Beam Design for Geometric Nonlinearities

description

Transcript of Beam Design for Geometric Nonlinearities

BEAM DESIGN FOR GEOMETRIC NONLINEARITIES

Jordan RadasKantaphat SirisonWendy Zhao

PREMISE

Large deflectionLinear assumptions no longer applyIs necessary form many real life applications

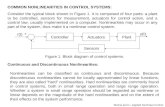

DESIGN OVERVIEW Nonlinear Linear

GEOMETRIC NONLINEARITY ASSUMPTIONS Large deformation Plane cross section remains plane Linear elastic material Constant cross section

ux1

ux2

KINEMATICS

Location of particle at deformed configuration relative to displacement and original configuration

KINEMATICS

e

(1 u'x )cos u'y sin 1 1(1 u'x )sin u'y cos

'

Characterize axial strain, shear strain and curvature in terms of the derivatives of the displacement

Green Lagrange Strain Tensor

STRAIN DISPLACEMENT MATRIX

[h]31 [B]36[d]61

e

dedux1

...dedu 2

ddux1

...ddu 2

ddux1

...ddux1

31

ux1...u 2

61

[B]The components of the strain displacement matrix can be

determined explicitly by differentiation.

B cos sin N1a cos sin N2asin cos N1b sin cos N2b0 0 1 0 0 1

where

a (1 u'x )sin u'y cos

b (1 u'x )cos u'y sin

TANGENT STIFFNESS MATRIX

dV ubdx uAtV 0

V 0

(EA GA EI)dx uyqV 0

[K][d]

R

Through discretization and linearization of the weak form

k BTDBdx kgeometricV 0

kmaterial

kg EAL

GAL

sin2 cos2 0 sin2 cos2 0 cos2 sin2 0 cos2 sin2 00 0 0 0 0 0

sin2 cos2 0 sin2 cos2 0cos2 sin2 0 cos2 sin2 00 0 0 0 0 0

NEWTON-RAPHSON METHOD

k ttu R tt

F tt R tt

F tt F t ku

k( i 1)u( i) R F ( i 1)

u(i) u(i 1) u( i)

Displacement

Load

F 4 R tt

F 0,u0

F1

F 2

F 3

K1

K 2

u1

u2

u3

u4

NEWTON-RAPHSON METHOD

RESTORING LOAD dVBF iTii )1()1()1(

XuI

XxF

URF

]ln[U

3

1

lni

Tiii ee

Definition of deformation gradient

Spatial Decomposition

Corresponds to element internal loads of current stress state.

From right polar decomposition theorem

INCREMENTAL APPROXIMATION

1 nnn

][][ nDed

2/12/1 RR nT

n

]ln[ U

From

11

nn FFURF

With

With

XuIURF

2/12/12/12/1

12/1 21

nn uuu

nn uB 2/1~ Wit

h 12/1 2

1 nn XXX

B Evaluated at midpoint geometry

NONLINEAR SOLUTION LEVELS

Load steps:Adjusting the number of load steps account for:

abrupt changes in loading on a structurespecific point in time of response desired

Substeps:Application of load in incremental substeps to obtain a solution within each load step

Equilibrium Iterations:Set maximum number of iterations desired

SUBSTEPSEquilibrium iterations performed until convergenceOpportunity cost of accuracy versus time

Automatic time stepping featureChooses the size and number of substeps to optimize

Bisections methodActivates to restart solution from last converged step if a solution does not converge within a substep

MODIFIED NEWTON-RAPHSON

Incremental Newton-Raphson Initial-Stiffness Newton-Raphson

DISPLACEMENT ITERATIONAs opposed to residual iteration

ANSYS FEATURESPredictor

Line Search Option

ANSYS FEATURESAdaptive Descent

DESIGN CHALLENGE: OLYMPIC DIVING BOARD

L = 96in b = 19.625in h = 1.625in P = -2500lbs

Al 2024 – T6 (aircraft alloy)

E = 10500ksi v = .33 Yield Strength = 50ksi

SOLID BEAM: LINEAR/NONLINEAR

Mesh Size Linear Nonlinear

.125in 8.1043in 2.1671 2.2383 8.1082in 2.1757 2.2442

.25in 8.0255in 2.2170 2.2675 7.9951in 2.2254 2.2749

.5in 8.0566in 2.3051 2.3144 8.0282in 2.3151 2.3195

OPTIMIZATION PROBLEM

ANSYS Goal Driven Optimization is used to create a geometry where hole diameter is the design variable.

Goals include minimizing volume and satisfying yield strength criterion.

OPTIMIZATION AND ELEMENT TECHNOLOGY Optimization samples points in the user specified design space.

The number of sampling points is minimized using statistical methods and an FEA calculation is made for each sample.

Samples are chosen based on goals set for output variables, such as volume and safety factor.

OPTIMIZATION RESULTS

Problem Method Volume Deflection

Max Tensile

Von Mises

Solid Beam

Linear 3061.5in38.0566in 2.3051 2.3144

Nonlinear 8.0282in 2.3151 2.3195Optimiz

ed Beam

Linear2719.5in3

8.7993in 1.2754 1.2555Nonlinear 8.7576in 1.2756 1.2757

CONCLUSION Analysis serves as a proof of concept that real-world situations involving large structural displacements benefit from nonlinear modeling considerations

Extra computing power and time is worth it Recommendations/suggestions

QUESTIONS?