Bonding of Composite Materials in Automotive · PDF fileBonding of Composite Materials ......

Transcript of Bonding of Composite Materials in Automotive · PDF fileBonding of Composite Materials ......

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

International AVK Conference

13./14. September 2010

Dr. Hartwig Lohse

Bonding of Composite Materialsin Automotive Engineering –

Opportunity for a Reduction of CO2-Emissions

1/26

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Introduction

Introduction

Adhesive Bonding – a next generation technology

Adhesives for bonding composite materials

Joint design for adhesive bonding

Processing and cross-linking of adhesive in series production

New applications, progress and trends - Outlook

Inhalt

2/26

www.Howwww.How--DoDo--YouYou--Glue.deGlue.de

2/26

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

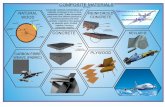

Composites in Automotive Engineering

1946: Stout `46 Case study by Owens Corning – fullcomposite car body

1972: Renault 5 First SMC bumper

1980: Audi Ur-Quattro boded SMC trunklid

1984: Renault Espace Composite side panels bonded to thehot dipped steel body structure

1982: Citroen BX First high volume passenger car withSMC/BMC exterior body parts (SMC-front hood, BMC liftgate)

1989: Volvo Truck bonded SMC air deflector

2002: PSA/FIAT individualization through SMCliftgates

www.Howwww.How--DoDo--YouYou--Glue.deGlue.de

3/26

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Introduction

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

Design freedom

Individualization

Cost benefits at low to medium volumes – speed to market

Fully permeable to radio signals – antennas can be invisiblymounted within the component

Sound dampening properties

Corrosion resistance

Weight reduction

Composite Materials in Automotive Engineering

4/26

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Introduction

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

Government regulators demand ever high fuel economyperformance and lower CO2-emissions. – EU 443/2009 definesthe OEM-average CO2-emission of newly registered cars haveto be below 95 g/km.

Car manufacturer‘s response:

Optimization of the power train (engine, gear box).Cylinder capacity reduction by maintaining performance

Hybrid engine – Electro car

Reduction of air and rolling drag

Weight reduction (100 kg 8,5 g CO2/km = 0,3 l/100 km)

…

www.Howwww.How--DoDo--YouYou--Glue.deGlue.de

5/26

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Introduction

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de6/26

An Assessment of Mass Reduction

Opportunities for a 2017 – 2020 Model YearVehicle Program

Prepared by: Lotus Engineering Inc.

Submitted to: The International Council on CleanTransportation (ICCT)

March 2010

Weitere Informationen ICCT: www.theicct.org

Based on Toyota‘s Verza 2009 model weight reduction measures by usingalternative materials and joining technologies are discussed

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Introduction

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de7/26

Steel

100 %

> 400 individual parts/ 382 kg 211 individual parts/221 kg

Steel

5%

Aluminum

37%

Magesium

30%

Composites

21%

High strength steel

7%

An Assessment of Mass ReductionOpportunities for a 2017 – 2020 Model

Year Vehicle Program

Prepared by: Lotus Engineering Inc.

Submitted to: The International Council on CleanTransportation

March 2010

Body Structure

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Introduction

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

2002: Aston Martin Vanquish

CFRP-transmissiontunnel bonded to the

aluminum bodystructure

www.Howwww.How--DoDo--YouYou--Glue.deGlue.de

Source: J. Hill, Automotive CircleInternational Bad Nauheim 2002

CFRP-Crash structurebonded to cast

aluminum strut towers

SMC-Side panel

~ 15 Liter Adhesive

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Introduction

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

2004: BMW M3 CSL – CFRP-Roof, bondedto the body structure

9/26

Weight reduction andimproving center ofgravity

m = 5,6 kg

9,2

4,7

11

6,9

3,6

0

2

4

6

8

10

12

Stahl (0,8 m m) Alu (1,2 m m) SMC (4 mm ) GFK (3 mm) CFK (1,8 m m)

Material (Stärke)

Ma

ss

eD

ac

h[k

g]

BMW Group

BMW M3

BMW M3 CSL

BMW M3

BMWM3 CSL

Today : Standard for all BMW M-models

Source: R. Haider, H. Lohse -Adäsion 12/2004

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Introduction

Steel (0,8 mm) Al (1,2 mm) SMC ( 4 mm) FRP 3 mm) CFRP 1,8 mm)

Material (thickness)

Weig

ht

of

the

roof[k

g]

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

BondingBonding –– a nexta nextgenerationgenerationtechnologytechnology

Material:

Combination of differentmaterials

(e.g. thermoset/thermoplastic,plastic/metal, …)

Processing:

Maintaining materialproperties

(e.g. surface, no thermal defects,stress distribution to a large area,…)

Integration of additionalfunctions:

e.g. tightness, therm./electr.conductivity, sound dampening, …)

Construction/Design:

Improved part performance

(e.g. weight reduction, stiffness,design opportunities, …)

www.Howwww.How--DoDo--YouYou--Glue.deGlue.de

10/26

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Bonding – A next generation technology

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

Factors determining strength and durability of a bondaccording to: G. Habenicht, Kleben – Grundlagen, Technologien, Anwendungen, Springer Verlag, 4.Aufl.

Adhesive

Part geometry Stress

Quality of thebond

Bond

Bond design

Adhäsionsschicht

Substrate

Surface

www.Howwww.How--DoDo--YouYou--Glue.deGlue.de

11/26

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Bonding – A next generation technology

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

Due to it’s interdisciplinary character a successful introduction ofadhesive bonding into production requires a close cooperationbetween all involved parties and a competent project management.

This is the only way to assure that all parameters fit together.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

Material properties

Surface preparationPart-handlingCycle timeTolerancesVolumeApplication technologyCure conditionAdhesion

Form of the adhesivemechanical propertieschemical resistance of the AdhesiveEH&SQuality assurancecostsetc.

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Bonding – A next generation technology

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

A competent, experiencedproject management is required

to avoid that at the end onepiece is missing in puzzle.

Material supplier

Customer

Equipment supplier

Adhesive user

Adhesive supplier

(external Consultant)

Part supplier

‚legislative body‘

www.Howwww.How--DoDo--YouYou--Glue.deGlue.de

13/26

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Bonding – A next generation technology

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering–Adhesives for bonding composites

Lap

Sgear

Str

ength

[MPa]

Elongation [%]

10

20

30

40

100 200 300 400

2-k Epoxy

2-k-Acrylate

structural2-k-Polyurethane

1- & 2-k highelongation adhesives

Adhesives in use for composite bonding

14/26

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

Outer panel

Reinforcement

Metal insert(KTL)

Hinge (KTL)

16-25 mm

>3 mm

1 – 1,5mm

15/26

Example: Fronthood

Source: S.Schäfer -European Alliance for SMC, Bremen 2004

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Bond line design

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

16/26

Avoiding Bond Line Read Through (BLRT)

Besides the mechanical properties of the materials to be bondedthe following has to be considered:

Use of adhesives with low shrinkage

Maintain constant joint thickness

Substrate 1

Substrate 2

Adhesive

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Bond line design

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

17/26

Avoiding Bond Line Read Through (BLRT)

Besides the mechanical properties of the materials to be bondedthe following has to be considered:

Use of adhesives with low shrinkage

Maintain constant joint thickness

Avoid molded-in spacers

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Bond line design

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

18/26

SMC

SMC

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Bond line design

Avoiding Bond Line Read Through (BLRT)

Besides the mechanical properties of the materials to be bondedthe following has to be considered:

Use of adhesives with low shrinkage

Maintain constant joint thickness

Avoid molded-in spacers

Avoid adhesive squeeze out

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

19/26

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Bond line design

Avoiding Bond Line Read Through (BLRT)

Besides the mechanical properties of the materials to be bondedthe following has to be considered:

Use of adhesives with low shrinkage

Maintain constant joint thickness

Avoid molded-in spacers

Avoid adhesive squeeze out

Avoid stress resulting from different thermal elongation

Assure constant cure conditions

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

Avoiding Bond Line Read Through (BLRT)

Besides the mechanical properties of the materials to be bondedthe following has to be considered:

Use of adhesives with low shrinkage

Maintain constant joint thickness

Avoid molded-in spacers

Avoid adhesive squeeze out

Avoid stress resulting from different thermal elongation

Assure constant cure conditions

Avoid a thermal damage of the surface as a effect of a too highcure temperature

www.Howwww.How--DoDo--YouYou--Glue.deGlue.de

20/26

ThermischeSchädigung derOberfläche

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Bond line design

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Bonding process

21/30

Reinforcement Outer panel

cleaning cleaning

MixingPot Life

PartA

PartB

Dispensing

Joining

Open Time

Clamping

Heat acceleratedCure to reach

handling strength

Further Processing

Remove from FixtureAmbienttemperature cure to

reach handlingstrength

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

Bonding process

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

23/26

Hybrid – Liftgate

ThermoplastischeAussenhaut

MagnesiumStrukturteil

A ICCT proposal is mentioning magnesium as material for the reinforcing part.Based on experience from VW‘s Lupo-based 3-Liter-vehicle, showing problemswith corrosion protection of magnesium (costly to achieve) a SMC reinforcementhas been considered for a new model being introduced to the market this year.

Novel adhesives with special properties, mainly in regard to BLRT, goodadhesion to thermoplastics as well as SMC and good low temperature cureproperties are required.

SMCreinforcement

A first car with a hybridlifgate will be launched at

the Paris Autoshow02. – 17. Oct. 2010

Thermoplasticouter panel

(PP/EPDM, ABS,ABS/PC, etc.)

Abb.: ICCT

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

New applications, progress and trends - Outlook

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

24/26

Use of Carbon-Fiber-Materials

Carbon-Fiber-SMC for closures, e.g. Porsche 911 GT3 II

CFRP Body and Body parts, e.g. Tesla Roadster

SMC outer panel, C-SMC reinforcement

1,3 kg weight reduction compared to SMC/SMC

High performance electric sports car(288 PS - 212 km/h – 3,7 sec 0 – 96 km/h)Epoxy- und Polyester- carbon fiber body panels in conjunction with analuminum monocoque chassis

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

New applications, progress and trends - Outlook

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

25/26

Use of Carbon-Fiber-Materials

BMW MEGACITY CAR –

First volume-produced vehicle with a passenger cell madefrom carbon fiber materials – SOP 2013

The light weight concept allows topractically offset the extra 250-350 kgof weight typically found in electricallypowered vehicles.

2 horizontally separated modules

• Drive Module: aluminum chassis as solidfoundation integrating the battery, drive systemand basic crash functions

• Life Module: high strength light weight CFRPpassenger cell

Dr. Hartwig Lohse

Bonding of Composite Materials in Automotive Engineering

New applications, progress and trends - Outlook

©© Klebtechnik Dr. Hartwig Lohse e.K.Klebtechnik Dr. Hartwig Lohse e.K.

www.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.dewww.Howwww.How--DoDo--YouYou--Glue.deGlue.de

26/26

Many Thanks For YourAttention

Questions?

www.Howwww.How--DoDo--YouYou--Glue.deGlue.de26/36

Dr. Hartwig Lohse

Klebtechnik Dr. Hartwig Lohse e.K.Fraunhoferstr. 325524 ItzehoeTel.: +49 4822 95180E-Mail: [email protected]

International AVK Conference

13./14. September 2010