bluetooth controlled folk lifter

-

Upload

mukul-mohal -

Category

Engineering

-

view

230 -

download

3

Transcript of bluetooth controlled folk lifter

1

TABLE OF CONTENTS`

CONTENTS

PAGE NO

COVER PAGE i

TITLE PAGE ii

CONTENTS iii

CERTIFICATE iv

ACKNOWLEDGMENT v

DECLARATION vi

DECLARATION vii

LIST OF FIGURES vii

LIST OF TABLES ix

CHAPTER-1 INTRODUCTION TO ―MINOR PROJECT

11 What Is A Fork Lifter 1

111 Stability 2

112 Fulcrum Point 2

113 Center Of Gravity (Cg) 3

12 Block Diagram Of Bluetooth Control Folk Lifter Car 4

13 Pic16f887 Microcontroller 5

131 Microcontroller Versus Microprocessor 5 132 Features of Pic 16f887 Microcontrollers 6

133 Inside A Pic Microcontroller 9

2

134 Program Memory 9

135 Data Memory (Ram) 10

136 Bus 10

137 IO Unit 10

138 Ports 10

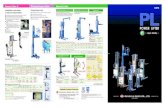

14 Component Used 11

15 Hc-05 Bluetooth Module Bluetooth 11

151 Setting Up Connections 12

152 Pairing and Bonding 13

153 Implementation 13

154 Pairing Mechanisms 14

155 Notifications 17

156 Description of Command 19

16 L293d H Bridge 20

17 Lm 7805 Voltage Regulator 22

171 Description 22

18 Capacitor 25

181 Function 25

182 Polarised Capacitors (Large Values 1microf +) 26

183 Electrolytic Capacitors 26

3

19 Diodes 27

191 Function 27

192 Forward Voltage Drop 27

193 Reverse Voltage 27

194 Connecting and Soldering 28

110 Resistor 28

1101 Function 29

1102 Resistor Shorthand 29

111 Zener Diode 29

112 Dc Gear Motor 31

1121 External Structure 31

1122 Rear View 33

1123 How Geared Dc Motor Works 33

113 Variable Resistors 37

1131construction 37

1132 Linear (Lin) and Logarithmic (Log) Tracks 38

1133 Potentiometer 39

CHAPTER 2

21 Overview 40

22 Creating A Circuit Design Using Capture 41

4

23 Using Component To Make Schematics 43

24 Connecting Two Components By Wire Connection 45

25 Creating The Netlist 47

26 Designing The Pcb With Layout Plus 49

27 Opening Layout Plus 50

28 Converting Connections Into Tracks 54

29 Broad Outline 55

210 Power Supply For Folk Lifter Car 57

2101 Connectors of A Battery 58

CHAPTER-3 RESULTS AND DISCUSSION

31 Results 60

32 Discussion 60

CHAPTER-4 CONCLUSIONS AND FUTURE SCOPE

41 Conclusion 62

42 Future Scope of Embedded System 63

421 Opportunities 65

5

LIST OF FIGURES

Name of Figure

Page No

Fig 11 folk lifter car 2

Fig 12 fulcrum point 2

Fig 13 center of gravity 3

Fig 14 block diagram of Bluetooth controlled car 4

Fig 15 Microcontroller vs Microprocessor 6

Fig 16 40 Pin Microcontrollers 9

Fig 17 HC-05 Bluetooth Module 16

Fig 18 Interfacing of Bluetooth module with microcontroller 17

Fig 19 L293 h bridge IC 20

Fig 110 L293 h bridge IC with dc motor 21

Fig 111 IC 7805 voltage regulator 22

Fig 112 LM 7805 23

Fig 113 polar and non-polar capacitor 26

Fig 114 diodes 27

Fig 115 diode terminal 28

6

Fig 116 color coded register 29

Fig 117 gear dc motor 32

Fig118 gear dc motor external structure 32

Fig119 geared head 33

Fig120 DC gear motor rear view 33

Fig121 dc gear motor internal structure 34

Fig122 Connection of the shaft with the gear 34

Fig123 gear dc motor 34

Fig124 gear dc motor gear 35

Fig125 gear dc motor in working 36

Fig 126 variable resistor 37

Fig 127 rheostate symbol 38

Fig128 potentiometer symbol 39

Fig 21flow chart of PCB layout 41

Fig 22 New project dialog 42

Fig 23 Powersupplydsn file 42

Fig 24 Place part dialog 44

Fig 25 GND 44

Fig 26 Placing components 45

Fig 27 Connecting components using wire 46

Fig 28 Display properties of the component 46

Fig29 Orcad capture of Bluetooth controlled folk lifter car 47

Fig 210 Left click power supplydsn 48

7

Fig 211 Create Netlist option 48

Fig 212 Create Netlist tab 49

Fig 213 Netlist created 49

Fig 214 Creating new layout 50

Fig 215 Auto ECO tab after creating new design 51

Fig 216 After all footprints are selected 52

Fig 217 Display DRC 52

Fig 218 Edit component 53

Fig 219 Designing circuit 53

Fig 220 Edit segment mode 54

Fig 221 Selecting layer for tracks 54

Fig 222 Converting connection to tracks 55

Fig 223 Selecting obstacle tool 55

Fig 224 Selecting obstacle new 56

Fig 225 Drawing board outline on global layer 56

Fig 226 Orcad layout of Bluetooth controlled folk lifter car 57

Fig 227 9 volt battery 58

Fig 228 Battery cap 58

8

CHAPTER-1

INTRODUCTION TO ldquoMINOR PROJECTrdquo

Our project is based on microcontroller in which we have used several steps for

making our project so here we are giving introduction to all the component which we

have used in our project work This project is a Bluetooth controlled folk lifter car

For this the android mobile user has to install an application on herhis mobile Then

user needs to turn on the Bluetooth in the mobile The wireless communication

techniques used to control the robot is Bluetooth technology User can use various

commands like move forward reverse stop move left move right These commands

are sent from the Android mobile to the Bluetooth receiver Android based folk lifter

car has a Bluetooth receiver unit which receives the commands and give it to the

microcontroller circuit to control the motors The microcontroller then transmits the

signal to the motor driver IClsquos to operate the motors

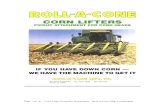

11 WHAT IS A FORK LIFTER

A forklift is one type of power industrial truck that comes in different shapes

sizes and forms A forklift can be called a pallet truck rider truck fork truck

or lift truck Yet the ultimate purpose of a forklift is the same to safely allow

one person to lift and move large heavy loads with little effort For the purposes

of this training a forklift is a small or large A forklift operator should be aware

of the multiple parts on a forklift (see diagram below) in order to safely operate

the forklift and be able to detect when an unsafe vehicle needs to be removed

from service industrial truck with a power-operated pronged platform(commonly

known as forks)

9

Fig 11 folk lifter car

111 STABILITY

Forklift stability is an important topic because the leading cause of death and serious

injury involving forklifts stems from overturns caused by forklift instability Forklift

stability can be described by four elements the fulcrum point center of gravity the

stability triangle and the load center

112 FULCRUM POINT

The fulcrum point may sound complicated but think of it this way As children we all

played on seesaws which have a board that is balanced in the riddle by a support

piece This support piece is what is called the fulcrum point On a fork lifterthe

fulcrum point is the front wheels The fulcrum point serves as a support piece to

balance the load and counterweight The illustration at the right displays this concept

Fig 12 fulcrum point

10

113 CENTER OF GRAVITY (CG)

In addition to balancing both ends of the fork lifter we must also balance in all

directions Balancing in all directions is better known as the center of gravity The

center of gravity is that point where all parts of a load or truck are balanced in all

directions and will remain at rest As a driver it is important to remember that anew

center of gravity is created when youre handling a load (as opposed to an empty

load) one that combines both the loads and the truckt cenrer of gravityThink of it like

riding a tricycle If you peddle a tricycle around a corner and shift the center of

gravity forward over the narrowest part of the tricycle you are likely to turn over

But if you shift your weight on the rear and place the center of gravity over the

widest part of the tricycle you are less likely to tip over

Fig 13 center of gravity

Some factors that could cause instability are

Carrying the load too high

Excessively tilting the load forward

Operating on a decline

Heavy braking

Inappropriate use of forklift attachments

11

Off-center loads

uneven terrain

Quick turns

However your potential to turn over can be reduced if you follow a few safety rules

Make sure the load is stable and safely arranged on the forklift

Do not tilt the forks forward except when picking up or depositing a load

Keep the load low just above the pavement with the forks tilted back when traveling

Enter tractor-trailers or elevators squarely when picking up or depositing loads

Drive at a slow enough speed to allow you to stop safely

Drive slowly on wet or slippery surfaces

Avoid driving on unstable surfaces or where there are loose objects on the surface

12 BLOCK DIAGRAM OF BLUETOOTH CONTROL FOLK

LIFTER CAR

Fig 14 block diagram of Bluetooth controlled car

12

13 PIC16F887 MICROCONTROLLER

PIC stands for ―Peripheral Interface Controller It is having 16 bit CPU amp introduced

by ―Microchip company It is RISC (Reduced Instruction Set Computing)

compatible controller This controller has only 35 instructions Its maximum operated

speed is 20 MHz oscillatorclock input The nice things about the controller is that

they are compatible with each other and a program for one model can very easily be

used in many cases with no modification be run on other models of family The basic

assembler instruction set of PIC microcontroller consist of only 35 instructions and

most of family members (except the newly developed devices) use same instruction

set ie why a program developed for one model can run on another model with

same architecture without any changes The PIC microcontroller has INTRRUPT

capability

131 MICROCONTROLLER VERSUS MICROPROCESSOR

A microcontroller differs from a microprocessor in many ways The

first and most important difference is its functionality In order the microprocessor

may be used other components such as memory or components for data transfer must

be added to it Even though the microprocessor is considered to be a powerful

computer machine the weak point is that it is not adjusted to communication to

peripheral environment Simply in order to communicate with peripheral

environment the microprocessor must use specialized circuits added as external

chips It means in short that microprocessors are the pure heart of the computers That

is how it was when they appeared and the same is now On the other hand the

microcontroller is designed to be all of that in one No other specialized external

components are needed for its application because all necessary circuits which

otherwise belong to peripherals are already built into it It in any case saves the time

and space needed to design a device

13

Figure 15 Microcontroller vs Microprocessor

132 FEATURES OF PIC 16f887 MICROCONTROLLERS

RISC architecture

o Only 35 instructions to learn

o All single-cycle instructions except branches

Operating frequency 0-20 MHz

Precision internal oscillator

o Factory calibrated

o Software selectable frequency range of 8MHz to 31KHz

Power supply voltage 20-55V

o Consumption 220uA (20V 4MHz) 11uA (20 V 32 KHz) 50nA (stand-

by mode)

14

Power-Saving Sleep Mode

Brown-out Reset (BOR) with software control option

35 inputoutput pins

o High current sourcesink for direct LED drive

o software and individually programmable pull-up resistor

o Interrupt-on-Change pin

a8K ROM memory in FLASH technology

o Chip can be reprogrammed up to 100000 times

In-Circuit Serial Programming Option

o Chip can be programmed even embedded in the target device

256 bytes EEPROM memory

o Data can be written more than 1000000 times

368 bytes RAM memory

AD converter

o 14-channels

o 10-bit resolution

3 independent timerscounters

Watch-dog timer

Analogue comparator module with

o Two analogue comparators

15

o Fixed voltage reference (06V)

o Programmable on-chip voltage reference

PWM output steering control

Enhanced USART module

o Supports RS-485 RS-232 and LIN20

o Auto-Baud Detect

Master Synchronous Serial Port (MSSP)

o supports SPI and I2C mode

Although there are several hundred models of PIC microcontrollers choosing a

microcontroller for an application is not a difficult task and requires taking into

account these factors

Number of IO pins required

Required peripherals (eg USARTUSB)

The minimum size of program memory

The minimum size of RAM

Whether or not EEPROM non volatile data memory is required

Speed

Physical size

Cost

16

Figure 16 40 Pin Microcontrollers

133 INSIDE A PIC MICROCONTROLLER

Although there are many models of microcontrollers in PIC family they all share

some common features such as program memory data memory IO ports and timers

Some devices have additional features such as AD converters USARTs and so on

Because of these common features we can look at these attributes and cover the

operations of most of devices in family

134 PROGRAM MEMORY

The program memory is where your program resides In early microprocessors and

microcontrollers the program memory was EPROM which meant that it had to be

erased using UV light before it could be programmed Most PIC microcontrollers are

based on flash technology where the memory chip can be erased or reprogrammed

using a programmer device Most PIC microcontrollers can also be programmed

without removing from their circuits This process (called in-circuit serial

programming or ISP) speeds up the development cycle and lowers the development

costs Although the program memory is mainly used to store a program there is no

reason why it cannot be used to store constant data used in programsA PIC basis

program have several pages of codes and still fit inside a 1K of program memory The

width of a 14-bit program memory is actually 14-bits It is interesting to note that

PICs are known as 8-bit Microcontrollers This is actually true as far as the width of

17

data memory is concerned which is 8-bit wide Microchip calls the 14-bits a word

even though a word is 16-bit wide When a power is applied to Microcontroller or

when MCLR (Master Clear) input is lowered logic 0 execution starts from the Reset

Vector which is first word of program memory Thus the first instruction executed

after a reset is the one located at address 0 of the program memory

135 DATA MEMORY (RAM)

The data memory is used to store all of your program variables This is a RAM which

means that all the data is lost when power is removed The data memory is 8-bit wide

and that is why the PIC microcontrollers are called 8-bit microcontrollers

136 BUS

It is a group of 8 or 16 wires There are three types of buses ie address bus control

bus data bus Address bus consists of many lines as the amount of memory we wish

to address and serves to transmit address from CPU memory Data bus is wide as

data in our case the 8-bit or the connection lines and connect all blocks inside the

microcontroller Control bus is between memory unit and CPU IO unit and CPU

137 IO UNIT

The input and output pins which we have to set which is input or output key is set by

this All these are also called as ―ports There are several types of ports input output

or bidirectional ports When working with ports first of all it is necessary to choose

which port we need to work with and then to send data to or take it from port When

working with it the port acts like a memory location Something is simply being

written into or read from it and it could be noticed on pins of microcontroller

138 PORTS

Port is register inside a microcontroller which is connected by wires to the pin of

controller Ports represent physical connection of Central Processing unit with an

outside world Microcontroller uses them in order to monitor or control other

components or devices Due to functionality some pins have two fold roles like

18

RA4T0CK1 for instance which is simultaneously the fourth bit of port A and an

external input for free-run counter Selection of one of these two pins functions is

done in one of the configurationally registers PIC has 5 IO PORTS

14 COMPONENT USED

SN Equipment Quality

1 PIC16F887 1

2 HC-05 BLUETOOTH MODULE 1

3 L293D H BRIDGE IC 2

4 LM 7805 VOLTAGE REGULATOR 1

5 LM 7812 VOLTAGE REGULATOR 1

6 DC GEAR MOTOR 3

7 VARIABLE RESISTANCE 3

8 CAPACITANCE (01 uF) 1

9 LM 7812 VOLTAGE REGULATOR 1

10 CAPACITANCE (100 nF) 2

11 LED 1

12 ZENER DIODE (33 V) 1

13 RESISTANCE (10K18K) 1

14 SWITCH PUSHBUTTON

15 HC-05 BLUETOOTH MODULE BLUETOOTH

Bluetooth is a wireless technology for communication over distances of up to

10m Offering reasonably fast data transfer rates of around 1 Mbs principally

between Battery-powered devices Bluetoothlsquos primary intentis to support the creation

of adhoc Personal area networks (PANs) for small data transfers (or voice

communication) Between devices such as Laptop PDA mobile phones PClsquos

printers digital cameras and video game consoles over a secure globally unlicensed

short-range radio frequency

Bluetooth wireless technology works anywhere in the world because it

19

operates at

24 GHz in the globally available license free industrial scientific

and medical (ISM) band

151 SETTING UP CONNECTIONS

Any Bluetooth device in discoverable mode will transmit the following information

on demand

Device name

Device class

List of services

Technical information (for example device features manufacturer Bluetooth

specification used clock offset)

Any device may perform an inquiry to find other devices to connect to and any

device can be configured to respond to such inquiries However if the device trying to

connect knows the address of the device it always responds to direct connection

requests and transmits the information shown in the list above if requested Use of a

devices services may require pairing or acceptance by its owner but the connection

itself can be initiated by any device and held until it goes out of range Some devices

can be connected to only one device at a time and connecting to them prevents them

from connecting to other devices and appearing in inquiries until they disconnect from

the other device

Every device has a unique 48-bit address However these addresses are generally not

shown in inquiries Instead friendly Bluetooth names are used which can be set by

the user This name appears when another user scans for devices and in lists of paired

devices

Most cellular phones have the Bluetooth name set to the manufacturer and model of

the phone by default Most cellular phones and laptops show only the Bluetooth

names and special programs are required to get additional information about remote

devices This can be confusing as for example there could be several cellular phones

in range named T610

20

152 PAIRING AND BONDING

Many of the services offered over Bluetooth can expose private data or allow the

connecting party to control the Bluetooth device For security reasons it is necessary

to be able to recognize specific devices and thus enable control over which devices

are allowed to connect to a given Bluetooth device At the same time it is useful for

Bluetooth devices to be able to establish a connection without user intervention (for

example as soon as they are in range)

To resolve this conflict Bluetooth uses a process called bonding and a bond is

generated through a process called pairing The pairing process is triggered either by a

specific request from a user to generate a bond (for example the user explicitly

requests to Add a Bluetooth device) or it is triggered automatically when

connecting to a service where (for the first time) the identity of a device is required

for security purposes These two cases are referred to as dedicated bonding and

general bonding respectively

Pairing often involves some level of user interaction this user interaction is the basis

for confirming the identity of the devices Once pairing successfully completes a

bond will have been formed between the two devices enabling those two devices to

connect to each other in the future without requiring the pairing process in order to

confirm the identity of the devices When desired the bonding relationship can later

be removed by the user

153 IMPLEMENTATION

During the pairing process the two devices involved establish a relationship by

creating a shared secret known as a link key If a link key is stored by both devices

they are said to be paired or bonded A device that wants to communicate only with a

bonded device can cryptographically authenticate the identity of the other device and

so be sure that it is the same device it previously paired with Once a link key has

been generated an authenticated Asynchronous Connection-Less (ACL) link between

the devices may be encrypted so that the data that they exchange over the airwaves is

protected against eavesdropping

Link keys can be deleted at any time by either device If done by either device this

will implicitly remove the bonding between the devices so it is possible for one of the

21

devices to have a link key stored but not be aware that it is no longer bonded to the

device associated with the given link key

Bluetooth services generally require either encryption or authentication and as such

require pairing before they allow a remote device to use the given service Some

services such as the Object Push Profile elect not to explicitly require authentication

or encryption so that pairing does not interfere with the user experience associated

with the service use-cases

154 PAIRING MECHANISMS

Pairing mechanisms have changed significantly with the introduction of Secure

Simple Pairing in Bluetooth v21 The following summarizes the pairing mechanisms

Legacy pairing This is the only method available in Bluetooth v20 and before

Each device must enter a PIN code pairing is only successful if both devices enter

the same PIN code Any 16-byte UTF-8 string may be used as a PIN code

however not all devices may be capable of entering all possible PIN codes

o Limited input devices The obvious example of this class of device is a

Bluetooth Hands-free headset which generally have few inputs These

devices usually have a fixed PIN for example 0000 or 1234 that are

hard-coded into the device

o Numeric input devices Mobile phones are classic examples of these

devices They allow a user to enter a numeric value up to 16 digits in

length

o Alpha-numeric input devices PCs and smartphones are examples of these

devices They allow a user to enter full UTF-8 text as a PIN code If pairing

with a less capable device the user needs to be aware of the input

limitations on the other device there is no mechanism available for a

capable device to determine how it should limit the available input a user

may use

Secure Simple Pairing (SSP) This is required by Bluetooth v21 although a

Bluetooth v21 device may only use legacy pairing to interoperate with a v20 or

earlier device Secure Simple Pairing uses a form of public key cryptography and

some types can help protect against man in the middle or MITM attacks SSP has

the following characteristics

22

o Just works As implied by the name this method just works No user

interaction is required however a device may prompt the user to confirm the

pairing process This method is typically used by headsets with very limited

IO capabilities and is more secure than the fixed PIN mechanism which is

typically used for legacy pairing by this set of limited devices This method

provides no man in the middle (MITM) protection

o Numeric comparison If both devices have a display and at least one can

accept a binary YesNo user input they may use Numeric Comparison This

method displays a 6-digit numeric code on each device The user should

compare the numbers to ensure they are identical If the comparison succeeds

the user(s) should confirm pairing on the device(s) that can accept an input

This method provides MITM protection assuming the user confirms on both

devices and actually performs the comparison properly

o Passkey Entry This method may be used between a device with a display and

a device with numeric keypad entry (such as a keyboard) or two devices with

numeric keypad entry In the first case the display is used to show a 6-digit

numeric code to the user who then enters the code on the keypad In the

second case the user of each device enters the same 6-digit number Both of

these cases provide MITM protection

o Out of band (OOB) This method uses an external means of communication

such as Near Field Communication (NFC) to exchange some information used

in the pairing process Pairing is completed using the Bluetooth radio but

requires information from the OOB mechanism This provides only the level

of MITM protection that is present in the OOB mechanism

o 24 Blue tooth Devices

HC-05 embedded Bluetooth serial communication module (can be short for module)

has two work modes order-response work mode and automatic connection work

mode And there are three work roles (Master Slave and Loopback) at the automatic

connection work mode When the module is at the automatic connection work mode

it will follow the default way set lastly to transmit the data automatically When the

module is at the order-response work mode user can send the AT command to the

module to set the control parameters and sent control order The work mode of

module can be switched by controlling the module PIN (PIO11) input level

23

Figure 17 HC-05 Bluetooth Module

SERIAL MODULE PINS

1 PIO8 connects with LED When the module is power on LED will flicker

And the flicker style will indicate which work mode is in using since different

mode has different flicker time interval

2 PIO9 connects with LED It indicates whether the connection is built or not

When the Bluetooth serial is paired the LED will be turned on It means the

connection is built successfully

3 PIO11 is the work mode switch When this PIN port is input high level the

work mode will become order-response work mode While this PIN port is

input low level or suspended in air the work mode will become automatic

connection work mode

4 The module can be reset if it is re-powered since there is a reset circuit at the

module

24

Figure 18 Interfacing of Bluetooth module with microcontroller

155 NOTIFICATIONS

HOW TO GET TO THE AT MODE

Way 1

Step 1 Input low level to PIN34

Step 2 Supply power to the module

Step 3 Input high level to the PIN34 Then the module will enter to AT mode The

baud rate is as same as the communication time such as 9600 etc

Way 2

Step 1 Connect PIN34 to the power supply PIN

Step 2 Supply power to module (the PIN34 is also supplied with high level since the

PIN34 is connected with power supply PIN) Then the module will enter to AT

module But at this time the baud rate is 38400 In this way user should change the

25

baud rate at the AT mode if they forget the communication baud rate

HOW TO GET TO THE COMMUNICATION MODE

Step 1 Input low level to PIN34

Step 2 Supply power to the module Then the module will enter to communication

mode It can be used for pairing

HOW TO SET THIS MODULE BE THE MASTER ROLE

Step 1 Input high level to PIO11

Step 2 Supply power to the module And the module will enter to the order-response

work mode

Step 3 Set the parameters of the super terminal or the other serial tools (baud rate

38400 data bit8 stop bit1 no parity bit no Flow Control)

Step 4 Sent the characters ―AT+ROLE=1rn through serial then receive the

characters ―OKrn Here ―rn is the CRLF

Step 5 Input low level to PIO and supply power to the module again Then this

module will become master role and search the other module (slave role)

automatically to build the connection

NOTES

(1) HC-03 and HC-05lsquos command should end up with ―rn It means when you

finish programming you should add terminator (―ENTER or ―0x0d 0x0a) to the

program Itlsquos different from HC-04 and HC-06 (They donlsquot need terminator)

(2) The most common commands for HC-03 and HC-05 are AT+ROLE (set masterndash

slave) AT+CMODE( set address pairing) AT+PSWD (set password)

If you want the master module has the function of remembering slave module the

most simply way is First set AT+CMODE=1 Make the master module pair with the

slave

module Second set AT+CMODE=0 Then the master module just can make pair

with that specified slave module

(3) When PIN34 keeps high level all commands can be used Otherwise only some

of them can be used

26

156 DESCRIPTION OF COMMAND

AT command is case- sensitive should end up with terminator (―enter or ―rn)

1 Test

2 Reset

3 Get the soft version

4 Restore default status

5 Get module Bluetooth address

6 Set inquire devicelsquos name

7 Get the remote Bluetooth devicelsquos name

27

8 Set inquire module role

16 L293D H BRIDGE

L293D is a dual h bridge motor driver integrated circuit (IC) Motor drivers act as

current amplifiers since they take a low-current control signal and provide a higher-

current signal This higher current signal is used to drive the motorsL293D contains

two inbuilt H-bridge driver circuits In its common mode of operation two DC motors

can be driven simultaneously both in forward and reverse direction The motor

operations of two motors can be controlled by input logic at pins 2 amp 7 and 10 amp 15

Input logic 00 or 11 will stop the corresponding motor Logic 01 and 10 will rotate it

in clockwise and anticlockwise directions respectively Enable pins 1 and 9

(corresponding to the two motors) must be high for motors to start operating When

an enable input is high the associated driver gets enabled As a result the outputs

become active and work in phase with their inputs Similarly when the enable input is

low that driver is disabled and their outputs are off and in the high-impedance state

Fig 19 L293 h bridge IC

28

Fig 110 L293 h bridge IC with dc motor

Pin

No

Function Name

1 Enable pin for Motor 1 active high Enable 12

2 Input 1 for Motor 1 Input 1

3 Output 1 for Motor 1 Output 1

4 Ground (0V) Ground

5 Ground (0V) Ground

6 Output 2 for Motor 1 Output 2

7 Input 2 for Motor 1 Input 2

8 Supply voltage for Motors 9-12V (up to 36V) Vcc 2

9 Enable pin for Motor 2 active high Enable 34

10 Input 1 for Motor 1 Input 3

11 Output 1 for Motor 1 Output 3

12 Ground (0V) Ground

13 Ground (0V) Ground

14 Output 2 for Motor 1 Output 4

15 Input2 for Motor 1 Input 4

16 Supply voltage 5V (up to 36V) Vcc 1

29

17 LM 7805 VOLTAGE REGULATOR

Voltage regulator ICs are the IClsquos that are used to regulate voltage A regulated

power supply is very much essential for several electronic devices due to the

semiconductor material employed in them have a fixed rate of current as well as

voltage The device may get damaged if there is any deviation from the fixed rate

The AC power supply gets converted into constant DC by this circuit By the help of a

voltage regulator DC unregulated output will be fixed to a constant voltage The

circuit is made up of linear voltage regulator 7805 along with capacitors and resistors

with bridge rectifier made up from diodes From giving an unchanging voltage supply

to building confident that output reaches uninterrupted to the appliance the diodes

along with capacitors handle elevated efficient signal conveyal

171 DESCRIPTION

ICs regulator is mainly used in the circuit to maintain the exact voltage which is

followed by the power supply A regulator is mainly employed with the capacitor

connected in parallel to the input terminal and the output terminal of the IC regulator

For the checking of gigantic alterations in the input as well as in the output filter

capacitors are used While the bypass capacitors are used to check the small period

spikes on the input and output level Bypass capacitors are mainly of small values that

are used to bypass the small period pulses straightly into the Earth

A circuit diagram having regulator IC and all the above discussed components

arrangement revealed in the figure below

Fig 111 IC 7805 voltage regulator

30

The working of the components coupled in the circuit above is revealed in the

following table

Component Function

C1

This capacitor is known as bypass capacitor and is employed to bypass

extremely tiny duration spikes to the ground with no distress the other

components

C2

C2 is the filter capacitor employed to steady the slow changes in the

voltage applied at the input of the circuit Escalating the value of the

capacitor amplify the stabilization as well as the declining value of the

capacitor reduces the stabilization Moreover this capacitor is not alone

capable to ensure very constricted period spikes emerge at the input

C3

C3 is known as a filter capacitor employed in the circuit to steady the

slow alterations in the output voltage Raising the value of the capacitor

enlarges the stabilization furthermore declining the value of the capacitor

declined the stabilization Moreover this capacitor is not alone capable to

ensure very fine duration spikes happen at the output

C4 C4 is known as bypass capacitor and worked to bypass very small period

spikes to the earth with no influence the other components

U1

U1 is the IC with positive DC and it upholds the output voltage steady

exactly at a constant value even although there are major deviation in the

input voltage

As we have made the whole circuit till now to be operated on the 5V DC supply so

we have to use an IC regulator for 5V DC And the most generally used IC regulators

get into the market for 5V DC regulation use is 7805 So we are connecting the

similar IC in the circuit as U1

IC 7805 is a DC regulated IC of 5V This IC is very flexible and is widely employed

in all types of circuit like a voltage regulator It is a three terminal device and mainly

called input output and ground Pin diagram of the IC 7805 is shown in the diagram

below

31

Fig 112 LM 7805

The pin explanation of the 7805 is described in the following table

PIN

NO PIN DESCRIPTION

1 INPUT In this pin of the IC positive unregulated voltage is given in

regulation

2 GROUND In this pin where the ground is given This pin is neutral for

equally the input and output

3 OUTPUT The output of the regulated 5V volt is taken out at this pin of the

IC regulator

In the circuit diagram C2 as well as C3 are filter capacitor while bypass capacitors are

the C1 and C4The electrolytic polarized capacitors are employed for this purposeFor

the purpose of filter capacitors normally 10mfd value of the capacitor used And in

these projects we also used 100mfd value of the capacitor While in all kinds of circuit

the value of bypass capacitor is 01 mfd And in generally un-polarized mainly disc

capacitors employed for this purpose Currently we have the circuit for the 5V DC

positive regulation and we are also familiar with the component values used in the

circuit In the table below we have mentioned the value in detail of all the components

used in the circuit of 5V DC positive regulator

SNO COMPONENT TYPE VALUE

1 C1 CAPACITOR 01 mfd

32

SNO COMPONENT TYPE VALUE

2 C2 CAPACITOR 1000 mfd

3 C3 CAPACITOR 1000 mfd

4 C4 CAPACITOR 01 mfd

5 U1 POSITIVE DC REGULATOR 7805

18 CAPACITOR

Capacitor is electronic component constructed electronic circuit There are a variety

of capacitors which have various materials and construction Typical classification of

capacitors shows in Fig1 This technical guide summarizes the outline and use

technique of aluminum electrolytic capacitor which is increasing in accordance with

miniaturization of electronic components The type of capacitors can be selected from

the circuit characteristics Generally you can select it by capacitance and voltage in

Table-1 About what each type have in common reliability and price will be

considered as well as performances such as frequency characteristics and temperature

dependence etc shown in Table-2We have many types of capacitors trying to meet

various customerlsquos needs Capacitors (especially aluminum electrolytic capacitors)

are sensitive to operating condition

181 FUNCTION

Capacitors store electric charge They are used with resistors in timing circuits

because it takes time for a capacitor to fill with charge They are used to smooth

varying DC supplies by acting as a reservoir of charge They are also used in filter

circuits because capacitors easily pass AC (changing) signals but they block DC

(constant) signals This is a measure of a capacitors ability to store charge A large

capacitance means that more charge can be stored Capacitance is measured in farads

symbol F However 1F is very large so prefixes are used to show the smaller values

Three prefixes (multipliers) are used micro (micro) n (nano) and p (pico)

micro means 10-6

(millionth) so 1000000microF = 1F

n means 10-9

(thousand-millionth) so 1000nF = 1microF

33

p means 10-12

(million-millionth) so 1000pF = 1nF

Capacitor values can be very difficult to find because there are many types of

capacitor with different labeling systems There are many types of capacitor but they

can be split into two groups polarised and unpolarised Each group has its own circuit

symbol

182 POLARISED CAPACITORS (LARGE VALUES 1microF +)

Examples Circuit symbol

Fig 113 polar and non-polar capacitor

183 ELECTROLYTIC CAPACITORS

Electrolytic capacitors are polarized and they must be connected the correct way

round at least one of their leads will be marked + or - They are not damaged by heat

when soldering There are two designs of electrolytic capacitors axial where the

leads are attached to each end (220microF in picture) and radial where both leads are at

the same end (10microF in picture) Radial capacitors tend to be a little smaller and they

stand upright on the circuit board It is easy to find the value of electrolytic capacitors

because they are clearly printed with their capacitance and voltage rating The voltage

rating can be quite low (6V for example) and it should always be checked when

selecting an electrolytic capacitor If the project parts list does not specify a voltage

choose a capacitor with a rating which is greater than the projects power supply

voltage 25V is a sensible minimum for most battery circuits

34

19 DIODES

Example Circuit symbol

Fig 114 diodes

191 FUNCTION

Diodes allow electricity to flow in only one direction

The arrow of the circuit symbol shows the direction in which the current can flow

Diodes are the electrical version of a valve and early diodes were actually called

valves

192 FORWARD VOLTAGE DROP

Electricity uses up a little energy pushing its way through the diode rather like a

person pushing through a door with a spring This means that there is a small voltage

across a conducting diode it is called the forward voltage drop and is about 07V for

all normal diodes which are made from silicon The forward voltage drop of a diode is

almost constant whatever the current passing through the diode so they have a very

steep characteristic (current-voltage graph)

193 REVERSE VOLTAGE

When a reverse voltage is applied a perfect diode does not conduct but all real diodes

leak a very tiny current of a few microA or less This can be ignored in most circuits

because it will be very much smaller than the current flowing in the forward direction

However all diodes have a maximum reverse voltage (usually 50V or more) and if

this is exceeded the diode will fail and pass a large current in the reverse direction

this is called breakdown Ordinary diodes can be split into two types Signal diodes

which pass small currents of 100mA or less and Rectifier diodes which can pass large

35

currents In addition there are LEDs (which have their own page) and Zener diodes (at

the bottom of this page)

194 CONNECTING AND SOLDERING

Diodes must be connected the correct way round the diagram may be labeled a or +

for anode and k or - for cathode (yes it really is k not c for cathode) The cathode is

marked by a line painted on the body Diodes are labeled with their code in small

print you may need a magnifying glass to read this on small signal diodes Small

signal diodes can be damaged by heat when soldering but the risk is small unless you

are using a germanium diode (codes beginning OA) in which case you should use

a heat sink clipped to the lead between the joint and the diode body A standard

crocodile clip can be used as a heat sink

Fig 115 diode terminal

110 RESISTOR

bull A resistor is an electrical component designed to have a specific resistance (or

opposition) to the flow of electrons measured in ohms (Ω)

bull When installing a remote start or security system resistors of a specific resistance

may be needed to interface with the vehiclelsquos circuits Some of a vehiclelsquos circuits

may require a reduced voltage to operate a specific accessory or function A resistor

can be added to reduce the trigger voltage to the circuit Resistors will not be required

on most installations but will be required for installations on many newer vehicles

For example on a 2002 Dodge Intrepid a positive pulse through a 2700-Ohm resistor

to the door lock wire will lock the doors If resistors are not included with the system

36

you purchased they can be found at almost any electronics parts store such as Radio

Shack

bull Carbon-film resistors are the type most commonly used in vehicle security and

convenience applications Color bands on the resistor will indicate the value in ohms

as well as its tolerance in a plus or minus percentage of accuracy Resistors also have

a watt rating to indicate the amount of power it can handle If you exceed the power

rating of a resistor it will overheat and burn

Example Circuit symbol

Fig 116 color coded register

1101 FUNCTION

Resistors restrict the flow of electric current for example a resistor is placed in series

with a light-emitting diode (LED) to limit the current passing through the LED

1102 RESISTOR SHORTHAND

Resistor values are often written on circuit diagrams using a code system which

avoids using a decimal point because it is easy to miss the small dot Instead the

letters R K and M are used in place of the decimal point To read the code replace

the letter with a decimal point then multiply the value by 1000 if the letter was K or

1000000 if the letter was M The letter R means multiply by 1

111 ZENER DIODE

It was noted earlier that the reverse-bias saturation current of a general-purpose

junction diode is so small that it ordinarily is masked by currents associated with

high-resistance conducting paths across the junction But currents associated with

other phenomena occurring in what is a very complex physical junction environment

also can mask the leakage current If the reverse-bias voltage magnitude is increased

above a threshold (the specific value depends on the junction geometry and material

37

parameters) one or the other (possibly even both concurrently) of two new phenomena

occur These phenomena which are different from the junction phenomena described

before establish a new mechanism of current flow generically referred to as Zener

breakdownlsquo which masks the junction reverse-bias leakage current In the breakdown

region of operation large current changes occur with very small changes in reverse-

bias voltage similar to forward-bias operation but for quite different reasons These

phenomena occur in all semiconductor junction diodes However the reverse-bias

breakdown voltage characteristic can be reproduced with considerable precision by

controlling doping and other manufacturing process parameters For ordinary use

diode breakdown is characterized simply by specification of a minimum reverse-bias

breakdown voltage and current the magnitude of the breakdown voltage is

guaranteed to be no less and the current (for a specified lower voltage) no more than

specified values Such diodes are not intended specifically for operation in reverse

breakdown and are expected to maintain a low-conduction state when operated in

reverse-bias within the specified breakdown voltage limit Diodes whose reverse-

breakdown characteristics are controlled precisely during manufacture commonly are

called Zener diodes Zener diodes command a premium because of the special

production controls and selection and are intended specifically for operation in the

reverse-breakdown mode primarily as inexpensive voltage references Zener Diode

Breakdown Characteristics ordinarily the reverse-bias blocking action of a PN

junction allows only a small leakage current to flow However if a sufficiently large

reverse-bias is applied other junction phenomena develop which dominate the leakage

current allowing in effect much larger reverse-bias currents This is the breakdown

part of the diode characteristic breakdown here refers to the overshadowing of the

semiconductor junction behavior by other phenomena rather than to a destructive

effect While all diodes display this reverse-bias breakdown phenomenon Zener

diodes are manufactured specifically for operation in the breakdown condition with

guaranteed specifications The breakdown parameters of these Zener (or voltage

reference) diodes receive special processing attention during their manufacture Two

distinct phenomena acting individually or concurrently depending on diode details

are involved in the breakdown phenomena One mechanism is associated with the

acceleration of carriers across the very strong junction electric field Kinetic energy

gained by an accelerated carrier if sufficiently great can cause additional impurity

atom ionization during a collision with the atom Each additional carrier is then also

38

accelerated and may cause additional ionization the ionization grows exponentially

This is termed the avalanche effectlsquo recalling the initiation of a massive snow slide

by a small initial snowball Circuits Zener Diode 2 M H Miller The second

mechanism is a quantum mechanical effect more difficult to describe by a familiar

analogy Quantum mechanics predicts the possibility of a spontaneous crossing of a

semiconductor junction by carriers subject to a strong electric field This is called the

tunnel effectlsquo because the phenomena is not associated with ordinary mechanics it

was suggested facetiously that some sort of metaphysical tunnel existed through

which carriers somehow traveled out of ordinary sight While the breakdown

characteristics for the two phenomena are not exactly the same they are close enough

so that the distinction largely may be ignored in general for purposes of circuit design

Thus although the Zener effect originally referred to the quantum mechanical

phenomena the label Zener diode is applied almost universally whatever the details of

the breakdown mechanism

112 DC GEAR MOTOR

Geared DC motors can be defined as an extension of DC motor which already had its

Insight details demystified A geared DC Motor has a gear assembly attached to the

motor The speed of motor is counted in terms of rotations of the shaft per minute and

is termed as RPM The gear assembly helps in increasing the torque and reducing the

speed Using the correct combination of gears in a gear motor its speed can be

reduced to any desirable figure This concept where gears reduce the speed of the

vehicle but increase its torque is known as gear reduction This Insight will explore

all the minor and major details that make the gear head and hence the working of

geared DC motor

1121 EXTERNAL STRUCTURE

At the first sight the external structure of a DC geared motor looks as a straight

expansion over the simple DC ones

39

Fig 117 gear dc motor

The lateral view of the motor shows the outer protrudes of the gear head A nut is

placed near the shaft which helps in mounting the motor to the other parts of the

assembly

Fig118 gear dc motor external structure

Also an internally threaded hole is there on the shaft to allow attachments or

extensions such as wheel to be attached to the motor The outer body of the gear head

is made of high density plastic but it is quite easy to open as only screws are used to

attach the outer and the inner structure The major reason behind this could be to

lubricate gear head from time to time The plastic body has a threading through which

nut can be easily mounted and vice versa from the gear head

40

Fig119 geared head

1122 REAR VIEW

The rear view of the geared motor is similar to the DC motor and it has two wires

soldered to it

Fig120 DC gear motor rear view

1123 HOW GEARED DC MOTOR WORKS

On opening the outer plastic casing of the gear head gear assemblies on the top as

well as on bottom part of the gear head are visible These gear assemblies are highly

lubricated with grease so as to avoid any sort of wear and tear due to frictional forces

Shown below is the top part of the gear head It is connected to rotating shaft and has

one gear that allows the rotation A strong circular imprint shows the presence of the

gear that rotates the gear at the upper portion

41

Fig121 dc gear motor internal structure

Fig122 Connection of the shaft with the gear

A closer look at the bottom gear assembly shows the structure and connection with

other gears

Fig123 gear dc motor

42

Gear assemblylsquos association with the motor (bottom gear assembly) can be

understood with the help of the image shown below

Fig124 gear dc motor gear

The gear assembly is set up on two metallic cylinders whose working can be called as

similar to that of an axle A total of three gears combine on these two cylinders to

form the bottom gear assembly out of which two gears share the same axle while one

gear comes in between them and takes a separate axle The gears are basically in form

of a small sprocket but since they are not connected by a chain they can be termed as

duplex gears in terms of a second cog arrangement coaxially over the base Among

the three gears two are exactly same while the third one is bigger in terms of the

number of teeth at the upper layer of the duplex gear The third gear is connected to

the gear at the upper portion of the gear head The manner in which they are located

near the upper part of the gear head can be seen through the image shown below The

combination of bottom gear assembly with the upper one can be seen down under

The DC motor works over a fair range of voltage The higher the input voltage more

is the RPM (rotations per minute) of the motor For example if the motor works in the

range of 6-12V it will have the least RPM at 6V and maximum at 12 V

In terms of voltage we can put the equation as

RPM= K1 V where

K1= induced voltage constant

V=voltage applied

43

Fig125 gear dc motor in working

The working of the gears is very interesting to know It can be explained by the

principle of conservation of angular momentum The gear having smaller radius will

cover more RPM than the one with larger radius However the larger gear will give

more torque to the smaller gear than vice versa The comparison of angular velocity

between input gear (the one that transfers energy) to output gear gives the gear ratio

When multiple gears are connected together conservation of energy is also followed

The direction in which the other gear rotates is always the opposite of the gear

adjacent to itIn any DC motor RPM and torque are inversely proportional Hence the

gear having more torque will provide a lesser RPM and converse In a geared DC

motor the concept of pulse width modulation is applied The equations detailing the

working and torque transfer of gears In a geared DC motor the gear connecting the

motor and the gear head is quite small hence it transfers more speed to the larger

teeth part of the gear head and makes it rotate The larger part of the gear further turns

the smaller duplex part The small duplex part receives the torque but not the speed

from its predecessor which it transfers to larger part of other gear and so on The third

gearlsquos duplex part has more teeth than others and hence it transfers more torque to the

gear that is connected to the shaft

113 VARIABLE RESISTORS

Resistors found on circuit boards are normally fixed in value Some resistors found in

the motor vehicle are variable Variable resistors can have their value altered by

movement of a slide or by temperature change The three types of variable resistors

44

are Rheostats Potentiometers and Thermistors Variable resistors can be linear

meaning that their resistance value varies proportionally with movement or

temperature change or non-linear where the resistance change is not proportional

with movement

1131CONSTRUCTION

Variable resistors consist of a resistance track with connections at both ends and

a wiper which moves along the track as you turn the spindle The track may be made

from carbon cermet (ceramic and metal mixture) or a coil of wire (for low

resistances) The track is usually rotary but straight track versions usually called

sliders are also available Variable resistors may be used as

a rheostat with two connections (the wiper and just one end of the track) or as

a potentiometer with all three connections in use Miniature versions

called presets are made for setting up circuits which will not require further

adjustment

Variable resistors are often called potentiometers They are specified by their

maximum resistance linear or logarithmic track and their physical size The standard

spindle diameter is 6mmThe resistance and type of track are marked on the body 4K7

LIN means 47 k linear track 1M LOG means 1 M logarithmic track

Some variable resistors are designed to be mounted directly on the circuit board but

most are for mounting through a hole drilled in the case containing the circuit with

stranded wire connecting their terminals to the circuit board

Fig 126 variable resistor

45

1132 LINEAR (LIN) AND LOGARITHMIC (LOG) TRACKS

Linear (LIN) track means that the resistance changes at a constant rate as you move

the wiper This is the standard arrangement and you should assume this type is

required if a project does not specify the type of track Presets always have linear

tracks

Logarithmic (LOG) track means that the resistance changes slowly at one end of the

track and rapidly at the other end so halfway along the track is not half the total

resistance This arrangement is used for volume (loudness) controls because the

human ear has a logarithmic response to loudness so fine control (slow change) is

required at low volumes and coarser control (rapid change) at high volumes It is

important to connect the ends of the track the correct way round if you find that

turning the spindle increases the volume rapidly followed by little further change you

should swap the connections to the ends of the track

Rheostat This is the simplest way of using a variable resistor Two terminals are

used one connected to an end of the track the other to the moveable wiper Turning

the spindle changes the resistance between the two terminals from zero up to the

maximum resistance Rheostats are often used to vary current for example to control

the brightness of a lamp or the rate at which a capacitor charges

If the rheostat is mounted on a printed circuit board you may find that all three

terminals are connected However one of them will be linked to the wiper terminal

This improves the mechanical strength of the mounting but it serves no function

electrically

Fig 127 rheostate symbol

46

1133 POTENTIOMETER

Variable resistors used as potentiometers have all three terminals connected This

arrangement is normally used to vary voltage for example to set the switching point

of a circuit with a sensor or control the volume (loudness) in an amplifier circuit If

the terminals at the ends of the track are connected across the power supply then the

wiper terminal will provide a voltage which can be varied from zero up to the

maximum of the supply

Fig128 potentiometer symbol

47

CHAPTER 2

21 OVERVIEW

There are several basic steps involved in producing a printed circuit board (PCB)

Most designs begin with a hand drawn schematic and design plan With these the

circuit is prototyped and tested to verify that the design works correctly Then using

software an electronic version of the schematic is created A net list file is created

from the electronic schematic and used in other software to create the physical layout

of the PCB Next the components are placed and routed in the physical layout

software and Gerber files are created These Gerber files are used in a prototyping

system to mill drill and cut the PCB substrate The components are then placed and

soldered to the substrate Finally the board is tested to verify that it works as

expected

The major steps in the PCB design and fabrication process are as follows

1 Design and test the prototype circuitmdash by hand

2 Capture the circuitlsquos schematic using- Or CAD Capture or similar software

3 Perform the physical layout of the circuitmdash using OrCAD Layout or similar

software

4 Fabricate populate and test the PCBmdash done by ECE shop personnel or similar

personnel

With this general procedural framework in mind read on to learn more about each

step in this process

48

Fig 21flow chart of PCB layout

1 Prototyping

With a basic idea in mind a circuit schematic is developed and analyzed to ensure the

desired functionality and performance When creating a circuit for PCB production a

designer would also select specific components at this time Commonly the next step

is to prototype and to test the circuit It is also possible to use the schematic capture

software along with related software to simulate the circuit without building it on a

prototyping board In the case of the example circuit a rough sketched schematic was

initially created along with some design specifications The necessary components

were chosen and the circuit was built on a prototyping board to verify that it met the

design criteria During the prototype board layout phase thought was given to the best

way to arrange the components for the final PCB layout As a result the PCB layout

is very similar to the protoboard layout you

22 CREATING A CIRCUIT DESIGN USING CAPTURE

Before you make a PCB layout you need to have a circuit to layout You will use

capture to make tke schematic so the first step is to start the capture capture is started

by following steps

49

To open capture CIS from windows start menu select programgtgtorcad

103gtgtcapture CIS

Select filegtgtproject from the new project window give your project a name

select ldquoschematicrdquoclick ok

Figure 22 New project dialog

In the browse option give the location of a folder where you want to save your

file and click ok

On this page double click on the power supplydsn on left side then double

click on schmetic then double click on page1 to on schematic page

On double clicking a empty page will opened We will draw our schematic on

this page We can increase and decrease the size of our page according to

50

requirement This page contain scales in X and Y direction Which give

location of any point

Figure 23 Powersupplydsn file

23 USING COMPONENT TO MAKE SCHEMATICS

Next we draw the schematic To get parts go to places -gtpart if no parts are visible

in the ―place part dialog simply click the ―add library button Inside the browse file

dialog click on the olb file then press ctrl+Arrow to select certain files and hit the

―open file button

51

Figure 24 Place part dialog

Remember we always need a ground in the circuit this can be found in the

place ground menu accessible by clicking GND button on the right side of the

screen The ground we will use is the 0source identified by the symbol

Figure 25 GND

Moving rotating and other part manipulation functions can be accomplished

through the edit menu at the top of the screen or right click with part selected

Warning When making changes be careful parts may become disconnected

52

Figure 26 Placing components

24 CONNECTING TWO COMPONENTS BY WIRE

CONNECTION

Once part has been placed use placewire or click on the ―wire icon to

allow you to wire the circuit The cursor changes to a cross hair which can be

used to connect valid connection points The cursor changes to a cross hair

which may be used to connect between valid connection point and then release

it To change the direction of a wire left-click at the point where the direction

is to be changed

53

Figure 27 Connecting components using wire

To change the values double click on the value itself (not on the component)

and in the resulting window after the value eg in the value window change

the 0 to 5 (for 5V DC)

Figure 28 Display properties of the component

With the help of this dialog box we can change the orientation of our

components We can rotate it through 90180 angle

54

The final schematic is shown as

Fig29 Orcad capture of Bluetooth controlled folk lifter car

25 CREATING THE NETLIST

Minimize the schematic that you have made in capture and left click on the

power supplydsn

55

Figure 210 Left click power supplydsn

From the tool menu click on the create netlistoption to make netlist

Figure 211 Create Netlist option

Once net list is created it will be shown in the output folder While creating the

net list select the layout tab

56

Figure 212 Create Netlist tab

Figure 213 Netlist created

Now we are ready for the layout creation because we will use this netlist file in

the layout

26 DESIGNING THE PCB WITH LAYOUT PLUS

Layout plus is a circuit board layout tool that accepts a layout-compatible circuit

netlist (ex From capture CIS) and generates an output layout files that suitable for

57

PCB fabrication Simple steps in producing PCB layout involve importing netlist

placing components routing and generating output files and reports

27 OPENING LAYOUT PLUS

To open the layout plus from windows start menu select programgtgtOrCAD

103gtgtlayout plus

Go to filegtgtnew to create a new design You will see the dialog as shown in fig

below

Figure 214 Creating new layout

Dialog box as shown in figure below enter the default technology template

located on cCrCAD CrCAD_103toolslayout plusdata_defaulttch in

―Input layout TCH text box

Enter the net list (generated in the capture CIS) of your design in ―input MNL

textbox And then the location and file name that you want the file design to

be saved in output ―layout text box

58

Layout plus will give the output layout file name as same as the input netlist

file by default If you change file do not change the output file extension

(max) Then apply ECO

There are three browse boxes In first box we have to provide the path for the

input layout file that we have created in capture

Figure 215 Auto ECO tab after creating new design

Layout will display the dialog shown in figure 213 after you apply ECO In

case footprint linking error (missing footprint on same components) you will

need to give the footprint to all missing components to complete AutoECO

Hit ―Accept this ECO to import the netlist into layout plus Figure shows the

layout plus window after importing a netlist

59

Figure 216 After all footprints are selected

As you apply the ECO a new design is opened

All the yellow line shown in the layout is the connection If you want to

change the pad of the any components first disable the drc from the tool

menu

Figure 217 Display DRC

Now double click the component

60

Figure 218 Edit component

Now place the component according to the requirement so the minimum

connections overlap each other

Figure 219 Designing circuit

61

28 CONVERTING CONNECTIONS INTO TRACKS

Now click on the edit segment mode button from tool menu to start

conversion of connection into tracks

Figure 220 Edit segment mode

Left click on the any connection how it get started to change in red line

Before this select the bottom layer from the tool bar

Figure 221 Selecting layer for tracks

62

Now move the cursor toward the yellow connection so that we will completely

convert connection into track

Figure 222 Converting connection to tracks

29 BROAD OUTLINE

Now make the board outline For this select the obstacle option from the tool

Figure 223 Selecting obstacle tool

63

Now again go to tools obstacle option click newand broad outline

Figure 224 Selecting obstacle new

Figure 225 Drawing board outline on global layer

The empty space is filled by copper pour

64

Fig226 Orcad layout of Bluetooth controlled folk lifter car

210 POWER SUPPLY FOR FOLK LIFTER CAR

The most common form of nine-volt battery is commonly called the transistor

battery which was introduced for the early transistor radios It has a rectangular prism

shape with rounded edges and a polarized snap connector at the top This type is

commonly used in pocket radios and other small electronic devices They are also

used as backup power to keep the time in certain electronic clocks This format is

commonly available in primary carbon-zinc and alkaline chemistry in primary

lithium iron disulfide and in rechargeable form in nickel-cadmium nickel-metal

hydride and lithium-ion Mercury oxide batteries in this form have not been

manufactured in many years due to their mercury content This type is designated

NEDA 1604 IEC 6F22 and Ever Ready type PP3 (zinc-carbon) or MN1604 6LR61

(alkaline)Most nine-volt alkaline batteries are constructed of six individual 15V

LR61 cells enclosed in a wrapperThese cells are slightly smaller than LR8D425

AAAA cells and can be used in their place for some devices even though they are

35 mm shorter Carbon-zinc types are made with six flat cells in a stack enclosed in

a moisture-resistant wrapper to prevent drying As of 2007 9-volt batteries accounted

65

for 4 of alkaline primary battery sales in the US In Switzerland as of 2008 9-volt

batteries totalled 2 of primary battery sales and 2 of secondary battery sales Other

nine-volt batteries of different sizes exist such as the British Ever Ready PP series

and certain lantern battery

Fig 227 9 volt battery

2101 CONNECTORS OF A BATTERY

Fig 228 Battery cap

The battery has both terminals in a snap connector on one end The smaller circular

(male) terminal is positive and the larger hexagonal or octagonal (female) terminal is

the negative contact The connectors on the battery are the same as on the connector

itself the smaller one connects to the larger one and vice versa The same snap style

66

connector is used on other battery types in the Power Pack (PP) series Battery

polarization is normally obvious since mechanical connection is usually only possible

in one configuration A problem with this style of connector is that it is very easy to

connect two batteries together in a short circuit which quickly discharges both

batteries generating heat and possibly a fire An advantage is that several nine-volt

batteries can be connected to each other in series to provide higher voltages

67

CHAPTER-3

RESULTS AND DISCUSSION

31 RESULTS

In our minor project we have made a Bluetooth control folk lifter car with the help of

Bluetooth module By using interfacing of these modules we made this projects which

are application of the module which are discussed above This projects using modules

helps in making the devices which we use in our daily life or we may increase the part

of technology in our life The projects that we made using the modules

Bluetooth Module

- Bluetooth based LCD display

- Bluetooth based LED display

-Bluetooth based robotic car

- Bluetooth based home appliances controlling

- Bluetooth based motor monitoring system

32 DISCUSSION

Embedded Technology is now in its prime and the wealth of knowledge available is

mind blowing There are many open source designs available for study and use by

anyone from a hobbyist to an engineer Before moving into a detailed discussion on

embedded systems it is best to understand the essence of an embedded system What

can we call an embedded system and how is it different from a computer There are

many answers each coming from experts treating these systems from different point

of views But almost all definitions agree on a few basic characteristics of an

embedded system

It is a system built to perform its duty completely or partially independent of human

intervention

It is specially designed to perform a few tasks in the most efficient way

68

It interacts with physical elements in our environment viz controlling and driving a

motor sensing temperature etc

One of the most important distinguishing factor between an embedded system and a

computer is the constraints on system resources Unlike modern day computers an

embedded system is usually designed to be compact energy efficient and

inexpensive Another factor is that a computer is capable of performing a variety of

tasks completely independent of each other Though many advanced embedded

systems exhibit multi-tasking capabilities it is unreasonable to expect a system

operating on washing machines to provide capability to play digital music From an

implementation viewpoint there is a major difference between a computer and an

embedded system Embedded systems are often required to provide Real-Time

response A Real-Time system is defined as a system whose correctness depends on

the timeliness of its response Examples of such systems are flight control systems of

an aircraft sensor systems in nuclear reactors and power plants For these systems

delay in response is a fatal error A more relaxed version of Real-Time Systems is the

one where timely response with small delays is acceptable An example of such a

system would be the Scheduling Display System on the railway platforms In

technical terminology Real-Time System scan be classified as

Hard Real-Time Systems- Systems with severe constraints on the timeliness of the

response

Soft Real-Time Systems- Systems which tolerate small variations in response

times

Hybrid Real-Time Systems- Systems which exhibit both hard and soft constraints

on its performance

As we go into more detail about these systems we will learn that Real-Time

constraints pose a very difficult implementation problem Complex problems like

scheduling and resource management do tend to appear like ten headed fire breathing

dragons to most newcomers in this field

69

CHAPTER-4

CONCLUSIONS AND FUTURE SCOPE

41 CONCLUSION

Embedded systems are very different from any general-purpose computer in many

ways Typical characteristics of such systems are explained below

1 Single function Unlike software packages such as word processor spreadsheet and

web browser or a database in a library or in a bank embedded system executes only

one program repeatedly

2 Interact with real world directly These systems are usually directly connected to

real-world environment via various sensors and interfacing modules Users can

directly control or change their parameters as and when needed

3 Works under tight constraints Embedded systems have limited resources in terms

of memory processing power and peripherals to interact with other systems Power

constraints are also major such that many devices need to run using small sized

batteries for many years without faltering Besides this the form factor (physical

footprint) weight material cost etc are common constraints on embedded systems

4 Mostly built as reactive mechanism Since embedded systems are built for specific

purpose and dedicated function they are usually built as a reactive mechanism such

that their functioning is triggered by external response or feedback

5 Highly reliable Many embedded systems are deployed in severely hostile

environment where common machines or instruments computers would usually failto

operate Yet embedded systems in such conditions operate without any problems

Additionally these systems often reside in machines that are expected to run

continuously for years without errors and in some cases recover on its own if an error

occurs

70

For using embedded system programming you have to be much more aware of the

resources used in embedded systems programming than you have to in ―ordinary

programs

Time

Space

Communication channels

Files

Flash memory

ROM (Read-Only Memory)

In order to catch up with international trends in embedded systems industry and

institutions both have to do some work on their part

1 Mature electronic prototyping methods and systems need to be established so that

ideas could be validated faster and products would come well in time in the market

2 Ecosystem for electronic manufacturing esp low level hardware support as well as

high level product development needs to be augmented Since there is sheer lack of

such an ecosystem it not only poses challenges to industries but also to institutions in

terms of futuristic research and studies

3 Work towards innovations ndash not only in terms of technology but also in developing

new products and uses New generation engineers are coming up with many new and

novel ideas in this field however lack of end-to-end support is becoming key