Bondstrand 2425 - OPS · Bondstrand® 2425 Glassfiber ... Filament-wound Glassfiber Reinforced...

Transcript of Bondstrand 2425 - OPS · Bondstrand® 2425 Glassfiber ... Filament-wound Glassfiber Reinforced...

A complete library of Bondstrand pipe and fittings in PDS and PDMS-format is available on CD-ROM; please contact NOV Fiber Glass Systems for details. For specific fire protection requirements, additional passive fire protection is available. For pipe systems with external pressure requirements, please contact your Bondstrand representative.

ISO/FDIS 14692 is an international standard intended for offshore applications on oth fixed and floating topsides facilities. It is used as guidance for the specification, manufacture, testing and installation of GRE (Glassfiber Reinforced Epoxy) piping systems. The United Kingdom Offshore Operators Association (UKOOA) Document Suite, issued in 1994, formed the basis of the ISO 14692 standard.

Bondstrand pipe series that are used in the offshore industry are designed in accordance with the above standards and/or type-approved by major certifying bodies. (A complete list is available, on request).

Maximum operating temperature: up to 121°C;Pipe diameter: 2-28 inch (50-700 mm);Pipe system design for pressure ratings up to 25 bar;The pipe system is also available in lower and higher pressure classes (10 bar, up to 50 bar);ASTM D-2992 Hydrostatic Design Basis (Procedure B -service factor 0.5);ASTM D-1599 Safety factor of 4:1.

Bondstrand 2400ASTM D-2310 Classification: RTRP-11AW for static hydrostatic design basis.

Approvals

Characteristics

● Ballast water ● Drilling muds ● Saltwater/seawater● Cassions ● Fresh water ● Sanitary/sewage● Cooling water ● Potable water ● Column piping● Disposal ● Produced water ● Vent lines● Drains ● Fire water

Bondstrand® 2425 Glassfiber Reinforced Epoxy (GRE) pipe systems for Marine and Offshore services for 25 bar pressure

Uses and applications

Taper/Taper joint2 - 28 Inch

Joining Systems

Taper/Taper adhesive-bonded joint

3

Table of Contents GENERAL DATA

Adhesive ............................................................................................................... 19

Conversions ......................................................................................................... 20

Engineering design & installation data ................................................................ 20

Hydrostatic testing ............................................................................................... 20

Important notice ................................................................................................... 20

Joining system and configuration ......................................................................... 3

Mechanical properties ........................................................................................... 4

Physical properties ................................................................................................ 4

Pipe series .............................................................................................................. 3

Pipe length ............................................................................................................. 4

Pipe dimensions and weights ................................................................................ 6

Pipe performance .................................................................................................. 5

Span length ............................................................................................................ 7

Surge pressure .................................................................................................... 20

FITTINGS DATA

Couplings ............................................................................................................. 17

Deluge Couplings ................................................................................................ 13

Elbows ................................................................................................................ 8-9

Flanges ............................................................................................................ 19-21

Joint dimensions Quick-Lock® ............................................................................ 7

Joint dimensions Taper/Taper ................................................................................ 7

Nipples ................................................................................................................. 18

Reducers ......................................................................................................... 14-15

Saddles ........................................................................................................... 18-19

Specials ................................................................................................................ 20

Stub-ends ............................................................................................................. 16

Tees ...................................................................................................................... 13

4

Pipe series PipeFilament-wound Glassfiber Reinforced Epoxy (GRE) pipe for Bondstrand adhesive-bonding systems. MDA (diaminodiphenylmethane) or IPD (isophoronediamine) cured.

FittingsA wide range of lined filament-wound Glassfiber Reinforced Epoxy (GRE) fittings for Bondstrand adhesive-bonding systems. For special fittings, not listed in this product guide, please contact your Bondstrand® representative.

FlangesFilament-wound Glassfiber Reinforced Epoxy (GRE) heavy-duty and stub-end flanges for Quick-Lock and Taper/Taper adhesive bonding systems. Standard flange drilling patterns as per ANSI B16.5 (150 Lb). Other flange drilling patterns, such as ANSI B16.5 (> 150 Lb), DIN, ISO and JIS are also available.

Bondstrand® 2425/3425Glassfiber Reinforced Epoxy (GRE) pipe system; MDA or IPD cured;Standard 0.5 mm internal resin-rich reinforced liner;Maximum operating temperature: 93°C (IPD) or 121°C (MDA);For higher temperatures, please contact NOV Fiber Glass Systems;Maximum pressure rating: 25 bar.

ConductiveConductive pipe systems are available to prevent accumulation of potentially dangerous levels of static electrical charges. Pipe, fittings and flanges contain high strength conductive filaments. Together with a conductive adhesive this provides an electrically continuous system.

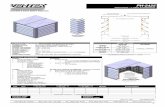

Description Bondstrand Bondstrand 2425 3425 Pipe Diameter 2-28 inch 2-28 inchJoining system Taper/Taper Taper/TaperLiner* 0.5 mm 0.5 mmTemperature** 121 °C 93 °CCure MDA IPD Pressure rating 25 bar 25 bar * Also available without liner.** Above 93°C, derate the pressure rating lineairly to 50% at 121°C.

Pipe50-700 mm (2-28 inch): Taper/Taper adhesive joint;End configuration: Integral Taper bell x shaved taper spigot.

Fitting50-700 mm (2-28 inch): Taper/Taper adhesive joint. End configuration: Integral Taper bell ends.

Flange50-700 mm (2-28 inch): Taper/Taper adhesive joint. End configuration: Integral Taper bell ends.

Note: Pipe nipples, saddles and flanged fittings have different end configurations.

Joining system &configuration

5

Typical pipe length

Typical physical properties

Typical mechanicalproperties

Nominal Joining Approximate overall Length* SystemPipe Size Europe Plant Asia Plant[mm] [inch] [m] [m]50 2-4 Taper/Taper 6.15 5.85/9.0150 6 Taper/Taper 6.1 5.85/9.0200-600 8-24 Taper/Taper 6.1/11.8 9.0/11.89700 28 Taper/Taper 11.8 11.89

Pipe property MDA cured Units 21°C 93°C MethodBi-axial Ultimate hoop stress at weeping N/mm2 250 — ASTM D-1599Circumferential Hoop tensile strength N/mm2 220 — ASTM D-2290Hoop tensile modulus N/mm2 25200 ASTM D-2290Poisson’s ratio axial/hoop — 0.65 0.81 NOV FGSLongitudinal Axial tensile strength N/mm2 80 65 ASTM D-2105 Axial tensile modulus N/mm2 12500 9700 ASTM D-2105Poisson’s ratio hoop/axial — 0.40 0.44 ASTM D-2105Axial bending strength — 85 — NOV FGSBeam Apparent elastic modulus N/mm2 12500 8000 ASTM D-2925Hydrostatic Design Basis Static N/mm2 124* — ASTM D-2992 (Proc. B.)

Pipe property Units Value Method Thermal conductivity pipe wall W(m.K) .33 NOV FGSThermal expansivity (lineair) 10-6 mm/mm °C 18.0 NOV FGSFlow coefficient Hazen-Williams 150 Absolute roughness 10-6 m 5.3 — Density kg/m3 1800 — Specific gravity - 1.8 ASTM D-792

6

Bondstrand 2425 (MDA cured) at 21°C with integral Taper/Taper (2-28 inch) socket ends for adhesive bonding. Nominal Internal *Ultimate STIS Stifness PipePipe Pressure Collapse Factor StiffnessSize **Rating Pressure [mm] [inch] [bar] [bar] [N/m2] [lb.in] [psi]50 2 25 23.4 73612 108 573.180 3 25 11.9 37727 198 293.7100 4 25 11.5 36595 408 284.9150 6 25 10.5 33359 1281 259.7200 8 25 10.0 31856 2767 248.0250 10 25 10.1 32232 5590 250.9300 12 25 9.8 31128 9163 242.3350 14 25 9.9 31411 12238 244.5400 16 25 10.0 31919 18585 248.5450 18 25 10.0 31762 24737 247.3500 20 25 9.9 31574 33748 245.8600 24 25 9.8 31309 57839 243.8700 28 25 9.4 29963 97906 233.3

* No safety factor included;** At 93°C using NOV Fiber Glass Systems approved adhesive.

Typical pipeperformance

7

Typical pipe dimensions and weights

Bondstrand 2425 (MDA-cured) with integral Taper/Taper (2-28 inch) socket ends for adhesive bonding. Nominal Pipe Minimum Average Designation perPipe Inside Structural Wall Pipe ASTMSize Diameter Thickness [t] Weight D-2996[ mm] [inch] [mm] [mm] [kg/m] (RTRP-11...)50 2 53.0 1.8 0.7 AW1-211180 3 81.8 2.2 1.2 AW1-2111100 4 105.2 2.8 1.9 AW1-2112150 6 159.0 4.1 4.1 AW1-2113200 8 208.8 5.3 6.8 AW1-2116250 10 262.9 6.7 10.7 AW1-2116300 12 313.7 7.9 15.0 AW1-2116350 14 344.4 8.7 18.1 AW1-2116400 16 393.7 10.0 23.6 AW1-2116450 18 433.8 11.0 28.5 AW1-2116500 20 482.1 12.2 35.1 AW1-2116600 24 578.6 14.6 50.1 AW1-2116700 28 700.0 17.4 72.0 AW1-2116

8

Bondstrand 2425 (MDA) at 21 °C Nominal Single Continuous Pipe Span* Span* Size 2425 2425 [mm] [inch] [m] [m] 50 2 2.9 3.680 3 3.3 4.2100 4 3.7 4.7150 6 4.5 5.7200 8 5.1 6.5250 10 5.7 7.3300 12 6.2 7.9350 14 6.5 8.3400 16 6.9 8.8450 18 7.3 9.3500 20 7.7 9.7600 24 8.4 10.6700 28 9.2 11.7

* Span recommendations are based on pipes filled with water having a density of 1000 kg/m3 and include no provisions for weights caused by valves, flanges or other heavy objects. At 93°C, span lengths are approx. 10% lower.

Span length

Taper/Taper dimensions

Dimensions for adhesive Taper Spigots for adhesive Taper/Taper joints.

Nominal Taper Insertion Nominal Dia ofPipe Angle Depth Spigot SpigotSize Nose Thickn. at Nose X Ds nose Sd[mm] [inch] [degrees] [mm] [mm] [mm]50 2 1.75 50 1.0 55.280 3 1.75 80 1.0 83.8100 4 1.75 80 1.0 107.2150 6 2.5 110 1.0 161.0200 8 2.5 140 1.0 210.8250 10 2.5 170 1.5 265.9300 12 2.5 200 1.5 316.9350 14 2.5 170 2.0 384.4400 16 2.5 230 2.5 398.7450 18 2.5 200 2.5 438.8500 20 2.5 230 3.0 488.1600 24 2.5 260 3.5 585.6700 28 1.75 350 7.0 714.0

Filament-wound 90° elbows with integral Taper/Taper (2-28 inch) socket ends foradhesive bonding. Nominal Laying Overall AveragePipe Size Length (LL) Length (OL) Weight[mm] [inch] [mm] [mm] [kg]50 2 87 137 0.680 3 110 190 2.1100 4 155 235 3.8150 6 240 350 8.7200 8 315 455 24250 10 391 561 39300 12 463 663 61350 14 374 544 51400 16 402 632 84450 18 497 679 87500 20 548 778 173600 24 650 910 266700 28 726 1076 365

Elbows 90°.

Elbows 45° Filament-wound 45° elbows with integral Taper/Taper (2-28 inch) socket ends foradhesive bonding. Nominal Laying Overall AveragePipe Length Length WeightSize (LL) (OL) [mm] [inch] [mm] [mm] [kg]50 2 45 95 0.580 3 61 141 1.7100 4 73 153 2.4150 6 106 216 7.0200 8 137 277 15.5250 10 169 339 32300 12 196 396 47350 14 135 305 38400 16 142 372 80450 18 229 429 78500 20 250 480 109600 24 293 553 184700 28 310 660 333

Taper/Taper

Taper/Taper

Elbows 22½º Filament-wound 22½°elbows with integral Taper/Taper (2-28 inch) socket ends for adhesive bonding. Nominal Laying Overall AveragePipe Length Length WeightSize (LL) (OL) [mm] [inch] [mm] [mm] [kg]50 2 29 79 1.480 3 37 117 1.5100 4 43 123 2.0150 6 60 170 5.9200 8 76 216 10.5250 10 68 238 19.1300 12 77 277 32350 14 81 251 26400 16 85 315 57450 18 131 331 51500 20 141 371 71600 24 161 421 114700 28 157 507 221

Taper/Taper

Equal Tees

Nominal Laying Overall Laying Overall AveragePipe Length Length Length Length WeightSize total run total run branch branch (LL1) (OL1) (LL2) (OL2) [mm] [inch] [mm] [mm] [mm] [mm] [kg]50 2 148 248 74 124 1.680 3 192 352 96 179 3.6100 4 230 390 115 195 6.4150 6 306 526 153 263 18200 8 376 656 188 328 37250 10 452 792 226 396 55300 12 528 928 264 464 92350 14 564 904 282 452 80400 16 590 1050 295 525 126450 18 728 1128 364 564 218500 20 790 1250 395 625 297600 24 918 1438 459 719 483700 28 994 1694 497 847 828

Filament-wound equal Tee with integral Taper/Taper (2-28 inch) socket ends for adhesive bonding.

Taper/Taper

Reducing Tees Filament-wound standard and fabricated reducing tees with integral Taper/Taper(2-28 inch) socket ends for adhesive bonding.

Taper/Taper standard

Taper/Taper fabricated

Nominal Laying Overall Laying Overall AveragePipe Length Length Length Length WeightSize (LL1) (OL1) (LL2) (OL2) (runxrunxbranch) half run half run branch [mm] [inch] [mm] [mm] [mm] [mm] [kg]80x80x50 3x3x2 96 176 86 136 3.0100x100x50 4x4x2 115 195 99 149 5.4100x100x80 4x4x3 115 195 108 188 5.5150x150x50 6x6x2 153 263 124 174 12.2150x150x80 6x6x3 153 263 134 214 12.6150x150x100 6x6x4 153 263 140 220 13.7200x200x2 8x8x2 88 228 179 229 24.6200x200x80 8x8x3 188 328 159 239 19.3200x200x100 8x8x4 188 328 172 252 26200x200x150 8x8x6 188 328 178 288 33250x250x50 10x10x2 88 258 206 256 30250x250x80 10x10x3 100 270 206 286 32250x250x100 10x10x4 226 396 194 274 42250x250x150 10x10x6 226 396 204 314 42250x250x200 10x10x8 226 396 213 353 53300x300x50 12x12x2 88 288 232 282 35300x300x80 12x12x3 100 300 232 312 37300x300x100 12x12x4 264 464 216 296 60300x300x150 12x12x6 264 464 229 339 86300x300x200 12x12x8 264 464 239 379 90300x300x250 12x12x10 264 464 251 421 92350x350x50 14x14x2 88 258 247 297 37350x350x80 14x14x3 100 270 247 327 40350x350x150 14x14x6 282 452 254 364 66350x350x200 14x14x8 282 452 264 404 69350x350x250 14x14x10 282 452 277 447 74350x350x300 14x14x12 282 452 289 489 79400x400x50 16x16x2 88 318 272 322 50400x400x80 16x16x3 100 330 272 352 53400x400x150 16x16x6 295 525 274 384 97400x400x200 16x16x8 295 525 283 423 102400x400x250 16x16x10 295 525 293 463 107400x400x300 16x16x12 295 525 305 505 117400x400x350 16x16x14 295 525 325 495 100450x450x50 18x18x2 88 288 292 342 54450x450x80 18x18x3 100 300 292 372 58450x450x200 18x18x8 364 564 316 456 158450x450x250 18x18x10 364 564 329 499 165450x450x300 18x18x12 364 564 329 529 172450x450x350 18x18x14 364 564 340 510 172450x450x400 18x18x16 364 564 330 560 182500x500x50 20x20x2 88 318 316 366 59500x500x80 20x20x3 100 330 316 396 63500x500x250 20x20x10 395 625 355 525 257500x500x300 20x20x12 395 625 355 555 265500x500x350 20x20x14 395 625 366 536 267500x500x400 20x20x16 395 625 356 586 279500x500x450 20x20x18 395 625 390 590 285600x600x50 24x24x2 88 348 364 414 71600x600x80 24x24x3 100 360 364 444 75600x600x300 24x24x12 459 719 405 605 422600x600x350 24x24x14 459 719 416 586 423600x600x400 24x24x16 459 719 406 636 438600x600x450 24x24x18 459 719 453 653 448600x600x500 24x24x20 459 719 453 683 462700x700x350 28x28x14 497 847 485 655 700700x700x400 28x28x16 497 847 483 713 720700x700x450 28x28x18 497 847 508 708 726700x700x500 28x28x20 497 847 516 746 745700x700x600 28x28x24 497 847 516 776 774

Note: Regular numbers are filament wound tees; italic numbers are fabricated tees

Filament-wound deluge couplings with O-ring sealed reversed taper bushings with ½ inch or ¾ inch threaded outlets with integral Taper/Taper (2-24 inch) socket ends for adhesive bonding. Nominal Laying Overall Outside AveragePipe Length Length Diameter WeightSize (LL) (OL) (OD) [mm] [inch] [mm] [mm] [mm[ [kg]50 2 160 260 95 2.380 3 160 320 124 3.8100 4 160 320 147 4.6150 6 160 380 201 7.5200 8 160 440 251 10.8250 10 160 500 305 14.2300 12 160 560 356 18.1350 14 160 500 386 21400 16 160 620 436 23450 18 160 560 476 23500 20 160 620 524 26600 24 160 680 621 32

Fabricated reducing tees with integral Taper/Taper (2-28 inch) socket ends and flanged branch.

Nominal Laying Overall Laying AveragePipe Length Length Length WeightSize (LL1) (OL1) (LL2) (runxrunxbranch) half run half run branch [mm] [inch] [mm] [mm] [mm] [kg]50x50X25 2x2x1 88 138 179 4.480x80x25 3x3x1 88 168 193 5.880x80X40 3x3x1½ 88 168 198 6.5100x100x25 4x4x1 88 168 225 12.6100x100x40 4x4x1½ 88 168 230 13.3150x150x25 6x6x1 88 198 252 17.8150x150x40 6x6x1½ 88 198 257 23200x200x25 8x8x1 88 228 276 25200x200x40 8x8x1½ 88 228 281 26200x200x50 8x8x2 88 228 316 26250x250x25 10x10x1 88 258 303 30250x250x40 10x10x1½ 88 258 308 31250x250x50 10x10x2 88 258 343 31250x250x80 10x10x3 100 270 343 34300x300x25 12x12x1 88 288 329 35300x300x40 12x12x1½ 88 288 334 36300x300x50 12x12x2 88 288 369 36300x300x80 12x12x3 100 300 369 39350x350x25 14x14x1 88 258 344 38350x350x40 14x14x1½ 88 258 349 38350x350x50 14x14x2 88 258 384 39350x350x80 14x14x3 100 270 384 42400x400x25 16x16x1 88 318 369 50400x400x40 16x16x1½ 88 318 374 51400x400x50 16x16x2 88 318 409 51400x400x80 16x16x3 100 330 409 55450x450x25 18x18x1 88 288 389 55450x450x40 18x18x1½ 88 288 394 55450x450x50 18x18x2 88 288 429 56450x450x80 18x18x3 100 300 429 60500x500x25 20x20x1 88 318 413 60500x500x40 20x20x1½ 88 318 418 61500x500x50 20x20x2 88 318 453 61500x500x80 20x20x3 100 330 453 65600x600x25 24x24x1 88 348 462 71600x600x40 24x24x1½ 88 348 467 72600x600x50 24x24x2 88 348 501 72600x600x80 24x24x3 100 360 501 77

Fabricated Reducing Tees with Flanged Branch

Note: • Outlets are NPT or BSP, to be specified with order;• Other configurations are available on request;• Bushings to be specified with order.

Deluge Couplings

Taper/Taper

Taper/Taper

Filament-wound concentric reducers with integral Taper/Taper (2-28 inch) socket ends for adhesive bonding.

Nominal Laying Overall AveragePipe Length Length WeightSize (LL) (OL) (runxrun) [mm] [inch] [mm] [mm] [kg]80x50 3x2 74 204 0.9100x50 4x2 96 226 2.7100x80 4x3 94 254 2.0150x80 6x3 117 307 3.9150x100 6x4 124 314 4.2200x100 8x4 163 383 9.5200x150 8x6 129 379 9.5250x150 10x6 148 428 14.5250x200 10x8 135 445 16300x200 12x8 180 520 33300x250 12x10 167 537 35350x250 14x10 224 564 31350x300 14x12 218 588 34400x300 16x12 195 625 42400x350 16x14 193 593 45450x400 18x16 153 583 51500x400 20x16 274 734 81500x450 20x18 201 631 78600x400 24x16 511 1001 108600x450 24x18 438 898 100600x500 24x20 317 807 106700x400 28x16 796 1376 264700x450 28x18 723 1273 257700x500 28x20 602 1182 262700x600 28x24 365 975 263

Concentric Reducers

Taper/Taper

Filament-wound eccentric reducers with Taper/Taper (2-24 inch) socket endsfor adhesive bonding.

Nominal Laying Overall Eccentricity AveragePipe Size Length Length Weight(runxrun) (LL) (OL) (X)* [mm] [inch] [mm] [mm] [mm] [kg]80x50 3x2 140 270 14 0.9100x50 4x2 225 355 27 2.7100x80 4x3 120 280 12 2.0150x80 6x3 320 510 38 3.9150x100 6x4 230 420 27 4.2200x100 8x4 415 635 52 9.5200x150 8x6 215 465 25 4.3250x150 10x6 420 700 52 14.5250x200 10x8 235 545 27 16300x200 12x8 420 760 52 33300x250 12x10 220 590 25 35350x250 14x10 350 690 41 31350x300 14x12 160 530 16 34400x300 16x12 335 765 41 42400x350 16x14 225 625 25 45450x350 18x14 400 770 45 48450x400 18x16 205 635 20 51500x400 20x16 390 850 45 81500x450 20x18 265 695 25 78600x400 24x16 750 1240 93 108600x450 24x18 625 1085 73 100600x500 24x20 440 930 48 106

Eccentric Reducers

Taper/Taper

Filament-wound heavy-duty flanges with integral Taper/Taper (2-14 inch) socket endfor adhesive bonding. Nominal Laying Overall Average Weight Pipe Length Length ANSI DINSize (LL) (OL) B16.5 2634 CL.300 PN25[mm] [inch] [mm] [mm] [kg] [kg]50 2 5 55 1.7 1.980 3 5 55 2.6 2.6100 4 5 85 5.9 5.3150 6 5 85 8.1 7.7200 8 6 116 14.8 13.8250 10 6 146 22.0 22.0300 12 6 176 37.0 33.0350 14 6 176 48.0 46.0

Note: • Other drillings may be possible. Please consult NOV Fiber Glass Systems;• Full-face elastomeric gaskets may be used suitable for the service pressure, service temperature and fluid.

Shore A durometer hardness of 60 ±5 is recom mended (3 mm thick). Compressed fibre gaskets (3 mm thick), compatible with pressure, temperature and medium may also be used. Mechanical properties should be in accordance with DIN 3754 (IT 400) or equal;

• For maximum bolt torque refer to the appropriate Bondstrand literature;• A torque-wrench must be used, since excessive torque may result in flange damage.

Heavy-Duty Flanges

Taper/Taper

Filament-wound stub-ends, O-ring sealed or flat faced, with integral Taper/Taper (2-28 inch) socket, for adhesive bonding with loose steel ring flanges. Nominal Laying Overall Face Ring AveragePipe Length Length Diameter to Face Weight Size (LL) (OL) (RF) (H) Stub-end[mm] [inch] [mm] [mm] [mm] [mm] [kg]50 2 15 65 92 10 0.280 3 15 95 127 16 0.7100 4 15 95 157 16 1.1150 6 15 125 216 23 2.3200 8 15 155 270 29 4.0250 10 15 185 324 33 5.5300 12 15 215 378 38 7.6350 14 15 185 413 33 6.5400 16 20 250 470 47 11.6450 18 20 220 532 42 17.9500 20 20 250 580 47 22600 24 20 280 674 57 23700 28 20 370 800 63 26

Note: • Flat faced stub-ends can be sealed using reinforced elastomeric, compressed fiber or steel reinforced

rubber gaskets, depending on size; • Make sure that when using O-ring sealed stub-end, its counter flange is compatible, e.g. use a flat faced

stub-end (without O-ring groove) or another flat surface flange as counter flange.

Stub-ends

Taper/Taper

Nominal ANSI Average DIN 2634 AveragePipe B16.5 Weight PN25 WeightSize CLASS.300 (D) [mm] [inch] [mm] [kg] [mm] [kg]50 2 22.2 2.5 20 2.480 3 28.6 4.8 24 3.7100 4 28.6 7.1 24 4.6150 6 36.5 12.3 28 7.6200 8 41.3 18.6 32 11.2250 10 47.6 26.4 37 17.1300 12 50.8 39 45 25350 14 54.0 57 45 39400 16 58.2 71 51 52450 18 63.6 87 -- --500 20 66.5 109 59 73600 24 78.4 185 69 115700 28 95.0 253 75 136

Note: • Ring flanges will standard be made from galvanised steel. Other materials are available on request;• Other drillings are available. Please consult NOV Fiber Glass Systems.

Steel Ring Flanges forStub-ends

Filament-wound couplings with integral Taper/Taper (2-28 inch) socket endsfor adhesive bonding.

Nominal Laying Overall Outside AveragePipe Length Length Diameter WeightSize (LL) (OL) (OD) [mm] [inch] [mm] [mm] [mm] [kg]50 2 70 170 70 0.480 3 70 230 100 0.9100 4 70 230 124 1.2150 6 70 290 180 2.2200 8 70 350 238 5.0250 10 70 410 296 7.9300 12 70 470 350 11.6350 14 70 410 381 11.3400 16 70 530 435 17.4450 18 70 470 472 15.8500 20 70 530 524 21600 24 70 590 634 39700 28 70 770 752 39

Couplings

Taper/Taper

Nipples Filament-wound nipples with integral Taper/Taper (2-28 inch) male endsfor adhesive bonding. Nominal Laying Gap AveragePipe Length + WeightSize (LL) [mm] [inch] [mm] [mm] [kg]50 2 125 25 0.180 3 185 25 0.2100 4 185 25 0.3150 6 245 25 0.8200 8 310 30 1.5250 10 370 30 2.9300 12 440 40 4.7350 14 380 40 4.6400 16 500 40 8.6450 18 460 60 8.6500 20 520 60 12.4600 24 580 60 19700 28 760 60 35

+ Remaining gap after bonding (is distance between the edges of the socket ends).

Taper/Taper

Adhesive Number of Adhesive Kits per joint with integral Taper/Taper (2-28 inch) socket endsfor adhesive bonding. Nominal Required Minimum number Pipe Adhesive Kit of Adhesive Kits Size Size required per joint[mm] [inch] [cm3] [Oz] nr. 50 2 89 3 0.280 3 89 3 0.4100 4 89 3 0.4150 6 89 3 0.8200 8 89 3 2.050 10 177 6 1.0300 12 177 6 2.0350 14 177 6 2.0400 16 177 6 2.0450 18 177 6 2.0500 20 177 6 3.0600 24 177 6 4.0700 28 177 6 6.0

Note: • Adhesive Kits should never be split. If remainder is not used for other joints made at the same time, the

surplus must be discarded;• Required adhesive for saddles is shown in the dimension table of the respective saddles;

• For type of adhesive to be used, please refer to the Bondstrand® Corrosion Guide.

Engineering design &installation

Consult de following literature for recommendations about design, installation and use of Bondstrand pipe, fittings and flanges:

Marketing Bulletin Engineering and Design Support Services Assembly Instructions for Quick-Lock adhesive-bonded joints Assembly Instructions for Taper/Taper adhesive-bonded joints Assembly Instructions for Bondstrand fiberglass flanges Bondstrand Corrosion Guide for fiberglass pipe and tubing Bondstrand Pipe Shaver Overview Bondstrand Marine Design Manual

Please consult NOV Fiber Glass Systems for the current version of the above literature.

Note: Elbows with non-standard angles, non-standard drilled flanges, multi branch tees and special spools are available on request, please consult NOV Fiber Glass Systems.

Bondstrand® pipe systems are designed for hydrostatic testing with water at 150% of rated pressure.

The maximum allowable surge pressure is 150% of rated pressure.

1 psi = 6895 Pa = 0.07031 kg/cm2

1 bar = 105Pa = 14.5 psi = 1.02 kg/cm2

1 MPa = 1 N/mm2 = 145 psi = 10.2 kg/cm2 1 inch = 25.4 mm1 Btu.in/ft2h°F = 0.1442 W/mK°C = 5/9 (°F-32)

Field testing

Surge pressure

Conversions

Specials

North America South America Europe Asia Pacific Middle East17115 San Pedro Avenue Estrada de Acesso à Zona P.O. Box 6, 4190 CA No. 7A, Tuas Avenue 3 P.O. Box 17324Suite 200 Industrial Portuária de Suape, s/no. Geldermalsen, The Netherlands Jurong, Singapore 639407 Dubai, UAESan Antonio, TX 78232 USA Recife, PE, Brazil 55.590-000 Phone: +31 345 587 587 Phone: +65 6861 6118 Phone: +971 4881 3566 Phone: +1 210 477 7500 Phone: +55 81 3501 0023

© 2012 National Oilwell Varco. All rights reserved.MOS2425 supersedes FP943-25 - November 2012

National Oilwell Varco has produced this brochure for general information only, and it is not intended for design purposes. Although every effort has been made to maintain the accuracy and reliability of its contents, National Oilwell Varco in no way assumes responsibility for liability for any loss, damage or injury resulting from the use of information and data herein. All applications for the material described are at the user’s risk and are the user’s responsibility.All brands listed are trademarks of National Oilwell Varco.

www.fgspipe.com • [email protected]