BEFORE THE DEPUTY CONTROLLER OF PATENTS...

Transcript of BEFORE THE DEPUTY CONTROLLER OF PATENTS...

1

BEFORE THE DEPUTY CONTROLLER OF PATENTS

Patent office, Chennai

THE PATENTS ACT, 1970

&

THE PATENTS RULES, 2003

In the matter of an application for Patent bearing number

1120/CHE/2007

Titled

―Shock Absorber with helper spring‖

Filed by

M/s TVS MOTOR COMPANY LIMITED---Applicant

In the matter of Section 15

&

In the matter of a representation by way of opposition to grant of patent filed U/S 25(1)

by M/s BAJAJ AUTO LIMITED ----- Opponent 1

&

In the matter of a representation by way of opposition to grant of Patent filed U/S 25(1)

by M/s ENDURANCE TECHNOLOGIES LIMITED--- Opponent 2.

Present during the hearing proceedings on the dates as mentioned against their names

2

(1) Mr. Damodar P Vaidya Of Lakshmi Kumaran & Sridharan, Patent agent for

Applicant. (25/04/2016 &10/05/2016)

(2) Mr. S.Jayaram, Member R&D,of TVS Motor Company Limited.( 25/04/2016

&10/05/2016)

(3) Ms. Brindha Mohan of Mohan Associates, Patent agent for the Opponent 1.(

10/05/2016)

(4) Mr. Milind V. Joshi of M/s Bajaj Auto Limited.( 10/05/2016)

(5) Mr. Rakesh Kumar of RK Dewan & Co, Patent agent for Opponent 2. Conducted

on 25/04/2016 &10/05/2016

(6) Mr.Soumya Prakash Patra,of M/s Endurance technologies limited. (25/04/2016 )

(7) Mr. Deep Prakash Gupt, Examiner of Patents and Designs. (25/04/2016

&10/05/2016)

1. An application for Patent filed by M/s TVS MOTOR COMPANY LTD with a

Provisional specification on 29/05/2007 and thereafter a complete specification was filed

on 21/05/2008. A request of Examination was filed on 27/01/2009 and First Examination

report (FER) was issued on 24/02/2014. A pregrant representation filed by way of

opposition was filed on 23/03/2012 by M/s BAJAJ AUTO LIMITED (Opponent 1) and

same representation along with the documents was forwarded to the applicant on

05/03/2014.Applicant filed their response on 05/06/2014. A pregrant representation filed

by way of opposition was filed on 05/09/2011 by M/s ENDURANCE TECHNOLGIES

LIMITED (Opponent 2) and the same representation along with the documents was

forwarded to the applicant on 05/03/2014 and applicant filed their response on

05/06/2014.

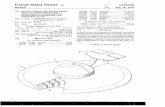

2. Summary of the invention

The present subject matter of the invention relates to a shock absorber for a vehicle and

in particular relates to a shock absorber with helper spring .According to at least one

embodiment of the present subject matter , the shock absorber includes a helper spring

122 that is slidably and concentrically disposed on a piston rod 108.The helper spring

122 is made up of polyurethane that has the property of absorbing and dissipating

energy efficiently, thereby increasing the passenger ride comfort and durability of the

shock absorber.

3

3. Back ground of the invention

Conventionally shock absorbers are provided with nonlinear rated springs to achieve

progressive stiffening. Progressive stiffening of a spring enables effective absorption of

road shocks over a wider range, thereby providing the ride comfort to the passengers.

The challenge associated with nonlinear rated springs is that the extent of non-linearity

achieved is limited primarily because of cost and manufacturing constraints. Further,

non-linearity achieved is not very progressive due to mechanical nature of the springs.

Another challenge associated is providing the shock absorber with only non-linear

springs is that absorption and dissipation of energy released during the dampening

process is not very effective and efficient. This primarily happens because of the time

lag of the damper in absorbing the energy and then releasing this absorbed energy to

the surroundings. This results in momentary discomfort to the occupants of the vehicle.

Aiding the shock absorber with a polyurethane helper spring though addresses this

challenge but it substantially increases the manufacturing cost of the shock absorber

.On the other hand , using a rubber helper spring does not reduce the time lag

substantially and hence it is not very effective in addressing the afore said challenge.

4. Objective of the invention:

Present invention proposes a method of increasing the performance and durability of

shock absorbers by ensuring the energy absorbed by the spring of the shock absorber

is efficiently and effectively dissipated to the surroundings and this leads to substantially

improvement in passenger ride comfort and durability of the shock absorber.

5. Solution for the problem

A shock absorber comprises of single rated coil spring , made up of a grade 2 wire ,

supports the weight of the vehicle and absorbs road shocks rapidly .The energy

absorbed by the single rated coil spring is then dissipated in the form of heat by

dampening fluid of the shock absorber. the said shock absorber also comprises of a

helper spring that is slidably and concentrically disposed on the piston rod .The helper

spring is made of polyurethane and has diameter that is substantially less than that of

the single rated coil spring, Polyurethane possesses the property of efficiently absorbing

and dissipating energy, thereby aiding single rated coil spring in energy dissipation.

4

6. Claims as originally filed

1. A shock absorber 100 for a vehicle, said shock absorber comprising:

a first fluid chamber 102 having a first end 104 and a second end 106;

a piston rod assembly comprising:

a piston rod 108 having a first end 110 and a second end 112;a piston 114 disposed

concentrically on said first end 110 of said piston rod 108 wherein said first end 110

of said piston rod 108 along with said piston 114 is capable of axially sliding through

said second end 106 of said first fluid chamber 102 towards said first end 104 of said

first fluid chamber 102;

a single rated coil spring 116 that opposes slidable movement of said piston rod

assembly in compression direction; said single rated coil spring 116 having an

upper end 118 and a lower end 120;

a helper spring 122 slidably and concentrically disposed on said second end112 of said

piston rod 108 wherein said helper spring 122 is having diameter substantially lesser

than said single rated coil spring 116;

characterized in that

said single rated coil spring 116 being made from Grade-2 wire and said helper spring

122 being made from polyurethane.

2. A twin tube shock absorber 200 for a vehicle, said shock absorber comprising:

a first fluid chamber 102 having a first end 104 and a second end 106;

a inner chamber 202 having a first end 204 and a second end 206; wherein said first

fluid chamber 102 is having a diameter substantially larger than said inner chamber

202, wherein said inner chamber 202 is disposed coaxially inside said first fluid

chamber 102 such that said first 104 and second 106 ends of said first fluid chamber

102 are disposed in close proximity to said first 204 and second 206 ends of said inner

chamber 202 respectively;

a piston rod assembly comprising:

a piston rod 108 having a first end 110 and a second end 112;

5

a piston 114 disposed concentrically on said first end 110 of said piston rod 108

wherein said first end 110 of said piston rod 108 along with said piston 114 is capable

of axially sliding through said second end 206 of said inner chamber 202 towards said

first end 204 of said inner chamber 202;

a single rated coil spring 116 that opposes slidable movement of said piston rod

assembly in compression direction; said single rated coil spring 116 having an upper

end 118 and a lower end 120;

a helper spring 122slidably and concentrically disposed on said second end 112 of said

piston rod 108 wherein said helper spring 122 is having diameter substantially lesser;

than said single rated coil spring 116;

characterized in that

said single rated coil spring 116 being made from Grade-2 wire and said helper spring

122 being made from polyurethane.

3. The shock absorber as claimed in claim I or 2, wherein said damping fluid is oil.

4. The shock absorber as claimed in claim I or 2, wherein said damping fluid is gas.

5. The shock absorber as claimed in claim I or 2, wherein said damping fluid is a

mixture of oil and gas.:

6. The shock absorber as claimed in claim I or 2, wherein said upper end 118 and lower

end 120 of said single rated coil spring 116 is having closed pitch coils.

7. Applicant has replied to the first examination report (FER) with amended claims on

18/02/2015

I. A shock absorber (100) for a vehicle, said shock absorber (I 00) comprising:

a first fluid chamber (102) having a first end (104) and a second end (106);a piston rod

assembly comprising:

a piston rod (I 08) having a first end (II 0) and a second end (112);

a piston (114) disposed concentrically on said first end (II 0) of said piston rod (I08)

wherein said first end (110) of said piston rod (I08) along with said piston (114) is

6

capable of axially sliding through said second end (106) of said first fluid chamber (102)

towards said first end (104) of said first fluid chamber (I02);

a single rated coil spring (116) that opposes slidable movement of said piston rod

assembly in compression direction, wherein said single rated coil spring (116) having an

upper end (118) and a lower end (120);

a helper spring (122) slidably and concentrically disposed on said second end (112) of

said piston rod (I 08), wherein said helper spring (122) is having diameter substantially

lesser than said single rated coil spring (116);

characterized in that

said single rated coil spring (116) being made from Grade-2 wire and said helper spring

(122) being made from polyurethane.

2. A twin tube shock absorber (200) for a vehicle, said shock absorber comprising: a

first fluid chamber (102) having a first end (104) and a second end (106);

a inner chamber (202) having a first end (204) and a second end (206); wherein said

first fluid chamber (102) is having a diameter substantially larger than said inner fluid

chamber (I02) such that said first (104) and second (106) ends of said first fluid

chamber (I02) are disposed in close proximity to said first (204) and second (206) ends

of said inner chamber (202) respectively;

a piston rod assembly comprising:

a piston rod (108) having a first end (II 0) and a second end (112);

a piston (114) disposed concentrically on said first end (110) of said piston rod(108)

wherein said first end (110) of said piston rod (108) along with said piston (114) is

capable of axially sliding through said second end (206) of said inner chamber (202)

towards said first end (204) of said inner chamber (202),

a single rated coil spring (116) that opposes slidable movement of said piston rod

assembly in compression direction; said single rated coil spring (116) having an upper

end (118) and a lower end (120);

a helper spring (122) slidably and concentrically disposed on said second end (112) of

said piston rod (108) wherein said helper spring (122) is having diameter substantially

lesser than said single rated coil spring (116);

7

characterized in that

said single rated coil spring (116) being made from Grade-2 wire and said helper spring

(122) being made from polyurethane.

3. The shock absorber as claimed in claim I or 2, wherein said damping fluid is oil.

4. The shock absorber as claimed in claim I or 2, wherein said damping fluid is gas.

5. The shock absorber as claimed in claim 1 or 2, wherein said damping fluid is a

mixture of oil and gas.

6. The shock absorber as claimed in claim I or 2, wherein said upper end (118) and

lower end (120) of said single rated coil spring (116) is having closed pitch coils.

8.This office has given due consideration to the reply given by the applicant and being

this office was not satisfied with the reply a hearing notice was issued to the applicant

on 02/02/2016 with the following objections and hearing was fixed on 02/03/2016 and

due to adjournments, hearing conducted on 25/04/2016

1. Claim(s) fall(s) within the scope of such clause (f) of section 3.

2. The alleged invention does not meet the requirement of section 2(1) (ja) of The

Patent Act, because the claimed subject matter does not constitute an Inventive step in

view of documents

D1: US3263983

D2: US5462140

D3: US5996978

DI teaches, a combined shock-absorber spring unit for a motor vehicle suspension (see

Division B7) comprises a double-acting telescopic shock-absorber 26 with a corrugated

rubber spring 72 surrounding the piston-rod 34 and surrounded by a coil-spring 56, the

arrangement being such that as the unit is compressed the coil spring and rubber spring

come into operation successively after an initial movement as rubber spring retainer 62

contacts stop 70 and then rubber spring 72 contacts retainer 62. The retainer 62 has

radial projections 68 which hold it on the coil spring. The spring 58 is held against the

lower spring seat by clips 58 retained by snap ring 60. The snap-ring 60 also holds the

two half-annular lower spring seat portions 50 in engagement with ridge 54 of the

reservoir tube 38.

8

D2 teaches, twin tube shock absorber has concentric inner and outer tubes connected

to the wheel of a vehicle. A piston in the inner tube is connected to the chassis of the

vehicle and divides the interior of the inner tube into upper and lower chambers. Fluid

passes between these chambers and an annular reservoir between the tubes for

absorbing shock in a conventional manner. An orifice is provided through the sidewall of

the lower portion of the inner tube and is surrounded by a lower sleeve, which normally

keeps the orifice closed. Upon upward acceleration of the tubes, the sleeve essentially

remains fixed in space. The relative movement between the sleeve and tubes aligns a

passage through the sleeve with the orifice and permits fluid to flow from the lower

chamber below the piston to the annular reservoir. This provides a softer shock

absorber when high upward acceleration is felt by the tubes of the shock absorber and

a stiffer shock absorber during times when there is no large upward acceleration. A

similar orifice and sleeve are provided at the upper end of the inner tube for permitting

fluid to flow from the upper chamber into the reservoir during rapid downward

acceleration of the tubes. The orifices are spaced apart from the ends of the inner tube

so that when the piston passes an orifice, the characteristics of the shock may change

from soft to stiff before the end of the stroke of the piston.

D3 comprises, A fluid pressure from an outside pressure source is supplied to the

pressurizing chamber to push down a damper piston via the free piston to thereby

forcibly contract the damper. In a second type, there is provided inside an inner tube a

cylinder which is slidably fit onto an outer surface of a rod, and a piston mounted on the

rod is inserted into the cylinder. A fluid pressure from the pressure source is supplied to

the pressurizing chamber inside the cylinder to push down the rod via the piston to

thereby forcibly contract the damper. In a third type, a rod is slidably inserted into a

partition wall in an intermediate portion of a damper main body of a mono-tube type of

damper. A free piston which is prevented by a stopper member from dropping out of

position downwards is slidably mounted onto an outer surface of a rod portion below the

partition wall. A fluid pressure from a pressure source is supplied to a pressurizing

chamber to be defined between the partition wall and the free piston. The rod is pushed

down via the free piston and the stopper member to thereby forcibly contract the

damper.

Hence a person skilled in the art will be motivated to combine the teachings of the cited

documents and come to a conclusion similar to present alleged invention.

The dependent claim [s] also do not provided any new feature with respect to the prior

art. Hence the present claim[s] are not allowable u/s 2(1)(ja) of the Patents Act.

9

3. Reference numerals shall be inserted inside the brackets in the claims.

4. FER of the application sent on 24/02/2014, the reply from the applicant received on

18/02/2015, applicant has produced amended claims along with the reply, but the

amended claims doesn‘t show any improvements or seems like earlier filed claims as

such. The inventive step in using single rated spring with spring aids or helper springs is

well known and doesn‘t show any improvements, also clearly falls under 3(f) of Indian

Patent act. With regard to objection 2 of FER, the applicant merely trying to combine

well known features like hydraulic dampers with helper springs made of PU (progressive

pressure/compression behavior) is well known in the prior art.Moreover no detailed

drawings are provided for structural constructional features of the claimed invention.

9. The learned agent appeared for the hearing u/s 14 hearing submitted their written

response on 26/05/2016.

The Learned agent for the applicant submitted that the invention as claimed discloses

the shock absorber to provide a comfortable ride to a passenger of a vehicle without

impacting the cost. The purpose is achieved by providing a combination of the

polyurethane helper spring and the single rated spring made of grade 2 steel wire,

working in close cooperation with each other to reduce the time lag between a release

of energy and dissipation of heat and further this provides a smooth ride over a larger

stroke /travel of the spring.

With regard to the objection Section 3(f), the learned agent for the applicant argued that

submitted that claims 1 to 6 is mere arrangement of known devices and the learned

agent submitted that while some individual components may be well known in the art

and may have been used for the purpose, the combination of such components acting

in tandem to provide comfort to a passenger of a two wheeler is not known in the art. In

fact such combination produces a significant technical advantage over the previously

known art.

A single rated coil spring of grade-2 wire and a polyurethane helper spring, working in

tandem with each other, provide an effective absorption and dissipation of energy

without any time lag. The polyurethane helper spring is activated by one end of a fluid

chamber after first part of travel of the single rated coil spring. Thereafter, the

polyurethane helper spring and the single rated coil spring work in tandem during the

latter part of the stroke to provide comfort to the rider by effectively dissipate the energy

without any time lag. Figure 4 of the specification clearly shows the enhanced

dissipation of energy by the single rated coil spring of grade-2 wire when used in

combination with the helper spring made of polyurethane. Therefore, the invention is not

10

mere arrangement or re- arrangement of known devices, but involves working of the

helper spring and the single rated coil spring in tandem with each other. Therefore, the

Applicant respectfully requested the Controller to withdraw the objection. Without

prejudice, the Applicant has amended the claim by way of explanation and by way of

disclaimer to highlight working of all the components in tandem with each other to

achieve the stated objective of the invention. The Applicant submits that the claims after

amendment are narrow and are fully supported in the specification, i.e., in the

drawings and description. The Applicant is amending the description by way of

explanation and the amendments are based on the drawings and as discussed with the

Controller. The Applicant is attaching the support chart.

With regard to the objection related to the inventive with in accordance with section

2(1)(ja) of the Patents Act in view of the documents D1: US3263983, D2: US5462140,

and D3: US5996978.

In response to this objection, the learned agent for the applicant had respectfully

explained that the cited references D1-D3 either alone or in combination, are not

relevant and also do not disclose or do not teach the invention. Therefore, these

documents cannot be considered relevant and disclosing or teaching the inventive

step of the present subject matter.

Concerning the inventive step of independent claim 1, the Applicant had submitted that

the following features as claimed in the invention are not disclosed in any cited

documents D1-D3:

a single rated coil spring (116) that opposes slidable movement of the piston rod

assembly in compression direction; the single rated coil spring (116) having an upper

end (118) and a lower end (120); wherein the single rated coil spring (116) is disposed

concentrically, and wherein the lower end (120) of the single rated coil spring (116) is

attached to the second end of the piston rod assembly and the upper end (118) of the

single rated coil spring is attached to the first end (104) of the first fluid chamber (102);

and

a helper spring (122) slidably and concentrically disposed on the second end (112) of

the piston rod (108) wherein the helper spring (122) is having diameter substantially

lesser than the single rated coil spring (116); wherein

the single rated coil spring (116) being made from Grade-2 wire and the helper spring

(122) being made from polyurethane, and wherein

11

the single rated coil spring (116) is compressed during the first part of the sliding of the

piston rod (108), and wherein

the second end (106) of the first fluid chamber (102) activates the helper spring (122) at

end of the first part of the sliding of the piston rod (108) so that the helper spring (122)

and the single rated coil spring (116) are compressed in tandem during the second part

of the sliding of the piston rod (108).‖

The learned agent for the applicant submitted that none of cited references D1-D3,

taken either alone or in combination, would enable a skilled person to arrive at the

invention. Furthermore, the invention also has a distinct advantage when considered in

light of cited references D1-D3. For example, the invention provides comfortable ride to

a passenger of a two wheeled vehicle, because the tandem working of the single rated

coil spring made of grade-2 wire and the helper spring made of polyurethane, enhances

the dampening property by dissipating the shock load without any time lag. Further this

advantage is achieved without impacting the cost, because the extra cost of the helper

spring made of polyurethane is compensated by lower cost of single rated spring made

of Grade-2 steel. The Applicant explained that a person skilled in the art would not

use Grade-2 steel wire for single rated coil spring, which is subjected to dynamic

load. For all these reasons, the Applicant, therefore, submitted that the subject matter

claimed in independent claim 1 involves an inventive step over cited references D1-D3.

Reference numerals have been incorporated in the claims.

10. A notice of P re grant Opposition hearing was issued to the applicants and

Opponents on 03/02/2016 and hearing was fixed on 03/03/2014.However based on the

requests of adjournments, hearing is refixed to 25/04/2016 and hearing for the applicant

and opponent 2 has conducted on the same day. Hearing for the applicant and

opponent 1 has conducted on 10/05/2016.

11. Learned agent for the applicant provided written submission to Section 14 hearing

along with the amended claims, description and drawings.

Amended claims filed on 26/05/2016 is reproduced here with and major portions which

are amended (added) underlined for clarity

1. A shock absorber (100) for a two-wheeled vehicle, the shock absorber (100)

comprising:

a first fluid chamber (102) having a first end (104) and a second end(106);

12

a piston rod assembly having a first end (124) and a second end(126), the piston rod

assembly comprising:

a piston rod (108) having a first end (110) and a second end(112), wherein the second

end (112) is attached to the second end (126) of the piston rod assembly; and

a piston (114) disposed at the first end (124) of the piston rod assembly, wherein the

piston (114) is concentrically mounted on the first end (110) of the piston rod (108), and

wherein the first end (110) of the piston rod (108) along with the piston (114) is capable

of axially sliding through the second end (106) of the first fluid chamber (102)

towards the first end (104) of the first fluid chamber (102), and wherein the sliding of the

piston rod (108) comprises a first part of the sliding and a second part of the sliding;

a single rated coil spring (116) that opposes slidable movement of the piston rod

assembly in compression direction, the single rated coil spring (116) having an upper

end (118) and a lower end (120), wherein the single rated coil spring (116) is disposed

concentrically, and wherein the lower end (120) of the single rated coil spring (116) is

attached to the second end (126) of the piston rod assembly and the upper end (118) of

the single rated coil spring is attached to the first end (104) of the first fluid chamber

(102); and

a helper spring (122) slidably and concentrically disposed on the second end (112) of

the piston rod (108), wherein the helper spring (122) is having diameter lesser than the

single rated coil spring (116); wherein

the single rated coil spring (116) being made from Grade-2 wire and the helper spring

(122) being made from polyurethane, and wherein the single rated coil spring (116) is

compressed during the first part of the sliding of the piston rod (108), and wherein the

second end (106) of the first fluid chamber (102) activates the helper spring (122) at end

of the first part of the sliding of the piston rod (108) so that the helper spring (122) and

the single rated coil spring (116) are compressed in tandem during the second part of

the sliding of the piston rod (108).

2. A twin tube shock absorber (200) for a two-wheeled vehicle, the shock absorber

(200) comprising:

a first fluid chamber (102) having a first end (104) and a second end (106);

a inner chamber (202) having a first end (204) and a second end (206); wherein the

first fluid chamber (102) is having a diameter larger than the inner chamber (202),

wherein the inner chamber (202) is disposed coaxially inside the first fluid chamber

13

(102) such that the first (104) and second (106) ends of the first fluid chamber (102) are

disposed in close proximity to the first (204) and second (206) ends of the inner

chamber (202) respectively;

a piston rod assembly having a first end (124) and a second end (126), the piston rod

assembly comprising:

a piston rod (108) having a first end (110) and a second end(112), wherein the second

end (112) is attached to the second end (126) of the piston rod assembly and;

a piston (114) disposed at the first end (124) of the piston rod assembly, wherein the

piston (114) is concentrically mounted on the first end (110) of the piston rod (108), and

wherein the first end (110) of the piston rod (108) along with the piston (114) is capable

of axially sliding through the second end (206) of the inner chamber (202) towards the

first end (204) of the inner chamber (202), and wherein the sliding of the piston rod

(108) comprises a first part of the sliding and a second part of the sliding;

a single rated coil spring (116) that opposes slidable movement of the piston rod

assembly in compression direction; the single rated coil spring (116) having an upper

end (118) and a lower end (120), wherein the single rated coil spring (116) is disposed

concentrically, and wherein the lower end (120) of the single rated coil spring (116) is

attached to the second end (126) of the piston rod assembly and the upper end (118) of

the single rated coil spring is attached to the first end (104) of the first fluid chamber

(102); and a helper spring (122) slidably and concentrically disposed on the second end

(112) of the piston rod (108) wherein the helper spring (122) is having diameter lesser

than the single rated coil spring (116); wherein the single rated coil spring (116) being

made from Grade-2 wire and the helper spring (122) being made from polyurethane,

and wherein the single rated coil spring (116) is compressed during the first part of the

sliding of the piston rod (108), and wherein the second end (106) of the first fluid

chamber (102) activates the helper spring (122) at end of the first part of the sliding of

the piston rod(108) so that the helper spring (122) and the single rated coil spring

(116)are compressed in tandem during the second part of the sliding of the piston rod

(108).

3. The shock absorber as claimed in claim 1 or 2, wherein the damping fluid is oil.

4. The shock absorber as claimed in claim 1 or 2, wherein the damping fluid is gas.

5. The shock absorber as claimed in claim 1 or 2, wherein the damping fluid is a mixture

of oil and gas.

14

6.The shock absorber as claimed in claim 1 or 2, wherein the upper end (118) and

lower end (120) of the single rated coil spring (116) is having closed.

In Para 0016 antitheft device has been deleted in the description

In para (0031) ] As it is apparent from FIG. 2 and FIG. 3, the piston rod assembly has a

first end 124 and a second end 126. The piston 114 is disposed at the first end 124 of

the piston rod assembly. The piston rod 108 along with the piston 114 axially slides

through the second end 106 of the first fluid chamber 102 towards the first end 104 of

the first fluid chamber 102. During a first part of the sliding of the piston rod 108, the

single rated coil spring 116 is compressed until the second end 106 of the fluid chamber

102 touches the helper spring 122. At the end of the first part of the sliding of the piston

rod 108, the helper spring 122 is activated by the first fluid chamber 102, as the second

end 106 of the first fluid chamber 102 comes in contact with the helper spring 122.

Further, during a second part of the sliding of the piston rod 108, the helper spring 122

and the single rated coil spring 116 are compressed in tandem.(has been added as

amendment in the description).

[0033] It is apparent from FIG. 4 that the curve 400 representing the energy

dissipated in the conventional non-linear coil spring used in combination with a Bump-

Stop is linear in nature while the curve 402 representing the energy dissipated by the

single rated coil spring 116 used in combination with the helper spring 122 is logarithmic

in nature. This shows that the tandem working of the single rated coil spring 116 and the

helper spring 122 provides the effective dissipation of heat (has been added in the

description).

Learned agent for the applicant provided statement under rule 14(2) of the Patent

amendment rules, 2016 for reason for amendment

1. Amendment: Page 5, Para [0016], Line 1 of the specification The term ―anti-theft

device‖ has been deleted. Instead, the word ―shock-absorber‖ has been added.

Reason for the amendment: The amendment is by way of correction of typographical

error.

2. Amendment: Page 8, Para [0031], Lines 17-27 of the specification The following

paragraph has been added by way of explanation of the FIG. 2 and FIG. 3. It is

submitted that no new matter is added.

―[0031] As it is apparent from FIG. 2 and FIG. 3, the piston rod assembly has a

first end 124 and a second end 126. The piston 114 is disposed at the first end 124 of

15

the piston rod assembly. The piston rod 108along with the piston 114 axially slides

through the second end 106 of the first fluid chamber 102 towards the first end 104 of

the first fluid chamber 102. During a first part of the sliding of the piston rod 108, the

single rated coil spring 116 is compressed until the second end 106 of the fluid chamber

102 touches the helper spring 122. At the end of the first part of the sliding of the piston

rod 108, the helper spring 122 is activated by the first fluid chamber 102, as the second

end 106 of the first fluid chamber 102 comes in contact with the helper spring 122.

Further, during a second part of the sliding of the piston rod 108, the helper spring 122

and the single rated coil spring 116 are compressed in tandem.‖

Reason for the amendment: Amendment is by way of explanation of the FIG. 2 and FIG.

3 to bring out more clarity.

3. Amendment: Page 9, Para [0033], Lines 6-11 of the specification The

following paragraph has been added by way of explanation of the FIG. 4. It is

submitted that no new matter is added.

―[0033] It is apparent from FIG. 4 that the curve 400 representing the energy

dissipated in the conventional non-linear coil spring used in combination with a Bump-

Stop is linear in nature while the curve 402 representing the energy dissipated by the

single rated coil spring 116 used in combination with the helper spring 122 is logarithmic

in nature. This shows that the tandem working of the single rated coil spring 116 and the

helper spring 122 provides the effective dissipation of heat.‖

Reason for the amendment: Amendment is by way of explanation of the FIG. 4 to bring

out more clarity.

4. Amendment: Page 9, Para [0035], Line 18 of the specification The word ―spirit‖

has been deleted.

Reason for the amendment: The use of improper term is avoided.

5. Amendment: Sheet 2 of the drawing

Numeral 124 (first end of the piston rod assembly) and numeral 126 (second end of the

piston rod assembly) have been added.

Reason for the amendment: The amendment brings out more clarity to the drawing

and subsequent description. The amendment also fulfils the requirement under rule

14(2) of the Patents (Amendment) Rules, 2016.

6. Amendment: Sheet 3 of the drawing

16

Numeral 124 (first end of the piston rod assembly) and numeral 126 (second end of the

piston rod assembly) have been added.

Reason for the amendment: The amendment brings out more clarity to the drawing and

subsequent description. The amendment also fulfils the requirement under rule 14(2) of

the Patents (Amendment) Rules, 2016.

Claim Chart showing the support from the description

Amended Claim 1 Relevant portion of the description

A shock absorber (100) for a two-wheeled vehicle, the shock absorber (100) comprising:

Para [0001] - The subject matter described herein, in general, relates to a shock absorber

for a vehicle and in particular, relates to a

shock absorber with a helper spring.

a first fluid chamber (102) having a first end (104) and a second end (106);

Para [0019] - The mono-tube shock absorber 100 includes a first fluid chamber 102, having

a first end 104 and a second end 106 that

stores a damping fluid.

a piston rod assembly having a first end (124) and a second end (126), the piston rod

assembly comprising:

Para [0031] - As it is apparent from FIG. 2 and FIG. 3, the piston rod assembly has a first

end 124 and a second end 126.

a piston rod (108) having a first end (110) and a second end (112), wherein the second end

(112) is attached to the second end (126) of

the piston rod assembly; and

Para [0019] - The mono-tube shock absorber also includes a piston rod 108 having a first

end 110 and a second end 112, a piston 114

and valving components.

a piston (114) disposed at the first end of the piston rod assembly, wherein the piston (114)

is concentrically mounted on the first end

(110) of the piston rod (108), and wherein the

first end (110) of the piston rod (108) along

with the piston (114) is capable of axially

sliding through the second end (106) of the

first fluid chamber (102) towards the first end

(104) of the first fluid chamber (102), and

wherein the sliding of the piston rod (108)

comprises a first part of the sliding and a

second part of the sliding;

Para [0019] - The mono-tube shock absorber also includes a piston rod 108 having a first

end 110 and a second end 112, a piston 114

and valving components. The piston 114

along with the valving components is

disposed concentrically on the first end 110 of

piston rod 108. The piston rod 108, the piston

114 and the valving components form a

piston rod assembly that axially slides

through the second end 106 of the first fluid

chamber 102 towards the first end 104 of the

first fluid chamber 102.

17

a single rated coil spring (116) that opposes slidable movement of the piston rod assembly

in compression direction; the single rated coil

spring (116) having an upper end (118) and a

lower end (120), wherein the single rated coil

spring (116) is disposed concentrically, and

wherein the lower end (120) of the single

rated coil spring (116) is attached to the

second end (126) of the piston rod assembly

and the upper end (118) of the single rated

coil spring is attached to the first end (104) of

the first fluid chamber (102); and

Para [0020] - The single rated coil spring 116 opposes slidable movement of the piston rod

assembly in the compression direction and

also supports the weight of the vehicle. The

energy absorbed by the single rated coil

spring 116 is then dissipated in the form of

heat by the damping fluid of the shock

absorber 100. The single rated coil spring 116

has an upper end 118 and a lower end 120.

a helper spring (122) slidably and concentrically disposed on the second end

(112) of the piston rod (108), wherein the

Para [0021] - A helper spring 122 is slidably and concentrically disposed on the second end

112 of the piston rod 108. The helper spring

helper spring (122) is having diameter lesser than the single rated coil spring (116),

wherein

122 has a diameter substantially lesser than that of the single rated coil spring 116.

the single rated coil spring (116) being made from Grade-2 wire and the helper spring (122)

being made from polyurethane, and wherein

Para [0020] - Further, the single rated coil spring 116 is made up of a Grade-2 steel wire,

which is substantially cheaper than the

commonly used Grade-3 steel wires.

Para [0021] - The helper spring 122 is made

up of polyurethane material that has the

property of efficiently absorbing and

dissipating energy.

the single rated coil spring (116) is compressed during the first part of the sliding

of the piston rod (108), and wherein

Para [0031] - During a first part of the sliding of the piston rod 108, the single rated coil

spring 116 is compressed until the second end

106 of the fluid chamber 102 touches the

helper spring 122.

the second end (106) of the first fluid chamber (102) activates the helper spring

(122) at end of the first part of the sliding of

the piston rod (108) so that the helper spring

(122) and the single rated coil spring (116)

are compressed in tandem during the second

part of the sliding of the piston rod (108).

Para [0031] - At the end of the first part of the sliding of the piston rod 108, the helper spring

122 is activated by the first fluid chamber 102, as the second end 106 of the first fluid

chamber 102 comes in contact with the helper

spring 122. Further, during a second part of

the sliding of the piston rod 108, the helper

spring 122 and the single rated coil spring 116

are compressed in tandem.

18

12. I have to decide on two issues for further proceedings of this case

(a) Whether amendments carried out by the applicant in the description, claims and

drawings and submitted after all hearing proceedings falls within the scope of

Section 59(1) of the Patents Act?

(b) Whether Opponents were allowed to submit their arguments or a hearing

opportunity should be given to them regarding the amendments carried out in the

description, claims and drawings and submitted after hearing proceedings?

13.Analysis of the amendments carried out during the opposition proceedings.

Claim1 as on 18/02/2015 Amended claim1 filed on 25/05/2016

. A shock absorber (100) for a vehicle, said shock absorber (I 00) comprising: a first fluid chamber (102) having a first end (104) and a second end (106);a piston rod assembly comprising: a piston rod (I 08) having a first end (II 0) and a second end (112); a piston (114) disposed concentrically on said first end (II 0) of said piston rod (I08) wherein said first end (110) of said piston rod (I08) along with said piston (114) is capable of axially sliding through said second end (106) of said first fluid chamber (102) towards said first end (104) of said first fluid chamber (I02); a single rated coil spring (116) that opposes slidable movement of said piston rod assembly in compression direction, wherein said single rated coil spring (116) having an upper end (118) and a lower end (120); a helper spring (122) slidably and concentrically disposed on said second end (112) of said piston rod (I 08), wherein said helper spring (122) is having diameter substantially lesser than said single rated coil spring (116); characterized in that said single rated coil spring (116) being

A shock absorber (100) for a two-wheeled vehicle, the shock absorber (100) comprising: a first fluid chamber (102) having a first end (104) and a second end(106); a piston rod assembly having a first end (124) and a second end(126), the piston rod assembly comprising: a piston rod (108) having a first end (110) and a second end(112), wherein the second end (112) is attached to the second end (126) of the piston rod assembly; and a piston (114) disposed at the first end (124) of the piston rod assembly, wherein the piston (114) is concentrically mounted on the first end (110) of the piston rod (108), and wherein the first end (110) of the piston rod (108) along with the piston (114) is capable of axially sliding through the second end (106) of the first fluid chamber (102) towards the first end (104) of the first fluid chamber (102), and wherein the sliding of the piston rod (108) comprises a first part of the sliding and a second part of the sliding; a single rated coil spring (116) that opposes slidable movement of thepiston rod assembly in compression direction, the

19

made from Grade-2 wire and said helper spring (122) being made from polyurethane.

single rated coil spring (116) having an upper end (118) and a lower end (120), wherein the single rated coil spring (116) is disposed concentrically, and wherein the lower end (120) of the single rated coil spring (116) is attached to the second end (126) of the piston rod assembly and the upper end (118) of the single rated coil spring is attached to the first end (104) of the first fluid chamber (102); and a helper spring (122) slidably and concentrically disposed on the second end (112) of the piston rod (108), wherein the helper spring (122) is having diameter lesser than the single rated coil spring (116); wherein the single rated coil spring (116) being made from Grade-2 wire and the helper spring (122) being made from polyurethane, and wherein the single rated coil spring (116) is compressed during the first part of the sliding of the piston rod (108), and whereinthe second end (106) of the first fluid chamber (102) activates the helper spring (122) at end of the first part of the sliding of the piston rod (108) so that the helper spring (122) and the single rated coil spring (116) are compressed in tandem during the second part of the sliding of the piston rod (108).

14. In view of the amendments,

Following four conditions to be satisfied for passing amendment‘s in accordance with

Section 59(1) of the Patents Act.

(1).The amendment can only be by the way of disclaimer, correction and

explanation.

20

(2).No amendment shall be allowed except for this purpose of incorporation of

actual fact.

(3).Amendment, the effect of which would be that of the specification as amended

would claim or describe the matter not in substance disclosed or shown in the

specification before the amendment, shall not be allowed.

(4).Amendment, the effect of which would be that any claim as amended would

not fall wholly within the scope of a claim of the specification before the

amendment, shall not be allowed.

15. I have referred the following case laws

1.OA/4/2009/PT/CH (ORDER NO:189/2012) of The Hon’ble IPAB: Amended claims are beyond the scope of the

claims as originally filed specification in view of the additional elements and amended claims were not allowed.

2.ORA/17/2009/PT/CH and ORA/31/2009/PT/CH (ORDER NO:140/2012 The Hon’ble IPAB: “We are convinced

that amendments carried out duing the prosecution of the application in the specification , drawings and claims

extend beyond the scope of disclosed matter and claims which is particularly prohibited by Section 59”.

a. In Order no. 140/2012, the Intellectual Property Appellate Board has stated:

In Bonzel (T.) and Anr.v.Intervention Limited and Anr.(No:3) (1991) RPC 553 at page

no: 574 the well-known test for deciding if new matter has been added has been set out

clearly .According to this task of the court is threshold

(1) To ascertain through the eyes of the skilled addressee what is disclosed , both

explicitly and implicitly in the application.

(2) To do same in respect of the Patent as granted.

(3) To compare the two disclosures and decide whether any subject matter relevant to

the invention has been added whether by deletion or addition. The comparison is strict

in the sense that subject matter will be added unless such matter is clearly and un

ambiguously disclosed in the application either explicitly or implicitly.

Further the court of Appeal in A.C. Edwards Ltd.V.Acme Signs & Displays Ltd (1992)

RPC 131 quoted from the decision of the EPO technical board of Appeals in Thomson-

CST (T151/84) (1998) E.P.O.R 29 as follows

3. In order to determine whether or not the modification made to a claim extends the

subject matter of the patent application beyond the contents of the application as filed, it

21

is necessary to find out whether the resulting modification to the contents of the

application (Whether by addition, modification or withdrawal) is such that information

presented to the skilled man is not derived directly and un ambiguously from that which

the application contained previously, even taking account of the elements which are

implicit to the skilled man (Guidelines For Examination at the EPO,C-V1,5.4).In other

words , it is necessary to find out whether the new claim presented is supported by the

original description.

3.1.In the case in point , the important thing is therefore not that a logical analysis of the

text be carried out in order to determine whether or not the initial intention of the

applicants was to limit the protection claimed to a particular combination of

characteristics described and represented, but rather that it to be discovered whether

the skilled man reading the patent application as filed would consider that the

characteristics under discussion, namely the presence of permanent magnets, is or is

not a characteristic which is dispensable to the operation of the device described in the

application.

As Whitford J observed in Polymer corporation patent (1972) RPC 39 at 45

―Explanation means making plain or making clear‖ I t can make the ambiguous clear ,

but no the insufficient sufficient. It is therefore a question of the fact in each case as to

the information contained in the original specification and it requires to be further

explained. The essence of the explanatory amendments are in that they often make

explicit what is clearly implicit to a fair minded and properly instructed person reading

the document carefully as a whole, but might be so clear in the more casual or biased

reader. They are made for the avoidance of the doubt, even an unreasonable doubt.

The amendments shall be in a sense of the kind which otherwise necessary‖.

31. if we see the purpose of the amendments under section 57(6) and the limitation

imposed on the amendments under section 59 we find that it is necessary , in our view

to take consideration the following;

1. Does Section 57(6) permit an applicant to file an application which is

defective in it’s description of the invention inorder that he may subsequently

make good that defect by providing additional further descriptive material?

2. Are all routes for amending defects, subject to Section 59?

22

3. Does even refining of description in the specification by way of explanation be

held to be an amendment to cure the deficiencies that are not permissible under section

59?

In considering the whole question of discretion in respect of amendments under section

57(6) in present case it is also necessary , in our view to take in to consideration the

nature and extent of amendment, when they are primarily for explanation and it is in

public interest to allow them, In absence of very compelling reason to the contrary.

However these amendments in any case will not be stretched beyond the limitations

imposed by section 59.The purpose of Section 57(6) is not to permit an applicant to

file an application which is defective in it’s description of the invention inorder he

may subsequently make good that defect by providing additional further

descriptive material.

When we apply the above tests relating to the amendment to the present case we find

all the matter which was added during the prosecution of application was not merely

explanatory as additional elements such as ----- were added. These elements were not

disclosed in the specification even implicitly. Additional drawings relating to additional

matter were also filed to support the claims for these elements. We find that effect of the

added matter in the specification and claims is such that it described the matter not in

substance disclosed or shown in the specification before the amendment. Further

amended claims 1-20 do not fall wholly within the scope of the claims 1-4 as originally

filed. We are convinced that amendments carried out during the prosecution of

the application in the specification, drawings and claims extend the scope of

disclosed matter and claims, which is particularly prohibited by Section 59. The

applicants therefore succeed in proving that new matter has been added by the

Respondent 1 during the prosecution of the application which was allowed by

Respondent 2. The Respondent 2 ought to have sought for explanation from the

Respondent 1. Respondent 2 ought to have applied his discretion more cautiously and

judiciously under section 57(6), especially when there are large scale amendments as in

the present case. Therefore, we are constrained to set aside the amendments

allowed during prosecution of the application.

b. In Order no. 189/2012, the Intellectual Property Appellate Board has stated:

65. The counsel relied on the following Judgments/Case Laws

(a) Smith Kline & French Laboratories Limited vs. Evans Medical Limited - 1989 (1)

Fleet Street Reports 561

23

The principles in respect of law on amendment of specification/claims have been

enunciated in the above mentioned case in para 2 at page 569 as under:

"The discretion as to whether or not to allow amendment is a wide one and the cases

illustrate some principles which are applicable to the present case. First, the onus to

establish that amendment should be allowed is upon the patentee and full disclosure

must be made of all relevant matters. If there is a failure to disclose all the relevant

matters, amendment will be refused. Secondly, amendment will be allowed provided the

amendments are permitted under the Act and no circumstances arise which would lead

the court to refuse the amendment. Thirdly, it is in the public interest that amendment is

sought promptly. Thus in cases where a patentee delays for an unreasonable period

before seeking amendment, it will not be allowed unless the patentee shows reasonable

grounds for his delay. Such includes cases where a patentee believed that amendment

was not necessary and had reasonable grounds for that belief. Fourthly, a patentee who

seeks to obtain an unfair advantage from a patent, which he knows or should have

known should be amended, will not be allowed to amend. Such a case is where a

patentee threatens an infringer with his unamended patent after he knows or should

have known of the need to amend. Fifthly, the court is concerned with the conduct of the

patentee and not with the merit of the invention. "

b. Bristol-Myers Co. (Johnson & Hardcastle's) [1974] RPC 389

------ The reasoning, ratios and precedents cited in this case to arrive at the said

conclusions clearly suggest that the amendments sought in the present case are liable

to be rejected. Few of such reasoning/ratios are reproduced as under:

At page 400, para 2 it is observed as under:

"Lord MacDermott quotes from the speech of Lord Westbury in the Ralston case and

refers in particular to a passage where Lord Westbury said: (see Lord MacDermott's

speech, page 66, line 41):

"But it was never intended that you should convert a bad specification in the sense of its

containing no description of any useful invention at all into a good specification by

adding words that would convert what has been properly called in the court below a

barren and unprofitable generality into a specific and definite and practical description. It

is quite clear that, if that could be done. you would have an opportunity of introducing

into a bad patent which contained no useful invention whatever. some discovery that

might be developed by further experiment, and which was altogether unknown at the

time of the original specification, and not at all included in the description contained in it

24

", and later ―...the statute never contemplated that the patentee should have the power.

under the form of a disclaimer, of making material additions to the original specification,

so as bv the aid of the corrected form of words. and the additions so made. to introduce

into the specification an accurate and perfect description of an invention which you seek

for in vain in the original specification."

At the same page, it was further observed as under:

"He also cited a passage from a decision of Mr. Justice Luxmoore in Eveno's Patent

(1932) 2 Ch. 167, where Luxmoore, J. said:

"Can it be said that any amendment which in fact results in a narrower claim than that

originally put forward is by way of disclaimer? In my judgment, it is necessary to

consider not whether the amended claim is narrower or more restricted than the original

claim, but whether it covers something not claimed or suggested as constituting the

original invention, or part of the original invention. If it does. then it seems to me that the

amendment can only properly be described as covering a fresh claim, and it would be

an abuse of language to say that such a claim arose owing to amendment by way of

disclaimer.‖

In para 4 at page 402, it is held as under:

"It is plain that the present case differs in certain important respects from AMP Inc. v.

Hellerman Ltd. By this amendment the applicants are not seeking to limit a construction

by adding a further feature. They are seeking to discard one form of starting material,

and that not because they want to give it up because they want voluntarily to relinquish

this part of a properly claimed monopoly, but because they must exclude the hydrated

salt if " their patent is to stand valid. I do not think this is truly disclaimer.

73. Respondent 1 disallowed these amendments stating that the amendments in claims

are ‗not fairly supported by description and requires addition of new subject matter‘. We

are convinced that the amendment of claims is not permissible but for the different

reason that the amended claims would not fall wholly within the scope of a claim of the

specification before the amendment as required under section 59. We however affirm

his decision for the reason stated above.

16. Applicants have carried out two types of amendments

(1) Voluntary amendment

(2) Amendment in order to meet office objections.

25

17.On my observation amendment carried out in the page no:5, Para (0016), line of the

specification ―the term antitheft device ―has been deleted and shock absorber has been

added and reason provided by the applicant is the amendment is by a way of correction

of typographical error. Neither form 13 nor request for correction of clerical error has

been submitted along with the prescribed fees being it is considered as voluntary

amendment. Further In page no: 9, Para (0035), Line 18 of the specification the word

spirit has been deleted being it was use of improper term which is deleted by the

applicant voluntarily and no prescribed form along with the fees has been filed.

18. Amendment carried out in the page 8, para (0031), lines 17-27 of the specification

and the following paragraph has been added by the way of explanation of Fig: 2 and Fig

:3.Further description has been added in para (0033) by way of explanation of Fig

:4.And two reference numerals (124 & 126) has been added in sheet 2 and sheet 3 of

the drawings. It is very clear that additional technical features have been incorporated in

the description which is substantially contributing to the invention and further these

additional features are incorporated in the claim1 and claim 2 as well which makes

claims elaborate. It is clearly ordered by the Hon‘ble IPAB that the purpose of the

Section 57(6) is not to permit an applicant to file an application which is defective in its

description of the invention in order; he may subsequently make good that defect by

providing additional further descriptive material.

19. I carefully considered the arguments put forward by the learned agent for the

applicant and based on the decisions issued by the Hon‘ble IPAB and my own analysis,

I have concluded that the amendments carried out in the description, claims and

drawings and submitted along with the written submission after all hearing proceedings

goes beyond the scope of section 59 of the Patents Act. In view of the reasons stated,

this office is not in position to allow these amendments carried out and submitted after

all hearing proceedings.

20. Learned agents for applicants submitted their written response on 1/06/2016 and

they have also filed an expert affidavit, for the hearing proceedings happened with

Opponent 2 on 25/04/2016. Learned agents for Opponent 2 have filed their written

response on 13/05/2016. Learned agents for applicant filed their written response on

03/06/2016 for the hearing proceedings happened with Opponent 1 on 10/05/2016 and

learned agents for the Opponent 1 has filed their written response on

4/06/2016.However the learned agent for opponent 1 requested time for filing expert

affidavit based on the natural justice principle and based on the decisions taken by the

Hon‘ble Madras High court and the Hon‘ble IPAB, It is decided to take that expert

affidavit from the opponent 1 along with a Petition U/R 137.

26

Extracts of High Court decision is reproduced here with for clarity

Hon’ble High Court of Madras in the case Novartis AG Vs. Union of India and

others ( W.P.No. 15736 of 2015)in the matter against the decision of Hon’ble IPAB

(ORA/21/2013/PT/CH) for reception of additional documents and raising additional

grounds. The Hon‘ble High court ordered that ― We have no hesitation to hold that the

appellate Board is vested with powers to regulate its own procedure as it is vested with

same powers of a civil court under code of civil procedure, More particularly for the

purpose of receiving evidence. Thus the Appellate Board was fully justified in

entertaining the Miscellaneous Petition filed by the second respondent. In the Light of

the above --- discussion, the order impugned passed by the IPAB was held and was not

interfered. Accordingly, the writ petition failed and was dismissed.

This office has noted that request from both the opponents that an opportunity may be

provided in case this office is considering the amendments put forward by the applicant

after the hearing proceedings, being this office have decided not to allow the

amendments carried out by the applicant that requests are not considered. So I proceed

further with the claims on 18/02/2015 on which hearing proceedings are happened

between two opponents and the applicant and for better clarity claims are reproduced

herewith.

I. A shock absorber (100) for a vehicle, said shock absorber (I 00) comprising:

a first fluid chamber (102) having a first end (104) and a second end (106);a piston rod

assembly comprising:

a piston rod (I 08) having a first end (II 0) and a second end (112);

a piston (114) disposed concentrically on said first end (II 0) of said piston rod (I08)

wherein said first end (110) of said piston rod (I08) along with said piston (114) is

capable of axially sliding through said second end (106) of said first fluid chamber (102)

towards said first end (104) of said first fluid chamber (I02);

a single rated coil spring (116) that opposes slidable movement of said piston rod

assembly in compression direction, wherein said single rated coil spring (116) having an

upper end (118) and a lower end (120);

a helper spring (122) slidably and concentrically disposed on said second end (112) of

said piston rod (I 08), wherein said helper spring (122) is having diameter substantially

lesser than said single rated coil spring (116);

27

characterized in that

said single rated coil spring (116) being made from Grade-2 wire and said helper spring

(122) being made from polyurethane.

2. A twin tube shock absorber (200) for a vehicle, said shock absorber comprising: a

first fluid chamber (102) having a first end (104) and a second end (106);

a inner chamber (202) having a first end (204) and a second end (206); wherein said

first fluid chamber (102) is having a diameter substantially larger than said inner fluid

chamber (I02) such that said first (104) and second (106) ends of said first fluid

chamber (I02) are disposed in close proximity to said first (204) and second (206) ends

of said inner chamber (202) respectively;

a piston rod assembly comprising:

a piston rod (108) having a first end (II 0) and a second end (112);

a piston (114) disposed concentrically on said first end (110) of said piston rod(108)

wherein said first end (110) of said piston rod (108) along with said piston (114) is

capable of axially sliding through said second end (206) of said inner chamber (202)

towards said first end (204) of said inner chamber (202),

a single rated coil spring (116) that opposes slidable movement of said piston rod

assembly in compression direction; said single rated coil spring (116) having an upper

end (118) and a lower end (120);

a helper spring (122) slidably and concentrically disposed on said second end (112) of

said piston rod (108) wherein said helper spring (122) is having diameter substantially

lesser than said single rated coil spring (116);

characterized in that

said single rated coil spring (116) being made from Grade-2 wire and said helper spring

(122) being made from polyurethane.

3. The shock absorber as claimed in claim I or 2, wherein said damping fluid is oil.

4. The shock absorber as claimed in claim I or 2, wherein said damping fluid is gas.

5. The shock absorber as claimed in claim 1 or 2, wherein said damping fluid is a

mixture of oil and gas.

28

6. The shock absorber as claimed in claim I or 2, wherein said upper end (118) and

lower end (120) of said single rated coil spring (116) is having closed pitch coils.

24. Opponents submitted following documents for proving lack of novelty and

inventive step.

1. DE 10034563 A1(herein after referred as D1) relates to a spring element containing

an insert (1) consisting of a compact material that is more rigid than the material that the

spring element consists of, a part (2) that functions as a helper spring and a part (3) that

functions as a spring pad. The spring elements produced from polyurethane elastomers

are used in automobiles addition products, for example within the chassis, example, on

the basis of elastic plastic materials, such as rubber or elastomers based on

polyisocyanate poly, such as polyurethanes and / or polyureas, uses, and are well

known. They are particularly used in motor vehicles as overload springs, impact

dampers or stops.

2.DE 10337175 (herein after referred as D2) relaters to a spring construction, in

particular in automotive suspensions, comprising spiral spring , at the end thereof of a

spring seat is positioned as well as a preferably cylindrical , preferably hollow auxiliary

spring , preferably on the basis of cellular polyisocyanate poly addition products ,

particularly preferably based on the cellular polyurethane elastomers preferably having

a density according to DIN53420 from DIN 200 TO 1100. In addition , the invention

relates to automobiles, that vehicles of all kinds eg. Passenger cars, lorries or buses ,

as well as motor cycles and bicycles, but preferably motor vehicles comprising spring

elements according to the invention and/or spring structures, particularly in the chassis.

Made from polyurethane elastomer suspension elements are used in automobiles , for

example within the chassis and are generally known. Typical spring designs are

constructed such that on the piston rod of the shock absorber from an additional spring

polyurethane elastomers is fixed.In addition, there is usually a helical spring, which is

fixed on a spring pad.

3.DE10344102 (herein after referred as D3) relates to a spring carrier with an auxiliary

spring according----- the additional spring often made of cellular elastomer.

4.DE20309425 (U1) (here in after referred as D4) relates a spring based on a

polyisocynate polycondensation product, preferably polyurethane , and is 105-115mm

high and of diameter 53-56 mm.

29

5.DE20311243 ( herein after referred as D5) relates a helper spring is based on a

polyisocyanate condensation product, preferably polyurethane, and is 78-82 mm high

and of diameter 59-63 mm. The end is in the form of a lip and the element has a hollow

internal diameter of 20-24 mm. Preferably the outside of the spring has grooves and

protuberances with a distance between protuberances of 5-15 mm.product,.

6.US3263983 (herein after referred as D6) discloses a shock absorber and auxiliary

spring unit. In FIGURE 4 discloses the various components of the unit 24 when in a full

jounce position. Under these conditions, the retainer 62 is in engagement with the stop

member 70 causing the spring 56 to carry a large portion of the sprung vehicle weight.

By rigidly securing the lower end of the coil spring 56 to the shock absorber tube 38,

there is less tendency for it to buckle as compared with designs wherein the lower end

of the coil spring is merely seated on a support member. A rubber corrugated spring 72

may also be provided. A spring of this type is shown in Patent No. 168,845. This spring

comes into operation only during extreme jounce deflection such as shown in FIGURE

4. That figure discloses the manner in which the spring 72 is distorted. It has a sliding fit

on the rod 34.

7.US4486028A (herein after referred as Y1). discloses a front wheel support structure

for an automobile comprises a first support fixed to a body, a second support disposed

beneath and spaced at the inner portion thereof from the first support, contacting a

bound stopper at the underside of the inner peripheral portion and secured fixedly to the

first support at the outer peripheral portion, a mount rubber disposed between both

supports, a connecting member secured fixedly to the mount rubber and mounted on

the upper portion of a piston rod of a shock absorber and a bearing seat disposed at the

underside of the second support and contacting a spring seat for receiving the upper

end of a coil spring. In use of the support structure, force from the piston rod is

transmitted from the mount rubber through the first support to the body, force from the

bound stopper is transmitted from the second support through the first support to the

body and force from the coil spring is transmitted from the spring seat to the bearing

seat and further through the second and first supports to the body respectively.

8. US4477061 (herein after referred as Y2) discloses a MacPherson strut type

suspension including a shock absorber operatively disposed between vehicle wheels

and a vehicle body of a motor vehicle, the shock absorber having a piston rod; a coil

spring disposed in association with the shock absorber to elastically support the vehicle

body; a core member secured to an end of the piston rod of the shock absorber; an

insulator rubber securely connected between the core member and the vehicle body;

and a stop device for restricting the movement of the core member in the axial direction

30

of the piston rod of the shock absorber when the axial movement of the piston rod

exceeds a predetermined distance, thereby effectively damping high and low frequency

vibrations applied to the suspension while prolonging the life of the insulator rubber.

9. US4175770 (herein after referred as Y3) relates to suspension struts for motor

vehicles, utilising a telescopic damper.

10. US4438660 (herein after referred as Y4) relates to an operator-movable control

lever assembly with a single lever having both friction-held and spring-centered

operational modes .

11.US 4042259 (herein after referred as Y5) relates to suspension strut assemblies for

wheel suspensions of motor vehicles.

12.US3263983 (herein after referred as Y6) relates to A vehicle suspension system

having sprung and unsprung parts, a suspension spring interposed between said parts

and constructed for resiliently supporting said sprung parts on said unsprung parts, a

direct acting telescopic shock absorber interposed between said parts, said shock

absorber having a body portion connected to one of said parts and a piston rod portion

connected to the other of said parts, a spring seat secured to said body portion, a coil

spring disposed concentrically about said body portion and having one end secured to

said spring seat, a cupshaped rubber retaining member connected to the other end of

said coil spring and slidably receiving said piston rod portion, a rubber'spring

surrounding said piston rod portion and situated within said coil spring between said

retaining member and said body portion, a stop member secured to the end of said

piston rod portion, said stop member being spaced apart from said retaining member

when said shock absorber is in an extended rebound position but engaging said

retaining member when in a jounce position.

13 .US 2003137091 (herein after referred as Y7)concerns a suspension stop device, for

a motor vehicle driving wheels, comprising a filtering block, consisting of an upper

housing fixed relative to the vehicle body and co-operating with a lower housing mobile

in rotation about a shock absorber rod and supporting a suspension spring, and a ball

bearing. Said upper (21) and lower (23) housings are made of thermoplastic material

and have opposite surfaces hollowed out in a circle, about the rotation axis (d) of the

shock absorber rod (24), to receive a raceway for the ball bearing (22). The upper

housing (21) further incorporates an impact stop (42) moulded around the leading stop

(41) of the shock absorbing device, and the thermoplastic structure of the upper housing

(21)is reinforced by a ring (45) made of overmoulded elastomer.

31

14. US6227527 (Herein after referred as Y8) relates to a pneumatic suspension system

forming a McPherson strut.

15. US5676355 (herein after referred as Y9) relates to a suspension system which is

applicable to automobiles.

16. US 5257730 (herein after referred as Y10) relates to a bound stopper for use in a

suspension of a motor vehicle, which is fitted on a piston rod of a shock absorber of the

suspension, for elastically limiting a stroke of the piston rod by abutting contact with a

cylinder of the shock absorber. The bound stopper includes a cylindrical main elastic

body formed of a rubber material and having an engaging portion at one axial end on

the side of the cylinder of the shock absorber, and a cylindrical auxiliary elastic body

formed of a foam material and having an engaging portion at one axial end remote from

the cylinder of the shock absorber, one of the engaging portions of the main and

auxiliary elastic bodies having at least one recess while the other of the engaging

portions having at least one protrusion. The engaging portion of the auxiliary elastic

body is fitted on the engaging portion of the main elastic body such that the protrusion is

fitted in the corresponding recess for engagement of the two elastic bodies.

17.US5052665 (herein after referred as Y11) discloses a bumper rubber comprises: a

bumper rubber body being elastically deformable and having a substantially cylindrical

shape, wherein the bumper rubber body is inserted into a rod extending from a top end

portion of a cylinder of a shock absorber, a top end surface thereof is brought into

contact with a bottom end portion of a suspension insulator disposed on a vehicle body,

and a bottom end surface thereof is brought into contact with a top end portion of the

cylinder, thereby being elastically deformed and absorbing the excessive displacements

of the shock absorber; and a rigid ring integrally insert-molded on an outer periphery

surface of the bumper rubber body and having an engagement groove on an exposed

outer periphery surface thereof to be engaged with a dust cover, and the engagement

groove going round on the exposed outer periphery surface of the rigid ring in a ring-like

shape.

18.US 4756516 ( herein after referred as Z1) relates to a resiliently deformable element

made of an elastomeric material having a microcellular structure, which can be used as

an end stop in a motor vehicle suspension, in particular a suspension of the Mac

Pherson type.

19. US4962916 ( herein after referred as Z2) discloses an elastomeric spring useful as

an automotive shock or strut end-of-travel bumper having at least three distinct spring

rates made possible by a series of roughly cylindrical, hollow elastomeric tubes stacked

32

with the axes of the tubes normal to the axis of deflection of the spring. The tubes

collapse sequentially to yield multiple spring rates. Non uniform wall thickness tubes, roll

axially over the outer peripheral surface of the thicker walls of adjacent tubes during

deflection.

20. US4105194 (herein after referred as Z3) relates to combined shock absorber and