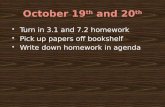

Bologna, 26 th October, 2011

description

Transcript of Bologna, 26 th October, 2011

Simulations of Coupled Core and Simulations of Coupled Core and Steam Generator DynamicsSteam Generator Dynamics (Contribution to Task 4.4: “Preliminary definition of (Contribution to Task 4.4: “Preliminary definition of the Control Architecture” Status Report)the Control Architecture” Status Report)

Bologna, 26th October, 2011

Authors:Dumitru Dobrea, Laurentiu Aioanei

1. Introduction1. Introduction• Coupled core-SG control-oriented dynamic

simulations allow a quantitative insight on the control architecture, contributing to WP4, Task 4.4. It was already introduced in [1].

• We attempted to reproduce the transient conditions, steady-state data and heat transfer correlations used in [1].

• The results obtained do not deviate significantly from those reported in [1], and that may add confidence in models and methods.

2

Outline of methodOutline of method

There are not major differences between methods used in our work and that of [1].

Point kinetics and 0-dimensional thermal-hydraulics describes the core and moving boundary (MVB) zero-dimensional describes SG.

The difference may consist in systematic use of enthalpy and pressure as state variables in SG and the averaging procedure for other variables (temperature, density) in single phase regions. Average T or ρ are computed at an enthalpy h* expressed as a linear combination of enthalpies at region boundaries a and b:

h*=αh(a)+(1- α)h(b) The coefficients of the linear combination could be obtained from 1-

D simulations with enough fine mesh. In this work they are adjusted iteratively by imposing a constraint on SG tube length.

3

Figures present a comparison between the results obtained with constant Figures present a comparison between the results obtained with constant =1/2 for both =1/2 for both sub-cooled and superheated regions and the results obtained with sub-cooled and superheated regions and the results obtained with computed with the computed with the iterative procedure, when coolant flow rate is stepwise increased by 10%.iterative procedure, when coolant flow rate is stepwise increased by 10%.

4

Model observationsModel observations

Subbotin correlation found in [3] was used for lead convective heat transfer coefficient in SG;

Water convective heat transfer coefficients, following ref. [1]: Kandiklar correlation [6] was used for in two-phase regime and Dittus-Boelter for single-phase regimes;

Average void fraction over the two-phase region is computed with Zivi correlation reported in [7];

The nozzle at SG steam outlet is modeled as ,where Kadm

is the “turbine admission coefficient”, p is the steam pressure at nozzle inlet and pc is the imposed nozzle outlet pressure

cadmout ppKm

5

Analysis StageAnalysis Stage In non-linear option thermal conductivities and convective heat transfer

coefficients are computed at each time value used by the non-linear solver for SG system, while time constants and reactivity coefficients were kept time-independent for the core

The non-linear solver is a stiff ODE solver for core and a non-stiff ODE solver for SG. The SG and the core are coupled when a solution is obtained at a given time step.

At that moment the first order lags representing heat transport from core to SG, from SG to core, and pump response to a flow change command, are updated.

In the linear option the systems, including first order lags, are represented by MIMO (multiple input/multiple output) or SISO (single input/single output) linear models, coupled through common input/output names.

For closed loops, PID compensators are used together transducer models having their own dynamics

Simulation results curves for three sets of time constants are presented

6

Non-Linear System SimulationsWater Flow Rate 10% Step Increase

7

SG Inlet Water Temperature 1 oC/s in 10 s Ramp Increase

8

Turbine Admission Coefficient 10% Step Increase

9

Reactivity Step Increase by 20 pcm

10

Linearized System Simulations Turbine Admission Coefficient Step Increase by 1%

11

Lead Flow Rate 1% Step Increase

12

SG Water Inlet Temperature 1oC/s in 10 seconds Ramp Increase

13

1% Water Flow Rate Step Increase

14

20 pcm Reactivity Step Increase

15

Core Variation Power [MW] 8.38Fuel temperature [°C] 42.17Clad temperature [°C] 7.84Coolant inlet temperature [°C] 5.88Coolant outlet temperature [°C] 8.11Steam generatorSub-cooled length [m] -0.64Two-phase length [m] -1.33Pressure [MPa] -0.077Lead outlet temperature [°C] 5.88Water outlet temperature [°C] 12.90

Output Variation for Reactivity Step Increase by 20 pcm

16

Closed LoopsClosed Loops

The figures below are examples of control applied to lead outlet temperature and core power as outputs when control rod reactivity is used as step input for core dynamics. The controlled parameters are normalized to one both in free and closed loops.

17

ConclusionsConclusions

1. By adapting the MVB model using an enthalpy averaging procedure to satisfy the imposed value of SG tube, the simulation results of the non-linear dynamics of coupled SG and core do not deviate significantly from those reported in ref. [1], as regarding final steady-states. As regarding shape, including peak heights, comparisons could pe performed based a common set of heat transport core-SG and pump. Most important differences at final steady-state could be observed for coolant flow rate variation. But the final values are close to initial values and slight differences in thermophysical data or correlations for water and lead could produce the deviations. 2. The linearized model results fit well the non-linear results for 1%, or 1 oC input variations for all transients, except turbine admission coefficient variations, where several percent deviations persist at very small input variation. This issue may be further investigated.3. Restricting the range of heat transport time constants and working with actualized values of reactivity coefficients (for ALFRED) would be desired.

18

ReferencesReferences

1. Antonio Cammi, Sara Bortot, Roberto Ponciroli, Stefano Lorenzi, “Preliminary Definition of the Control Architecture”, Task 4.4, LEADER Lead-cooled European Advanced Demonstrator Reactor, Status Report, Milano, 11 th May 20112. Sara Bortot, Conceptual Core Design Study for a Lead-cooled Fast Reactor Demonstrator, Doctoral Dissertation, 2010 – XXIII3. W. Pfrang, D. Struwe, Assessment of Correlations for Heat Transfer to the Coolant for Heavy Liquid Metal Cooled Core Designs, FZKA 7352, Oct. 20074. M. Ottolini, Steam Generator Design Report & Drawing, ELSY European Lead-cooled System, DEL/10/016, 20105. V. Sobolev, Thermophysical Properties of Liquid Lead, ELSY European Lead-cooled System, DEL/07/032, 20076. Kandlikar, S. G., A Model for Predicting the Two-Phase Flow Boiling Heat Transfer Coefficient in Augmented Tube and Compact Heat Exchanger Geometries, Journal of Heat Transfer, vol. 113, pp. 966-972, 19917. Jensen J. M., Tummescheit H.: Moving Boundary Models for Dynamic Simulations of Two-Phase Flows, Second International Modelica Conference, proceedings, pp. 235-2448. E. Bubelis, M. Shikorr, Results of Analysis for Design Extended Conditions (DEC), ELSY European Lead-cooled System, DEL/10/31, 2010

19

![[24 th ICNTS @ Bologna (Italy) 04/09/2008]](https://static.fdocuments.net/doc/165x107/56815a9c550346895dc820ba/24-th-icnts-bologna-italy-04092008.jpg)