Bahan Teknik Advanced Ceramics-1

-

Upload

arlita-nurmaya-asri -

Category

Documents

-

view

227 -

download

3

description

Transcript of Bahan Teknik Advanced Ceramics-1

MATA KULIAH PILIHAN KERAMIK TEKNIK (ENGINEERING CERAMICS) (TKM 6322)

ADVANCED ENGINEERING CERAMICSMuhammad Kusumawan Herliansyah(Dept. of Mechanical and Industrial Eng. Gadjah Mada University)

What is Ceramic?Ceramics can be defined asInorganic and nonmetallic materials. They are typically crystalline in nature and are compounds formed between metallic and nonmetallic elements. (American Chemical Society)3Nanophase ceramics are ceramics in the nanophase.Keramik

Keramik

KeramikDefinisi:

material padat anorganik yang bukan logam

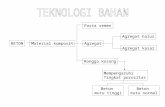

material yang sebagian besar merupakan senyawa antara unsur logam dan non logam dimana sebagian besar ikatannya adalah ikatan ion dan sedikit ikatan kovalenCeramics ..Ti+OCNBTiO2TiCTiNTiB2OxideCarbideNitrideBoride7Nanophase ceramics are ceramics in the nanophase.KeramikOksida (CaO, SiO2, Al2O3, MgO, K2O, dan Na2O)Nitrida (Si3N4, AlN, GaN, InN, TiN, dan ZrN)Karbida (Fe3C, ZrC, TiC, VC, dan NbC)Senyawa logam + non logam:powderWhat is ADVANCED CERAMICS?Klasifikasi KeramikKeramik Tradisional

B.Keramik TeknikAtas dasar asal:CERAMIC MATERIALSTRADITIONAL CERAMICS(a range of ceramic products formed of bodies based on natural materials such as clay and silicates)ADVANCED CERAMICS(high chemical purity, careful processing and high values of the useful properties). Structural Ceramics Electro-ceramics Bio-ceramics Magnetic ceramics Opto-ceramics Technical CeramicsKeramik TradisionalKeramik yang bahan dasarnya berasal dari clay (lempung), silica, dan feldsparContoh:Keramik CinaPorselinBatu bataGelasSemenRefraktoriBahan abrasif

Traditional ceramics

Keramik TeknikKeramik yang berupa senyawa dari unsur logam dan non logam Contoh:Oksida (CaO, SiO2, Al2O3, MgO, K2O, dan Na2O)Nitrida (Si3N4, AlN, GaN, InN, TiN, dan ZrN)Karbida (Fe3C, ZrC, TiC, VC, dan NbC)

Products made from technical ceramics. Neurochip mounted in a 40-pin IC ceramics socket

Bio-ceramics

thermal barrier coating for gas turbine engine applications (Padture, et al, Science 2002)

Turbine blades are among parts subject to wear that are made of ceramic material. This prototype gas turbine rotor is made of injection-molded monolithic silicon nitride.

WHY SHOULD ENGINEERS KNOW ABOUT CERAMICS?Ceramics are materials that generally have excellent properties such as:high melting pointgood high temperature strengthhigh Youngs Modulushigh hardness and good wear resistancegood corrosion resistance relatively low thermal conductivityrelatively low thermal expansionrelatively low density.Compare to other types of materials, ceramics materials still have limitations in engineering applications because of their BRITTLENESS and LOW FRACTURE TOUGHNESS.Karakteristik umum keramikKerasKakuKuatGetasStabil pada suhu tinggiIsolatorTahan korosi dan tahan abrasiKekuatan tarik rendah sedangkan kekuatan tekannya tinggiKonduktifitas termal rendahMANUFACTURING PROCESS OF CERAMICSPowderForming Sintering Proper-tiesThe Properties of Ceramics Products are influenced by:Raw materials (Powder)Manufacturing Process (Forming and Sintering)Teknik fabrikasi keramik

Proses pembentukan gelasGelas dibentuk dengan cara memanaskan raw material di atas temperatur cairRaw material:SilicaNa2OCaONa2CO3CaCO3Metode pembentukan gelas Pressing

Blowing

Drawing

Fiber FormingPressingDigunakan untuk fabrikasi gelas dengan tebal tipisCetakan dan material awal dipanaskan dan selanjutnya dikompaksi dengan tekananCetakannya biasanya terbuat dari besi cor, mild steel, atau baja perkakas (tool steel) yang dilapisi dengan grafitProses pembentukan gelas

Proses Pressing dan blowing Bentuk gelas awal/parison dibentuk dengan mechanical pressing di dalam cetakanParison dimasukkan ke dalam finishing atau blow mold dan ditekan/press untuk mengisi bentuk kontur cetakan dengan menggunakan tekanan dari blast airProses penarikan lembaran gelas

DrawingDigunakan untuk fabrikasi gelas yang panjang dengan luas melintang konstan seperti lembaran, batangan, pipa, seratGelas cair diisikan ke dalam platinum heating chamberLembaran/serat gelas dibentuk dengan cara menarikan gelas cair melewati small orifices pada dasar chamberPowder Pressing Uniaxial Pressing

Isostatic/hydrostatic Pressing

Hot PressingCERAMICS MANUFACTURING PROCESSNatural and Synthetic Raw materials Milling Mixing Filtering Spray Drying Forming QPreparation for Sintering Drying Binder BurnoutBody Preparation Wet or Dry Pressing Cold Isostatic Pressing Extruding Slip Casting, etcQQQPowders Body Green BodySintering Q Presureless sintering Reaction Sintering HP (Hot Pressing) Hot Isostatic Pressing, etc FinishingQ Cutting Grinding, Polishing Joining, etcFinal Quality ControlQ examination of the Finished Product Raw Piece/ sintered body Product Sintering

STAGES OF SINTERING

HIP (Hot Isostatics Pressing)

HP (Hot Pressing)

Slip Casting Slip casting refers to the filling of a mould, a negative of the desired shape, with a slip consisting of a suspension of micrometer size ceramic particles in liquid.