-10-19 iv

ACRONYMS AND ABBREVIATIONS

2,3,7,8-TCDD 2,3,7,8-tetrachlorodibenzodioxin

60PD 60 Percent Design

AASHTO American Association of State Highway and Transportation Officials

ASTM ASTM International

Arcadis Arcadis U.S., Inc.

CDF confined disposal facility

CFR Code of Federal Regulations

COC constituent of concern

cy cubic yard

EDD electronic data deliverable

FFS Focused Feasibility Study

GRO gasoline range organics

GSH Glenn Springs Holdings, Inc.

HASP Health and Safety Plan

HMW high-molecular weight

LMW low-molecular weight

LPRSA Lower Passaic River Study Area

NJDEP New Jersey Department of Environmental Protection

NJDOT New Jersey Department of Transportation

OCC Occidental Chemical Corporation

OSHA Occupation Safety and Health Administration

OU1 Operable Unit 1

OU2 Operable Unit 2

PAC powdered-activated carbon

PAH polycyclic aromatic hydrocarbons

PCB polychlorinated biphenyl

PDI WP Pre-Design Investigation Work Plan

QA quality assurance

QC quality control

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 BORROW SOURCE SAP_FINAL_REV 2_07-10-19 v

RD Remedial Design

RM River Mile

ROD Record of Decision

SAP Sampling and Analysis Plan

Settlement Agreement Administrative Settlement Agreement and Order on Consent for Remedial Design

Site Diamond Alkali Superfund Site

SOP Standard Operating Procedure

SVOC semivolatile organic compound

TAL Target Analyte List

TCL Target Compound List

Tilcon Tilcon New York, Inc

TPH total petroleum hydrocarbon

TSWP Treatability Study Work Plan

UFP-QAPP Uniform Federal Policy Quality Assurance Project Plan

USACE U.S. Army Corps of Engineers

USEPA U.S. Environmental Protection Agency

VOC volatile organic compound

v/v volume/volume

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 1

1 INTRODUCTION

This Borrow Site Assessment Sampling and Analysis Plan (Borrow Site SAP) has been prepared

pursuant to the requirements set forth in the Administrative Settlement Agreement and Order on Consent

for Remedial Design (Settlement Agreement) between the U.S. Environmental Protection Agency

(USEPA) and Occidental Chemical Corporation (OCC) (USEPA 2016a) for the lower 8.3 miles of the

Lower Passaic River (Operable Unit 2 [OU2]) of the Diamond Alkali Superfund Site (Site) located in and

about Essex, Hudson, Bergen, and Passaic Counties, New Jersey (Figure 1-1).

The Settling Party, as defined in the Settlement Agreement (USEPA 2016a), is OCC. Communications

associated with, and execution of, the Settlement Agreement are being led by Glenn Springs Holdings,

Inc. (GSH) on behalf of OCC. The Settlement Agreement provides that the Settling Party shall undertake

a Remedial Design (RD), including various procedures and technical analyses, to produce a detailed set

of plans and specifications for implementation of the Remedial Action selected in USEPA's March 3, 2016

Record of Decision (ROD) (USEPA 2016b). RD activities include the completion of all pre-design and

design activities and deliverables associated with implementation of the RD for the remedy selected in the

ROD. The selected alternative was chosen by USEPA in accordance with the Comprehensive

Environmental Response, Compensation, and Liability Act of 1980, as amended; 42 United States Code

§§9601-9675; and, to the extent practicable, the National Oil and Hazardous Substances Pollution

Contingency Plan.

Borrow materials are needed to construct the engineered cap, backfill, armor, and habitat restoration

components of the OU2 remedy. The borrow materials will be imported to OU2 from suitable sources that

meet the final RD specifications. In accordance with the Appendix K of the Pre-Design Investigation Work

Plan (PDI WP; Tetra Tech 2018a), this Borrow Site SAP has been developed to identify and evaluate

potential borrow sources and prepare a framework to characterize potential borrow sources proposed for

the OU2 remedy. This Borrow Site SAP was developed separately from the PDI WP because the

sampling schedule depends on determination of borrow material needs; therefore, it will be implemented

when the engineered cap, backfill, armor, and habitat restoration material needs have been specified in

the 60 Percent Design (60PD). This Borrow Site SAP satisfies the Borrow Site PDI WP reporting

requirement, as all assessment and data reporting will be associated with future design documents.

Samples from candidate borrow source sites will be collected and analyzed to provide a screening check

of the potential source-provided information after submittal of the 60PD.

After the borrow source sample collection and analyses have been completed, the results and the

selection of borrow sources for use in remedy construction planning will be included in the Construction

Quality Assurance/Quality Control Plan. If any of those sources ultimately cannot be used, or a more

suitable source is found, the Borrow Site SAP procedures will be replicated for any new sources

identified.

The information summarized in this Borrow Site SAP includes:

• Estimated type and quantities of borrow materials required

• Candidate borrow site sources

• SAP to characterize potential borrow source material

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 2

1.1 Site Description and Background

The Passaic River spans more than 80 miles from headwaters in Morristown, New Jersey, to Newark

Bay. The watershed includes 935 square miles located in New York and New Jersey and has been

subject to industrial and urban development from the 1800s through present. Industries and municipalities

often discharged wastewater directly to the river. This history ultimately led USEPA to list the Site on the

National Priorities List in 1984, initiating the Superfund cleanup process, which was subsequently

expanded to include the entire Lower Passaic River Study Area (LPRSA).

USEPA currently has divided the Site into four Operable Units. Operable Unit 1 (OU1) consists of the

upland facility known as the Diamond Alkali facility, located at 80-120 Lister Avenue in Newark, New

Jersey. OU2 includes the lower 8.3 miles of the LPRSA (Figure 1-1). Operable Unit 3 is the Newark Bay

Study Area. Operable Unit 4 comprises 17 miles of the LPRSA inclusive of OU2.

OU2 consists of approximately 650 acres extending from the confluence of the LPRSA with Newark Bay

at River Mile (RM) 0 to RM 8.3. It is in a highly developed urban area, with Essex County to the west and

Hudson County to the east (Figure 1-1).

Two sediment Removal Actions were previously implemented; one within and one upstream of OU2, and

they provided useful information, including types and sources for capping material for this Borrow Site

SAP. The Phase I Removal Action was implemented in 2012 in an area adjacent to OU1 (Diamond Alkali

facility located at 80-120 Lister Avenue) at approximately RM 3.4 and consisted of dredging

approximately 40,000 cubic yards (cy) of sediments with the highest 2,3,7,8-tetrachlorodibenzodioxin

(2,3,7,8-TCDD) concentrations within OU2, followed by placement of approximately 47,850 cy of backfill

(Arcadis U.S., Inc. [Arcadis] 2013). The sediment was mechanically dredged, hydraulically off-loaded,

dewatered with filter presses, and the water was treated onsite and discharged to the Passaic River. The

sand backfill material for the Phase I Removal Action was obtained from the Tilcon Clinton Point Quarry in

New Hamburg, New York (Arcadis 2013). The backfill below 2 feet was a sand and silt, while above 2

feet, a coarser sand was used to resist erosion. The RM 10.9 Removal Action was implemented in 2013

and consisted of mechanical dredging of approximately 16,000 cy of sediments, followed by placement of

a reactive cap over 5.5 acres. The capping consisted of a mixture of 25% (volume/volume [v/v]) of

AquaGate® and powdered-activated carbon (PAC), with 10% PAC and 75% (v/v) of sand with a

thickness of 10 inches and 12 inches of armoring layer (CH2MHill 2013). Sand and stone capping

material for the RM 10.9 Removal Action was obtained from Amboy Aggregates in South Amboy, New

Jersey (CH2MHill 2018).

An engineered cap will be constructed over the river bottom of the lower 8.3 miles, except in areas where

backfill may be placed because all contaminated fine-grained sediments have been removed. Dredging

will also be conducted to allow for the continued commercial use of a federally authorized navigation

channel in the 1.7 miles of the Passaic River closest to Newark Bay, and to accommodate reasonably

anticipated future use of a recreational channel to remain above RM 1.7. Mudflats dredged during remedy

implementation will be covered with an engineered cap and will include a habitat restoration layer. For the

ROD (USEPA 2016b), it was assumed that this will consist of 1 foot of sand and up to 1 foot of mudflat

habitat substrate. The actual thickness and composition of this layer will be determined as part of the cap

design. The specific design of caps for chemical isolation and base material for habitat substrates will be

developed as part of the 60PD. Where needed, the cap will be armored to protect against flood-induced

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 3

and propeller scour, as well as localized scour protection around structures. These and other scour force

protection needs, such as potential for ice scour, are being evaluated during the 60PD.

The Focused Feasibility Study (FFS; USEPA 2014) assumed a 2-foot-thick engineered sand cap, with 6

inches of armor stone in some areas for cost estimation purposes; however, the ROD (USEPA 2016b)

indicated that USEPA would evaluate thin-layer and reactive capping technologies during the RD where

conditions are conducive to such approaches, and armor design would be completed during the RD as

well. More details on the elements of the selected alternative described in the ROD for OU2 can be found

in the ROD (USEPA 2016b).

1.2 Remedial Design Considerations

The following sections discuss the basic components of the borrow materials that are expected to include

backfill, chemical isolation, armor, and habitat restoration materials.

1.2.1 Backfill

Backfill may be placed in areas where no or limited residual impacts remain in sediment following

dredging. The conceptual approach for backfilling is to place a layer of material, such as sand, directly

over the remaining sediment, potentially allowed to be supplemented by natural infill of deposited

sediment. The final thickness of the backfill may vary based on local conditions and the potential for

complete or partial backfilling through natural deposition. Backfill fill placement methods will be by

mechanical or hydraulic methods.

1.2.2 Chemical Isolation

Chemical isolation will consist of varying designs across OU2. The chemical isolation layer is expected to

be constructed from a range of materials, including sand, sand with topsoil, or reactive amendments or a

reactive layer, such as a thin reactive sorptive mat. The chemical isolation layer will vary based on the

material used and is anticipated to range from thin-layer caps than can be less than 6 inches up to a 2-

foot-thick sand layer. Thinner layers will be used where sediment bed conditions, contamination levels,

and groundwater flux rates are supportive of thinner caps. The potential use of reactive amendments is

being evaluated through the Treatability Study Work Plan (TSWP; Arcadis 2018). Armor stone will be

included where needed to protect the cap as discussed below. Chemical isolation placement methods will

be by mechanical or hydraulic methods for granular materials.

1.2.3 Armor

Cap armor will likely be crushed stone, and the stone dimension will be determined through design

analysis. Armor stone sizes will range from small to large stone, with large stone in areas needed to

protect the cap from higher scour forces where needed, such as in locations of significant vessel usage

and high-flow velocity around bridges or other structures. Armor stone placement will likely be completed

by mechanical methods, although smaller stone could be hydraulically placed.

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 4

1.2.4 Habitat Restoration

In mudflat areas, restoration will include a habitat restoration layer. The restoration layer is anticipated to

ultimately have comparable organic carbon content to the existing mudflat sediments following integration

and mixing of naturally deposited sediment. Initially, habitat layers placed in mudflats will be

predominantly sand. Habitat restoration layer placement methods will be by mechanical or hydraulic

methods.

1.3 Borrow Site Assessment Objectives and Approach

The objectives of this Borrow Site SAP are as follows:

• Review and compile data from previous studies and RAs within OU2 for potential borrow materials

used and their associated sources

• Identify the types and quantities of borrow materials needed for engineered capping, backfill, armor,

and habitat restoration

• Identify and pre-screen candidate potential borrow sources to support the OU2 remedy based on their

location, availability of material, and logistical considerations with delivery to OU2

• Develop a SAP to obtain representative data (i.e., physical and chemical testing data) from potential

borrow material sources

The information and data generated during the implementation of this Borrow Site SAP will be used to

identify the technically appropriate and logistically viable borrow material sources to meet RA needs. The

source selection process will also include consideration of material staging sites and onsite storage

capacity prior to placement.

1.4 Plan Organization

The remainder of this Borrow Site SAP is organized as follows:

• Section 2 – Borrow Material Characteristics

• Section 3 – Borrow Source Identification

• Section 4 – Borrow Source Sampling and Analysis Plan

• Section 5 – Health and Safety

• Section 7 – References

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 5

2 BORROW MATERIAL CHARACTERISTICS

This section discusses the preliminary types and quantities of material anticipated to be required for the

OU2 remedy based on available information and current understanding of the RD.

2.1 Preliminary Material Characteristics

2.1.1 Engineered Cap and Backfill

The primary material anticipated for backfill and the chemical isolation layer in the engineered cap is a

well-graded sand. Preliminary modeling conducted during the FFS (USEPA 2014) and information in the

ROD (USEPA 2016b) indicate that sand meeting New Jersey Department of Transportation (NJDOT)

Specification I-7 would remain stable under normal flow conditions. Soil aggregate material meeting

NJDOT Specification I-7 consists of clean, free-draining sand, gravel, or stone that is free of organic

matter, garbage, metal, debris, lumps of clay, or other deleterious matter and conforms to the size

gradation specified (NJDOT 2007; Table 4.1). It is anticipated that the cap and backfill materials will be

from licensed quarry/mine materials, with contaminant levels not exceeding the material acceptance

criteria established in the Borrow Site Assessment Work Plan (Appendix K to the PDI WP). Similar coarse

sand material was used as backfill for the Phase I Removal Action and RM 10.9 Removal Action. This

Borrow Site SAP is focused on identifying sources of NJDOT Specification I-7 (details in Section 3.1.1)

and similar materials for the primary cap material.

2.1.2 Armor Layer

The armor layer will consist of a larger-diameter material than the cap material to resist scouring and

erosion. Over time, deposition of fine-grained material on top of the armor layer will cause the sediment

surface to become similar in composition and bed roughness to the existing river bottom over much of

OU2. During subsequent scour events, the armor layer may be re-exposed. Stone diameters will be

further established during the 60PD once scour and erosion analyses are completed. This Borrow Site

SAP identifies sources capable of providing the needed quantities of crushed stone.

2.1.3 Habitat Restoration Layer

The habitat restoration layer will be placed in the mudflats and will consist principally of sand. USEPA

anticipates that re-deposition of fine-grained material over capped and armored areas will occur over

time, making these areas similar in grain size to non-capped areas (USEPA 2016b).

Alternative habitat layer cap designs are being considered to minimize disturbance of mudflats, including

thin-layer amendments. Cap amendment materials are considered as part of the TSWP (Arcadis 2018).

2.2 Preliminary Material Quantities

The engineered capping, backfilling, armoring, and habitat restoration will include multiple configurations

and construction approaches throughout OU2. The configurations will be evaluated and selected during

the RD to accommodate diverse shoreline conditions, bridges and other structures, water depth and

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 6

bathymetry, river uses, and/or varying nature and extent of constituents of concern (COCs) and

groundwater fluxes. The material quantities required for the OU2 remedy will be determined during the

60PD. The following preliminary estimates are used for the purpose of developing this Borrow Site SAP:

Table 2-1. Preliminary Material Quantities

Material Preliminary Estimate

(approximate range) Note

Sand for Cap/Backfill 1 to 2.5 million cy All quantities and material types are

preliminary estimates for purposes of

developing this Borrow Site SAP and

will change during design.

Stone for Armor 50,000 to 100,000 cy

Sand for Habitat Restoration 100,000 to 200,000 cy

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 7

3 BORROW SOURCE IDENTIFICATION

This section discusses the previous borrow source assessments and the process used to identify

potential borrow sources, presents the initial screening criteria to evaluate borrow sources, and provides

the potential borrow sources identified and primary and additional criteria that will be used to further

screen and rank the borrow sources. The focus of this assessment is on commercial licensed

quarries/mines with additional evaluation conducted for clean fills and alternative fills (e.g., material from

treatment facilities, recycling facilities offshore sand mining).

As discussed in Section 2.2, for the OU2 remedy, backfill and engineered capping materials (primarily

clean sand), as well as armoring and habitat restoration material, will be needed. Due to the quantities

required, several borrow sources were evaluated as part of this source identification.

3.1 Borrow Source Identified Through Previous Work and NJDOT

Database

3.1.1 Potential Borrow Source Identification Process

The following information and references were used to identify and screen potential sources to supply the

required material for the OU2 remedy:

• The previous borrow source identification conducted as part of the FFS (USEPA 2014) and by Tetra

Tech as part of the PDI WP (Tetra Tech 2018a)

• Previous borrow source identification conducted as part of the Phase I Removal Action (Arcadis

2011) and the RM 10.9 Removal Action (CH2MHill 2018)

• The NJDOT Qualified Materials Database

(https://www.state.nj.us/transportation/eng/materials/qualified/QPLDB.shtm)

The following sections briefly describe information available and obtained from the above references.

Each of the references were reviewed and additional research was conducted to compile information from

the various references, sources were contacted to obtain relevant information, and grouped to identify

potential borrow sources. The evaluation focused on commercial licensed quarries/mines but also

considered clean fill and alternative fill sources. The initial list of potential sources is included as

Appendix A.

3.1.1.1 Previous Borrow Source Identification

As part of the evaluation of dredging and capping as a remedial option for OU2, the FFS (USEPA 2014)

identified that an NJDOT Specification I-7 or similar sand would remain stable under normal flow

conditions. Evaluation of borrow sources was conducted assuming an NJDOT Specification I-7 sand or

similar material would be used for the engineered cap and backfill material. Several potential borrow

sources for this type of material were identified within 50 miles of the FFS study area, but no details were

provided in the FFS on the identified sources or what additional criteria were used for the evaluation.

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 8

As part of pre-design investigation planning activities, Tetra Tech developed a Borrow Site Assessment

Work Plan (Appendix K to the PDI WP; Tetra Tech 2018a). Commercial quarries for use as potential

borrow sites were evaluated based on various screening criteria, including proximity to OU2. Commercial

maintenance dredging in regional waterways outside of OU2 was considered as a borrow source but was

considered less viable due to the variety, volume, and quantity of required materials, as well as logistical

problems with planning and coordination with those dredging projects. Ten potential borrow sources were

identified for native and recycled fine aggregate products and 28 potential sources for coarse aggregate

products. Appendix A provides these and other identified potential borrow sources.

3.1.1.2 Phase I and River Mile 10.9 Removal Action

For the Phase I Removal Action, the backfill consisted of 20 to 90% sand and 10 to 80% silt. For the top

layer scour protection layer, a 2-foot layer of a coarser sand with a D50 of 2 to 4 millimeters was placed

over the backfill.

Five local borrow sources were initially identified for the backfill material and included the following:

• Amboy Aggregates, South Amboy, New Jersey

• Belvidere Sand & Gravel (H & K Group), Belvidere, New Jersey

• Cedar Hill Landscaping, Somerset, New Jersey

• Clayton Concrete, Jackson, New Jersey

• Eastern Concrete Materials, Inc, Bloomfield, New Jersey

Amboy Aggregates was selected as the preferred material source; however, when they could not provide

material to meet design specifications for the scour protection layer, an alternate source, Tilcon New

York, Inc (Tilcon) was selected and used. Tilcon was able to barge materials from their Clinton Point

Quarry in Hamburg, New York and supplied all backfill and scour protection materials (Arcadis 2013).

For the RM 10.9 Removal Action, the cap was composed of four layers starting with an active layer of

blended sand and AquaGate + PACTM amendment followed by a geotextile layer, armor stone layer, and

habitat layer. The sand used for the cap was a modified ASTM International (ASTM) C33 aggregate with

a reduced percentage of material passing through a No. 200 sieve. Material for the RM 10.9 Removal

Action was obtained from Amboy Aggregates in South Amboy, New Jersey (CH2MHill 2018). The list of

backfill sources considered for the RM 10.9 Removal Action is not available.

3.1.1.3 New Jersey Department of Transportation Materials Database

NJDOT maintains a database that contains available producers and corresponding sizes of aggregate

materials that have been approved according to the NJDOT Standard Specifications for Road and Bridge

Construction (NJDOT 2007). These materials are to be used for the construction or maintenance of any

NJDOT projects. The NJDOT I-7 sand specification was used as a starting point to identify potential

borrow sources within close proximity to the OU2 area.

Outlined within the NJDOT Standard Specifications (NJDOT 2007) are specifications for soil aggregates.

The soil aggregates must be made of natural or prepared mixtures consisting of predominantly hard,

durable particles of stone, gravel, or sand. There are approved gradations for 15 different product

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 9

designations (I-1 through I-15). Some product designations contain some silt, clay, or stone dust. The

majority of the product designations are optimized for upland fill or structural fill applications.

Table 3-1A (attached) summarizes the gradations (including NJDOT I-7 gradation) of each of the

available product designations approved by the NJDOT and contain varying sand and silt contents. ASTM

and American Association of State Highway and Transportation Officials (AASHTO) standard aggregate

gradations are also presented in Table 3-1B (attached).

The NJDOT database was reviewed to identify local and NJDOT-approved sources of material, including

sand, aggregates, and topsoil.

3.2 Licensed Quarries or Mines Identified as Potential Sources

Potential sources throughout New Jersey, New York, and Pennsylvania were considered as part of the

preliminary source identification considering the proximity of these three states to the OU2 area –

focusing on licensed quarries and mines. A licensed quarry/mine is a facility permitted or authorized to

operate as a commercial quarry/mine by the New Jersey Department of Labor and Workforce

Development, New York State Department of Environmental Conservation, Pennsylvania Department of

Environmental Protection, and other state authorities. Commercial quarries produce sand, gravel, and

other materials for construction, concrete manufacturing, and other uses primarily by excavating natural

deposits and/or crushing, screening, and washing the materials. Both rock and sand and gravel quarries

are used to develop man-made materials, while sand and gravel quarries can also provide bank run

materials. For the purposes of this evaluation, only quarries providing man-made materials were identified

as potential sources. Depending on the location of the quarry, multiple transportation methods may be

available, including trucking, rail, and/or barging of the material.

Following development of the initial list of potential sources (49 identified initially including those provided

in the PDI WP [Tetra Tech 2018a]; Appendix A), a screening review resulted in several potential sources

being removed from further evaluation because either they were not operational, declined consideration,

only focused on specific industries (e.g., concrete), were not capable of producing the required materials

and quantities, provided only recycled materials (not native materials), or were potentially under

regulatory enforcement actions. Several sources were identified under a single common parent company,

in which case, they were consolidated into a single source under the parent company. The narrowed list

of potential borrow sources for capping and backfill materials that were retained for additional evaluation

is presented in Table 3-2 (attached).

A map of the locations of the potential sources retained for further consideration is presented on Figure 3-

1. Additional sources may be contacted if no source or combination of sources can meet the

requirements of the project.

Additional criteria to further screen and evaluate commercial quarries is discussed further in Section 3.4.

3.3 Other Potential Sources

In addition to licensed quarries or mines, other kinds of borrow sources were evaluated, including:

• Material from treatment or recycling facilities

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 10

• Offshore sand mining

• Large-scale dredging projects

• Confined disposal facility (CDF) material reuse

• Development of a new borrow source

3.3.1 Treatment or Recycling Facilities

Treatment or recycling facilities accept excavated material and construction debris and process it to

remove residual impacts. There are a few facilities identified within approximately 100 miles of OU2 that

use thermal desorption, bioremediation, and/or physical treatment to process material for reuse that can

be used for landfill cover, commercial/industrial fill, and/or structural fill. Overall, this type of source is not

considered a preferred source of sediment backfill due to the potential for residual impacts above

applicable criteria (e.g., Section 4.1.2.2 [Chemical Parameters], per Appendix K of the PDI WP [Tetra

Tech 2018a]) requiring additional processing and screening and the potential additional sorting required

to ensure the material meets the physical parameters required by the project. This option is not being

retained as a potential source.

3.3.2 Offshore Sand Mining

Offshore sand mining projects operate through leases provided by the Bureau of Ocean Energy

Management in coordination with the U.S. Army Corps of Engineers (USACE), NJDEP, and New Jersey

Geological and Water Survey. Material obtained through this method must be used for shore protection,

beach restoration, or coastal wetlands restoration by a federal, state, or local government agency, or in a

construction project either authorized by or funded by the federal government. There are designated and

additional delimited sand resource areas in Monmouth and northern Ocean Counties in New Jersey that

contain an estimated volume of 157.4 million cy (New Jersey Geological and Water Survey 2015). Due to

permitting requirements and unknown material characterization at this time, this source was not

considered a preferred source, but is being retained as a potential source.

3.3.3 Large-Scale Dredging Projects

Large-scale dredging projects for navigation or other purposes may be able to generate sufficient

volumes of clean material to meet the needs of this project. The material would need to be transferred

from the dredging location to OU2. Dredge materials from navigation dredging projects through the

Engineering Division of the New York District USACE were considered as a potential material source. The

New York District has one of the largest active coastal programs, including beach fill placement, borrow

area determination, sand bypassing, and many other coastal-related analyses. There are many examples

of the beneficial reuse of sand from large dredging projects that address navigation issues (e.g., severe

shoaling) through removal and shoreline erosion through replacement.

This source is not considered a preferred source due to logistical issues associated with identifying an

appropriate dredging project being conducted concurrent with the OU2 dredging, sampling to confirm

physical and chemical parameters of the dredged material are suitable for the needs of the OU2 remedy,

permitting, and coordination of transport and staging of the material based on timing of the dredging

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 11

operations and RA construction for OU2. The primary limitation is the availability of a temporary storage

site for the material, as it is unlikely that the timing of the OU2 RA and other dredging projects could be

sequenced close enough to allow immediate placement of materials arriving onsite from other projects.

Furthermore, post-Hurricane Sandy, there are other needs for dredged materials that could make these

materials less available. However, depending on the timing of the various maintenance dredging projects

in the New York/New Jersey estuary or nearby coastal locations, it is possible that these challenges could

be solved to allow use of this type of material. This option is being retained as a potential source.

3.3.4 Confined Disposal Facility Reuse

CDFs built to retain dredged sediment could be a source of material for the OU2 remedy. There are CDFs

in proximity to OU2 where dredged materials have been reused primarily for upland applications, such as

engineered fill, landfill cover materials, and other uses. In addition, CDF materials have been reused for

restoration, creation, and enhancement of intertidal marshes and mudflats. Overall, this type of source is

not considered a preferred source of sediment backfill due to the potential for residual impacts above

applicable criteria (Section 4.1.2.2 [Chemical Parameters], per Appendix K of the PDI WP [Tetra Tech

2018a]). This option is not being retained as a potential source.

3.4 Screening and Ranking Criteria

Screening and ranking criteria were used to select and rank potential sources of capping and backfill

material. Primary criteria are used to evaluate if they meet the project requirements. If they do, then the

secondary criteria support ranking the potential facilities. The narrowed list of potential sources resulting

from the screening process is included as Table 3-2 (attached).

Primary criteria:

• Proximity to OU2

• Types of materials produced

• Chemical and environmental properties

• Production capability and available quantities

• Material transport and handling

Secondary criteria:

• Seasonal or daily operational limits

• Other contractual obligations

• Onsite and offsite quality control (QC) capabilities

• Health and safety record

A description of each of the primary and additional criteria is provided below.

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 12

3.4.1 Primary Criteria

As set forth in Section 3.2, only licensed quarry/mine sources producing man-made materials were

retained for screening. The following criteria will be used to evaluate and determine the suitability of these

potential sources to provide material for the OU2 remedy. Potential borrow sources were grouped into

tiers based on their proximity to OU2.

3.4.1.1 Proximity to Operable Unit 2

The initial evaluation focused on potential sources within 150 miles, with priority given to sources within

50 miles of OU2. Table 3-2 (attached) presents the initial list of screened sources, where sources under

Tier 1 sources are located within 50 miles of OU2 and sources under Tier 2 are located between 50 and

100 miles of OU2.

3.4.1.2 Types of Materials Produced

Sources supplying materials meeting NJDOT Specification I-7 or similar sand and can also produce

armor stone of various sizes were retained.

3.4.1.3 Chemical and Environmental Properties

Licensed quarry/mine material in New Jersey must meet NJDEP standards, including being excavated

from undisturbed geologic formations, obtained from a licensed quarry/mine, not located on or impacted

by other contaminant sources, not comingled with any other material, not known or suspected of being

contaminated, not adversely impacted by discharges of hazardous materials or chemical application, not

affected by conditions or processes that would result in the introduction of contaminants into the licensed

quarry/mine material in concentrations above regulatory concern, and not affected by conditions or

processes that would increase the concentrations of contaminants already present in the licensed

quarry/mine material to concentrations above regulatory concern (NJDEP 2015).

Potential sources contacted were requested to provide information on the environmental quality of the

borrow material, including any documentation of the site/source history and geology of the formation to

show that the borrow source is not located or impacted by other contaminant sources, and to provide

analytical data from any previous characterization of the source material used to evaluate compliance

with the acceptance criteria (see Section 4.1.2.2).

3.4.1.4 Production Capability and Available Quantities

Borrow sources with high production capabilities and ability to maintain large stockpiles of available

suitable materials will be preferred over sources with limited supply or production capability. Sources with

high production, multiple locations and quarries, and large available quantities of material will help buffer

against delays caused by shortfalls in daily production of required materials. The initial screening only

selected high-capacity sources or multiple sources under one parent company.

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 13

3.4.1.5 Material Transport and Handling

The transportation and handling of the material is dependent on the source location and the

transportation options, including:

• Trucking the material to a staging site along or nearby OU2 for transfer to a barge (providing a

staging site would be the responsibility of the OU2 contractor and would be addressed within the

OU2 RD)

• Barging the material to the OU2 area from a loading point away from OU2, for direct placement

(providing barge loading site would be responsibility of the supplier)

• Rail transport to a staging site along or nearby OU2, for transfer to a barge (providing a staging site

would be responsibility of the OU2 contractor, and would be addressed within the OU2 RD)

Trucking is the most commonly available transportation method. Most of the sources contacted have their

own fleet of trucks or contracts with trucking vendors to transport material. Using trucking as the primary

transportation method would have limitations, including transport through communities surrounding the

OU2 area, additional handling steps to unload and load material for placement, and requiring a large fleet

of trucks and multiple trips to deliver the large quantities of material required for the project.

Barging material to OU2 would allow efficient transportation of large quantities, require no trucking

material through communities surrounding OU2, and may allow direct transfer of material from the

transport barges to placement locations (at least downstream of bridges with clearance height limitations),

eliminating and/or reducing the need for shoreline staging sites. Most sources contacted indicated that

they are open to barging options to deliver material to OU2. The Tilcon facility located along the Hudson

River in New York (Table 3-2 [attached]) has a large fleet of barges available and are considered as a

viable borrow source for the project.

Rail transport is available for some potential sources. Rail transport would allow transportation of large

volumes efficiently and avoid trucking through neighboring communities. Use of rail for transportation

would require either having a rail spur and associated off-loading equipment available at the staging sites,

or a transloading facility with trucks or conveyors transporting the material from this source to the staging

sites.

3.4.2 Secondary Criteria

The following criteria will be used to further rank and screen the sources that meet the primary criteria for

use as borrow source.

3.4.2.1 Seasonal or Daily Operational Limits

It is estimated that to sustain capping operations, approximately 2,000 to 3,000 cy of material per day

may be needed. For screening purposes, the selected source(s) need to produce at this rate to be

considered viable. If seasonal or daily limits prevent an individual source from meeting the project

requirements, multiple sources may be required.

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 14

3.4.2.2 Other Contractual Obligations

The sources with existing contractual obligations may not have as much flexibility to meet the project

material requirements compared to other sources without comparable obligations. The source(s) with

fewer existing or anticipated obligations will be preferred over sources with high volume commitments to

minimize the risk of disruptions during remedy implementation.

3.4.2.3 Onsite and Offsite Quality Control Capabilities

Potential borrow material sources will be further evaluated based on available testing (physical and

analytical data) and onsite QC capabilities. It is expected that sources should have onsite QC capabilities

for material testing and certification for the material and source. Procedures to document or confirm the

QC and certification of the material and procedures at the facility to maintain quality assurance (QA)/QC

will be requested. If offsite QC laboratories are used, the facility must be able to provide documentation

that the laboratory will be able to provide the required QC for the project.

3.4.2.4 Health and Safety Record

Potential sources will be preferred to have an Occupational Health and Safety Administration- (OSHA-) or

Mine Safety and Health Administration compliant health and safety program. Current health and safety

information about their health and safety program will be requested from each potential source. Any

source lacking a compliant program, unwilling or unable to provide current health and safety statistics, or

that provides statistics that do not demonstrate a sufficient commitment to health and safety, will not be

considered for use as a borrow source during this project.

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 15

4 BORROW SOURCE SAMPLING AND ANALYSIS PLAN

This section describes sampling and analytical testing of the borrow material to be conducted at the top

three potential material sources. Sampling and analytical testing processes outlined in this section are

only applicable to licensed certified, quarry/mine sources. Based on the borrow source screening, enough

materials are available from licensed quarries/mines; therefore, other clean and alternate fill sources are

not needed at this time. If other materials are needed or become available, this Borrow Site SAP will be

amended. Sampling is intended to further screen the borrow source materials and check the information

provided by the potential sources as part of the pre-screening process (Section 3.4.1.3). Verification of

material during construction, including borrow material sampling procedures and analytical methods, are

not part of this Borrow Site SAP and will be included in the RD. Sampling will be conducted in accordance

with Standard Operating Procedure (SOP) No. 17 – Soil Stockpile Sampling (Appendix B) and the site-

specific Uniform Federal Policy Quality Assurance Project Plan (UFP-QAPP; Tetra Tech 2018b). Other

sources may be added, depending on testing results and/or updated information on design needs during

development of the 60PD. USEPA will be notified in advance of any other sources to be sampled in

accordance with this Borrow Site SAP.

4.1 Material Sampling, Testing, and Evaluation Criteria

Samples from the top three potential borrow sources will be collected and analyzed for contaminants and

geotechnical properties listed in Section 4.1.2 in accordance with SOP No. 17 – Soil Stockpile Sampling

(Appendix B) and the UFP-QAPP (Tetra Tech 2018b). Samples will be collected from stockpiles, and no

in-situ sampling will be conducted as borrow sources are licensed quarry/mine sources producing man-

made materials.

Analytical data will be compared to project-specific remediation goals, New Jersey ambient levels

(median and 90th percentile), and the background concentrations for specific chemicals specified in the

ROD [USEPA 2016b]). Grain size test results and stone or rock geological classification will be reported

for evaluation for cap material suitability during the 60PD. Bulk samples of sand (approximately 50

pounds) and stone (approximately 100 pounds) will be obtained from each source and stored for potential

additional design testing or evaluation later in the design process.

4.1.1 Sampling Methodology and Frequency

One composite sample will be collected from a representative stockpile of each potential material type

from each of the top three potential borrow sources for that material type. A front-end loader will be used

to dig into each stockpile and form a sampling pad. The sampling pad will then be divided into four

quadrants, and one sample from each of the four quadrants will be collected to form a composite sample

from each sampling pad (ASTM D75/D75M – 14). Composite samples collected from each sampling pad

(except for volatile organic compound [VOC] analysis where one representative discrete sample will be

collected) will then represent each stockpile. There is potential for VOC losses during homogenization;

therefore, composite samples are generally not acceptable for VOC characterization. If visual differences

in material appearance (e.g., color, texture) are observed between locations within a stockpile, then the

discrete samples from such locations will be composited separately instead of compositing samples from

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 16

all locations into a single sample. Sample volume will be consistent with volume requirements outlined in

the UFP-QAPP (Tetra Tech 2018b) for the list of selected analytes outlined in Section 4.1.2.

Dimensioned plot plans will be provided by each potential source to aid in the selection of stockpile

locations to sample. The exact sampling location, appropriate sampling equipment, and procedures will

be determined based on available stockpile material and accessibility at each potential source. Sampling

protocols will be consistent with procedures outlined in SOP No. 17 – Soil Stockpile Sampling (Appendix

B) for soil stockpile sampling.

4.1.2 Analytical Testing

4.1.2.1 Physical Parameters

Physical and geotechnical testing will be performed for each type of potential source material (e.g., sand,

stone). The acceptance criteria for physical parameters will be developed during the 60PD and will be

documented in the Construction Quality Assurance/Quality Control Plan. The following physical

parameters will be analyzed in accordance with the site-specific UFP-QAPP (Tetra Tech 2018b):

• Absorption (AASHTO T84 for fine aggregates; AASHTO T85 for coarse aggregates)

• Atterberg limits (ASTM D4318) (applicable to materials with 5% fines content or more by weight)

• Specific gravity (ASTM D854)

• Grain size distribution (ASTM D6913 – Standard Test Methods for Particle-Size Distribution

[Gradation] of Soils Using Sieve Analysis)

• Grain size finer than #200 sieve (ASTM D7928 – Standard Test Methods for Particle Size Distribution

[Gradation] of Fine-Grained Soils Using the Sedimentation [Hydrometer] Analysis) (applicable to

materials with 5% fines content or more by weight)

• Percent organic matter (ASTM D2974) (applicable for materials to be used for the habitat restoration) layer

• Angularity (ASTM D5821)

• Soundness test for aggregates (AASHTO T104)

• Los Angeles abrasion test for aggregates (AASHTO T96; rock/stone size to be determined during

evaluation of borrow sources).

4.1.2.2 Chemical Parameters

Chemical testing will be used to evaluate whether the borrow source materials contain COCs identified

within OU2 or other contaminants (e.g., pH, chlorides, sulfate) that would not be acceptable or may

impact the long-term effectiveness of the cap and remedy. Chemical testing will be consistent with the

requirements of the UFP-QAPP (Tetra Tech 2018b).

Testing will be conducted for select organic compounds and metals to develop chemical characterization

of the potential borrow sources and to determine how the data compares to ranges of corresponding

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 17

criteria. The following chemical testing parameters will be analyzed in accordance with the site-specific

UFP-QAPP (Tetra Tech 2018b):

• Target Analyte List (TAL) metals by SW-846 Method 6010C/7471B

• Target Compound List (TCL) VOCs by SW-846 Method 8260D (collected from an undisturbed

stockpile)

• TCL semivolatile organic compounds (SVOCs) by SW-846 Method 8270D

• Polychlorinated biphenyl (PCB) congeners by USEPA Method 1668A

• TCL pesticides by USEPA Method 1699 Modified, except toxaphene by Low Level (LL) Method 8081

• Total petroleum hydrocarbons (TPH), including gasoline range organics (GRO), diesel range

organics, and oil range organics, by SW-846 Method 8015D (TPH GRO will be collected from an

undisturbed stockpile)

• Dioxins/furans reported as congeners and homologues by USEPA Method 1613B

• Total organic carbon by the Lloyd Kahn method

• pH (ASTM D4972-13), chlorides (AASHTO T291), sulfate (ASTM C1580-15)

Multiple levels of screening and data comparison have been established for both organics and metals and

will include the criteria available to evaluate the capping, backfill, armor, and habitat restoration material.

Per the PDI WP (Tetra Tech 2018b), the test results for metals and organics are expected to be

compared to material acceptance criteria developed during the Phase I Removal Action (Arcadis 2011) to

group the potential borrow sources. The groupings and associated criteria that are anticipated are

summarized below:

Table 4-1. Material Acceptance Criteria for Group 1

Parameter Group 1

TAL Metals Less than median ambient concentrations (NJDEP 2003)

TCL VOCs Consistent with UFP-QAPP (Tetra Tech 2018b) detection limits (as

applicable) TCL SVOCs

PCB Congeners

TCL Pesticides

TPH

2,3,7,8-TCDD

Dioxins/Furansa

Notes: a Dioxin/Furans includes all dioxin congeners, including 2,3,7,8-TCDD.

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 18

Table 4-2. Material Acceptance Criteria for Group 2

Parameter Group 2

TAL Metals Less than 90th percentile ambient concentrations (NJDEP 2003)

2,3,7,8-TCDD Less than remediation goals or less than ROD background

concentrations (as applicable)b VOCsa

PCBs

Total DDxc

Dieldrin

Copper

Lead

Mercury

LMW PAHs

HMW PAHs

TPHa

Notes:

HMW = high-molecular weight

LMW = low-molecular weight

PAH = polycyclic aromatic hydrocarbons a Remediation goals and ROD background concentrations for VOCs and TPH are not specified. As part of the Group 1 evaluation,

VOCs and TPH will be compared to the UFP-QAPP (Tetra Tech 2018b) detection limits (i.e., determination of detection or no

detection). b Consistent with previously conducted investigations along the Lower Passaic River, for calculating total concentrations for a

particular chemical group, only detected values will be included. A constituent that was reported as non-detect are considered to

have a “zero” value for the calculation. c Total DDx represents Total (4,4’) DDx (the sum of 4,4’-dichlorodiphenyldichloroethane, 4,4’-dichlorodiphenyldichloroethylene, and

4,4’-dichlorodiphenyltrichloroethane)

Material acceptance concentrations are summarized below:

Table 4-3 Material Acceptance Concentrations

Analyte Median Ambient

Concentration

(mg/kg)a

90th Percentile

Ambient

Concentration

(mg/kg)a

Overall

PRGs

(mg/kg)b

Background

(mg/kg)b

Aluminum 10,500 14,400 N/A N/A

Antimony <DL 3.48 N/A N/A

Arsenic 5.2 24.2 N/A N/A

Barium 80.6 168 N/A N/A

Beryllium 0.51 0.82 N/A N/A

Cadmium <DL 0.67 N/A N/A

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 19

Analyte Median Ambient

Concentration

(mg/kg)a

90th Percentile

Ambient

Concentration

(mg/kg)a

Overall

PRGs

(mg/kg)b

Background

(mg/kg)b

Calcium 1,425 3,010 N/A N/A

Chromium 18.5 29.9 N/A N/A

Cobalt 6.3 10.4 N/A N/A

Copper 29.5 75.5 N/A 63

Iron 14,600 20,000 N/A N/A

Lead 111 297 N/A 130

Magnesium 2,190 4,614 N/A N/A

Manganese 311 859 N/A N/A

Mercury 0.18 0.63 0.074 0.72

Nickel 12.4 24.6 N/A N/A

Potassium 693 1,524 N/A N/A

Selenium 0.41 0.71 N/A N/A

Silver <DL 0.86 N/A N/A

Sodium 90.1 141 N/A N/A

Thallium <DL 0.25 N/A N/A

Vanadium 29.6 41.7 N/A N/A

Zinc 75.3 162 N/A N/A

Total PCBs N/A N/A 0.05 0.46

Total DDT N/A N/A 0.0003 0.03

2,3,7,8-TCDD N/A N/A 8.30E-06 2.00E-06

Dieldrin N/A N/A N/A 0.005

LMW PAHs N/A N/A N/A 7.9

HMW PAHs N/A N/A N/A 53

Notes: a Adapted from Table 1-1 from the NJDEP, Ambient Levels of Metals in New Jersey Soils (NJDEP 2003). Metal concentrations in

the urban Piedmont region of New Jersey reported. b Risk-based sediment PRGs and Background concentration reported in the ROD (USEPA 2016b).

DDT = dichlorodiphenyltrichloroethane

N/A = not analyzed

PRG = Preliminary Remediation Goal

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 20

Borrow sources identified as Group 1 would be preferred potential borrow sources, while Group 2 would

be acceptable for consideration based on the criteria listed above. Any potential borrow sources that do

not meet acceptance criteria for Groups 1 and 2 will fall into Group 3 and will be reserved for possible

future re-evaluation if needed, using additional criteria that may be developed during later stages of the

design and prior to remedy implementation, if reliable sources considered Group 1 or Group 2 are not

available.

If at the end of this sampling and analysis program, a minimum of two Group 1 borrow sources are not

identified within the initial search radius established as described in Section 3.1.1, additional sites will be

identified, pre-screened, and sampled by expanding the search radius in 50-mile increments until two

Group 1 borrow sources are identified.

4.1.3 Quality Control and Data Management

To maintain QC and collection of reliable data to meet project objectives, sampling and analytical testing

will be performed in accordance with the UFP-QAPP (Tetra Tech 2018b).

At a minimum, samples will be collected as described in Sections 4.1.1 and 4.1.2 and in accordance with

SOP No. 17 – Soil Stockpile Sampling (Appendix B). Sample collection and analysis data will include the

following:

• Field notes documented in a bound notebook(s) and sample collection and processing logs

• Photographs of the source locations, stockpiles, and samples

• Chain of custody

• Laboratory analytical reports

• Electronic data deliverables (EDDs) from the laboratory

• Data QA/QC review reports prepared according to the UFP-QAPP (Tetra Tech 2018b)

• Documentation generated by the laboratories conducting the treatability studies

Samples will be submitted for laboratory analysis for the testing parameters listed in Sections 4.1.2.1 and

4.1.2.2 in accordance with the UFP-QAPP (Tetra Tech 2018b). QC samples, including field and

equipment rinsate blanks and laboratory QC samples, will be collected at the frequency described in the

UFP-QAPP.

As outlined in Worksheets #26 and #27 of the UFP-QAPP (Tetra Tech 2018b), to improve data

access/usability and data ownership/transferability, GSH has contracted with GHD to serve as the Data

Management and Laboratory Program Contractor for the project. Data deliverables for sampling and

analysis data will consist of laboratory EDDs, database update files, and raw data processed into

electronic format. Data will be managed as described below, by task and overall based on the type

collected, and will be shared with the project team. The Data Management and Laboratory Program

Coordinator for the project will perform the following:

• Oversee contracted laboratory services.

• Select appropriate laboratories upon analytical request.

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 21

• Coordinate directly with assigned laboratories, interfacing with GSH and its Contractor, and other

subcontractors as needed.

• Resolve any quality issues, with input from GSH and its Contractor.

• Perform data verification/validation of laboratory data packages in accordance with Worksheet #36 of

the UFP-QAPP (Tetra Tech 2018b), including validation levels of S1VM, S2bVEM, and S4VEM, as

required.

• Perform data quality review/reporting.

• Consolidate project data into a centralized database, including field and laboratory data.

• Provide options for the project team to access data, including tables, figures, graphs, and electronic

deliverables.

GSH will work closely with the Data Management and Laboratory Program Coordinator during sampling

events to facilitate requests for, and shipment of, samples, as well as management of field data and

access to laboratory results.

The data collected will be presented in tables and/or graphically and evaluated in subsequent reports, as

described in Section 4.3. Data will be submitted in USEPA Region 2 standardized EDD format in

accordance with Worksheets #26 and #27 of the UFP-QAPP (Tetra Tech 2018b).

4.2 Records Management and Retention

Documentation collected for each potential source during the focused verification assessment, including

information received from the potential source, dimensioned plot plans, boring logs, and data collection

field notes will be retained and submitted with the Borrow Site Assessment Memo, which will be an

attachment of the Construction Quality Assurance/Quality Control Plan with associated geotechnical and

analytical data.

Bulk samples obtained for potential additional RD testing or evaluation will be discarded after the final

design is submitted to USEPA.

4.3 Reporting

The Borrow Site Assessment Memo will describe the borrow sources tested; present the sampling and

analytical data collected; provide a list of material sources to be considered for the OU2 remedy

implementation, including types of materials available, production capacity, transportation options to OU2,

and other pertinent information; and include communication records with borrow suppliers related to

material availability during the anticipated remedy implementation period and a borrow source ranking

table. This document will be an attachment to design deliverables in the Construction Quality

Assurance/Quality Control Plan and will be removed from the PDI Evaluation Reporting sequence.

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 22

5 HEALTH AND SAFETY

A Health and Safety Plan (HASP) was developed as one of the supporting deliverables of the RD (Tetra

Tech 2018a). The HASP addresses the health and safety practices that will be employed for the project

and has been prepared pursuant to the requirements set forth in the Settlement Agreement between

USEPA and the Settling Party, effective September 30, 2016, for the project. If needed, an updated

HASP will be prepared to support the treatability study activities.

Activities performed under the HASP will comply with applicable parts of OSHA regulations, primarily 29

Code of Federal Regulations (CFR) Parts 1910 and 1926. In addition, because some of the site activities

are being performed on or adjacent to water, the HASP must also comply with 29 CFR 1917 Marine

Terminals and the U.S. Coast Guard regulations. The health and safety practices detailed in the HASP

will be followed during all studies conducted as part of the TSWP (Arcadis 2018).

Before starting field activities, field personnel will become familiar with the HASP, and respective activity

hazard analyses included in the HASP, as well as the Emergency Response Plan (Appendix A to the

Remedial Design Work Plan; Tetra Tech 2017). Task leads and/or field leads will conduct a mandatory

health and safety tailgate meeting before each day’s field events. The Site Safety Officer will document

the topics covered and personnel in attendance. All personnel (including subcontractors) who will be

working onsite will receive site-specific safety training from the Health and Safety Lead and/or Site Safety

Officer.

BORROW SITE ASSESSMENT SAMPLING AND ANALYSIS PLAN

arcadis.com OU2 Borrow Source SAP_Final_Rev 2_07-10-19 23

6 REFERENCES

Arcadis. 2011. Backfill Design Analysis Memorandum, Phase I Removal Action, CERCLA Non-Time-

Critical Removal Action, Lower Passaic River Study Area. July 12.

Arcadis. 2013. Final Construction Report, Lower Passaic River Study Area, Phase I Removal Action.

March.

Arcadis. 2018. Treatability Study Work Plan, Lower 8.3 Miles of the Lower Passaic River, Operable Unit

2, Diamond Alkali Superfund Site, Essex, Hudson, Bergen, and Passaic Counties, New Jersey.

CH2MHill. 2013. River Mile 10.9 Removal Action Final Design Report, Lower Passaic River Study Area

CH2MHill 2018. River Mile 10.9 Removal Action Final Construction Report, Lower Passaic River Study

Area. April 26.

New Jersey Geological and Water Survey. 2015. Significant Sand Resource Areas in State and Federal

Waters Offshore Monmouth County, New Jersey. Michael V. Castelli et.al. 2015.

NJDEP. 2003. Ambient Levels of Metals in New Jersey Soils. May.

NJDEP. 2015. Fill Material Guidance for Site Remediation Program Sites. Version 3.0. April.

NJDOT. 2007. Standard Specifications for Road and Bridge Construction. 2007.

Tetra Tech. 2017. Remedial Design Work Plan. Lower 8.3 Miles of the Lower Passaic River, Operable

Unit Two of the Diamond Alkali Superfund Site, In and About Essex, Hudson, Bergen, and Passaic

Counties – New Jersey.

Tetra Tech. 2018a. Pre-Design Investigation Work Plan, Remedial Design – Lower 8.3 Miles of the Lower

Passaic River, Operable Unit Two of the Diamond Alkali Superfund Site, In and About Essex,

Hudson, Bergen, and Passaic Counties – New Jersey. Revision 3, January 2018.

Tetra Tech. 2018b. Uniform Federal Policy – Quality Assurance Project Plan (UFP-QAPP) [Field

Sampling Plan (FSP) and Quality Assurance Project Plan (QAPP)]. Remedial Design – Lower 8.3

Miles of the Lower Passaic River, Operable Unit Two of the Diamond Alkali Superfund Site, In and

About Essex, Hudson, Bergen and Passaic Counties – New Jersey. Parsippany, New Jersey.

Revision 13, November 2018.

USEPA. 2014. Focused Feasibility Study Report for the Lower Eight Miles of the Lower Passaic River.

Prepared by The Louis Berger Group, Inc. in conjunction with Battelle HDR|HydroQual. 2014.

USEPA. 2016a. Administrative Settlement Agreement and Order on Consent for Remedial Design,

Operable Unit Two of the Diamond Alkali Superfund Site. USEPA Region 2, CERCLA Docket No.

2016-2021.

USEPA. 2016b. Record of Decision. Lower 8.3 Miles of the Lower Passaic River Part of the Diamond

Alkali Superfund Site Essex and Hudson Counties, New Jersey. March 3.

TABLES

Table 3-1ANJDOT Standard Soil Aggregate GradationsBorrow Site Assessment Sampling and Analysis PlanDiamond Alkali Superfund SiteNewark, New Jersey

6" 4" 2" 1.5" 1" 3/4" 1/2" No.4 No.8 No.16 No.50 No.100 No.200I-1 100 70-100 50-95 30-60 5-25 0-7I-2 100 65-100 40-75 5-30 0-7I-3 100 60-90 40-80 10-35 0-8I-4 100 60-100 40-100 25-100 20-100 15-85 8-45 5-10I-5 100 70-100 30-80 10-35 5-12I-6 100 80-100 45-100 30-90 0-20 0-3I-7 100 80-100 35-100 25-90 5-50 0-8 0-2I-8 100 95-100 45-70 5-25 0-5I-9 100 80-100 60-100 40-100 20-70 5-35 0-20 0-8I-10 100 80-100 60-100 40-100 20-70 5-35 0-30 0-20I-11 100 80-100 60-100 40-100 0-75 0-9I-12 100 70-100 0-75 0-9I-13 100 30-100 0-12I-14I-15 100 80-100 30-80 0-25 0-10

Notes:

References:NJDOT. 2007. Standard Specifications for Road and Bridge Construction. 2007.

Gradation Designations (Percentage by weight passing square mesh sieves)

See Notes

Adapted from Table 901.11-1 from the New Jersey Department of Transportation (NJDOT) Standard Specifications for Road and Bridge Construction (NJDOT 2007).For NJDOT I-14 soil aggregate, the portion of material passing the 4-inch sieve contains no more than 35% percent by weight of material passing the No. 200 sieve.

Table 3-1A_NJDOT Soil Aggregates Specification 1/1

Table 3-1BASTM and AASHTO Standard Soil Aggregate GradationsBorrow Site Assessment Sampling and Analysis PlanDiamond Alkali Superfund SiteNewark, New Jersey

Size 4" 3.5" 3" 2.5" 2" 1.5" 1" 3/4" 1/2" 3/8" No.4 No.8 No. 16 No.30 No.50 No. 100 No. 2001 100 90-100 25-60 0-15 0-52 100 90-100 35-75 0-15 0-53 100 90-100 35-70 0-15 0-5357 100 95-100 35-70 10-30 0-54 100 90-100 20-55 0-15 0-5467 100 95-100 35-70 10-30 0-55 100 90-100 20-55 0-10 0-556 100 90-100 40-85 10-40 0-15 0-557 100 95-100 25-60 0-10 0-56 100 90-100 20-55 0-15 0-567 100 90-100 20-55 0-10 0-57 100 90-100 40-70 0-15 0-58 100 85-100 10-30 0-10 0-589 100 90-100 20-55 5-30 0-10 0-59 100 85-100 10-40 0-10 0-5Fine Aggregate 100 95-100 80-100 50-85 25-60 5-30 0-10 0-3

Notes:

References:ASTM C33 - Standard Specification for Concrete AggregatesAASHTO M 80 - Standard Specification for Coarse AggregateAASHTO M 6 - Standard Specification for Fine Aggregate

Gradation Designations (Percentage by weight passing square mesh sieves)

AASHTO grading limits for 300 mm (No. 50) and 150 mm (No. 100) vary slightly from the ASTM C33 limits at 10-30 and 2-10, respectively

Table 3-1B_ASTM Soil Aggregates Specification 1/1

Table 3-2Initial Screened Potential Borrow SitesBorrow Site Assessment Sampling and Analysis PlanDiamond Alkali Superfund SiteNewark, New Jersey

Parent Company Associated Facilities1,2 Facility AddressFacility Location(s)

(City, State)3 WebsiteApproximate Distance

from OU2 (miles)4 Available Material Type(s) Analytical/Geotechnical Data Transportation Options Transportation Cost Available QuantityProduction Rate

(tons/day)5 Material Cost ($/ton)

Sand- $12/tonSmall gabion stone - $12/ton

Sand - 100,000 tonsGabion stone - 200,000 tons

Quantity from two facilities combined

TBDSand- $15/ton

Small gabion stone - $18/ton

I-7 and C-33 sands, topsoil, washed and crushed gravels, quarry process

materials, boulders

Recommended stone be sourced more locally

Virgin Source of Sand

Trucking

Potential for Rail in the Future (Installation of Rail Spur would

be Required)

Sand - $9.92/tonSand - meet majority of

quantity required TBD I-7 Sand - $19/ton

Hanson Aggregates BMC, Inc. Hanson Aggregates BMC, Inc. PO Box 231Easton, PA 18044

Newtown, PABerlin, NJ

Ottsville, PANewtownville, NJ

https://www.lehighhanson.com/products/aggregates 70-100 Concrete sand

Analytical available from approximately 3 years ago

Can provide a virgin source certification letter

Some geotechnical (gradation) performed on a daily basis

Trucking

Potential for Barging in the Future