Biscuit and cookies

-

Upload

indian-institute-of-crop-processing-technology -

Category

Food

-

view

159 -

download

1

Transcript of Biscuit and cookies

Biscuit And CookiesBY

Pintu Choudhary

Master of Technology

( Food Science and Technology)

Indian Institute of Crop Processing Technology

Ministry of Food Processing Industries

Government of India

Thanjavur - 613005

Biscuit

• It is generally recognized that these products

are cereal based and baked to a moisture

content of less than 5%.

• Biscuits are delicate, crisp crust and peels

apart in tender layers

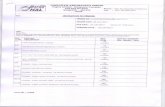

Status of bakery industry in India

• The annual production of bakery products was 50 lakh

tones in 2004-05 with estimated value of Rs. 69 billion

• The organized sector has a market share of 45 per cent

and the balance 55 per cent is with the unorganized sector

in the baked products.

• The large organized sector players who are prominent in

the high- and medium-price segments include Britannia,

Modern Industries Ltd.

Source: FSSAI report 2004-2005

Status of bakery industry in India

• Local manufacturers with numerous local brands cater to

populous segment and contribute considerably in the

bread segment.

• The major brands of biscuits are – Britannia, Parle,

Bakeman, Priya Gold etc.

• The per capita consumption of biscuits in our country is

about 1.52 kg as compared to more than 12 kg in

developed countries

Source: FSSAI report 2004-2005

Types Of Biscuit DoughB

iscu

it

Hard

High water content, Low fat and low sugar

Tough & Extensible

Crackers e.g. Krack Jack, Monaco

soft

Less Water

High fat & high sugar

Classification of Biscuits

By degree of enrichment and

processing

Hard dough biscuits

Semi hard dough biscuits

Soft dough biscuits

By method of shaping

Embossed cutting

Rotary mounding

Rotary cutting

Ingredient Of Biscuit

Major

Wheat flour

Sugar

Shortening

Water

Leavening agent

Minor

Milk powder

Liquid glucose

Emulsifier

Salt

Enzyme

Antioxidant

Colour

Invert sugar

Sodium meta bi-sulphide

General Steps In Biscuit Manufacturing

Step 1• Preparation of ingredients

Step 2• Mixing of ingredients

Step3• Rotary molding

Step 4• Baking & cooling

Step 5• Packaging

Step 6• Storage & distribution

Preparation Of Ingredient

• Maida sifting - it passes through 30 Mesh gyro screens to

remove foreign particle.

• Sugar grinding - after grinding the sugar, it is passed through

sieve size of about 0.7 mm.

• Flavour mix preparation

• Reprocessed biscuit

• SMP Sifting - The SMP is shifted through 20 meshes to

separate any foreign matters from the particle.

• Invert sugar syrup preparation

Mixing Section

Note

Batch size -168 kg (dry

basis)

Reprocessed biscuit added

- 5 kg /batch.

Final dough pH- 6.5

Final dough temp 28-30 C

Forcing roll

Die roll

Rubber roll

Transfer knife

Penning table

Oven conveyor

M

o

l

d

i

n

g

Scrap

Blower

Hopper

• Oven used for baking is divided into various zones

according

to temp employed.

• Number of zones required upon rpm used.

• There are 3 major sections:

(230-280˚C)(180-200 ˚C)

Puffing section

Baking section

Colouring section

Baking Section

Cooling Of Biscuit

• Source of heat used in oven is

propane

• Propane is injected along with air

under high pressure .

• RTD (Relative temperature display)

temperature measuring device.

• After baking :

- M/C of biscuits 1.8%

- Temp of biscuits 90-100 ˚C.

• Cooling of biscuits to 45 ˚C.

Cookies

• Cookies may be defined as small cakes made from dough that is sufficiently viscous to permit the dough pieces to be baked on flat surface.

• Cookies are often referred to as small cakes.

• In our country these are commonly known as biscuits

Types Of CookiesC

oo

kies

According to mixing

Batter type

Drop /short cookies

Stiff batter cookies

Short bread cookies

Foam type

Meringue

Sponge cookies

According to basic machine used for

production

Types of cookies

According to basic machine used for production

Deposit cookies Wire cut cookies Bar type cookiesCutting machine

cookies

Process Of Cookie Manufacturing

Sieving of Maida and baking powder

Creaming of fat and sugar

Beating of egg and vanilla

Mix Maida and half peanut

Folding of flour and mix

Process of cookies manufacturing

Addition of milk

Preparation of dough

Sheeting and molding

sprinkling

Baked at 350f for 20 minutes

References

• Oxford University Press, "Oxford Dictionaries Online: 'biscuit'“

• Biscuit" (http://www.merriamwebster. com/dictionary/biscuit).

Merriam Webster. Retrieved 14 January 2010.

• "Cookie" (http://www.merriamwebster. com/dictionary/cookie).

Merriam Webster. Retrieved 14 January 2010.

• 10. ^ David, Elizabeth (17 Nov 1977). "Yeast Buns and Small Tea

Cakes". English Bread and Yeast Cookery.

• Illustrated by Wendy Jones (1 ed.). Allen Lane. sec. "Soft Biscuits".

ISBN 9780713910261.

• "Biscuits & Cookies

(http://www.foodtimeline.org/foodcookies.html). Food Timeline.

Retrieved 15 January 2010

![Untitled-2 [kualalumpur.concordehotelsresorts.com] · Pineapple Tart, Kuih Kapit, Almond Biscuit, Seaweed Biscuit CNY 2 Pineapple Tart, Butter Cookies, Peanut Cookies, Kuih Bangkit](https://static.fdocuments.net/doc/165x107/5e52460991650e3ac33bdf73/untitled-2-pineapple-tart-kuih-kapit-almond-biscuit-seaweed-biscuit-cny-2.jpg)