Blast Chiller and Shock Freezer Systems - RHI Solutions · 2017-10-04 · Blast Chiller and Shock...

Transcript of Blast Chiller and Shock Freezer Systems - RHI Solutions · 2017-10-04 · Blast Chiller and Shock...

Blast Chiller and Shock Freezer Systems

Pizza/Cold Prep Tables Designed for convenience and efficiency with special temperature control

ThermalRite Blast Chillers and Shock Freezers offer

winner of the Kitchen Innovations® 2014 AwardPresented by the National Restaurant Association, Restaurant Hotel-Motel Show®

Walk-ins, Blast Chillers, Cold Prep Tables – ask us about ways to keep cool!

Blast Chillers and Freezers can help your operation run more efficiently and economically!

ThermalRite brings you superior products!Manufactured to rigorous standards – we offer our commitment to bring you the highest quality products designed for reliability, functional excellence, and ease of use.

Our primary concerns include:

1. Developing products designed to suit your needs.

2. Offering a range of models and sizes, all of which are easy to operate.

3. Focusing on features to promote food safety.

4. Saving energy (and focusing on ways to lower your energy bills).

5. Manufacturing with the environment in mind.

2

How does “Blast Chilling” work?A blast chiller is a forced ventilation refrigerating appliance. It works to remove heat rapidly using high-speed continuous, even air flow – so continuous that it chills the food to its core in a very short time. It could be compared to a convection oven in which air is used for rapid heating transmission.

Air Cooling Movement

ONLY 100mm WIDE

The Secret’s in the Wall!ThermalRite’s CypenVac™ Technology keeps cold in – keeps heat out. Offered on its blast chillers and freezers, can reduce energy consumption by up to 43%! That means lower energy bills for you.

CypenVac™ vacuum technology significantly increases the thermal resistance of insulation panels used in blast chillers and other insulated cabinets and, used in conjunction with conventional polyurethane insulation, can reduce energy consumption by up to 43%.

honored WiTh KiTChen

innovaTions® 2014

aWard

The Revolutionary CypenVac™ Vacuum-insulated Panel

CypenVac Technology forms a protective film layer that traps in the cold while resisting heat

CFC- and HCFC-free Polyurethane Foam is vacuum sealed for superior thermal conductivity resistance

The Environment Inside Your Kitchen… Inside Your ThermalRite Blast Chiller

3

4

Blast Chilling BasicsWhat is blast chilling?Blast chilling is a method of cooling food quickly to a low temperature so it is safe from bacterial growth. Bacteria multiples most rapidly between 50°F and 150°F. By reducing the temperature of cooked food to 38°F or below within 90 minutes, food is made safe for storage and later consumption.

Because blast chilling helps ensure the safety and quality of food, it is a method frequently used by chefs, restaurateurs, caterers, fast food producers, bakeries, confectioners, and ice cream makers.

Why does food need to be chilled so quickly? Only when food is chilled very quickly is its quality, flavor, taste and texture optimally maintained. Normal chillers cool foods slowly. This allows large ice crystals (macro-crystals) to be formed in the process, damaging the food’s cells, so when it is thawed, its consistency and quality have been compromised. Blast chilling utilizes very low temperatures so only small ice crystals (micro-crystals) are formed, and they are not damaging to the food’s structure.

Micro ice crystals form with ThermalRite Shock Freezing

Macro ice crystals form without Shock Freezing

+194°F

+149°F

CRITI

CAL

TEM

PERA

TURE

RA

NG

E

+37°F

+194°F

+37°F

0°F

With ThermalRite Blast Chiller, low bacterial proliferation

Without Blast Chiller, higher bacterial proliferation

Blast Chilling

Shock Freezing

Macro ice crystals (which form in ordinary freezers) damage the product structure

Micro ice crystals (which form in blast freezers) do not damage the product structure

Protecting and Preserving Your Food

Blast chillers are a necessity to meet HACCP guidelinesA blast chiller is indispensable if HACCP guidelines are to be met. Normal coolers simply do not bring temperatures down quickly enough. The blast chiller allows critical points to be controlled during chilling and ensures that the food’s quality, flavor, taste, texture and nutritional value are maximally preserved. Blast chilling inhibits the growth of bacteria on food while maintaining its proper moisture content. After defrosting, there will not be a loss of liquid, flavor, or firmness.

Keep Your Food Safe by Following HACCP GuidelinesAverage ambient air temperatures in a working kitchen range from 77°F to 95°F. Unfortunately, this is the ideal temperature to encourage the proliferation of bacteria. Blast chilling or shock freezing foods slows down the reproduction of micro-organisms and makes certain enzymes inactive. The result is increased stability of stored food and ensured food safety while maintaining its quality, flavor, taste and texture.

Using blast chilling/shock freezing technology, the core temperature of food can be brought down very quickly to 0°F. Though bacteria are not totally eliminated, their growth is seriously slowed by thermal shock as they are cooled from +194°F to 0°F within 270 minutes. The rapid cooling process works to extend shelf life for a few months.

On the other hand, normal refrigerators and freezers cool foods more slowly, a less desirable method. The slower cooling allows large ice crystals (macro-crystals) to be formed. These macro-crystals can rupture the food’s cell walls (allowing fluids to escape), breaking down the structure, spoiling its consistency and compromising the quality of the food. This damage is most apparent once the food has been thawed.

Ordinary freezers are intended for the storage of “ready-frozen” products, not as a place to quickly cool or freeze food – the cooling process is too slow and the product texture and consistency suffer.

Shock freezing quickly takes food to a core temperature of 0°F. Thanks to the appliance’s power, high-speed ventilating features, and very low operating temperatures, only small ice crystals (micro-crystals) are formed on food, so customers are pleased to find that product consistency, texture, taste, smell and nutritional value are maintained.

5

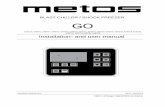

New Controller – Now in a Better Place!

Now more conveniently placed, our electronic, touch screen control panel is even easier to use. With the capability to hold 99 customized recipes, you can make operations easier by pre-loading the specifications for cooling and holding cycles for your most commonly prepared foods. Equipped with a USB port and an internal HACCP alarm with memory.

Optional Printing Module and Sterilizing Kit are available.

10 Facts You Need to Know About ThermalRite Blast Chillers and Freezers 1. CypenVac™ Technolgy, winner of the prestigious Kitchen Innovations® 2014 Award, is offered only

on ThermalRite Blast Chillers and Freezers. CypenVac™ Technology can reduce energy up to 43%.

2. Easy-to-use electronic, touch-screen control panel – now more conveniently placed!

3. 2-year Parts and Labor Warranty. Additional Warranty for Years 3-5 on Compressor (part only).

4. Meets the demands of HACCP Guidelines for proper food chilling and freezing.

5. Interior rounded corners for easy cleaning.

6. Easy to operate – intuitive design simplifies kitchen work process and saves time.

7. Saves Energy (and money) utilizing exclusive, new technology.

8. CFC-/HCFC-free cyclopentane foaming extends effectiveness of insulation.

9. Manufactured with the environment in mind.

10. Ambient Chill Advantage – Our internal fans blow cool air on the walls, not on your food. Other manufacturers’ units have internal fans blowing air on your food, which can dry it out and adversely affect its texture and integrity.

Ask us about it!

6

Pizza/Cold Prep Tables Unparalleled Quality and Authentic Italian Design Choose the right table for your needs from our wide selection of models. Features available include: refrigerated condiment rail, ambient temperature dough drawers, and under-counter storage space in various sizes and configurations.

See chart on pages 8-9 for the full range of models and sizes with information about which features are available on each unit.

Which Options Do You Need?Consider these to improve quality and make your job easier:

• Refrigerated Condiment Rail – available in two types

1. Refrigerated Cold Wall Rail - an independent unit which sits on the table - offers clear, protective cover, an attractive option in an “open kitchen” where condiment choices can be seen and selected. Rails come in two lengths (offered on GPZ165A, GPZ166A, GPZ223A, and GPZ225A) and can also be purchased separately.

2. Refrigerated Direct Airflow Rail offers one of the widest temperature ranges available in its class: 28°F to 46°F. Stainless steel rail is an integral part of the unit; lift-up covers protect condiments (offered only on models FPTM2-80 and FPTM3-80).

• Dough Drawers – seven, stainless steel, ambient temperature drawers are designed to hold dough temporarily during the preparation period (offered on models GPZ165, GPZ165A, GPZ223 and GPZ223A) and can also be purchased separately.

See Thermalrite.com to see the complete set of specifications sheets for our Pizza/Cold Prep Tables.

Refrigerated cold wall condiment rail

Easy-to-use electronic digital control panel

Granite top, backsplash and side rails

Seven ambient temperature dough drawers

Slide-out refrigeration system

Front locking casters

Under-the-counter refrigerated storage space

Self-closing doorsVentilated front breathing

Standard Features• Designedbyexpertstoofferawiderangeoffeatures

and options

• MeetsdemandsofHACCPGuidelines

• Easy-to-useelectronicdigitalcontrolpanel

• Granitetop,backsplashandsiderailsforeasymaintenance of a hygienic work space

• Slide-outrefrigerationsystemsimplifiesmaintenance

• Frontlockingcasters

• Under-the-counterrefrigeratedstoragespace

• Self-closingdoorswithpush-fitmagneticdoorseal

• Ventilatedfrontbreathing

• Interiorroundedcornersforeasycleaning

• WireShelvesforstorageintherefrigeratedstoragespace

• Automaticdefrost–cabinetunit

• AutomaticEvaporation

• AISI304GradeStainlessSteelinteriorandexterior(except galvanized steel exterior bottom)

Environment• Manufacturedwiththeenvironmentinmind

• Ecological,R404Arefrigerant

• CFC/HCFC-free,cyclopentanefoamingextendseffectiveness of insulation

• LowerenergyconsumptionandlowerCO2 emissions

• Madeofnearly99%recyclablematerials

• ISO14001Certified

Options• RefrigeratedcoldwallcondimentrailonourGAseries

keeps ingredients cool and close-at-hand (also available in two lengths for purchase separately)

• Refrigerated,built-in,directairflowcondimentrailsystemon the FPTtM Series offers one of the widest temperature ranges available in its class: 28°F to 46°F

• Ambienttemperaturedoughdrawersallowyoutokeepdough at a temperature that’s ready to use (also available for purchase separately)

Warranty• 2-yearPartsandLaborWarranty

• AdditionalWarrantyonYears3-5onCompressor (part only)

7

Choosing the Right Pizza/Cold Prep Table for Your Needs

Model FPTM2-80

Model FPTM3-80

Model GPZ165

Model GPZ165A

Model GPZ166

Model GPZ166A

Capacity Undercounter (not incl drawer capacity)

14.05 cubic feet 21.88 cubic feet 6.2 cubic feet 6.2 cubic feet 14 cubic feet 14 cubic feet

Outside DimensionsWxDxH

65-1/8"x31-1/2" x44-1/8"

88-1/4"x31-1/2" x44-1/8"

65-3/8" x 31-1/2" x 40-1/2"

65-3/8" x 31-1/2" x 58-1/8"

65-3/8" x 31-1/2" x 40-1/2"

65-3/8" x 31-1/2" x 58-1/8"

Doors 2 3 1 1 2 2

Wire Shelves WxD

2 incl (holds 8)17" x 25"

3 incl (holds 12)17" x 25"

1 incl (holds 4)17" x 25"

1 incl (holds 4)17" x 25"

2 incl (holds 8)17" x 25"

2 incl (holds 8)17" x 25"

Shelf Guides 8 12 4 4 8 8

Ambient Temp 109°F 109°F 109°F 109°F 109°F 109°F

Refrigerated Condiment RailWxDxH

Pan Capacity*Indicates pans included

Direct Airflow RailBuilt into Unit

Holds 10 pans(not included)

Direct Airflow RailBuilt into Unit

Holds 12 pans(not included)

No–

–

Cold Wall65-3/16" x15" x 17-3/4"

1 ea 2/8 pan*6 ea, 1/3 pans

No–

–

Cold Wall65-3/16" x15" x 17-3/4"

1 ea 2/8 pan*6 ea, 1/3 pans

Dough Drawers No–

No–

Yes (7 ea)18" x 26"

Yes (7 ea)18" x 26"

No–

No–

Refrigerant/Condiment Rail R404A R404A R404A R404A /R134a R404A R404A /R134a

Elec Supply CabinetRail

110-115/60/1–

110-115/60/1–

115/60/1–

115/60/1115/60/1

115/60/1–

115/60/1115/60/1

HP Compressor Cabinet Rail

1/4–

1/2–

1/4–

1/41/12

1/4–

1/41/12

FLA/Circuit Ampacity CabinetRail

7.9/15–

12/15–

10.3/15–

Need two separate 20 Amp circuits

11.7/15–

Need two separate 20 Amp circuits

Watts CabinetRail

620–

900–

420–

420140

620–

620140

Amps CabinetRail

6.5–

9.9–

5.4–

5.41.6

6.5–

6.51.6

Amp Fuse CabinetRail

15–

15–

15–

1515

15–

1515

NEMA CabinetRail

5-15–

5-15–

5-15–

5-155-15

5-15–

5-155-15

Cord Length CabinetRail

8’–

8’–

8’–

8’8’

8’–

8’8’

Shipping Wt (lbs) 331 464 660 770 661 772

Ship Pkg Dimensions (WxDxH)

70-1/2" x 35-3/4" x51-5/8"

93-1/4" x 35-3/4" x51-5/8"

70-1/8" x 35-7/8" x43-1/4"

70-1/8" x 35-7/8" x51-5/8"

70-1/8" x 35-7/8" x43-3/8"

70-1/8" x 35-7/8" x57-7/8"

Freight Class 150 150 150 150 150 150

8

Model GPZ223

Model GPZ223A

Model GPZ225

Model GPZ225A

Model GA166 Rail Only

Model GA223 Rail Only

Capacity Undercounter (not incl drawer capacity)

14 cubic feet 14 cubic feet 21.9 cubic feet 21.9 cubic feet – –

Outside DimensionsWxDxH

87-7/8”x 31-1/2” x 40-1/2”

87-7/8”x 31-1/2” x 58-1/8”

88-3/8” x 31-1/2” x 40-1/2”

88-3/8” x 31-1/2” x 58-1/8”

65-3/8” x 15” x 17-3/4”

87-7/8” x 15-1/8” x 17-3/4”

Doors 2 2 3 3 – –

Wire Shelves WxD

2 incl (holds 8)17” x 25”

2 incl (holds 8)17” x 25”

3 incl (holds 12)17” x 25”

3 incl (holds 12)17” x 25”

– –

Shelf Guides 8 8 12 12 – –

Ambient Temp 109°F 109°F 109°F 109°F 100°F 100°F

Refrigerated Condiment RailWxDxH

Pan Capacity*Indicates pans included

No

–

Cold Wall87-7/8”” x15-1/8” x 17-3/4”

10 ea, 1/3 pans(not included)

No

–

Cold Wall87-7/8” x15-1/8” x 17-3/4”

10 ea 1/3-pans(not included)

Cold Wall65-3/8” x15” x 17-3/4”

1 ea 2/8 pan*6 ea, 1/3 pans

Cold Wall87-7/8” x15-1/8” x 17-3/4”

10 ea 1/3-pans(not included)

Dough Drawers Yes (7 ea)18” x 26”

Yes (7 ea)18” x 26”

No–

No–

No–

No–

Refrigerant R404A R404A R404A R404A R134a R134a

Elec Supply CabinetRail

115/ 60/1–

115/ 60/1115/ 60/1

115/ 60/1–

115/ 60/1115/ 60/1

-115/ 60/1

-115/ 60/1

HP Compressor Cabinet Rail

1/4–

1/41/12

1/4–

1/41/12

–1/12

–1/12

FLA/Circuit Ampacity CabinetRail

11.7/15–

Need two separate 20 Amp circuits

15.9/20–

Need two separate 20 Amp circuits

–1.8/15

–1.8/15

Watts CabinetRail

620–

620140

690–

690140

–140

–140

Amps CabinetRail

6.5–

6.51.6

7–

71.6

–1.6

–1.6

Amp Fuse CabinetRail

15–

1515

20–

2015

–15

–15

NEMA CabinetRail

5-15–

5-155-15

5-15–

5-155-15

–5-15

–5-15

Cord Length CabinetRail

8’–

8’8’

10’–

10’8’

–8’

–8’

Shipping Wt (lbs) 882 992 882 992 110 132

Ship Pkg Dimensions (WxDxH)

95-1/2” x 35-7/8” x43-1/4”

95-1/2” x 35-7/8” x51-5/8”

93-3/8”x 35-7/8” x43-3/8”

93-3/8” x 35-3/4” x59-7/8”

67-3/4” x 17” x11-3/4”

90-1/8” x 16-1/8” x11-3/4”

Freight Class 150 150 150 150 150 150

9

REACH-IN MODELS

Model GBF15-11S

Model GBF44-26SP/TS

Model GBF52-37S/TS

Model GBF77-55S/TS

Model GBF143-110S/TS

Model GBF171-132S/TS

Capacity*

*Pans and racksnot included

3 pans12"x14"x2-1/2"

4 pans 12"x20"x2-1/2"

6 pans 12"x20"x2-1/2"

10 pans 12"x20"x2-1/2"

14 pans 12"x20"x2-1/2"

17 pans 12"x20"x2-1/2"

N/A5 pans18"x26"x1"

6 pans18"x26"x1"

10 pans18"x26"x1"

15 pans18"x26"x1"

18 pans18"x26"x1"

Distance Between Racks 2-3/4" 2-11/16" 2-11/16" 2-11/16" 2-11/16" 2-11/16"

Outside DimensionsWxDxH

23-5/8"x23-5/8"x15-3/16" high

31-1/2" x 31-11/16" x33-3/4" high

31-1/2" x 32-7/8" x 44-13/16" high

31-1/2" x 32-7/8" x64-5/16" high

31-1/2" x 32-7/8" x77-5/16" high

31-1/2" x 32-7/8" x84" high

Door Left-hinged Right-hinged Right-hinged Right-hinged Right-hinged Right-hinged

Output Chilling Capacity

+194°F / +37°F15 lbs within 90 minutes

+194°F / +37°F44 lbs within 90 minutes

+194°F / +37°F52 lbs within 90 minutes

+194°F / +37°F77 lbs within 90 minutes

+194°F / +37°F143 lbs within 90 minutes

+194°F / +37°F171 lbs within 90 minutes

Output Freezing Capacity

+194°F / 0°F11 lbs within 270 minutes

+194°F / 0°F26 lbs within 270 minutes

+194°F / 0°F37 lbs within 270 minutes

+194°F / 0°F55 lbs within 270 minutes

+194°F / 0°F110 lbs within 270 minutes

+194°F / 0°F132 lbs within 270 minutes

With use of stainless wire shelves, not incl.

11 lbs in ice cream pans (ea 3-4-5L)

26 lbs in ice cream pans (ea 3-4-5L)

37 lbs in ice cream pans (ea 3-4-5L)

55 lbs in ice cream pans (ea 3-4-5L)

110 lbs in ice cream pans (ea 3-4-5L)

132 lbs in ice cream pans (ea 3-4-5L)

Refrigeration DataRefrigerantR404A

RefrigerantR404A

RefrigerantR404A

RefrigerantR404A

RefrigerantR404A

RefrigerantR404A

CypenVac Energy-Saving Insulation Technology No No No No Yes Yes

Heat Load BTU/HR* 1850 9460 9625 11,850 18,600 18,600

Electrical Supply 110-115/60/1 110-115/30/1 208-220/60/1 220/60/3 220/60/3 220/60/3

FLA/Circuit Ampacity 5/15 8/20 11/20 9/11/15 20/24/40 20/24/40

Amps 5 8 11 9 20 20

Amp Fuse 15 20 20 15 40 40

NEMA 15 Amp 6-20 20 Amp 6-20 20 Amp Cord only Cord only Cord only

Cord Length 10' 10' 10' 16'-6" 16'-6" 16'-6"

Compressor HP 0.625 1.5 2.2 3.0 3.5 3.5

Shipping Weight (lbs)Pkg Dimensions (WxDxH)

11026" x 26" x 26"

26435" x 35" x 42"

33035" x 35" x 52"

40035" x 35" x 71"

49535" x 35" x 84"

55035" x 35" x 91"

Freight Class 150 150 150 150 150 150

* BTUs are rated at 104°F ambient and -40°F evaporator temp.

10

Models GBF242-209RS/TS

Model GBF440-385R/TS

Model GBF837-727R/TS

Condensing Unit Remote Remote Remote

Capacity*

*Pans and racksnot included

1 Roll-in Rack Max size: 27” W x 29”D x 72”H Roll-in rack holds up to twenty (20) 12 x20x2-1/2”D food pans.

1 Roll-in RackMax size: 29”W x 37”D x 74”HRoll-in Rack holds up to forty (40) 12x20x2-1/2”D food pans or up to twenty (20) 18x26” sheet pans

2 Roll-in RacksMax size: 29”Wx 30-1/2”D x 74”H. Each Roll-in Rack holds up to forty (40) 12x20x2-1/2”D food pans or up to twenty (20) 18x26” sheet pans

Outside Dimensions – not incl. Cond. Unit WxDxH

49-9/16” x 39-1/4” x 89-3/4”H 59-1/16” x 52-11/16” x 88-9/16”H 59-1/16” x 76-5/16” x 88-9/16”H

Outside DimensionsCOND. UNIT ONLY WxDxH

35-9/16” x32-1/8” x27”H 52-1/8” x 39-1/2” x 28”H 52-1/8” x39-1/2” x 28”H

Door Reversible Reversible Reversible

Output Chilling Capacity**+194°F / +37°F242 lbs within 90 minutes

+194°F / +37°F440 lbs within 90 minutes

+194°F / +37°F837 lbs within 90 minutes

Output Freezing Capacity***

+194°F / 0°F 209 lbs within 270 minutes

+194°F / 0°F 385 lbs within 270 minutes

+194°F / 0°F 727 lbs within 270 minutes

With use of roll-in rack, not incl.

209 lbs in ice cream pans (ea 3-4-5L)

385 lbs in ice cream pans (ea 3-4-5L)

727 lbs in ice cream pans (ea 3-4-5L)

Thaw Option Available Standard Standard Standard

Advanced Touch Screen Controller Yes Optional Optional

Refrigeration Data Refrigerant R404A Refrigerant R404A Refrigerant R404A

CypenVac Energy-Saving Insulation Technology Optional Optional Optional

Heat Load BTU/HR* 27,900 44,900 58,700

Electrical Supply 220/60/3 220/60/3 220/60/3

FLA/Circuit Ampacity 45/55/60 45/55/60 45/55/60

Amps 30 Amp Draw; 40 Amp Circuit 45 45

Amp Fuse 45 60 60

NEMA Cord only Cord only Cord only

Cord Length 16’-6” 16’-6” 16’-6”

Compressor HP 4.5 8.5 11.5

Shipping Weight (lbs)Pkg Dimensions (WxDxH)

55052" x 42-1/2" x 98" high

81565 x 57 x 97” high

88065” x 82” x 97” high

Freight Class 150 150 150

* BTUs are rated at 104°F ambient and -40°F evaporator temp.

11

We reserve the right to change specifications without notice.

ThermalRite15600 37th Ave N Suite 100Plymouth, MN 55446USA800-328-3968Thermalrite.com

Form # BlCh0215Copyright 2015

ThermalRite Products are Sold NationwideCall 800-328-3968 and ask for the contact information for your local rep. Or, visit thermalrite.com and click on “Find a Local Rep” on the home page.

We develop cold solutions for Restaurants, Hotels, Nursing Homes, Bakeries, Stadiums, Country Clubs, Universities, Self-serve, Hospitals, Caterers, Fast Casual, Banquet Facilities, Grocery Stores, Airport Catering, Ice Cream Producers, Marinas, Specialty Food Shops, Assisted Living, Fast Food, Canteens, and more!

25

25

25

24

22

20

27

15

16

19

18

17

7

1

2

4

5

11

1412

13

26

3

Plants are located in California, Minnesota, Mississippi and Tennessee.