Bhupinder Singh

-

Upload

andrew-meyer -

Category

Documents

-

view

25 -

download

3

Transcript of Bhupinder Singh

DBFGI/ME/2K11/1002511294481

INDUSTRIAL TRAINING REPORT

ON

PARTS OF TRACTORS

AT

KING EXPORTS LUDHIANA

SUBMITTED IN PARTIAL FULFILLMENT OF THE

REQUIREMENTS FOR THE AWARD OF

DEGREE OF BACHELOR OF TECHNOLOGY IN MECHANICAL ENGINEERING

Submitted By

BHUPINDER SINGH

University Roll No: - 100251129481

SUBMITTED TO:

DEPARTMENT OF MECHANICAL ENGINEERING

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONS

MOGA (PUNJAB)

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)1

DBFGI/ME/2K11/1002511294481

DECLARATION

I hereby declare that the Industrial Training report entitled “Parts of Tractor” is an

authentic record of my own work as requirements of 6-months Industrial Training during

the period from Jan.2014 to May.2014 for the degree of B.Tech (Mechanical

Engineering). Desh Bhagt Foundation Group of Institutions (Moga), under the guidance

of Joginder Singh.

Bhupinder Singh

Roll.No.100251129481

Date………………….

Certified that above statement made by the student is correct to the best of our knowledge

and belief.

Signatures

Examined by:

1. 2. 3. 4. 5.

Head of Department

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)2

DBFGI/ME/2K11/1002511294481

ACKNOWLEDGEMENT

I am highly thankful to Mr. Arvinder Padda (Managing Director), for permitting me to join

the industry & to get useful in information about the plant. For full completion of my Industrial

Training, Training Report and the help during the Training Period. It is also

my pleasure to express my gratitude towards the staff of King Export Department

for their full Co-operation and giving me the knowledge of instrument and project to their

best.

First of all I would like to convey thanks to Mr. Dipender Kumar Dev (H.O.D. Mech.

Dept.) for giving me a motivation to join the industry for six months.

To sum up a heavy thanks to all those who through formal and informal way guided me throughout

my project work, I will cherish their support for the years to come. Finally I would like to convey

thanks to all the workers.

Bhupinder Singh

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)3

DBFGI/ME/2K11/1002511294481

TABLE OF CONTENTS

S.No Title P.No

1. Industrial Safety……………………………………………………..………….1

2. Introduction……………………………………………………………..………2-5

a. Certification

b. Quality Control

3. Tractor Information…………………………………………………………….6-15

4. CNC Machine…………………………………………………………………16-17

5. Press Machine…………………………………………………………...…….18-19

6. Infrastructural Set-Up…………………………………………………………20

7. a. Forging…………………………………......................................................21-24

b. Machining

c. Stamping

d. Welding

e. Finish and coating

8. Production Process…………………………………………………..……….25-31

9. Electrical Lighting System……………………………………………..…….32-33

10.Tractor Assembly…………………………………………….………….…..34-42

a. Differential Housing Assembly

b. Assembly of Crown wheel

c. Tail Pinion Assembly

d. PTO Shaft

e. Gear Box

11. Parts of Tractors……………………………………………………..…….43-66

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)4

DBFGI/ME/2K11/1002511294481

INDUSTRIAL SAFETY

Some of the safety precaution hazard checks measures and rules required to be taken in

care which very much to check any sort of possible accident or loss of material

machine.

1. Concentration towards work in. the key most think one should not allow his mind

here and there.

2. Throwing of things here and there, fun with tools and teasing of con-worker

should not be there.

3. Safety training should be given to the worker & they must be made aware of

safety requirements by expert lectures, film, posters etc.

4. A hazard checks list of all industry should be made where its made be cleared

that were guards against accident is not presided and where it should be

provided.

5. Safety rule should be general, not much general, not much broad, changing

with new environment and should be too much then required.

6. Steps should be taken to reduce noise in the industry.

7. Fire fighting appliances and fire exists should be ready for immediate use.

8. As there is lot of welding work so goggles safety caps, jackets, should he there,

jewelers ring, wristwatch, chain should not be allowed around moving

machinery.

9. Proper earthling of machine and other appliances should be done.

10. Proper lighting, ventilation, equipment easy to use should be there.

11. Smoking, running, and working of drunk workers should not be allowed.

12. Employers should never operate any equipment unless authorized.

13. First aid facilities should be there .with all needed equipment in it.

14. The condition of building including floor, roots, walls should be proper,

Slippery floor should not be there.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)5

DBFGI/ME/2K11/1002511294481

INTRODUCTION OF KING EXPORT

King Exports was set up in 1992 to manufacture & export Fasteners. It was promoted by

two visionary brothers – Mr. Sushil Goel & Mr. Madan Lal. It stared exports for South

East Asia & then spread its wings globally. It now exports to over 40 countries having

diversified markets from Japan in the East, through Middle East Asia & Europe to USA

in the West. The King Group now has four manufacturing facilities covering 380000 sq ft

area. Its exports in the previous year was around 18 million USD consisting mainly of

Towing parts, Trailer parts & Tractors Linkage parts. We, at King are continuously

striving for synergy between technology, systems, and system resources to provide

products and services that meet the quality, performance, and price aspirations of our

customers. While doing so, we maintain the highest standards of ethics and societal

responsibilities, constantly innovate products and processes, and develop teams that keep

the momentum going to take the company to excellence in the new millennium.

Manufacturer and exporter

of tractor linkage parts, top link, labeling assembly, tractor lift arm, long pins and lower

link pin.

Our range of products

We offer a comprehensive range of highly reliable agricultural farm equipments

including:

Business Type Exporter , Manufacturer

Capital in Dollars 18 Million U.S $

Export Percentage 100%

Primary Competitive

Advantages

Customer satisfaction, timely delivery and quality

management systems

Sales Volume 10 Million U.S $

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)6

DBFGI/ME/2K11/1002511294481

No of Staff 500

Year of Establishment 1992

No of Production Lines 5

Export Markets North America, Europe, Far East

Investment on Manufacturing

Equipment

5 million U.S $

OEM Service Provided No

No of Engineers 30

Monthly Production Capacity 400 Tonnes

Memberships EEPC, COFIEO, FEMA ( U.S.A), SEMA ( U.S.A )

Product Range Tractor Linkage Parts, Trailer Parts, Harrow, Plough

Discs

Website www.kingexports.in

Annual Turnover 100 Crores

Company Branches 5

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)7

DBFGI/ME/2K11/1002511294481

CERTIFICATION

1. ISO 9001:2000 From TUV

2. Can offer PPAP documentation as per T.S 16949 Requirements (Awaiting

Certification)

3. ROHS Compliant – Zinc plating Certification having Chrome 6+free plating

4. Material Inspection Certificate as per 3.1EN10204 norms

5. Products Conform to EC/94/20 Directives

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)8

DBFGI/ME/2K11/1002511294481

QUALITY CONTROL

We are ISO 9001:2008 certified and follow all international Industry. Apart from testing

our products in our world-class in house testing facilities we also have independent

testing partner Stork Laboratories, Iowa, USA for certifications.

Spark Emission Spectrometer, Model DV-6 Baird USA, Quick Carbon Sulfur

Determinator, Model CS-300 LECO USA, for rapid analysis of Carbon &

Sulfur.

Metallurgical Testing, X-Ray Fluorescence Spectrometer, Model EX-3500 Baird

USA, for non-destructive analysis of elements in powders and solids.

Micro Hardness Tester, Mitutoyo Japan, Load range up to 2 kg.

Physical test Laboratory, Neutral Salt Spray Corrosion testing.

Universal Testing Machine, MTS USA capacity SOT, with servo hydraulic

actuator.

Fatigue Testing Machine, MTS USA with 10 ton servo hydraulic actuator.

Impact Testing Machine, Rockwell cum Brinell Hardness Tester.

Erichsen Cupping Tester.

Profile Projector, Magnification 5, 10, 25 and l00 x.

Surface Roughness tester, Mitutoyo Japan.

Digital height Gauge, Sylvac Swiss, Accuracy 3 Microns.

3-D Co-ordinate Measuring Machine, Model BHN 710 Mitutoyo Japan

MISSION

TO create long term value for customers by providing quality products in time at

economical prices and by promoting a culture of continual improvment among our

employees & vendors in the field of Three Point Linkage Parts, Agriculture Machinery

Parts, Towing & Trailer Parts & Hardware Parts.

QUALITY POLICY

We are fully committed to satisfy customer needs through continual improvment in

effectiveness of our quality mnagment system and its awarness among our employees.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)9

DBFGI/ME/2K11/1002511294481

TRACTOR

A tractor is an engineering vehicle specifically designed to deliver a high tractive

effort (or torque) at slow speeds, for the purposes of hauling a trailer or machinery used

in agriculture or construction. Most commonly, the term is used to describe a farm vehicle

that provides the power and traction to mechanize agricultural tasks, especially (and

originally) tillage, but nowadays a great variety of tasks. Agricultural implementsmay be

towed behind or mounted on the tractor, and the tractor may also provide a source of

power if the implement is mechanised.

The word tractor was taken from Latin, being the agent noun of trahere "to pull". The

first recorded use of the word meaning "an engine or vehicle for pulling wagons or

ploughs" occurred in 1901, displacing the earlier term "traction engine" (1859).

NATIONAL VARIATIONS

In Britain, Ireland, Australia, India, Spain, Argentina, Slovenia, Serbia, Croatia,

and Germany, the word "tractor" usually means "farm tractor", and the use of the word

"tractor" to mean other types of vehicles is familiar to the vehicle trade, but unfamiliar to

much of the general public. In Canada and the US, the word may also refer to the road

tractor portion of a tractor trailer truck, but also usually refers to the piece of farm

equipment.

HISTORY

TRACTION ENGINES

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)10

DBFGI/ME/2K11/1002511294481

John Fowler pioneered the application of steam power to agriculture in the 1850s, and

invented machines for ploughing and digging drainage channels.

The first powered farm implements in the early 19th century were portable engines –

steam engines on wheels that could be used to drive mechanical farm machinery by way

of a flexible belt. Richard Trevithick designed the first 'semi-portable' stationary steam

engine for agricultural use, known as a "barn engine" in 1812, and it was used to drive a

corn threshing machine.[4] The truly portable engine was invented in 1839 by William

Tuxford of Boston, Lincolnshire who started manufacture of an engine built around a

locomotive-style boiler with horizontal smoke tubes. A largeflywheel was mounted on the

crankshaft, and a stout leather belt was used to transfer the drive to the equipment being

driven. In the 1850s, John Fowler used a Clayton & Shuttleworth portable engine to drive

apparatus in the first public demonstrations of the application of cable haulage to

cultivation.

In parallel with the early portable engine development, many engineers attempted to

make them self-propelled – the fore-runners of the traction engine. In most cases this was

achieved by fitting a sprocket on the end of the crankshaft, and running a chain from this

to a larger sprocket on the rear axle. These experiments met with mixed success. The first

proper traction engine, in the form recognisable today, was developed in 1859 when

British engineer Thomas Aveling modified a Clayton & Shuttleworth portable engine,

which had to be hauled from job to job by horses, into a self-propelled one. The alteration

was made by fitting a long driving chain between the crankshaft and the rear axle.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)11

DBFGI/ME/2K11/1002511294481

1882 Harrison Machine Works steam-powered traction engine.

The first half of the 1860s was a period of great experimentation but by the end of the

decade the standard form of the traction engine had evolved and would change little over

the next sixty years. It was widely adopted for agricultural use. The first tractors were

steam-powered plowing engines. They were used in pairs, placed on either side of a field

to haul a plow back and forth between them using a wire cable. In

Britain Mann's and Garrettdeveloped steam tractors for direct ploughing, but the heavy,

wet soil of England meant that these designs were less economical than a team of horses.

In the United States, where soil conditions permitted, steam tractors were used to direct-

haul plows. Steam-poweredagricultural engines remained in use well into the 20th

century until reliable internal combustion engines had been developed.[7]

GASOLINE-POWERED TRACTOR

Dan Albone with his 1902 prototype Ivel Agricultural Motor, the first successful

gasoline-powered tractor.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)12

DBFGI/ME/2K11/1002511294481

In 1892, John Froelich invented and built the first gasoline/petrol-powered tractor

in Clayton County, Iowa, USA. A Van Duzen single-cylinder gasoline engine was

mounted on a Robinson engine chassis, which could be controlled and propelled by

Froelich's gear box.[11] After receiving a patent, Froelich started up the Waterloo Gasoline

Engine Company and invested all of his assets. However, the venture was very

unsuccessful, and by 1895 all was lost and he went out of business.[12][13][14][15]

Richard Hornsby & Sons are credited with producing and selling the first oil-engined

tractor in Britain invented by Herbert Akroyd Stuart. The Hornsby-Akroyd Patent Safety

Oil Traction Engine was made in 1896 with a 20 hp engine. In 1897, it was bought by Mr.

Locke-King, and this is the first recorded sale of a tractor in Britain. Also in that year, the

tractor won a Silver Medal of the Royal Agricultural Society of England. That tractor

would later be returned to the factory and fitted with a caterpillar track.

The first commercially successful light-weight petrol-powered general purpose tractor

was built by Dan Albone, a British inventor in 1901. He filed for a patent on 15 February

1902 for his tractor design and then formed Ivel Agricultural Motors Limited. The other

directors were Selwyn Edge, Charles Jarrott, John Hewitt and Lord Willoughby. He

called his machine the Ivel Agricultural Motor, the word 'tractor' did not come into

common use until later. The Ivel Agricultural Motor was light, powerful and compact. It

had one front wheel, with solid rubber tyre, and two large rear wheels like a modern

tractor. The engine used water cooling, by evaporation. It had one forward and one

reverse gear. A pulley wheel on the left hand side allowed it to be used as a stationary

engine, driving a wide range of agricultural machinery. The 1903 sale price was £300.

His tractor won a medal at the Royal Agricultural Show, in 1903 and 1904. About 500

were built, and many were exported all over the world.[18] The original engine was made

by Payne & Co. of Coventry. After 1906,French Aster engines were used.

The first successful American tractor was built by Charles W. Hart and Charles H. Parr.

They developed a two-cylinder gasoline engine and set up their business in Charles City,

Iowa. In 1903, the firm built 15 "tractors", a term with Latin roots coined by Hart and

Parr, and a combination of the words traction and power. Their 14,000-pound #3 is the

oldest surviving internal combustion engine tractor in the United States, and is on display

at the Smithsonian National Museum of American History in Washington D.C. The two-

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)13

DBFGI/ME/2K11/1002511294481

cylinder engine has a unique hit-and-miss firing cycle that produced 30 horsepower at the

belt and 18 at the drawbar.

An early Fordson discing a field in Princess Anne County, VA in 1925.

In 1908, the Saunderson Tractor and Implement Co. of Bedford introduced a four-wheel

design, and went on to become the largest tractor manufacturer in Britain at the time.

While unpopular at first, these gasoline-powered machines began to catch on in the

1910s, when they became smaller and more affordable. Henry Ford introduced

the Fordson, the first mass-produced tractor, in 1917. They were built in the U.S., Ireland,

England and Russia, and by 1923, Fordson had 77% of the U.S. market. The Fordson

dispensed with a frame, using the strength of the engine block to hold the machine

together.[citation needed] By the 1920s, tractors with gasoline-powered internal combustion

engines had become the norm.

Harry Ferguson applied for a British patent for his three-point hitch in 1926, a three point

attachment of the implement to the tractor and the simplest and the only statically

determinate way of joining two bodies in engineering. The Ferguson-Brown

Company produced the Model A Ferguson-Brown tractor with a Ferguson-

designed hydraulic hitch. In 1938 Ferguson entered into a collaboration with Henry

Ford to produce the Ford-Ferguson 9N tractor. The three-point hitch soon became the

favorite hitch attachment system among farmers around the world. This tractor model

also included a rear Power Take Off (PTO) shaft that could be used to power three point

hitch mounted implements such as sickle-bar mowers. This PTO location set the standard

for future tractor developments.

ENGINE AND FUELS

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)14

DBFGI/ME/2K11/1002511294481

The predecessors of modern tractors, traction engines, used steam engines for power.

Since the turn of the 20th century, internal combustion engines have been the power

source of choice. Between 1900 and 1960, gasoline was the predominant fuel,

with kerosene (the Rumely Oil Pull was the most notable of this kind) and ethanol being

common alternatives. Generally, one engine could burn any of those, although cold

starting was easiest on gasoline. Often, a small auxiliary fuel tank was available to hold

gasoline for cold starting and warm-up, while the main fuel tank held whatever fuel was

most convenient or least expensive for the particular farmer. Dieselisation gained

momentum starting in the 1960s, and modern farm tractors usually employ diesel engines,

which range in power output from 18 to 575 horsepower (15 to 480 kW). Size and output

are dependent on application, with smaller tractors used for lawn mowing, landscaping,

orchard work, and truck farming, and larger tractors for vast fields of wheat, maize, soy,

and other bulk crops. Liquified petroleum gas (LPG) or propane also have been used as

tractor fuels, but require special pressurized fuel tanks and filling equipment, so are less

prevalent in most markets. In some countries such as Germany, biodiesel is often used.

Some other biofuels such as straight vegetable oil are also being used by some farmers.

Precision agriculture

Space technology has been incorporated into agriculture in the form of GPS devices, and

robust on-board computers installed as optional features on farm tractors. These

technologies are used in modern, precision farming techniques. The spin-offs from

the space race have actually facilitatedautomation in plowing and the use of autosteer

systems (drone on tractors that are manned but only steered at the end of a row), the idea

being to neither overlap and use more fuel nor leave streaks when performing jobs such

as cultivating. Several tractor companies have also been working on producing

a driverless tractor.

Engineering tractors

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)15

DBFGI/ME/2K11/1002511294481

A tractor factory in Chelyabinsk in the Soviet Union circa 1930

Ebro farm tractor

The durability and engine power of tractors made them very suitable for engineering

tasks. Tractors can be fitted with engineering tools such as dozer blades, buckets, hoes,

rippers, etc. The most common attachments for the front of a tractor are dozer blades or

buckets. When attached to engineering tools, the tractor is called an engineering vehicle.

A bulldozer is a track-type tractor with a blade attached in the front and a rope-winch

behind. Bulldozers are very powerful tractors and have excellent ground-hold, as their

main tasks are to push or drag.

Bulldozers have been further modified over time to evolve into new machines which are

capable of working in ways that the original bulldozer can not. One example is

that loader tractors were created by removing the blade and substituting a large volume

bucket and hydraulic arms which can raise and lower the bucket, thus making it useful for

scooping up earth, rock and similar loose material to load it into trucks.

A front-loader or loader is a tractor with an engineering tool which consists of two

hydraulic powered arms on either side of the front engine compartment and a tilting

implement. This is usually a wide-open box called a bucket, but other common

attachments are apallet fork and a bale grappler.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)16

DBFGI/ME/2K11/1002511294481

Other modifications to the original bulldozer include making the machine smaller to let it

operate in small work areas where movement is limited. Also, tiny wheeled loaders,

officially called skid-steer loaders, but nicknamed "Bobcat" after the original

manufacturer, are particularly suited for small excavation projects in confined areas.

Backhoe loader

Main article: Backhoe loader

A common backhoe-loader - the backhoe is on the left, the bucket/blade on the right.

The most common variation of the classic farm tractor is the hoe, also called a hoe-

loader. As the name implies, it has a loader assembly on the front and a backhoe on the

back. Backhoes attach to a three-point hitch on farm or industrial tractors. Industrial

tractors are often heavier in construction, particularly with regards to the use of steel grill

for protection from rocks and the use of construction tires. When the backhoe is

permanently attached, the machine usually has a seat that can swivel to the rear to face

the hoe controls. Removable backhoe attachments almost always have a separate seat on

the attachment.

Backhoe-loaders are very common and can be used for a wide variety of tasks:

construction, small demolitions, light transportation of building materials, powering

building equipment, digging holes, loading trucks, breaking asphalt and paving roads.

Some buckets have retractable bottoms, enabling them to empty their loads more quickly

and efficiently. Buckets with retractable bottoms are also often used for grading and

scratching off sand. The front assembly may be a removable attachment or permanently

mounted. Often the bucket can be replaced with other devices or tools.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)17

DBFGI/ME/2K11/1002511294481

Their relatively small frames and precise controls make backhoe-loaders very useful and

common in urban engineering projects, such as construction and repairs in areas too small

for larger equipment. Their versatility and compact size makes them one of the most

popular urban construction vehicles.

In the UK, the word "JCB" is sometimes used colloquially as a genericized trademark for

any such type of engineering vehicle. The term JCB now appears in the Oxford English

Dictionary, although it is still legally a trademark of J. C. Bamford Ltd. The term "digger"

is also commonly used.

The ingenuity of farm mechanics, coupled in some cases

with OEM or aftermarket assistance, has often resulted in the conversion of automobiles

for use as farm tractors. In the United States, this trend was especially strong from the

1910s through 1950s. It began early in the development of vehicles powered by internal

combustion engines, with blacksmiths and amateur mechanics tinkering in their shops.

Especially during the interwar period, dozens of manufacturers (Montgomery

Ward among them) marketed aftermarket kits for convertingFord Model Ts for use as

tractors.[33] (These were sometimes called 'Hoover wagons' during the Great Depression,

although this term was usually reserved for automobiles converted to horse-drawn buggy

use when gasoline was unavailable or unaffordable. During the same period, another

common name was "Doodlebug"). Ford even considered producing an "official" optional

kit.[34] Many Model A Fords also were converted for this purpose. In later years, some

farm mechanics have been known to convert more modern trucks or cars for use as

tractors, more often as curiosities or for recreational purposes (rather than out of the

earlier motives of pure necessity or frugality).

During World War II, a shortage of tractors in Sweden led to the development of the so-

called "EPA" tractor (EPA was a chain of discount stores and it was often used to signify

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)18

DBFGI/ME/2K11/1002511294481

something lacking in quality). An EPA tractor was simply an automobile, truck or lorry,

with the passenger space cut off behind the front seats, equipped with two gearboxes in a

row. When done to an older car with a ladder frame, the result was not dissimilar to a

tractor and could be used as one.

After the war it remained popular, now not as a farm vehicle, but as a way for young

people without a driver's license to own something similar to a car. Since it was legally

seen as a tractor, it could be driven from 16 years of age and only required a tractor

license. Eventually, the legal loophole was closed and no new EPA tractors were allowed

to be made, but the remaining ones were still legal, which led to inflated prices and many

protests from people who preferred EPA tractors to ordinary cars.

In March 1975, a similar type of vehicle was introduced in Sweden, the A

tractor [from arbetstraktor (work tractor)]; the main difference is an A tractor has a top

speed of 30 km/h. This is usually done by fitting two gearboxes in a row and not using

one of them. The Volvo Duettwas, for a long time, the primary choice for conversion to

an EPA or A tractor, but since supplies have dried up, other cars have been used, in most

cases another Volvo.

Another type of homemade tractors are ones that are fabricated from scratch. The "from

scratch" description is relative, as often individual components will be repurposed from

earlier vehicles or machinery (e.g., engines, gearboxes, axle housings), but the tractor's

overallchassis is essentially designed and built by the owner (e.g., a frame is welded

from bar stock—channel stock, angle stock, flat stock, etc.). As with automobile

conversions, the heyday of this type of tractor, at least in developed economies, lies in the

past, when there were large populations of blue-collar workers for

whom metalworking and farming were prevalent parts of their lives. (For example, many

19th- and 20th-century New England and Midwestern machinists and factory workers had

grown up on farms.) Backyard fabrication was a natural activity to them (whereas it

might seem daunting to most people today).

Alternative machine types called tractors

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)19

DBFGI/ME/2K11/1002511294481

Road tractor pulling a flatbed trailer

The term "tractor" (US and Canada) or "tractor unit" (UK) is also applied to:

Road tractors, tractor units or traction heads, familiar as the front end of

an articulated lorry / semi-trailer truck. They are heavy-dutyvehicles with

large engines and several axles.

The majority of these tractors are designed to pull long semi-trailers, most often

to transport freight over a significant distance, and is connected to the trailer with

a fifth wheel coupling. In England, this type of "tractor" is often called an "artic

cab" (short for "articulated" cab).

A minority is the ballast tractor, whose load is hauled from a drawbar.

Pushback tractors are used on airports to move aircraft on the ground, most

commonly pushing aircraft away from their parking stands.

Locomotive tractors (engines) or Rail car movers - the amalgamation

of machines, electrical generators, controls and devices that comprise the traction

component of railway vehicles

Artillery tractors - vehicles used to tow artillery pieces of varying weights.

NASA and other space agencies use very large tractors to move large launch

vehicles and space shuttles between their hangars andlaunch pads.

A pipe-tractor is a device used for conveying advanced instruments into pipes for

measurement and data logging, and the purging of well holes, sewer pipes and other

inaccessible tubes.

WHAT IS THE CNC MACHINE

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)20

DBFGI/ME/2K11/1002511294481

Now that we have seen what the NC machine is and its various parts, it is easier to

understand what the CNC machine is. CNC is the short form for Computer Numerical

control. We have seen that the NC machine works as per the program of instructions fed

into the controller unit of the machine. The CNC machine comprises of the mini

computer or the microcomputer that acts as the controller unit of the machine. While in

the NC machine the program is fed into the punch cards, in CNC machines the program

of instructions is fed directly into the computer via a small board similar to the traditional

keyboard.

In CNC machine the program is stored in the memory of the computer. The programmer

can easily write the codes, and edit the programs as per the requirements. These programs

can be used for different parts, and they don’t have to be repeated again and again.

Compared to the NC machine, the CNC machine offers greater additional flexibility and

computational capability. New systems can be incorporated into the CNC controller

simply by reprogramming the unit. Because of its capacity and the flexibility the CNC

machines are called as “soft-wired” NC.

CNC Machine

How the CNC Machine Works?

The CNC machine comprises of the computer in which the program is fed for cutting of

the metal of the job as per the requirements. All the cutting processes that are to be

carried out and all the final dimensions are fed into the computer via the program. The

computer thus knows what exactly is to be done and carries out all the cutting processes.

CNC machine works like the Robot, which has to be fed with the program and it follows

all your instructions.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)21

DBFGI/ME/2K11/1002511294481

Some of the common machine tools that can run on the CNC are: Lathe, Milling

machines, Drilling Machine etc. The main purpose of these machines is to remove some

of the metal so as to give it proper shape such as round, rectangular, etc. In the traditional

methods these machines are operated by the operators who are experts in the operation of

these machines. Most of the jobs need to be machined accurately, and the operator should

be expert enough to make the precision jobs. In the CNC machines the role of the

operators is minimized. The operator has to merely feed the program of instructions in the

computer, load the required tools in the machine, and rest of the work is done by the

computer automatically. The computer directs the machine tool to perform various

machining operations as per the program of instructions fed by the operator.

You don’t have to worry about the accuracy of the job; all the CNC machines are

designed to meet very close accuracies. In fact, these days for most of the precision jobs

CNC machine is compulsory. When your job is finished, you don’t even have to remove

it, the machine does that for you and it picks up the next job on its own. This way your

machine can keep on doing the fabrication works all the 24 hours of the day without the

need of much monitoring, of course you will have to feed it with the program initially and

supply the required raw material.

Most of the manufacturing companies are now equipped with the CNC machines as the

markets have got very competitive; however, getting the expert labors for operating these

machines is becoming quite difficult. Even the machine operators of these days prefer to

operate the machine by programming instead of operating it manually. In most of the

machine tools training institutes the new operators are taught manual machining as well

as CNC machining and programming.

MACHINE PRESS

A forming press, commonly shortened to press, is a machine tool that changes the shape

of a workpiece by the application of pressure.[1] Presses can be classified according to

their mechanism: hydraulic, mechanical, pneumatic;

their function: forging presses, stamping presses, press brakes, punch press, etc.

their structure, e.g. Knuckle-joint press, screw press

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)22

DBFGI/ME/2K11/1002511294481

their controllability: conventional vs. servo-presses

An example of peculiar press structure: shop press

A simple frame, fabricated from steel, containing a bottle jack or simple hydraulic

cylinder. Good for general-purpose work in the auto mechanic shop, machine shop,

garage or basement shops, etc. Typically 1 to 30 tons of pressure, depending on size and

expense. Classed with engine hoists and engine stands in many tool catalogs.

Some examples of presses by application

A press brake is a special type of machine press that bends sheet metal into shape. A

good example of the type of work a press brake can do is the backplate of a computer

case. Other examples include brackets, frame pieces and electronic enclosures just to

name a few. Some press brakes have CNC controls and can form parts with accuracy

to a fraction of a millimetre. Bending forces can exceed 4,000 kilonewtons

(900,000 lbf).

A punch press is used to form holes.

A screw press is also known as a fly press.

A stamping press is a machine press used to shape or cut metal by deforming it with

a die. It generally consists of a press frame, a bolster plate, and a ram.

Capping presses form caps from rolls of aluminium foil at up to 660 per minute.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)23

DBFGI/ME/2K11/1002511294481

An example of peculiar press control: servo-press

A servomechanism press, also known as a servo press or a 'electro press, is a press driven

by an AC servo motor. The torque produced is converted to a linear force via a ball

screw. Pressure and position are controlled through a load cell and an encoder. The main

advantage of a servo press is its low energy consumption; its only 10-20% of other press

machines. Another advantage is a quiet and clean work environment.

INFRASTRUCTURAL SET-UP

Set up in 1992, King Exports now has five manufacturing units measuring 360,000 sq.ft.

Presently manufacturing & Exporting to over 40 countries

In house hot forging plant, CNC machining centers, vertical machining center and special

pupose machine

In house bright chrome planting plant, Powder coating plant, electro galvanzing plant

In house availablity stage of the art CAD software for drawings & Designing

In house Quality Control Room, Test Laboratory and Tool Room

Fully Computerized documentation system and a highly efficient inentory control and

managment system In house container stuffing

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)24

DBFGI/ME/2K11/1002511294481

FORGING

Equipped with state-of-the-art hot forging Hammers.

3 Hammers, Capacity: up to 2 Tons.

In-house tool room for Forging Dies.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)25

DBFGI/ME/2K11/1002511294481

Machining

5 CNC Machines with capability to create a variety of shapes and sizes, including

large O.D. (outside diameter) and tight tolerances. 15 Lathe Machines (Boring,

Copy turning, Chamfering, Facing, Collar Turning)

40 Drill machines (Drilling, Reaming, Tapping).

20 Power Presses (Punching, Cutting, Bending, Notching, Embossing)

8 Thread Rolling Machines (Threading)

30 Special Purpose machines (Weld on end, Under cutting, pipe tapping)

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)26

DBFGI/ME/2K11/1002511294481

Stamping

30 Mechanical Presses, with a Capacity: up to 250 Tons.

2 Hydraulic Presses, Capacity 300 Ton.

De-coilers are used for presses components.

EDD capability

5 pneumatic presses with auto feeders

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)27

DBFGI/ME/2K11/1002511294481

Welding

MIG Welding

Tool Room

Includes EDM wire cut

3 fully equipped tool rooms

Finish & coating

Automatic Powder Coating and Phosphate Plant.

Zinc plating-can offer 6+ free trivalent zinc plating.

Nickel-chrome plating.

E-Coating

Black Oxide

Paint / Primer

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)28

DBFGI/ME/2K11/1002511294481

Packaging & Fumigation

Retail packaging

Bulk packaging

As per ISDM 15 standards

In house test laboratory

physical testing

Chemical composition determination

In house developed ERP Solution

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)29

DBFGI/ME/2K11/1002511294481

PRODUCTION PROCESS

The process design in the assembly line of tractors consists of the following operations an

activities.

1. Gear Box

2. Transmission

3. Coupling of transmission with Gear-Box

4. Test Bench

5. Coupling engine with transmission

6. First line

7. Paint shop

8. Second line

9. Final inspection

GEAR-BOX

Engines and many parts of the tractors are imported from Fiat manufacturers in Italy and

Turkey. During the journey from Italy to the plant many parts of gearbox get loose. On

arriving in the plant, during assembling certain operations are performed by technical

individuals, are discussed as under.

1- CLEANING OF CASE FROM INSIDE

Here the case of gearbox is cleaned from inside because it is much effected due to dust.

The dust is removed from inside the case by cleaning it with some dust-removing agents.

2- COUNTER SHAFT NUT TIGHTING AND STAKING.

Some parts of gearbox get loosed because of journey in ship and later on trucks. Here

shaft is tightened and some other items are assembled to it.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)30

DBFGI/ME/2K11/1002511294481

3- TRANSMISSION SHAFT COVERS TIGHTENING.

After counter shaft nut tightening next the transmission shaft cover is tightened because

of above reasons.

4- SPILTER TIGHTENING AND LOCK PLATE BENING.

After transmission shaft cover tightening a splitter of weight of 9.5 kg is fixed into the

gearbox by tightening bolts and locking plates are bent.

5- CHECK POSITION OF MAIN SHAFT INNER AND SEAL AFTER INSERTION OF

P.T.O. SHAFT.

It is a final operation in the gearbox checking. Here it is checked and assures that our

shafts are on its right place or not, further corrective actions are taken to make it ready.

Then gearbox is totally sealed after insertion of P.T.O. shafts.

TRANSMISSION

The following are the operations that are performed during transmission.

6- CLEANING FROM INSIDE.

Here nozzles that are to be fitted into gearbox are cleaned. Others parts are also cleaned

and oiled.

7- BEVEL PINION NUT TIGHTENING.

It is the second operation in transmission. Here the bevel pinion nut is tightened into the

gear- box.

8- BEVEL PINION ROTATING TORQUE.

Bevel pinion rotating torque is cleaned and made ready for assembling into the gearbox.

9- DRIVE HEAD TIGHTENING.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)31

DBFGI/ME/2K11/1002511294481

Drive is a separate part, which is later adjusted to the gearbox, is tightened with some of

other parts.

10- BEVEL DRIVE ROTATING.

Bevel drive rotating is cleaned and its specification is checked and is sealed by adjusting

it into the gearbox.

11- BEVEL DRIVE BACKLASH.

Here the bevel drive is recoiled so that it is ready for coupling to gearbox and engine.

COUPLING OF TRANSMISSION WITH GEAR-BOX

Here gearbox and all other parts, which are prepared in transmission, are coupled and the

following operations are performed.

12- GEARBOX WITH TRANSMISSION TIGHTENING.

Here gearbox is coupled with transmission by tightening that integrates them.

13-FINAL DRIVES TIGHTENING.

Drive head, which is a separate part, is tightened into coupled gearbox and transmission.

14- BREAK PEDAL ADJUSTMENT .

Here the position of break pedal is adjusted for both forward and back Tires with the

engines.

TEST BENCH

Here the engine is checked to check that are its parts are at their its correct places or not,

further actions are taken later on.

15-OPERATION TEST.

Here the engine is checked by engintioning it and the performance of the engines are

checked to ensure its performance.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)32

DBFGI/ME/2K11/1002511294481

16- CLUTCH TO FLY WHEEL TIGHTENING

Here the flywheel are checked and tightened strongly with the transmission.

17- ENGINE WITH TRANSMISSION

Here the engine is combined with the transmission and bolts are strongly tightened.

18- MASTER CLUTCH PEDAL ADJUSTMENT

Here the master clutch pedal is adjusted.

19- P.T.O HAND LEVEL ADJUSTMENT

20- HYDRALIC LIFT TRANSMISSION TIGHTENING

Here hydraulic lift is fixed and tightening with transmission.

21- LEVER TO STEERING BOX TIGHTENING

Here lever of tractor is tightening with the lever to transmission.

22- FRONT AXLE SUPPORT TIGHTENING

The bolts of front axle are tightened to the transmission.

23- DRAG LINK TO STEERING ARM AND AXLE TIGHTENING

Here small and big axles are tightened to transmission.

24- CORRECT APPLICATION OF PROTECTION TO VARIOUS PARTS

Here different parts are checked and adjusted to their correct places.

PAINT SHOP

25- WASHING

Here to remove dust the body of engine , the body of the engine is washed with hot

mixture of hot water and chemicals.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)33

DBFGI/ME/2K11/1002511294481

26- PRIMER

Here the body is make prepared for paint by allowing to remained in the hot air.

27- PAINT

Here the steel body is painted in the “Paint Shop”.

SECOND LINE

28- INJECT GREASE IN ALL LUBRICANTS

Here grease and other lubricant oils are injected to engine and moving parts of the tractors

like wheel.

29-ELECTRICAL SYSTEM

Here all electrical wiring system is built ion to the tractor a d a battery is adjusted in the

tractor. All lighting bulbs are put bonnets relevant places.

30- ALIGNMENT OF STEEL METAL

Here the painted body of the tractor is aligned tom the engine and other body of the

tractors.

31- FRONT WHEEL TIGHTENING

Here the bolts of front line are tightened and also are injected grease to it

32- REAR WHEAL TIGHTENING

Here the bolts of the back wheel are tightened, and the inner parts are oiled with Mobil

Oil.

33- WHEEL ALIGNMENT

Here the front and back wheels are alighted and their bolts are tightened.

34- OIL CHECKING

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)34

DBFGI/ME/2K11/1002511294481

Here the oil levels are checked and fill oil to it and after it the final inspection is made.

FINAL INSPECTION

The following are the operations, which are performed during final inspection of finished

tractors.

CHECKING OF OIL LEVEL:

1) Engine oil level checking

2) Gear Box oil level checking

3) Air cleaner oil checking

4) Water level checking

5) Weight test of Hydraulic pressure

CHECKING OF OPERATING PARTS:

6) Clutch play tightening and sound test

7) Tightening of break L/H & R/H

8) P.T.O Clutch test

9) High, low gear sound checking

10) 1-2-3-4 & reverse gear checking

11) break seal of L/H & R/H

12) Final drive tube leak

13) Differential case hole and sound checking

14) Gear box top cover leak checking

15) P.T.O top cover leak checking

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)35

DBFGI/ME/2K11/1002511294481

16) P.T.O plate leak checking

17) P.T.O cover leak checking

18) P.T.O seal leak checking

19) Differential leak checking

20) Engine sound checking

21) Lift pump support checking

22) Automisophry support checking

23) Paint cover checking

24) Fuel engine pipe leak cover checking

25) Top hydraulic leak checking

26) High pressure pipe leak checking

27) Low pressure pipe checking

28) Steering plate leak checking

29) Steering loose/tight/free checking

30) Wheel alignment checking

31) Tie rood (rubber boot/pin) checking

32) 640 fender & distance checking

33) Sheet metal (paint/welding/crack) checking

34) Grease checking

35) Tire’s air checking

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)36

DBFGI/ME/2K11/1002511294481

36) Self starter checking

37) Leaving box checking

ELECTRICAL LIGHTING SYSTEM CHECKING :

38) Parking lights checking

39) Parking indicators checking

40) Neutral switch checking

41) Head light low checking

42) Head light high checking

43) Beam indicators checking

44) Oil pressure checking

45) Alternate light checking

46) Alternate junctions checking

47) Fan belt (extension/loose) checking

48) Fuel gauge checking

49) Temperature gauge checking

50) Main wire clip checking

51) Back lights checking

52) Horn checking

53) Yellow lamp checking

54) Fuse box checking

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)37

DBFGI/ME/2K11/1002511294481

55) Wire fitting checking

56) All body paint checking

57) Sheet metal checking

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)38

DBFGI/ME/2K11/1002511294481

TRACTOR ASSEMBLY

In this shop the different tractor parts like different housing, gearboxes, rear cover &

other components are assembled which are purchased from outside but these are

machined in the factory. After assembly tractor is sent to paint shop.

Following are the main phases of assembly: -

1. Differential housing assembly

2. Rear cover assembly

3. Gear box assembly

4. Main line assembly

5. Painting

6. Assembly of accessories

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)39

DBFGI/ME/2K11/1002511294481

DIFFERENTIAL HOUSING ASSEMBLY PHASE

It is rear part of the tractor body. The main function of differential in tractor to reduce

the final speed and also to turn the drive Round at 90 degree. The reduction of speed is

done in two stages. First stage reduction in tail pinion and crown wheel meshing and

second stage reduction in bull gear meshing with left and rights B.P. shatft. It's also

consisting the P T.O Shaft (power take off shaft), which is used to run the thrashers,

pumbps and other accessory components with the help of pulley attached on it. Following

are main parts of differential housing:-

1. Crown Wheel

2. Tgail pinion.

3. Cage assembly (with level, cross & pinion)

4. PT.O. Shaft

5.BP Shaft left.

6. B.P. shaft right

7. Bull gears.

8. Bearings

9. Bearing cones

10. Brakes housing assembly (with disc and etc.)

11. Oil seals, gaskets and fasteners etc.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)40

DBFGI/ME/2K11/1002511294481

ASSEMBLY OF CASK CROWN WHEEL

First of all components arc washed with oil remove the dirty particles. Cage having two

holes in these holes dowels are tightening fitted for accurate fitting of crown so that all

other holes of cage and crown come into same line. The crown wheel is pressed and then

tightens by bolts with lock washer. Then right bevel gear is placed on their cage seat.

The four pleat gears are put on cross with washer and then this assembly put on their

[placed on.

The placed left bevel gear on planet on gear operator to check the motion of gears

does manual inspection. Cage left is placed on left side of right cage assembly and then

tighten by bolts and washer. Blackish should be in spider kit 0-15 mm to 0.25 mm <fc m

crown wheel should be 0.15 to 0.30 mm.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)41

DBFGI/ME/2K11/1002511294481

TAIL PINION ASSEMBLY

First of all in tail pinion assembly the cone for taper roller bearing is pressed with

hydraulic press. The bearing is heated before the tight fit Then tail pinion is inserted

inside bearing. The diff. Size shims art also placed Before the tighten of rear cover of

cage. Whole assembly i tightening by nuts and bolt.

REAR AXLE ASSEMBLY

n rear axle assembly of tractor the bolts are tight fitted in holes of hub. Where the rear

tire is tighten with their bolts to whole assembly For I tight fitting the hydraulic press is

used and 120 Kg/ cm Sq. forces is apply Two bearing either side of trumpet housing are

tighten at their respective place of cone. The rear axle is passed through these two

bearing with seal I trumpet. The cove is used to cover the open side of trumpet housing

(hi I side). The inner side bearing is lubricated with oil and outer bearing I lubricated

with grease.

BRAKING ASSEMBLY

This tractor having heaving heavy duty self-energizing, water sealed disc with spherial

roller and ventilation pipe which gives better cooling The ventilated results in reduction

of about 30 in pad temperature. Break housing cover contain two disk made of asbestos.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)42

DBFGI/ME/2K11/1002511294481

Base non-metallic the max temp resistance 30' b/w these two discplate is fixed which

contains steel spherical roller and hold by spring when ever brake is applied the

spherical roller move or lift from these place in the plate and try to exploited the plate.

During expanding of C.I plate the disc are strongly mounted on B.P right shaft to ^top the

speed of differential. If also having actuators and links with rubber seal

P.T.O SHAFT ASSEMBLY

Two bearing are tightly fit on P. t .0 shaft at their proper placed with help of circlip lock,

which provided on both side of bearing first of all the P.T.O. shaft assembly is pass

through rear P.T.O. hole of differential housing.

Then two cones are one of B P left and other on B P right shaft assembly is placed

through their hole then cage housing of differentia] is placed b/w left wanted right B.P.

shaft the seal carrier with different size of shims is tightening by bolts on both side of

differential housing (rightand left B.P. shaft side) Then pre-loading test is done with 10

kg force to rotate the cage assembly. If pie load force is increase the efficiency of taper

bearing also decrease due to less contact with cover cage of bearing. Then tail pinion

assembly is inserted in to respective hole with shims and tail pinion teethes meshed with

crown wheel teethes after this writing in fair copy.

GEAR BOX ASSEMBLY

In these tractors the sliding mesh type gear box are used for transmission rhe

power at various speed from engine to differential. An improvement was achieved in the

form of CM. gear used in gearbox, which gives better results in higher mechanical

efficiencies and iower noise level due to the use of the some helical gcaes instead of

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)43

DBFGI/ME/2K11/1002511294481

straight spiral gears. It gives the tractor a top speed of 30 Km/hr and a mm speed of 2

Km/hr. there are 8 forward and 2 reverse gears with a high and low leve.

1-L 2.25 Km/hr. 1-H 8.86 Km/hr R-L2.81/hr

2-L 4.24 Km/hr. 2-H 16.76 Km/hr R-H 11.8/hr

3-L 45 Km/hr. 3-H 25.40 Km/hr

4-L 8.85/hr. 4-H 28.758 Km/hr

FOLLOWING ARFE THE MAIN COMPONETS OF GEAR BOX

a) Input shaft assembly

b) Output shaft assembly

c) Lay shaft assembly

d) Intermediate shaft assembly

e) Actuator shaft ass

f) Gears

g) Gear box housing

h) Shifter rods

i) Shifter forks

j) Bearings

k) Fastness, gaskets and spacers

1) Planet gear and carrier with internal gear

CLUTCH ACUTAATOR (C.A) ASSEMBLY

The lay shaft is hollow shaft with splins on outer. The one end of the lay shaft is

threaded (in case of single clutch) and tightened from front side of gearbox with a

hexagonal nut

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)44

DBFGI/ME/2K11/1002511294481

The hole assembly consist of gear 7,-45 (i.e. constant mesh gear with input shaft gear)

spacer 15mm, Z-36, Z-30 spacer 30mm, gear 7,-25 spacer 25 mm and bearing with

circlip. The whole ass. Is wased in case of dual clutch tractor model the drive shaft

consists of splines on one end and a gear (7-45) on the other end. The gear constantly

meshed with the gear of intermediate shaft The main function of lay shaft s to rotate

fixed gear on it from where we can get different speeds with the help of sliding gear on

drive shaft.

INPUT SHAFT ASSEMBLY

Input shaft consists of spiral gear on one end and splines on the other I lend,

Splined pan is attached to clutch and geared part (Z-19) is at ached the constant mesh

gear of la shaft i.e. Z-45, input shaft is put into the gearbox with the bearing, which is

locked by,

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)45

DBFGI/ME/2K11/1002511294481

OUTPUT SHAFT ASSEMBLY

Output shaft assembly is solid shaft with splines on outer surface. The shaft is

plased in to gear box with both ends supported by bearing and I locked by circlip. The

back part of shaft is projected out side the gear box to I get drive from it. The assembly

of shift consist idling gear 2431 and 34 I gears.

The sliding gear 34 is used for first and reverse gear, sliding gear 31 bracket over the

upper side of the gear box Z.F. cover plate is consist of the I I steering assembly and

high, low speed shifter assembly. Then whole I I assembled gearbox is send to the

main line assembly.

INTERNAL GEAR ASSEMBLY:

On internal gear two dowels arc inserted at their proper place and faceplate with thrust

plate is placed over dowels. The purpose of the dowels is to locate holes on the plate

gears, which arc fixed to carrier with, help of pins inserted the internal gear them thrust

plate and outer plate is placed and tightened by nuts.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)46

DBFGI/ME/2K11/1002511294481

ASSEMBLY OF GEAR BOX:

First of all the gearbox is placed over the trolley which is continuously moving

with the help of the chain system The idler gear is placed with their idler gear shaft in

gearbox its respective holes and tightened from front side by hexagonal nut. After this

input shall is placed from side of the gear box housing its Z-19 is meshed with CM. Z-

45 of lay shaft. Then the out put shaft assembly is placed into the gearbox where its

one side is inserted into the input shaft hole. For D.C. models the intermediate shaft,

which hollow, placed over the input shaft and its Z-21 gear is meshed with Z-43 of

connecting shaft, which placed through the hollow lay shaft. The internal gear assembly

is tightened on the out side of the gear box with output shaft. The forth selector froks

are inserted in to the groove of sliding gears and then tightened ot the gear shifter rods

with the help of bolts. The forth selector rod is ment for low and high speed selection.

This rod is connected to the drive shaft, which is placed into the internal gear. Then Z

F. cover. Pretreatment follows the visual inspection which primarily includes the

cleaning process. The cleaning process starts from the preparatory' to finishing process.

The cleaning includes removal of dirt, oil, sand oxides, scale, grease and other harmful

ingredients which ultimately hamper the life of components pretreatment process are

done in different steps.

CAOUPLER ASSEMBLY:

In coupler assembly a draft rod having a flange and position rod contains spring on it.

Draft rod assembly is connected to and borrow link., which push the sensor tube inside

and auto metrically control value eontro oil supply.

LINE ASSEMBLY PHASE

In line phase assembly all the components are assemble together, Firstly the

differential housing assembly is put on moving trolley, winch is connected over the

conveyor. The gearbox assembly is Joining with the help of bolts to differential housing

and then accessory and mounting is joined. Two lower links (LT and RT) are join with

link plate The anchor chain attached with angle plate (with attached to diff. Rear side)

and lower side attached with lower link hook. The life rod upper and right leveling a

assembly is attached with arm of rear cover. Two straight bars are attached with trumps

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)47

DBFGI/ME/2K11/1002511294481

housing and lower side link for supporting rocket link attached to the sensor tube of

rear cover assembly.

Tractor Assembly

We stand among the overruling tractor assembly manufacturers with exporters

Quality, our base is in India. Or products with Precisely designed, our tractor spare parts

are manufactured from the high Quality raw materials.

Draw Bar Assembly

Draw Bar Assembly is a device for coupling a hauling vehicle to a load. This usage may

be road, agriculture or rail.

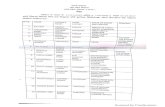

Part No. Cat

.

Sectio

n

B mm

C

mm

.

A

(mm

)

D

(mm

)

E

(mm

)

F

(mm

)

No .

of

Hole

s

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)48

DBFGI/ME/2K11/1002511294481

KSB288DBA

R

1 63 25 790 55 22 22 7

KSB289DBA

R

2 63 30 800 70 28 22 9

KSB290DBA

R

2 63 30 900 55 28 22 9

KSB291DBA

R

2 63 30 930 55 28 22 9

Tractor Top Link Assembly

We manufactured all kinds of spare parts of Tractor Top Link Assembly as per the

provided Drawing (Photo) or Sample . So please send us your required items drawing

(Photo) or sample.

Tractor Lower Link Assembly

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)49

DBFGI/ME/2K11/1002511294481

We manufactured all kinds of spare parts of tractor linkages as per the provided Drawing

(Photo) or Sample . So please send us your required items drawing (Photo) or sample.

Web Site :-

Tractor Stabilizer Assembly

We manufactured all kinds of spare parts of Tractor Stabilizer Assembly as per the

provided Drawing (Photo) or Sample . So please send us your required items drawing

(Photo) or sample.

Tractor Leveling Assembly

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)50

DBFGI/ME/2K11/1002511294481

We manufactured all kinds of spare parts of tractor linkages as per the provided Drawing

(Photo) or Sample . So please send us your required items drawing (Photo) or sample.

Leveling Gear

The Leveling Gears we offer are widely used in tractors all over. These are fabricated

using quality raw material and are acknowledged for their exclusive features like

dimensional accuracy, corrosion and abrasion resistance.

Leveling Shaft

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)51

DBFGI/ME/2K11/1002511294481

We offer Leveling Shafts that are appreciated for high tolerance level, robust construction

and precision engineering. Fabricated using quality raw material, these are available in

different sizes and dimensions. Owing to distinctive features, these shafts are used in

automotive industry.

TOP LINK ASSEMBLY (HEAVY DUTY)

We are recognized as the prominent manufacturer, exporter and supplier of wide

collection of Top Link Assembly. These top link are designed and manufactured with the

aid of latest technology and optimum quality raw material in relevance to the set industry

standards. Our quality controllers cautiously examine these top link on diverse quality

parameters in order to ensure defect-free bushes delivered at clients' end. We offer these

top link in different sizes as per the exact requirements of the clients.

Features:

Accurate dimensions

Longer service life

High strength

Technical Specification:

Top Link Assembly (Metric)

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)52

DBFGI/ME/2K11/1002511294481

CodeCat

D1 - D2

Pipe

L1 (MM)

Thread

D

Thread M 20X 2.5

LTLA 1900 L 0-0 (16) 190 M20X2.5

LTLA 2500 L 0-0 (16) 250 M20X2.5

LTLA 4000 L 0-0 (16) 400 M20X2.5

Thread M 22 X 2.5

LTLA 1201 B 1-1 120 M22X2.5

LTLA 1601 B 1-1 160 M22X2.5

LTLA 1801 B 1-1 180 M22X2.5

LTLA 2201 B 1-1 220 M22X2.5

LTLA 2301 B 1-1 230 M22X2.5

LTLA 3001 B 1-1 300 M22X2.5

LTLA 3201 B 1-1 320 M22X2.5

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)53

DBFGI/ME/2K11/1002511294481

Bucket Tooth

To meet the precise demands of clients, we manufacture and export a wide range of

bucket tooth. Engineered using premium quality iron, steel and other components, these

products are dimensionally accurate and praised for application specific design. We

quality test our products on well-defined parameters top ensure delivery of defect free

range at our clients end. One can also avail our bucket tooth products in customized

specifications.

Features:

Resistant to corrosion

High tensile strength

Cost effectiveness

Cultivator Tractor Part

Our organization specializes in manufacturing a wide range of Cultivators. These

products can be fitted with easily adjustable tines, two powerful coil springs and various

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)54

DBFGI/ME/2K11/1002511294481

other parts. Our durable products are anti-corrosive. Our customers can avail these from

us at market leading prices.

Features:

Highly Durable

Reliable

Draw Bar

We are one-step ahead of our competitors in manufacturing and exporting a wide range of

draw bars. These are available in ranges of heavy draw bar. Manufactured in accordance

with international industrial standards, these devices are widely demanded by large

number of industries. We implement latest technologies to manufacture our products and

ensure accurate dimensions and rugged construction of these products.

Heavy Drawbar

Enriched with vast industry experience, we are engaged in manufacturing and supplying a

premium quality range of heavy drawbars. Engineered in accordance with global

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)55

DBFGI/ME/2K11/1002511294481

standards, our devices are rust resistant, dimensionally accurate, durable and application

specific. Customers can avail these devices in various standard and customized sizes and

specifications. Precisely engineered our products are acclaimed for uninterrupted

performance.

Features:

Rugged construction

Optimum performance

Durable

TopLink Ends

We are one-step ahead of our competitors in manufacturing and supplying a qualitative

range of Toplink ends. Ergonomically designed and developed these devices are widely

demanded for purpose specific construction and accurate dimensions. The entire devices

are manufactured under strict supervision of quality controllers, who quality check these

on well-defines parameters and ensures good quality and high strength. These are

reasonably priced. Our range includes Top Link and Tractor Beld on Ball end.

Top Link

Keeping in mind the precise demands of clients, we manufacture and export a wide range

of Top links. The entire range of these products are manufactured in accordance with

international industrial standards and widely acclaimed for accurate dimensions,

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)56

DBFGI/ME/2K11/1002511294481

reliability and sturdiness. Specially designed using best available technologies our

devices are widely demanded by large number of industries. We also offer customized

solution.

Features:

Accurate dimensions

Precisely engineered

High usability

Tractor Beld On Ball Ends

Features:

Dimensional Accuracy

Fine Finish

Cone Ball

Knowing the precise demands of clients, we manufacture and export a comprehensive

range of Cone balls. Ergonomically designed and developed these devices are available in

different types including slip yoke, guide cone balls and many others. One can avail these

balls in different specifications and dimensions as per their requirements. We utilized

only quality approved materials to manufacture these devices and ensures long service

life of our products.

Guide Cone Ball

We specialize in manufacturing and exporting a wide range of Guide cone balls. We

implement best available technologies to manufacture these devices. Our products are

made under firm direction of expert quality controllers who check these on every step and

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)57

DBFGI/ME/2K11/1002511294481

ensure accurate dimensions and maximum usability of these products. Our products are

acclaimed for purpose specific design and sturdy construction. We offer these products at

cost effective prices.

Features:

Fine finish

Precise design

Reliability

Slip Yoke

We are instrumental in providing to our valuable customers excellent quality Slip Yoke.

Features:

Minimum Entrance of Dust

Longer life.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)58

DBFGI/ME/2K11/1002511294481

Harrow Disc

Customers can avail from us a qualitative range of Harrow discs, which are precisely

engineered using best quality components. The entire range of our products are

manufactured in accordance with international industrial standards and widely demanded

for long functional life and sturdiness. Following the demands of our clients, we offer

these products in various standard and customized dimensions, sizes and specifications.

Our range consists of Disc Blade.

Disc Blade

We hold expertise in manufacturing and exporting a qualitative range of Disc blades.

These blades are made in accordance with international industrial standards to ensure

better performance. Ergonomically designed and developed our devices are widely used

in different industries. Demands of our products are increasing day by day owing to

various salient features including sturdiness, rugged construction, high functionality and

consistency.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)59

DBFGI/ME/2K11/1002511294481

We hold expertise in manufacturing and exporting a qualitative range of Disc blades.

These blades are made in accordance with international industrial standards to ensure

better performance. Ergonomically designed and developed our devices are widely used

in different industries. Demands of our products are increasing day by day owing to

various salient features including sturdiness, rugged construction, high functionality and

consistency.

Features:

Corrosion resistance

Less maintenance

Precisely engineered

Hitch Assembly

We specialize in manufacturing and exporting a durable range of Hitch assembly. Made

as per international industrial standards, these devices are acclaimed for purpose specific

construction and durability. We employ premium quality components to manufacture

these devices and ensure durability and reliability. Knowing the precise demands of

clients, we offer our products in various standard and customized sizes and dimensions.

One can avail our products at budget friendly prices. Top Link Bracket constitutes our

range of products.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)60

DBFGI/ME/2K11/1002511294481

Top Link Bracket

With the help of our experienced team members, we have been able to manufacture and

supply a qualitative range of Top link brackets. Ergonomically designed and developed

these products are widely used in various heavy industries for different types of digging

process. Our products are manufactured from premium quality components sourced from

reliable vendors. To meet the desires specifications of our clients, we also offer

customized solution.

Features:

Durable

Ergonomic design

High strength

Assembly Kubota

We offer Superior quality of Assembly Kubota to fit the unique requirement of our

customer. These Assembly Kubota are designed to meet standard of quality and

reliability.

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)61

DBFGI/ME/2K11/1002511294481

Features:

Compatibility

Flexibility

Implement Pin

Enriched with vast industry experience, we are involved in offering a wide range of

Implement Pin. Our products are engineered by implementing latest technologies and

using best quality raw materials. Made in accordance with international industrial

standards, these products are acclaimed for rugged construction, accurate dimension and

long service life. We also offer double implement mounting pins and weld on implement

mounting pins as per the demands of clients.

Double Implement Mounting Pins

Enriched with vast industry experience, we are involved in offering a wide range of

Double implement mounting pins. Precisely engineered our pins are extensively

demanded for durability and purpose specific construction. Our products are corrosion

resistant and widely used in various heavy industries for types of digging purposes. To

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)62

DBFGI/ME/2K11/1002511294481

meet the precise demands of clients, we offer these pins in various standard and

customized specifications.

Features:

High tensile strength

Reliability

Cost effective

Weld On Implement Mounting Pin

We offer high quality Weld On Implement Mounting Pin pins. These pins are made up of

good quality raw material.

Features:

High Durability

Reliable

Jack

We specialize in manufacturing and exporting a comprehensive range of Jack. The entire

range of products offered by us is engineered as per international industrial standards and

using best available technologies. Manufactured under firm direction of quality

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)63

DBFGI/ME/2K11/1002511294481

controllers, these jacks are defect free and extensively used in various heavy industries.

Our products are manufactured using premium quality components to ensure durability

and corrosion resistance. Square Tube Jack and Trailer Wheel Jack comprise our range.

Square Tube Jack

With the help of our expert engineers, we have been able to manufacture and export a

wide range of Square tube jacks. Our products are precisely engineered using premium

quality components and widely demanded for high tensile strength and corrosion

resistance. Quality checked on well defined parameters, our products are ready to use.

Our products are extensively acclaimed for ergonomic design, dimensional accuracy and

smooth performance.

Features:

Consistent performance

Durability

Corrosion resistant

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)64

DBFGI/ME/2K11/1002511294481

Trailer Wheel Jack

We are offering a wide assortment of Trailer Wheel Jack. These products are

manufacturing from high grade of raw material which is procured from trusted vendor of

the Industry.

Features:

Completely Tested

Quality Raw Material

Levelling Arm

We are one of the most prominent names in the industry for manufacturing and exporting

a wide range of Levelling arms. Our products are engineered using best quality

components, which are sourced from reliable vendors of the industry. As the entire range

of these products is manufactured as per international industrial standards, these ensure

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)65

DBFGI/ME/2K11/1002511294481

consistent and uninterrupted performance. We offer two different types of Levelling arms

including levelling assembling arms and tractor adjustable levelling arms.

Tractor Adjustable Leveling Arm

Customers can avail from us a wide range of Tractor adjustable leveling arms, which are

manufactured from premium quality components and using best available technologies.

Applicability of these products is high in various heavy industries for different types of

digging purposes. These are precisely engineered using premium quality components our

products are synonymous with durability, reliability and consistent performance.

Features:

Economical prices

Consistency

Long service life

Levelling Assembly Left

Features:

Durability

Tensile strength

DESH BHAGAT FOUNDATION GROUP OF INSTITUTIONs, MOGA (PUNJAB)66

DBFGI/ME/2K11/1002511294481

TOP LINK ASSEMBLY (REPLACES IMT)

CODECAT

d1-d2

PIPE

L1(MM)

THREAD

D

KTL 450-650-2 2-2 210 M 36X3

KTL 490-690-2 2-2 245 M 36X3

TOP LINK ASSEMBLY (REPLACES IMT)

CODECAT

d1-d2

PIPE

L1 (MM)

THREAD

D

KTL IMT539 1-1 450 M30 X 3

KTL IMT560 1-2 470 M30 X 3