Biogas Flares (2.0)

-

Upload

natasha-martin -

Category

Documents

-

view

228 -

download

0

description

Transcript of Biogas Flares (2.0)

I.C.E.’s background

As a small branch derived from the

refinery models this kind of equipment is

now an hold point in every waste water

treatment plant.

With near twenty years of experience in

the design and manufacturing of biogas

flare system, coupling regulations and

practice, we can ensure to our customer

the right solution to their needs.

General equipment description

Biogas in excess from various sources

needs to be burnt across a flare system.

Here comes our specific knowledge and

experience in waste gases combustion,

derived from years of practice.

A typical installation consists of:

1- A main gas outlet (the flare tip), which

is the main biogas burner.

2- A support structure completed with

access ladder with bodyguard and

maintenance platform.

3- A valve train for gas control (in

weather or explosion proof execution,

electric or pneumatic).

4 - An adjustable syphon that enable to

change the safeguarding pressure of the

water seal.

5- A pilot burner, made from stainless

steel, for flare tip ignition.

6- A control panel that is mounted at

operator’s height which includes control

logic for ignition of the pilot burner, flame

revelation and the opening of the

interlock valves mounted on gas train.

7- The level indicator to check the height

of water seal level.

Special execution can be made of all of

our equipments, changing std. materials

for steelworks to AISI 304, 310 or 316

stainless steel.

Surface finish can be done in according

to our std. or to client’s specifications.

I.C.E. biogas flare system are designed

to minimize siteworks and installation

time and costs.

Equipment will be sent from workshop

completely assembled ready to be

erected and connected with supplies,

such as water for water seal feed, power

supply for control panel and biogas for

the flare itself.

Biogas flare systems

production:

● Ground flares (not visible

flame)

● Elevated flares

Mechanical features:

● Carbon steel body or 100%

stainless steel AISI from

grade 304 to 316-L special

executions

● All gas contacting parts are

rust free or in galvanised

steel

● Chrome nickel flare tip

● Pilot burner for flare

ignition or direct ignition on

small size flares

● Multiple platform system

Auxiliary equipment:

● Water seal

● Knock-out drums

● Flame arrestor

Instrumentations:

● Electric or electric /

pneumatic instrumentation

control

● Control panel in weather

proof or explosion proof

execution

● Pressure gauges or switch

on request

Ignition systems:

● High tension ignition with

H.T. transformer

● High energy ignition with

H.E. feeder

Control logic:

● Fully customizable control

logic according to plant

needs

● P&I engineered according

to major national and

international safety

standards

BIOGAS FLARE SYSTEMS - For waste water treatment plants

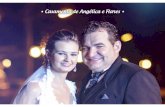

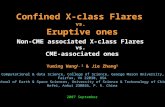

Plant overview with biogas flare Detail of Biogas flare installation

Since 1983 combustion equipment for the industries

INTERNATIONAL COMBUSTION EQUIPMENT S.r.l.

1

2

3

4

6

7

8

MAIN GAS INLET

5

STUD BOLTS

6

PILOT GAS LINE

MAIN GAS INLET

9

4

'A'

VIEW FROM 'A'

10

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

VIEW FROM 'A'

6

4

4

STUD BOLTS

7

8

MAIN GAS INLET

3

10

MAIN GAS INLET

PILOT GAS LINE

9

6

5

2

1

'A'

Height Depending on required radiation level at flare base, the flare’s height is affected by gas L.H.V., client’s specification or specific requests.

Capacity Typical from 5 Nmc/hr to more than 5.000 Nmc/hr

Inlet pressure Minimum required is 150 mm.w.c.

Flare tip dia. As required by flare capacity

Power supplies Line voltage 230V / 110V

Other supplies Water feeding to water seal Compressed air to pneumatic actuators (if required).

Safety devices Water seal Flame arrestor Temperature control

Characteristics (see also specifications & performances):

Specifications:

Equipments designed on

customer’s request,

including flow rate,

radiation at ground,

maximum noise level, etc.

Performances:

Performances based on the

carachteristics of the plant,

on the composition of the

gas to be burnt and on

specific requirements of the

plant

Basic design includes:

● Stable combustion with

CH4 percentage from

50%

● Suitable flame shape

taking into account biogas

flow from the tip, wind

velocity, discharge

pressure

Biogas flare system for waste water treatment plants

1 Flare tip

2 Flare body

3 Valve train

4 Adjustable syphon

5 Pilot burner

6 Maintenance platform

7 Control panel

8 Level indicator

9 Access ladder

10 Flame arrestor

Description:

Biogas flares assembly

International Combustion Equipment S.r.l. Technical & commercial offices : Via Forlanini 52 - 20043 Arcore (MI) - Italy

Phone : ++39.39.6180445 Fax : ++39.39.616884 - website : http://www.it-ice.com e-mail : [email protected] Workshop : Via degli Artigiani 26010 Cremosano (CR) - Italy - phone : ++39.373.273654 fax : ++39.373.291259