B0301 - PSC Plank Girder full set - rms.nsw.gov.au · psc plank girder b0301 standard drawing no...

Transcript of B0301 - PSC Plank Girder full set - rms.nsw.gov.au · psc plank girder b0301 standard drawing no...

GENERAL NOTES

IS LESS THAN 6mm.

THE SHEAR DEFLECTION DUE TO SELF WEIGHT OF THE SUPERSTRUCTURE

DENOTES THAT BEARINGS MAY BE INSTALLED ON AN INCLINE PROVIDED

THE SIDES OF THE GROUT PADS AFTER THE REMOVAL OF FORMWORK.

MINIMUM OF 3 DAYS AND CURING COMPOUNDS SHALL BE APPLIED TO

THE FORMWORK FOR THE GROUT PADS MUST REMAIN IN PLACE FOR A

EDGES OF BASE PLATES.

SIDE FACES OF GROUT PADS SHALL BE VERTICAL AND FLUSH WITH

UNDER THE BASE PLATES.

RECESSES ARE COMPLETELY FILLED AND THAT THERE ARE NO VOIDS

GROUTING SHALL BE CARRIED OUT TO ENSURE THAT THE FORMED

MINIMUM COMPRESSIVE STRENGTH OF GROUT SHALL BE 40MPa.

CEMENTITIOUS GROUT EPIREZ SUPERFLOW HF OR APPROVED EQUIVALENT.

GROUT PADS AND SHALL BE SHRINKAGE COMPENSATED HIGH FLOW

DENOTES THE GROUT USED TO FILL FORMED RECESSES AND CONSTRUCT

AND 70mm AT ANY LOCATION.

DENOTES THE MINIMUM AND MAXIMUM THICKNESS OF GROUT SHALL BE 15mm

WELDNG SYMBOLS COMPLY WITH AS 1101.3.

THE WELD CATEGORY SHALL BE 1C, IN ACCORDANCE WITH AS/NZS 1554.6.

STEEL PLATE SHALL BE STAINLESS STEEL GRADE 304 TO ASTM A276.

THE MINIMUM 28 DAY COMPRESSIVE STRENGTH OF GROUT SHALL BE 40MPa.

SCALE OR AS SHOWN.

100 200 300 400 500mm0

10050

COPYRIGHT ROADS AND MARITIME SERVICES 2018

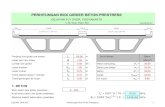

BEARING DETAILS

PSC PLANK GIRDER

B0301

STANDARD DRAWING No

EDMS No

DS2017/000886DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

21.12.2018

W.Ariyaratne

PSC PLANK

Mb

Ma

ABUTMENT A END

PSC PLANK

TABLE 1

PLANK TO SUIT BEARING USED

5 DEEP RECESS IN SOFFIT OF

ABUTMENT B END

LONGITUDINAL GRADE ON TOP OF BEARING BASEPLATE

%

%

%

%

%

%

NO

M NO

M

CAST-IN-PLACE CONCRETE DECK

PSC PLANK

ELEVATION OF PLANK AFTER DECK CONSTRUCTION

BEARING GROUT PAD

ELASTOMERIC BEARING

MODIFIED LAMINATED

TOP OF BEARING

25 MIN

No

SPAN

STRANDS AND LONGITUDINAL REINFORCEMENT

DENOTES 170 MIN SUBJECT TO ADEQUATE ANCHORAGE OF

TO SUIT BEARING DIMENSIONS

6 THICK BEARING BASE PLATE

1

-

1

-

-

B

SECTION 1

-

WITH DEPTH TO SUIT

Ø60 FORMED RECESS

100 200 300 400 500mm0

10050

100 200 300 400 500mm0

10050

OR SILL BEAM

TOP OF HEADSTOCK

90î€

AND PLANK

CL OF BEARING, DOWEL

CL OF BEARING

CL OF BEARING

MEASURED HOG Ma Mb

FROM THE FIGURES IN TABLE 1 ACCORDINGLY.

THE TOP OF BASEPLATES SHALL BE DETERMINED

THE ERECTION OF THE PLANKS AND THE GRADE OF

HOGS SHALL BE MEASURED WITHIN TWO WEEKS PRIOR TO

50 50

50

50

6 THICK PLATE

PLAN

BEARING BASEPLATE ASSEMBLY

A

==

B

==

50

10

LENGTH TO SUIT

GRADE 304 TO ASTM A276

Ø20 STAINLESS STEEL DOWEL

6

A

-

2

-

2

-

SECTION 2

-

0 100 200 300mm

100 50

LEVELLING SCREWS

Ø10 HOLES FOR Ø8

STAINLESS STEEL DOWEL

Ø21 HOLE FOR Ø20

FOR LEVELLING CONTROL

GRADE 304 TO ASTM A276

M8 STAINLESS STEEL NUT

PLATE - TYP

TO UNDERSIDE OF

TACK WELD NUT

PAD HAS SET AND VOID SHALL BE FILLED WITH GROUT

LEVELLING SCREWS SHALL BE REMOVED WHEN GROUT

DETAIL B

-

CO

VE

R

20 M

INØ60

IN R

EC

ES

S

50 M

IN E

MB

ED

ME

NT PAD

BEARING GROUT

FORMED RECESS

BASEPLATE

6 THICK BEARING

OF BEARING BASEPLATE

TO ASTM A276 FOR LEVELLING

MACHINE SCREW GRADE 304/A2

M8 x 75 LONG STAINLESS STEEL

DOWEL

Ø20 STAINLESS STEEL

DETAIL A

-

0

50

150mm10050

25

0

50

150mm10050

25

SCALE

GENERAL NOTES

COPYRIGHT ROADS AND MARITIME SERVICES 2018

STANDARD SIZES

PSC PLANK GIRDER

B0302

STANDARD DRAWING No

EDMS No

DS2017/000887DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

300mm2001000

50100

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

700 10

10

50

2 4

b t

3

b

3

9

9

9

9

6

7

7

7

7

7

6

7

7

7

7

7

455

535

600

348

291

265

226

188

148

(mm)

DEPTH

300

380

A (mm ) I (mm ) Y (mm) Z (mm ) Z (mm )

(m)

LENGTH(S)

SPAN

7 AND 8

9 AND 10

11 AND 12

13 AND 14

15 AND 16

17 AND 184.746 x 10

3.491 x 10

2.691 x 10

2.043 x 10

1.421 x 10

8.828 x 108.645 x 10

1.398 x 10

2.014 x 10

2.636 x 10

3.279 x 10

4.694 x 10 1.652 x 10

1.015 x 10

7.124 x 10

4.614 x 10

2.678 x 10

1.310 x 10 178 000

226 000

271 000

248 314

287 314

347 314

SECTION PROPERTIES

13m AND 14m SPANS 15m AND 16m SPANS 17m AND 18m SPANS

11m AND 12m SPANS9m AND 10m SPANS7m AND 8m SPANS

50500

300

600

5050050

380

600

5050050

455

600

5050050

700

350

300300

600600

300300

5050050

600

330

535

270

300300

600

5050050

300

VOID

300

VOID

300

VOID

20

20

20

20

20

20

� OF PLANK

� OF PLANK

� OF PLANK

AND VOID

� OF PLANK

AND VOID

� OF PLANK

AND VOID

� OF PLANK

� OF VOID� OF VOID

� OF VOID

S XA

DESIGN ASSUMPTIONS

STANDARD BAR SHAPES DIAGRAM

GENERAL NOTES

SCALE OR AS SHOWN

DESIGN LOADING: SM1600.

THE MAXIMUM GAP BETWEENS PSC PLANKS: 320mm.

DECK: 180mm.

THE NOMINAL THICKNESS OF CAST-IN-PLACE REINFORCED CONCRETE

6 880

160

160

375

230

230

460

460

430

WITH AS 5100.5.13.

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE

RIGHT ANGLE.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

AND ARE IN MILLIMETRES.

MEASURED FROM THE OUTSIDE FACES OF THE BARS

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE

300mm2001000

50100

COPYRIGHT ROADS AND MARITIME SERVICES 2018

7m SPAN

PSC PLANK GIRDER

B0303

STANDARD DRAWING No

EDMS No

DS2017/000888DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

EACH END.

UPRIGHT POSITION AND SUPPORTED AT NOT MORE THAN 600mm FROM

DURING STORAGE, TRANSPORT AND HANDLING, PLANK SHALL BE IN AN

MASS OF PLANK IS APPROXIMATELY 3.2 TONNES.

- NO LOADS EXCEPT PLANK SELF WEIGHT

TEMPERATURE AND RELATIVE HUMIDITY IN RANGE 50% - 75%

- STORAGE IN OPEN AIR, AFTER STEAM CURING, AT 20 deg C AVERAGE

- STEAM CURING AT 70 deg C FOR 8 HOURS AFTER CASTING

- ELASTIC MODULUS AT TRANSFER = 32 800 MPa

- DENSITY = 2550 kg/cu m

AND IS 8mm AT 28 DAYS, ASSUMING:

CALCULATED HOG OF PLANK AT TRANSFER IS 4mm

BY THE APPLICATION OF EPOXY RESIN.

THE END OF PLANK AND EXPOSED STRANDS SEALED AGAINST CORROSION

AFTER TRANSFER OF PRESTRESS, STRANDS SHALL BE CUT FLUSH WITH

BE 138 kN.

IMMEDIATELY AFTER THE RELEASE OF THE TENSIONING JACK SHALL

THE FORCE IN EACH 12.7mm DIA STRAND AT THE MID-SPAN OF THE PLANK

FORCE OF 184 kN.

STRENGTH 1870 MPa, RELAX 2, TO AS/NZS 4672.1 WITH MINIMUM BREAKING

STRANDS SHALL BE 7-WIRE, ORDINARY, DIAMETER 12.7mm, TENSILE

VIBRATING TABLE OR FORM VIBRATORS.

RIGID STEELFORMWORK MOULD WITH INTENSE COMPACTION USING A

THE REQUIRED COVER SPECIFIED IS BASED ON THE PLANK BEING CAST IN A

SURFACE SHALL BE 35mm UNLESS SPECIFIED OTHERWISE.

REQUIRED COVER TO REINFORCEMENT NEAREST TO THE CONCRETE

OF PRESTRESS SHALL BE 35 MPa.

MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT TRANSFER

MINIMUM 28 DAY COMPRESSIVE STRENGTH OF CONCRETE SHALL BE 50 MPa.

CONCRETE EXPOSURE CLASSIFICATION: ...

110 1-

STRANDS NOT SHOWN

110

6 950

Q2

OF STRANDS AND REINFORCEMENT

BY THE DESIGNER TO SUIT ANCHORAGE

DENOTES DIMENSION TO BE DETERMINED

5050

ELASTOMERIC BEARING (EACH END OF PLANK)

5 DEEP RECESS FOR LAMINATED

250150 250 150

TYP

475

PLANK TYPE C - ... REQUIRED

PLANK TYPE B - ... REQUIRED

PLANK TYPE A - ... REQUIRED Q2 2-N12-A-250

Q1 1-N12-X-250,

20 BUNDLES OF

Q2 6-N12-A-150

LAPPED WITH Q1 BARS

2 SETS OF

Q1 4-N12-X-150

Q1 5-N12-X-50

SHOWN IN SECTION

Q3 2-N16-S SPACED AS

2 SETS OF

Q2 6-N12-A-150

LAPPED WITH Q1 BARS

Q1 4-N12-X-150

Q1 5-N12-X-50

STRANDS AND INTERNAL REINFORCEMENT NOT SHOWN

2

-

2

-

1

-

1

-

PLANK TYPE C - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT EITHER END OF PLANK.

PLANK TYPE B - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT ONE END OF PLANK.

PLANK TYPE A - FIRST THREE PAIRS OF Q2 BARS ARE REQUIRED AT EACH END OF PLANK.

ELEVATION

PLAN

0 200 400 600 800

200 100

1 000mm

0 200 400 600 800

200 100

1 000mm

VIEW 1

-

600

300

300300

20

BROOM FINISHING TRANSVERSELY

THE MANUFACTURE OF THE PLANK BY

THIS SURFACE SHALL BE MADE ROUGH IN

CEMENT FORMWORK SHEETING

PLACEMENT OF 18 THICK FIBRE

50 x 20 DEEP RECESS FOR

ROUNDED TO R10

CHAMFERED 10 x 10 OR

BOTTOM EDGES SHALL BE

� OF PLANK

TYPE USED

SIZE OF RECESS TO SUIT BEARING

ELASTOMERIC BEARING.

5 DEEP RECESS FOR LAMINATED

PLANK TYPE ...

ON OUTER EDGE OF

RECESS NOT REQUIRED

50 50500

Q3

SECTION 2

-

10/�12.7mm STRANDS

Q1

Q2

110

55

50

55

75

AT 50 = 150

3 SPACES

150

AT 50 = 150

3 SPACES

75

ALL STRANDS TO BE STRAIGHT

S XA

STANDARD BAR SHAPES DIAGRAM

7 880

160

160

375

230

230

460

460

430

WITH AS 5100.5.13.

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE

RIGHT ANGLE.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

AND ARE IN MILLIMETRES.

MEASURED FROM THE OUTSIDE FACES OF THE BARS

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE

DESIGN ASSUMPTIONS

GENERAL NOTES

SCALE OR AS SHOWN

DESIGN LOADING: SM1600.

THE MAXIMUM GAP BETWEENS PSC PLANKS: 320mm.

DECK: 180mm.

THE NOMINAL THICKNESS OF CAST-IN-PLACE REINFORCED CONCRETE

300mm2001000

50100

COPYRIGHT ROADS AND MARITIME SERVICES 2018

8m SPAN

PSC PLANK GIRDER

B0304

STANDARD DRAWING No

EDMS No

DS2017/000889DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

EACH END.

UPRIGHT POSITION AND SUPPORTED AT NOT MORE THAN 600mm FROM

DURING STORAGE, TRANSPORT AND HANDLING, PLANK SHALL BE IN AN

MASS OF PLANK IS APPROXIMATELY 3.6 TONNES.

- NO LOADS EXCEPT PLANK SELF WEIGHT

TEMPERATURE AND RELATIVE HUMIDITY IN RANGE 50% - 75%

- STORAGE IN OPEN AIR, AFTER STEAM CURING, AT 20 deg C AVERAGE

- STEAM CURING AT 70 deg C FOR 8 HOURS AFTER CASTING

- ELASTIC MODULUS AT TRANSFER = 32 800 MPa

- DENSITY = 2550 kg/cu m

AND IS 11mm AT 28 DAYS, ASSUMING:

CALCULATED HOG OF PLANK AT TRANSFER IS 6mm

BY THE APPLICATION OF EPOXY RESIN.

THE END OF PLANK AND EXPOSED STRANDS SEALED AGAINST CORROSION

AFTER TRANSFER OF PRESTRESS, STRANDS SHALL BE CUT FLUSH WITH

BE 138 kN.

IMMEDIATELY AFTER THE RELEASE OF THE TENSIONING JACK SHALL

THE FORCE IN EACH 12.7mm DIA STRAND AT THE MID-SPAN OF THE PLANK

FORCE OF 184 kN.

STRENGTH 1870 MPa, RELAX 2, TO AS/NZS 4672.1 WITH MINIMUM BREAKING

STRANDS SHALL BE 7-WIRE, ORDINARY, DIAMETER 12.7mm, TENSILE

VIBRATING TABLE OR FORM VIBRATORS.

RIGID STEELFORMWORK MOULD WITH INTENSE COMPACTION USING A

THE REQUIRED COVER SPECIFIED IS BASED ON THE PLANK BEING CAST IN A

SURFACE SHALL BE 35mm UNLESS SPECIFIED OTHERWISE.

REQUIRED COVER TO REINFORCEMENT NEAREST TO THE CONCRETE

OF PRESTRESS SHALL BE 35 MPa.

MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT TRANSFER

MINIMUM 28 DAY COMPRESSIVE STRENGTH OF CONCRETE SHALL BE 50 MPa.

CONCRETE EXPOSURE CLASSIFICATION: ...

20

VIEW 1

-

300300

300

600

CEMENT FORMWORK SHEETING

PLACEMENT OF 18 THICK FIBRE

50 x 20 DEEP RECESS FOR

BROOM FINISHING TRANSVERSELY

THE MANUFACTURE OF THE PLANK BY

THIS SURFACE SHALL BE MADE ROUGH IN

ROUNDED TO R10

CHAMFERED 10 x 10 OR

BOTTOM EDGES SHALL BE

PLANK TYPE ...

ON OUTER EDGE OF

RECESS NOT REQUIRED

� OF PLANK

50 50500

TYPE USED

SIZE OF RECESS TO SUIT BEARING

ELASTOMERIC BEARING.

5 DEEP RECESS FOR LAMINATED

Q3

SECTION 2

-

12/�12.7mm STRANDS

Q1

Q2

110

55

50

55

75

AT 50 = 150

3 SPACES

150

AT 50 = 150

3 SPACES

75

ALL STRANDS TO BE STRAIGHT

STRANDS AND INTERNAL REINFORCEMENT NOT SHOWN

110 1-

STRANDS NOT SHOWN

110

Q2

OF STRANDS AND REINFORCEMENT

BY THE DESIGNER TO SUIT ANCHORAGE

DENOTES DIMENSION TO BE DETERMINED

5050

ELASTOMERIC BEARING (EACH END OF PLANK)

5 DEEP RECESS FOR LAMINATED

7 950

150

975 TYP

150 250 250

PLANK TYPE C - ... REQUIRED

PLANK TYPE B - ... REQUIRED

PLANK TYPE A - ... REQUIRED

ELEVATION

PLAN

LAPPED WITH Q1 BARS

Q2 6-N12-A-150

2 SETS OF

Q1 4-N12-X-150

SHOWN IN SECTION

Q3 2-N16-S SPACED ASLAPPED WITH Q1 BARS

Q2 6-N12-A-150

2 SETS OF

Q1 4-N12-X-150

Q1 5-N12-X-50

Q2 2-N12-A-250

Q1 1-N12-X-250,

24 BUNDLES OF

Q1 5-N12-X-50

PLANK TYPE C - FIRST THREE PAIRS OF Q1 BARS ARE NOT REQUIRED AT EITHER END OF PLANK.

PLANK TYPE B - FIRST THREE PAIRS OF Q1 BARS ARE NOT REQUIRED AT ONE END OF PLANK.

PLANK TYPE A - FIRST THREE PAIRS OF Q1 BARS ARE REQUIRED AT EACH END OF PLANK.

2

-

2

-

1

-

1

-0 200 400 600 800

200 100

1 000mm

0 200 400 600 800

200 100

1 000mm

S X

STANDARD BAR SHAPES DIAGRAM

8 880

310

310

460

460

430

WITH AS 5100.5.13.

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE

RIGHT ANGLE.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

AND ARE IN MILLIMETRES.

MEASURED FROM THE OUTSIDE FACES OF THE BARS

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE L160

450

DESIGN ASSUMPTIONS

GENERAL NOTES

SCALE OR AS SHOWN

DESIGN LOADING: SM1600.

THE MAXIMUM GAP BETWEENS PSC PLANKS: 320mm.

DECK: 180mm.

THE NOMINAL THICKNESS OF CAST-IN-PLACE REINFORCED CONCRETE

300mm2001000

50100

COPYRIGHT ROADS AND MARITIME SERVICES 2018

9m SPAN

PSC PLANK GIRDER

B0305

STANDARD DRAWING No

EDMS No

DS2017/000890DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

EACH END.

UPRIGHT POSITION AND SUPPORTED AT NOT MORE THAN 600mm FROM

DURING STORAGE, TRANSPORT AND HANDLING, PLANK SHALL BE IN AN

MASS OF PLANK IS APPROXIMATELY 5.2 TONNES.

- NO LOADS EXCEPT PLANK SELF WEIGHT

TEMPERATURE AND RELATIVE HUMIDITY IN RANGE 50% - 75%

- STORAGE IN OPEN AIR, AFTER STEAM CURING, AT 20 deg C AVERAGE

- STEAM CURING AT 70 deg C FOR 8 HOURS AFTER CASTING

- ELASTIC MODULUS AT TRANSFER = 32 800 MPa

- DENSITY = 2550 kg/cu m

AND IS 11mm AT 28 DAYS, ASSUMING:

CALCULATED HOG OF PLANK AT TRANSFER IS 6mm

BY THE APPLICATION OF EPOXY RESIN.

THE END OF PLANK AND EXPOSED STRANDS SEALED AGAINST CORROSION

AFTER TRANSFER OF PRESTRESS, STRANDS SHALL BE CUT FLUSH WITH

BE 138 kN.

IMMEDIATELY AFTER THE RELEASE OF THE TENSIONING JACK SHALL

THE FORCE IN EACH 12.7mm DIA STRAND AT THE MID-SPAN OF THE PLANK

FORCE OF 184 kN.

STRENGTH 1870 MPa, RELAX 2, TO AS/NZS 4672.1 WITH MINIMUM BREAKING

STRANDS SHALL BE 7-WIRE, ORDINARY, DIAMETER 12.7mm, TENSILE

VIBRATING TABLE OR FORM VIBRATORS.

RIGID STEELFORMWORK MOULD WITH INTENSE COMPACTION USING A

THE COVER REQUIRED SPECIFIED IS BASED ON THE PLANK BEING CAST IN A

SURFACE SHALL BE 35mm UNLESS SPECIFIED OTHERWISE.

REQUIRED COVER TO REINFORCEMENT NEAREST TO THE CONCRETE

OF PRESTRESS SHALL BE 35 MPa.

MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT TRANSFER

MINIMUM 28 DAY COMPRESSIVE STRENGTH OF CONCRETE SHALL BE 50 MPa.

CONCRETE EXPOSURE CLASSIFICATION: ...

110

STRANDS AND INTERNAL REINFORCEMENT NOT SHOWN

1-

STRANDS NOT SHOWN

Q2

OF STRANDS AND REINFORCEMENT

BY THE DESIGNER TO SUIT ANCHORAGE

DENOTES DIMENSION TO BE DETERMINED

50 50

ELASTOMERIC BEARING (EACH END OF PLANK)

5 DEEP RECESS FOR LAMINATED

8 950

250250150

ELEVATION

PLAN

SHOWN IN SECTION

Q3 2-N20-S SPACED AS110

Q1 9-N12-X-150

Q1 5-N12-X-50

LAPPED WITH Q1 BARS

Q2 11-N12-L-150

2 SETS OF

Q2 2-N12-L-250

Q1 1-N12-X-250,

22 BUNDLES OF

LAPPED WITH Q1 BARS

Q2 11-N12-L-150

2 SETS OF

Q1 5-N12-X-50 Q1 9-N12-X-150

PLANK TYPE C - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT EITHER END OF PLANK.

PLANK TYPE B - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT ONE END OF PLANK.

PLANK TYPE A - FIRST THREE PAIRS OF Q2 BARS ARE REQUIRED AT EACH END OF PLANK.PLANK TYPE C - ... REQUIRED

PLANK TYPE B - ... REQUIRED

PLANK TYPE A - ... REQUIRED

150

2

-

2

-

1

-

1

-

0 200 400 600 800

200 100

1 000mm

0 200 400 600 800

200 100

1 000mm

20

380

300300

600

BROOM FINISHING TRANSVERSELY

THE MANUFACTURE OF THE PLANK BY

THIS SURFACE SHALL BE MADE ROUGH IN

CEMENT FORMWORK SHEETING

PLACEMENT OF 18 THICK FIBRE

50 x 20 DEEP RECESS FOR

PLANK TYPE ...

ON OUTER EDGE OF

RECESS NOT REQUIRED

ROUNDED TO R10

CHAMFERED 10 x 10 OR

BOTTOM EDGES SHALL BE

� OF PLANK

TYPE USED

SIZE OF RECESS TO SUIT BEARING

ELASTOMERIC BEARING.

5 DEEP RECESS FOR LAMINATED

VIEW 1

-

50 50500

Q3

SECTION 2

-

12/�12.7mm STRANDS

Q1

Q2

110

55

50

55

75

AT 50 = 150

3 SPACES

150

AT 50 = 150

3 SPACES

75

ALL STRANDS TO BE STRAIGHT

S X

STANDARD BAR SHAPES DIAGRAM

9 880

310

310

460

460

430

WITH AS 5100.5.13.

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE

RIGHT ANGLE.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

AND ARE IN MILLIMETRES.

MEASURED FROM THE OUTSIDE FACES OF THE BARS

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE L160

450

DESIGN ASSUMPTIONS

GENERAL NOTES

SCALE OR AS SHOWN

DESIGN LOADING: SM1600.

THE MAXIMUM GAP BETWEENS PSC PLANKS: 320mm.

DECK: 180mm.

THE NOMINAL THICKNESS OF CAST-IN-PLACE REINFORCED CONCRETE

300mm2001000

50100

COPYRIGHT ROADS AND MARITIME SERVICES 2018

10m SPAN

PSC PLANK GIRDER

B0306

STANDARD DRAWING No

EDMS No

DS2017/000891DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

EACH END.

UPRIGHT POSITION AND SUPPORTED AT NOT MORE THAN 600mm FROM

DURING STORAGE, TRANSPORT AND HANDLING, PLANK SHALL BE IN AN

MASS OF PLANK IS APPROXIMATELY 5.7 TONNES.

- NO LOADS EXCEPT PLANK SELF WEIGHT

TEMPERATURE AND RELATIVE HUMIDITY IN RANGE 50% - 75%

- STORAGE IN OPEN AIR, AFTER STEAM CURING, AT 20 deg C AVERAGE

- STEAM CURING AT 70 deg C FOR 8 HOURS AFTER CASTING

- ELASTIC MODULUS AT TRANSFER = 32 800 MPa

- DENSITY = 2550 kg/cu m

AND IS 14mm AT 28 DAYS, ASSUMING:

CALCULATED HOG OF PLANK AT TRANSFER IS 9mm

BY THE APPLICATION OF EPOXY RESIN.

THE END OF PLANK AND EXPOSED STRANDS SEALED AGAINST CORROSION

AFTER TRANSFER OF PRESTRESS, STRANDS SHALL BE CUT FLUSH WITH

BE 138 kN.

IMMEDIATELY AFTER THE RELEASE OF THE TENSIONING JACK SHALL

THE FORCE IN EACH 12.7mm DIA STRAND AT THE MID-SPAN OF THE PLANK

FORCE OF 184 kN.

STRENGTH 1870 MPa, RELAX 2, TO AS/NZS 4672.1 WITH MINIMUM BREAKING

STRANDS SHALL BE 7-WIRE, ORDINARY, DIAMETER 12.7mm, TENSILE

VIBRATING TABLE OR FORM VIBRATORS.

RIGID STEELFORMWORK MOULD WITH INTENSE COMPACTION USING A

THE REQUIRED COVER SPECIFIED IS BASED ON THE PLANK BEING CAST IN A

SURFACE SHALL BE 35mm UNLESS SPECIFIED OTHERWISE.

REQUIRED COVER TO REINFORCEMENT NEAREST TO THE CONCRETE

OF PRESTRESS SHALL BE 35 MPa.

MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT TRANSFER

MINIMUM 28 DAY COMPRESSIVE STRENGTH OF CONCRETE SHALL BE 50 MPa.

CONCRETE EXPOSURE CLASSIFICATION: ...

20

VIEW 1

-

300300

380

600

BROOM FINISHING TRANSVERSELY

THE MANUFACTURE OF THE PLANK BY

THIS SURFACE SHALL BE MADE ROUGH IN

CEMENT FORMWORK SHEETING

PLACEMENT OF 18 THICK FIBRE

50 x 20 DEEP RECESS FOR

ROUNDED TO R10

CHAMFERED 10 x 10 OR

BOTTOM EDGES SHALL BE

PLANK TYPE ...

ON OUTER EDGE OF

RECESS NOT REQUIRED

� OF PLANK

50 50500

TYPE USED

SIZE OF RECESS TO SUIT BEARING

ELASTOMERIC BEARING.

5 DEEP RECESS FOR LAMINATED

Q3

SECTION 2

-

14/�12.7mm STRANDS

Q1

Q2

110

55

50

55

75

AT 50 = 150

3 SPACES

150

AT 50 = 150

3 SPACES

75

ALL STRANDS TO BE STRAIGHT

110 1101-

STRANDS NOT SHOWN

Q2

OF STRANDS AND REINFORCEMENT

BY THE DESIGNER TO SUIT ANCHORAGE

DENOTES DIMENSION TO BE DETERMINED

50 50

ELASTOMERIC BEARING (EACH END OF PLANK)

5 DEEP RECESS FOR LAMINATED

PLANK TYPE C - ... REQUIRED

PLANK TYPE B - ... REQUIRED

PLANK TYPE A - ... REQUIRED

9 950

250150 250 150

ELEVATION

PLAN

STRANDS AND INTERNAL REINFORCEMENT NOT SHOWN

1

-

1

-

2

-

2

-

Q1 5-N12-X-50

LAPPED WITH Q1 BARS

Q2 11-N12-L-150

2 SETS OF

SHOWN IN SECTION

Q3 2-N20-S SPACED AS

LAPPED WITH Q1 BARS

Q2 11-N12-L-150

2 SETS OF

Q1 5-N12-X-50 Q1 9-N12-X-150

Q2 2-N12-L-250

Q1 1-N12-X-250,

26 BUNDLES OF

Q1 9-N12-X-150

PLANK TYPE C - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT EITHER END OF PLANK.

PLANK TYPE B - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT ONE END OF PLANK.

PLANK TYPE A - FIRST THREE PAIRS OF Q2 BARS ARE REQUIRED AT EACH END OF PLANK.

0 200 400 600 800

200 100

1 000mm

0 200 400 600 800

200 100

1 000mm

DESIGN ASSUMPTIONS

GENERAL NOTES

SCALE OR AS SHOWN

DESIGN LOADING: SM1600.

THE MAXIMUM GAP BETWEENS PSC PLANKS: 320mm.

DECK: 180mm.

THE NOMINAL THICKNESS OF CAST-IN-PLACE REINFORCED CONCRETE

300mm2001000

50100

S X

STANDARD BAR SHAPES DIAGRAM

386

386

460

460

430

WITH AS 5100.5.13.

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE

RIGHT ANGLE.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

AND ARE IN MILLIMETRES.

MEASURED FROM THE OUTSIDE FACES OF THE BARS

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE L160

450

10 880

COPYRIGHT ROADS AND MARITIME SERVICES 2018

11m SPAN

PSC PLANK GIRDER

B0307

STANDARD DRAWING No

EDMS No

DS2017/000892DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

EACH END.

UPRIGHT POSITION AND SUPPORTED AT NOT MORE THAN 600mm FROM

DURING STORAGE, TRANSPORT AND HANDLING, PLANK SHALL BE IN AN

MASS OF PLANK IS APPROXIMATELY 7.6 TONNES.

- NO LOADS EXCEPT PLANK SELF WEIGHT

TEMPERATURE AND RELATIVE HUMIDITY IN RANGE 50% - 75%

- STORAGE IN OPEN AIR, AFTER STEAM CURING, AT 20 deg C AVERAGE

- STEAM CURING AT 70 deg C FOR 8 HOURS AFTER CASTING

- ELASTIC MODULUS AT TRANSFER = 32 800 MPa

- DENSITY = 2550 kg/cu m

AND IS 17mm AT 28 DAYS, ASSUMING:

CALCULATED HOG OF PLANK AT TRANSFER IS 9mm

BY THE APPLICATION OF EPOXY RESIN.

THE END OF PLANK AND EXPOSED STRANDS SEALED AGAINST CORROSION

AFTER TRANSFER OF PRESTRESS, STRANDS SHALL BE CUT FLUSH WITH

BE 138 kN.

IMMEDIATELY AFTER THE RELEASE OF THE TENSIONING JACK SHALL

THE FORCE IN EACH 12.7mm DIA STRAND AT THE MID-SPAN OF THE PLANK

FORCE OF 184 kN.

STRENGTH 1870 MPa, RELAX 2, TO AS/NZS 4672.1 WITH MINIMUM BREAKING

STRANDS SHALL BE 7-WIRE, ORDINARY, DIAMETER 12.7mm, TENSILE

VIBRATING TABLE OR FORM VIBRATORS.

RIGID STEELFORMWORK MOULD WITH INTENSE COMPACTION USING A

THE REQUIRED COVER SPECIFIED IS BASED ON THE PLANK BEING CAST IN A

SURFACE SHALL BE 35mm UNLESS SPECIFIED OTHERWISE.

REQUIRED COVER TO REINFORCEMENT NEAREST TO THE CONCRETE

OF PRESTRESS SHALL BE 35 MPa.

MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT TRANSFER

MINIMUM 28 DAY COMPRESSIVE STRENGTH OF CONCRETE SHALL BE 50 MPa.

CONCRETE EXPOSURE CLASSIFICATION: ...

110

1101-

STRANDS NOT SHOWN

Q2

OF STRANDS AND REINFORCEMENT

BY THE DESIGNER TO SUIT ANCHORAGE

DENOTES DIMENSION TO BE DETERMINED

50 50

ELASTOMERIC BEARING (EACH END OF PLANK)

5 DEEP RECESS FOR LAMINATED

PLANK TYPE C - ... REQUIRED

PLANK TYPE B - ... REQUIRED

PLANK TYPE A - ... REQUIRED

10 950

250 250150 150

Q1 5-N12-X-50 Q1 9-N12-X-150

LAPPED WITH Q1 BARS

Q2 11-N12-L-150

2 SETS OF

SHOWN IN SECTION

Q3 2-N20-S SPACED AS

WITH 12-X-1 BARS

Q2 11-N12-L-150 LAPPED

2 SETS OF

Q1 5-12-X-50

Q1 9-N12-X-150

STRANDS AND INTERNAL REINFORCEMENT NOT SHOWN

ELEVATION

PLAN

PLANK TYPE C - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT EITHER END OF PLANK.

PLANK TYPE B - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT ONE END OF PLANK.

PLANK TYPE A - FIRST THREE PAIRS OF Q2 BARS ARE REQUIRED AT EACH END OF PLANK.

Q2 2-N12-L-250

Q1 1-N12-X-250,

30 BUNDLES OF

2

-

2

-

1

-

1

- 1 000mm8006004002000

100200

1 000mm8006004002000

100200

20

VIEW 1

-

455

600

BROOM FINISHING TRANSVERSELY

THE MANUFACTURE OF THE PLANK BY

THIS SURFACE SHALL BE MADE ROUGH IN

CEMENT FORMWORK SHEETING

PLACEMENT OF 18 THICK FIBRE

50 x 20 DEEP RECESS FOR

PLANK TYPE ...

ON OUTER EDGE OF

RECESS NOT REQUIRED

ROUNDED TO R10

CHAMFERED 10 x 10 OR

BOTTOM EDGES SHALL BE TYPE USED

SIZE OF RECESS TO SUIT BEARING

ELASTOMERIC BEARING.

5 DEEP RECESS FOR LAMINATED

� OF PLANK

50 50500

300 300

Q3

SECTION 2

-

16/�12.7mm STRANDS

Q1

Q2

110

55

75

AT 50 = 150

3 SPACES

150

AT 50 = 150

3 SPACES

75

ALL STRANDS TO BE STRAIGHT

50

50

55

DESIGN ASSUMPTIONS

GENERAL NOTES

SCALE OR AS SHOWN

DESIGN LOADING: SM1600.

THE MAXIMUM GAP BETWEENS PSC PLANKS: 320mm.

DECK: 180mm.

THE NOMINAL THICKNESS OF CAST-IN-PLACE REINFORCED CONCRETE

300mm2001000

50100

S X

STANDARD BAR SHAPES DIAGRAM

385

385

460

460

430

WITH AS 5100.5.13.

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE

RIGHT ANGLE.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

AND ARE IN MILLIMETRES.

MEASURED FROM THE OUTSIDE FACES OF THE BARS

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE L160

450

11 880

COPYRIGHT ROADS AND MARITIME SERVICES 2018

12m SPAN

PSC PLANK GIRDER

B0308

STANDARD DRAWING No

EDMS No

DS2017/000893DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

EACH END.

UPRIGHT POSITION AND SUPPORTED AT NOT MORE THAN 600mm FROM

DURING STORAGE, TRANSPORT AND HANDLING, PLANK SHALL BE IN AN

MASS OF PLANK IS APPROXIMATELY 8.3 TONNES.

- NO LOADS EXCEPT PLANK SELF WEIGHT

TEMPERATURE AND RELATIVE HUMIDITY IN RANGE 50% - 75%

- STORAGE IN OPEN AIR, AFTER STEAM CURING, AT 20 deg C AVERAGE

- STEAM CURING AT 70 deg C FOR 8 HOURS AFTER CASTING

- ELASTIC MODULUS AT TRANSFER = 32 800 MPa

- DENSITY = 2550 kg/cu m

AND IS 18mm AT 28 DAYS, ASSUMING:

CALCULATED HOG OF PLANK AT TRANSFER IS 11mm

BY THE APPLICATION OF EPOXY RESIN.

THE END OF PLANK AND EXPOSED STRANDS SEALED AGAINST CORROSION

AFTER TRANSFER OF PRESTRESS, STRANDS SHALL BE CUT FLUSH WITH

BE 138 kN.

IMMEDIATELY AFTER THE RELEASE OF THE TENSIONING JACK SHALL

THE FORCE IN EACH 12.7mm DIA STRAND AT THE MID-SPAN OF THE PLANK

FORCE OF 184 kN.

STRENGTH 1870 MPa, RELAX 2, TO AS/NZS 4672.1 WITH MINIMUM BREAKING

STRANDS SHALL BE 7-WIRE, ORDINARY, DIAMETER 12.7mm, TENSILE

VIBRATING TABLE OR FORM VIBRATORS.

RIGID STEELFORMWORK MOULD WITH INTENSE COMPACTION USING A

THE REQUIRED COVER SPECIFIED IS BASED ON THE PLANK BEING CAST IN A

SURFACE SHALL BE 35mm UNLESS SPECIFIED OTHERWISE.

REQUIRED COVER TO REINFORCEMENT NEAREST TO THE CONCRETE

OF PRESTRESS SHALL BE 35 MPa.

MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT TRANSFER

MINIMUM 28 DAY COMPRESSIVE STRENGTH OF CONCRETE SHALL BE 50 MPa.

CONCRETE EXPOSURE CLASSIFICATION: ...

20

VIEW 1

-

300300

455

600

BROOM FINISHING TRANSVERSELY

THE MANUFACTURE OF THE PLANK BY

THIS SURFACE SHALL BE MADE ROUGH IN

CEMENT FORMWORK SHEETING

PLACEMENT OF 18 THICK FIBRE

50 x 20 DEEP RECESS FOR

ROUNDED TO R10

CHAMFERED 10 x 10 OR

BOTTOM EDGES SHALL BE

PLANK TYPE ...

ON OUTER EDGE OF

RECESS NOT REQUIRED

TYPE USED

SIZE OF RECESS TO SUIT BEARING

ELASTOMERIC BEARING.

5 DEEP RECESS FOR LAMINATED

� OF PLANK

50 50500

Q3

SECTION 2

-

18/�12.7mm STRANDS

Q1

Q2

110

55

75

AT 50 = 150

3 SPACES

150

AT 50 = 150

3 SPACES

75

ALL STRANDS TO BE STRAIGHT

50

50

55

OF 2 000mm AT EACH END

SHEATHED FOR DISTANCE

THESE STRANDS SHALL BE

110110

1-

Q2

50

11 950

250250150 150

50

2

-

2

-

1

-

1

-

ELEVATION

PLAN

PLANK TYPE C - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT EITHER END OF PLANK

PLANK TYPE B - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT ONE END OF PLANK

PLANK TYPE A - FIRST THREE PAIRS OF Q2 BARS ARE REQUIRED AT EACH END OF PLANK

WITH Q1 BARS

Q2 11-N12-L-150 LAPPED

2 SETS OF

Q1 9-N12-X-150Q1 5-N12-X-50

OF STRANDS AND REINFORCEMENT

BY THE DESIGNER TO SUIT ANCHORAGE

DENOTES DIMENSION TO BE DETERMINED

ELASTOMERIC BEARING (EACH END OF PLANK)

5 DEEP RECESS FOR LAMINATED

SHOWN IN SECTION

Q3 2-N20-S SPACED AS

WITH Q1 BARS

Q2 11-N12-L-150 LAPPED

2 SETS OF

Q1 5-N12-X-50Q1 9-N12-X-150Q2 2-N12-L-250

Q1 1-N12-X-250,

34 BUNDLES OF

STRANDS NOT SHOWN

PLANK TYPE C - ... REQUIRED

PLANK TYPE B - ... REQUIRED

PLANK TYPE A - ... REQUIRED

STRANDS AND INTERNAL REINFORCEMENT NOT SHOWN

1 000mm8006004002000

100200

1 000mm8006004002000

100200

DESIGN ASSUMPTIONS

GENERAL NOTES

SCALE OR AS SHOWN

DESIGN LOADING: SM1600.

THE MAXIMUM GAP BETWEENS PSC PLANKS: 320mm.

DECK: 180mm.

THE NOMINAL THICKNESS OF CAST-IN-PLACE REINFORCED CONCRETE

300mm2001000

50100

S X

STANDARD BAR SHAPES DIAGRAM

8 880

465

465

460

460

430

WITH AS 5100.5.13.

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE

RIGHT ANGLE.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

AND ARE IN MILLIMETRES.

MEASURED FROM THE OUTSIDE FACES OF THE BARS

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE L160

450

COPYRIGHT ROADS AND MARITIME SERVICES 2018

13m SPAN

PSC PLANK GIRDER

B0309

STANDARD DRAWING No

EDMS No

DS2017/000894DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

EACH END.

UPRIGHT POSITION AND SUPPORTED AT NOT MORE THAN 600mm FROM

DURING STORAGE, TRANSPORT AND HANDLING, PLANK SHALL BE IN AN

MASS OF PLANK IS APPROXIMATELY 8.4 TONNES.

- NO LOADS EXCEPT PLANK SELF WEIGHT

TEMPERATURE AND RELATIVE HUMIDITY IN RANGE 50% - 75%

- STORAGE IN OPEN AIR, AFTER STEAM CURING, AT 20 deg C AVERAGE

- STEAM CURING AT 70 deg C FOR 8 HOURS AFTER CASTING

- ELASTIC MODULUS AT TRANSFER = 32 800 MPa

- DENSITY = 2550 kg/cu m

AND IS 17mm AT 28 DAYS, ASSUMING:

CALCULATED HOG OF PLANK AT TRANSFER IS 11mm

BY THE APPLICATION OF EPOXY RESIN.

THE END OF PLANK AND EXPOSED STRANDS SEALED AGAINST CORROSION

AFTER TRANSFER OF PRESTRESS, STRANDS SHALL BE CUT FLUSH WITH

BE 138 kN.

IMMEDIATELY AFTER THE RELEASE OF THE TENSIONING JACK SHALL

THE FORCE IN EACH 12.7mm DIA STRAND AT THE MID-SPAN OF THE PLANK

FORCE OF 184 kN.

STRENGTH 1870 MPa, RELAX 2, TO AS/NZS 4672.1 WITH MINIMUM BREAKING

STRANDS SHALL BE 7-WIRE, ORDINARY, DIAMETER 12.7mm, TENSILE

VIBRATING TABLE OR FORM VIBRATORS.

RIGID STEELFORMWORK MOULD WITH INTENSE COMPACTION USING A

THE REQUIRED COVER SPECIFIED IS BASED ON THE PLANK BEING CAST IN A

SURFACE SHALL BE 35mm UNLESS SPECIFIED OTHERWISE.

REQUIRED COVER TO REINFORCEMENT NEAREST TO THE CONCRETE

OF PRESTRESS SHALL BE 35 MPa.

MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT TRANSFER

MINIMUM 28 DAY COMPRESSIVE STRENGTH OF CONCRETE SHALL BE 50 MPa.

CONCRETE EXPOSURE CLASSIFICATION: ...

VIEW 1

-

300300

535

270

600

300

VOID

BROOM FINISHING TRANSVERSELY

THE MANUFACTURE OF THE PLANK BY

THIS SURFACE SHALL BE MADE ROUGH IN

CEMENT FORMWORK SHEETING

PLACEMENT OF 18 THICK FIBRE

50 x 20 DEEP RECESS FOR

ROUNDED TO R10

CHAMFERED 10 x 10 OR

BOTTOM EDGES SHALL BE

PLANK TYPE ...

ON OUTER EDGE OF

RECESS NOT REQUIRED

� OF PLANK

50 50

20

500

TYPE USED

SIZE OF RECESS TO SUIT BEARING

ELASTOMERIC BEARING.

5 DEEP RECESS FOR LAMINATED

SECTION 2

-

16/�12.7mm STRANDS

Q1

Q2

110

55

ALL STRANDS TO BE STRAIGHT

50

50

55

Q3

OF 2 000mm AT EACH END

SHEATHED FOR DISTANCE

THESE STRANDS SHALL BE

75

9 SPACES AT 50= 450

75

110 110

STRANDS NOT SHOWN

1-

12 950

Q2

MIN MIN

200

OF STRANDS AND REINFORCEMENT

BY THE DESIGNER TO SUIT ANCHORAGE

DENOTES DIMENSION TO BE DETERMINED200

ELASTOMERIC BEARING (EACH END OF PLANK)

5 DEEP RECESS FOR LAMINATED

PLANK TYPE C - ... REQUIRED

PLANK TYPE B - ... REQUIRED

PLANK TYPE A - ... REQUIRED

Ø300 VOID

LAPPED WITH Q1 BARS

Q2 11-N12-L-150

2 SETS OF

SHOWN IN SECTION

Q3 4-N20-S SPACED AS

WITH Q1 BARS

Q2 11-N12-L-150 LAPPED

2 SETS OF

Q1 5-N12-X-50 Q1 9-N12-X-150

Q2 2-N12-L-250

Q1 1-N12-X-250,

38 BUNDLES OF

Q1 9-N12-X-150 Q1 5-N12-X-50

STRANDS AND INTERNAL REINFORCEMENT NOT SHOWN

PLANK TYPE C - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT EITHER END OF PLANK

PLANK TYPE B - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT ONE END OF PLANK

PLANK TYPE A - FIRST THREE PAIRS OF Q2 BARS ARE REQUIRED AT EACH END OF PLANK

250 250150 150

50 50

1

-

2

-

1

-

2

-

ELEVATION

PLAN

Ø300 VOID

0 200 400 600 800

200 100

1 000mm

0 200 400 600 800

200 100

1 000mm

DESIGN ASSUMPTIONS

GENERAL NOTES

SCALE OR AS SHOWN

DESIGN LOADING: SM1600.

THE MAXIMUM GAP BETWEENS PSC PLANKS: 320mm.

DECK: 180mm.

THE NOMINAL THICKNESS OF CAST-IN-PLACE REINFORCED CONCRETE

300mm2001000

50100

S X

STANDARD BAR SHAPES DIAGRAM

465

465

460

460

430

WITH AS 5100.5.13.

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE

RIGHT ANGLE.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

AND ARE IN MILLIMETRES.

MEASURED FROM THE OUTSIDE FACES OF THE BARS

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE L160

450

13 880

COPYRIGHT ROADS AND MARITIME SERVICES 2018

14m SPAN

PSC PLANK GIRDER

B0310

STANDARD DRAWING No

EDMS No

DS2017/000895DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

EACH END.

UPRIGHT POSITION AND SUPPORTED AT NOT MORE THAN 600mm FROM

DURING STORAGE, TRANSPORT AND HANDLING, PLANK SHALL BE IN AN

MASS OF PLANK IS APPROXIMATELY 9.0 TONNES.

- NO LOADS EXCEPT PLANK SELF WEIGHT

TEMPERATURE AND RELATIVE HUMIDITY IN RANGE 50% - 75%

- STORAGE IN OPEN AIR, AFTER STEAM CURING, AT 20 deg C AVERAGE

- STEAM CURING AT 70 deg C FOR 8 HOURS AFTER CASTING

- ELASTIC MODULUS AT TRANSFER = 32 800 MPa

- DENSITY = 2550 kg/cu m

AND IS 18mm AT 28 DAYS, ASSUMING:

CALCULATED HOG OF PLANK AT TRANSFER IS 12mm

BY THE APPLICATION OF EPOXY RESIN.

THE END OF PLANK AND EXPOSED STRANDS SEALED AGAINST CORROSION

AFTER TRANSFER OF PRESTRESS, STRANDS SHALL BE CUT FLUSH WITH

BE 138 kN.

IMMEDIATELY AFTER THE RELEASE OF THE TENSIONING JACK SHALL

THE FORCE IN EACH 12.7mm DIA STRAND AT THE MID-SPAN OF THE PLANK

FORCE OF 184 kN.

STRENGTH 1870 MPa, RELAX 2, TO AS/NZS 4672.1 WITH MINIMUM BREAKING

STRANDS SHALL BE 7-WIRE, ORDINARY, DIAMETER 12.7mm, TENSILE

VIBRATING TABLE OR FORM VIBRATORS.

RIGID STEELFORMWORK MOULD WITH INTENSE COMPACTION USING A

THE REQUIRED COVER SPECIFIED IS BASED ON THE PLANK BEING CAST IN A

SURFACE SHALL BE 35mm UNLESS SPECIFIED OTHERWISE.

REQUIRED COVER TO REINFORCEMENT NEAREST TO THE CONCRETE

OF PRESTRESS SHALL BE 35 MPa.

MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT TRANSFER

MINIMUM 28 DAY COMPRESSIVE STRENGTH OF CONCRETE SHALL BE 50 MPa.

CONCRETE EXPOSURE CLASSIFICATION: ...

110 110

STRANDS NOT SHOWN

1-

Q2

200

MIN MIN

200

OF STRANDS AND REINFORCEMENT

BY THE DESIGNER TO SUIT ANCHORAGE

DENOTES DIMENSION TO BE DETERMINED

5050

ELASTOMERIC BEARING (EACH END OF PLANK)

5 DEEP RECESS FOR LAMINATED

2

-

1

-

1

-

2

-

LAPPED WITH Q1 BARS

Q2 11-N12-L-150

2 SETS OF

Ø300 VOID

Ø300 VOID

STRANDS AND INTERNAL REINFORCEMENT NOT SHOWN

Q1 5-N12-X-50 Q1 9-12-X-150

PLANK TYPE C - ... REQUIRED

PLANK TYPE B - ... REQUIRED

PLANK TYPE A - ... REQUIRED

PLANK TYPE C - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT EITHER END OF PLANK

PLANK TYPE B - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT ONE END OF PLANK

PLANK TYPE A - FIRST THREE PAIRS OF Q2 BARS ARE REQUIRED AT EACH END OF PLANK

Q2 2-N12-L-250

Q1 1-N12-X-250,

42 BUNDLES OF

Q1 9-12-X-150 Q1 5-N12-X-50

WITH Q1 BARS

Q2 11-N12-L-150 LAPPED

2 SETS OF

SHOWN IN SECTION

Q3 4-N20-S SPACED AS

13 950

250 250 150150

ELEVATION

PLAN

1 000mm8006004002000

100200

1 000mm8006004002000

100200

20

VIEW 1

-

300300

535

270

600

300

VOID

BROOM FINISHING TRANSVERSELY

THE MANUFACTURE OF THE PLANK BY

THIS SURFACE SHALL BE MADE ROUGH IN

CEMENT FORMWORK SHEETING

PLACEMENT OF 18 THICK FIBRE

50 x 20 DEEP RECESS FOR

ROUNDED TO R10

CHAMFERED 10 x 10 OR

BOTTOM EDGES SHALL BE

PLANK TYPE ...

ON OUTER EDGE OF

RECESS NOT REQUIRED

� OF PLANK

TYPE USED

SIZE OF RECESS TO SUIT BEARING

ELASTOMERIC BEARING.

5 DEEP RECESS FOR LAMINATED

50 50500

SECTION 2

-

18/�12.7mm STRANDS

Q1

Q2

110

55

ALL STRANDS TO BE STRAIGHT

50

50

55

Q3

OF 2 000mm AT EACH END

SHEATHED FOR DISTANCE

THESE STRANDS SHALL BE

75

9 SPACES AT 50= 450

75

DESIGN ASSUMPTIONS

GENERAL NOTES

SCALE OR AS SHOWN

DESIGN LOADING: SM1600.

THE MAXIMUM GAP BETWEENS PSC PLANKS: 320mm.

DECK: 180mm.

THE NOMINAL THICKNESS OF CAST-IN-PLACE REINFORCED CONCRETE

300mm2001000

50100

S X

STANDARD BAR SHAPES DIAGRAM

530

530

460

460

430

WITH AS 5100.5.13.

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE

RIGHT ANGLE.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

AND ARE IN MILLIMETRES.

MEASURED FROM THE OUTSIDE FACES OF THE BARS

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE L160

450

14 880

COPYRIGHT ROADS AND MARITIME SERVICES 2018

15m SPAN

PSC PLANK GIRDER

B0311

STANDARD DRAWING No

EDMS No

DS2017/000896DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

EACH END.

UPRIGHT POSITION AND SUPPORTED AT NOT MORE THAN 600mm FROM

DURING STORAGE, TRANSPORT AND HANDLING, PLANK SHALL BE IN AN

MASS OF PLANK IS APPROXIMATELY 11.1 TONNES.

- NO LOADS EXCEPT PLANK SELF WEIGHT

TEMPERATURE AND RELATIVE HUMIDITY IN RANGE 50% - 75%

- STORAGE IN OPEN AIR, AFTER STEAM CURING, AT 20 deg C AVERAGE

- STEAM CURING AT 70 deg C FOR 8 HOURS AFTER CASTING

- ELASTIC MODULUS AT TRANSFER = 32 800 MPa

- DENSITY = 2550 kg/cu m

AND IS 20mm AT 28 DAYS, ASSUMING:

CALCULATED HOG OF PLANK AT TRANSFER IS 12mm

BY THE APPLICATION OF EPOXY RESIN.

THE END OF PLANK AND EXPOSED STRANDS SEALED AGAINST CORROSION

AFTER TRANSFER OF PRESTRESS, STRANDS SHALL BE CUT FLUSH WITH

BE 138 kN.

IMMEDIATELY AFTER THE RELEASE OF THE TENSIONING JACK SHALL

THE FORCE IN EACH 12.7mm DIA STRAND AT THE MID-SPAN OF THE PLANK

FORCE OF 184 kN.

STRENGTH 1870 MPa, RELAX 2, TO AS/NZS 4672.1 WITH MINIMUM BREAKING

STRANDS SHALL BE 7-WIRE, ORDINARY, DIAMETER 12.7mm, TENSILE

VIBRATING TABLE OR FORM VIBRATORS.

RIGID STEELFORMWORK MOULD WITH INTENSE COMPACTION USING A

THE REQUIRED COVER SPECIFIED IS BASED ON THE PLANK BEING CAST IN A

SURFACE SHALL BE 35mm UNLESS SPECIFIED OTHERWISE.

REQUIRED COVER TO REINFORCEMENT NEAREST TO THE CONCRETE

OF PRESTRESS SHALL BE 35 MPa.

MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT TRANSFER

MINIMUM 28 DAY COMPRESSIVE STRENGTH OF CONCRETE SHALL BE 50 MPa.

CONCRETE EXPOSURE CLASSIFICATION: ...

20

VIEW 1

-

300300

PLANK TYPE ...

ON OUTER EDGE OF

RECESS NOT REQUIRED

600

330

600

300

VOID

BROOM FINISHING TRANSVERSELY

THE MANUFACTURE OF THE PLANK BY

THIS SURFACE SHALL BE MADE ROUGH IN

CEMENT FORMWORK SHEETING

PLACEMENT OF 18 THICK FIBRE

50 x 20 DEEP RECESS FOR

ROUNDED TO R10

CHAMFERED 10 x 10 OR

BOTTOM EDGES SHALL BE

� OF PLANK

50 50500

TYPE USED

SIZE OF RECESS TO SUIT BEARING

ELASTOMERIC BEARING.

5 DEEP RECESS FOR LAMINATED

SECTION 2

-

20/�12.7mm STRANDS

Q1

Q2

110

55

ALL STRANDS TO BE STRAIGHT

50

50

55

75

9 SPACES AT 50= 450

75

Q3

OF 1 000mm AT EACH END

SHEATHED FOR DISTANCE

THESE STRANDS SHALL BE

110 110

STRANDS AND INTERNAL REINFORCEMENT NOT SHOWN

STRANDS NOT SHOWN

Q1 5-N12-X-50

1-

14 950

SHOWN IN SECTION

Q3 4-N20-S SPACED AS

LAPPED WITH Q1 BARS

Q2 11-N12-L-150

2 SETS OF

Q2

200

MIN

200

MIN

OF STRANDS AND REINFORCEMENT

BY THE DESIGNER TO SUIT ANCHORAGE

DENOTES DIMENSION TO BE DETERMINED

5050

ELASTOMERIC BEARING (EACH END OF PLANK)

5 DEEP RECESS FOR LAMINATED

PLANK TYPE C - ... REQUIRED

PLANK TYPE B - ... REQUIRED

PLANK TYPE A - ... REQUIRED

Ø300 VOID

Ø300 VOID

Q1 5-N12-X-50 Q1 9-N12-X-150

WITH Q1 BARS

Q1 11-N12-L-150 LAPPED

2 SETS OF

Q1 9-N12-X-150Q2 2-N12-L-250

Q1 1-N12-X-250,

46 BUNDLES OF

PLANK TYPE C - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT EITHER END OF PLANK

PLANK TYPE B - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT ONE END OF PLANK

PLANK TYPE A - FIRST THREE PAIRS OF Q2 BARS ARE REQUIRED AT EACH END OF PLANK

1

-

1

-

2

-

2

-

250150 250 150

ELEVATION

PLAN

1 000mm8006004002000

100200

1 000mm8006004002000

100200

DESIGN ASSUMPTIONS

GENERAL NOTES

SCALE OR AS SHOWN

DESIGN LOADING: SM1600.

THE MAXIMUM GAP BETWEENS PSC PLANKS: 320mm.

DECK: 180mm.

THE NOMINAL THICKNESS OF CAST-IN-PLACE REINFORCED CONCRETE

300mm2001000

50100

S X

STANDARD BAR SHAPES DIAGRAM

530

530

460

460

430

WITH AS 5100.5.13.

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE

RIGHT ANGLE.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

AND ARE IN MILLIMETRES.

MEASURED FROM THE OUTSIDE FACES OF THE BARS

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE L160

450

15 880

COPYRIGHT ROADS AND MARITIME SERVICES 2018

16m SPAN

PSC PLANK GIRDER

B0312

STANDARD DRAWING No

EDMS No

DS2017/000897DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

EACH END.

UPRIGHT POSITION AND SUPPORTED AT NOT MORE THAN 600mm FROM

DURING STORAGE, TRANSPORT AND HANDLING, PLANK SHALL BE IN AN

MASS OF PLANK IS APPROXIMATELY 11.8 TONNES.

- NO LOADS EXCEPT PLANK SELF WEIGHT

TEMPERATURE AND RELATIVE HUMIDITY IN RANGE 50% - 75%

- STORAGE IN OPEN AIR, AFTER STEAM CURING, AT 20 deg C AVERAGE

- STEAM CURING AT 70 deg C FOR 8 HOURS AFTER CASTING

- ELASTIC MODULUS AT TRANSFER = 32 800 MPa

- DENSITY = 2550 kg/cu m

AND IS 23mm AT 28 DAYS, ASSUMING:

CALCULATED HOG OF PLANK AT TRANSFER IS 15mm

BY THE APPLICATION OF EPOXY RESIN.

THE END OF PLANK AND EXPOSED STRANDS SEALED AGAINST CORROSION

AFTER TRANSFER OF PRESTRESS, STRANDS SHALL BE CUT FLUSH WITH

BE 138 kN.

IMMEDIATELY AFTER THE RELEASE OF THE TENSIONING JACK SHALL

THE FORCE IN EACH 12.7mm DIA STRAND AT THE MID-SPAN OF THE PLANK

FORCE OF 184 kN.

STRENGTH 1870 MPa, RELAX 2, TO AS/NZS 4672.1 WITH MINIMUM BREAKING

STRANDS SHALL BE 7-WIRE, ORDINARY, DIAMETER 12.7mm, TENSILE

VIBRATING TABLE OR FORM VIBRATORS.

RIGID STEELFORMWORK MOULD WITH INTENSE COMPACTION USING A

THE REQUIRED COVER SPECIFIED IS BASED ON THE PLANK BEING CAST IN A

SURFACE SHALL BE 35mm UNLESS SPECIFIED OTHERWISE.

REQUIRED COVER TO REINFORCEMENT NEAREST TO THE CONCRETE

OF PRESTRESS SHALL BE 35 MPa.

MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT TRANSFER

MINIMUM 28 DAY COMPRESSIVE STRENGTH OF CONCRETE SHALL BE 50 MPa.

CONCRETE EXPOSURE CLASSIFICATION: ...

VIEW 1

-

300300

330

600

600

300

VOID

BROOM FINISHING TRANSVERSELY

THE MANUFACTURE OF THE PLANK BY

THIS SURFACE SHALL BE MADE ROUGH IN

CEMENT FORMWORK SHEETING

PLACEMENT OF 18 THICK FIBRE

50 x 20 DEEP RECESS FOR

ROUNDED TO R10

CHAMFERED 10 x 10 OR

BOTTOM EDGES SHALL BE

PLANK TYPE ...

ON OUTER EDGE OF

RECESS NOT REQUIRED

� OF PLANK

20

TYPE USED

SIZE OF RECESS TO SUIT BEARING

ELASTOMERIC BEARING.

5 DEEP RECESS FOR LAMINATED

50 50500

SECTION 2

-

22/�12.7mm STRANDS

Q1

Q2

110

55

ALL STRANDS TO BE STRAIGHT

75

9 SPACES AT 50= 450

75

Q3

OF 1 000mm AT EACH END

SHEATHED FOR DISTANCE

THESE STRANDS SHALL BE

50

50

50

55

110

STRANDS NOT SHOWN

15 950

110

Q1 5-N12-X-50

1-

Q2

WITH Q1 BARS

Q2 11-N12-L-150 LAPPED

2 SETS OF

Q1 5-N12-X-50

Q2 2-N12-L-250

Q1 1-N12-X-250,

50 BUNDLES OF

200

MIN

200

MIN

OF STRANDS AND REINFORCEMENT

BY THE DESIGNER TO SUIT ANCHORAGE

DENOTES DIMENSION TO BE DETERMINED

5050

ELASTOMERIC BEARING (EACH END OF PLANK)

5 DEEP RECESS FOR LAMINATED

PLANK TYPE C - ... REQUIRED

PLANK TYPE B - ... REQUIRED

PLANK TYPE A - ... REQUIRED

1

-

2

-

1

-

2

-

Ø300 VOID

Ø300 VOID

STRANDS AND INTERNAL REINFORCEMENT NOT SHOWN

SPACED AS SHOWN IN SECTION

Q3 4-N20-S STAGGER IN PLAN

Q1 9-12-X-150

PLANK TYPE C - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT EITHER END OF PLANK

PLANK TYPE B - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT ONE END OF PLANK

PLANK TYPE A - FIRST THREE PAIRS OF Q2 BARS ARE REQUIRED AT EACH END OF PLANKLAPPED WITH Q1 BARS

Q2 11-N12-L-150

2 SETS OF

Q1 9-12-X-150

250250150 150

ELEVATION

PLAN

0 200 400 600 800

200 100

1 000mm

0 200 400 600 800

200 100

1 000mm

DESIGN ASSUMPTIONS

GENERAL NOTES

SCALE OR AS SHOWN

DESIGN LOADING: SM1600.

THE MAXIMUM GAP BETWEENS PSC PLANKS: 320mm.

DECK: 180mm.

THE NOMINAL THICKNESS OF CAST-IN-PLACE REINFORCED CONCRETE

300mm2001000

50100

S X

STANDARD BAR SHAPES DIAGRAM

630

630

460

460

430

WITH AS 5100.5.13.

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE

RIGHT ANGLE.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

AND ARE IN MILLIMETRES.

MEASURED FROM THE OUTSIDE FACES OF THE BARS

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE L160

450

15 000

COPYRIGHT ROADS AND MARITIME SERVICES 2018

17m SPAN

PSC PLANK GIRDER

B0313

STANDARD DRAWING No

EDMS No

DS2027/000898DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

EACH END.

UPRIGHT POSITION AND SUPPORTED AT NOT MORE THAN 600mm FROM

DURING STORAGE, TRANSPORT AND HANDLING, PLANK SHALL BE IN AN

MASS OF PLANK IS APPROXIMATELY 15.2 TONNES.

- NO LOADS EXCEPT PLANK SELF WEIGHT

TEMPERATURE AND RELATIVE HUMIDITY IN RANGE 50% - 75%

- STORAGE IN OPEN AIR, AFTER STEAM CURING, AT 20 deg C AVERAGE

- STEAM CURING AT 70 deg C FOR 8 HOURS AFTER CASTING

- ELASTIC MODULUS AT TRANSFER = 32 800 MPa

- DENSITY = 2550 kg/cu m

AND IS 25mm AT 28 DAYS, ASSUMING:

CALCULATED HOG OF PLANK AT TRANSFER IS 16mm

BY THE APPLICATION OF EPOXY RESIN.

THE END OF PLANK AND EXPOSED STRANDS SEALED AGAINST CORROSION

AFTER TRANSFER OF PRESTRESS, STRANDS SHALL BE CUT FLUSH WITH

BE 138 kN.

IMMEDIATELY AFTER THE RELEASE OF THE TENSIONING JACK SHALL

THE FORCE IN EACH 12.7mm DIA STRAND AT THE MID-SPAN OF THE PLANK

FORCE OF 184 kN.

STRENGTH 1870 MPa, RELAX 2, TO AS/NZS 4672.1 WITH MINIMUM BREAKING

STRANDS SHALL BE 7-WIRE, ORDINARY, DIAMETER 12.7mm, TENSILE

VIBRATING TABLE OR FORM VIBRATORS.

RIGID STEELFORMWORK MOULD WITH INTENSE COMPACTION USING A

THE REQUIRED COVER SPECIFIED IS BASED ON THE PLANK BEING CAST IN A

SURFACE SHALL BE 35mm UNLESS SPECIFIED OTHERWISE.

REQUIRED COVER TO REINFORCEMENT NEAREST TO THE CONCRETE

OF PRESTRESS SHALL BE 35 MPa.

MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT TRANSFER

MINIMUM 28 DAY COMPRESSIVE STRENGTH OF CONCRETE SHALL BE 50 MPa.

CONCRETE EXPOSURE CLASSIFICATION: ...

20

VIEW 1

-

300300

700

300

VOID

350

600

BROOM FINISHING TRANSVERSELY

THE MANUFACTURE OF THE PLANK BY

THIS SURFACE SHALL BE MADE ROUGH IN

CEMENT FORMWORK SHEETING

PLACEMENT OF 18 THICK FIBRE

50 x 20 DEEP RECESS FOR

ROUNDED TO R10

CHAMFERED 10 x 10 OR

BOTTOM EDGES SHALL BE

PLANK TYPE ...

ON OUTER EDGE OF

RECESS NOT REQUIRED

� OF PLANK

50 50500

TYPE USED

SIZE OF RECESS TO SUIT BEARING

ELASTOMERIC BEARING.

5 DEEP RECESS FOR LAMINATED

SECTION 2

-

Q1

Q2

110

55

ALL STRANDS TO BE STRAIGHT

75

9 SPACES AT 50= 450

75

Q3

22/�12.7mm STRANDS

50

50

55

OF 2 000mm AT EACH END

SHEATHED FOR DISTANCE

THESE STRANDS SHALL BE

110

STRANDS AND INTERNAL REINFORCEMENT NOT SHOWN

STRANDS NOT SHOWN

Q1 5-N12-X-50

16 950

1101-

Q2

LAPPED WITH Q1 BARS

Q2 11-N12-L-150

2 SETS OF

Q1 5-N12-X-50

200

MIN

200

MIN

OF STRANDS AND REINFORCEMENT

BY THE DESIGNER TO SUIT ANCHORAGE

DENOTES DIMENSION TO BE DETERMINED

50 50

SPACED AS SHOWN IN SECTION

Q3 4-N20-S STAGGER IN PLAN

ELASTOMERIC BEARING (EACH END OF PLANK)

5 DEEP RECESS FOR LAMINATED

PLANK TYPE C - ... REQUIRED

PLANK TYPE B - ... REQUIRED

PLANK TYPE A - ... REQUIRED

1

-

2

-

1

-

2

-

Ø300 VOID

Ø300 VOID

Q1 9-N12-X-150

PLANK TYPE C - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT EITHER END OF PLANK

PLANK TYPE B - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT ONE END OF PLANK

PLANK TYPE A - FIRST THREE PAIRS OF Q2 BARS ARE REQUIRED AT EACH END OF PLANK

Q1 9-N12-X-150

WITH Q1 BARS

Q2 11-N12-L-150 LAPPED

2 SETS OF

Q2 2-N12-L-250

Q1 1-N12-X-250,

54 BUNDLES OF

ELEVATION

PLAN250 250150 150

1 000mm8006004002000

100200

1 000mm8006004002000

100200

DESIGN ASSUMPTIONS

GENERAL NOTES

SCALE OR AS SHOWN

DESIGN LOADING: SM1600.

THE MAXIMUM GAP BETWEENS PSC PLANKS: 320mm.

DECK: 180mm.

THE NOMINAL THICKNESS OF CAST-IN-PLACE REINFORCED CONCRETE

300mm2001000

50100

S X

STANDARD BAR SHAPES DIAGRAM

630

630

460

460

430

WITH AS 5100.5.13.

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE

RIGHT ANGLE.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

AND ARE IN MILLIMETRES.

MEASURED FROM THE OUTSIDE FACES OF THE BARS

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE L160

450

15 000

COPYRIGHT ROADS AND MARITIME SERVICES 2018

18m SPAN

PSC PLANK GIRDER

B0314

STANDARD DRAWING No

EDMS No

DS2017/000899DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

EACH END.

UPRIGHT POSITION AND SUPPORTED AT NOT MORE THAN 600mm FROM

DURING STORAGE, TRANSPORT AND HANDLING, PLANK SHALL BE IN AN

MASS OF PLANK IS APPROXIMATELY 16.1 TONNES.

- NO LOADS EXCEPT PLANK SELF WEIGHT

TEMPERATURE AND RELATIVE HUMIDITY IN RANGE 50% - 75%

- STORAGE IN OPEN AIR, AFTER STEAM CURING, AT 20 deg C AVERAGE

- STEAM CURING AT 70 deg C FOR 8 HOURS AFTER CASTING

- ELASTIC MODULUS AT TRANSFER = 32 800 MPa

- DENSITY = 2550 kg/cu m

AND IS 28mm AT 28 DAYS, ASSUMING:

CALCULATED HOG OF PLANK AT TRANSFER IS 17mm

BY THE APPLICATION OF EPOXY RESIN.

THE END OF PLANK AND EXPOSED STRANDS SEALED AGAINST CORROSION

AFTER TRANSFER OF PRESTRESS, STRANDS SHALL BE CUT FLUSH WITH

BE 138 kN.

IMMEDIATELY AFTER THE RELEASE OF THE TENSIONING JACK SHALL

THE FORCE IN EACH 12.7mm DIA STRAND AT THE MID-SPAN OF THE PLANK

FORCE OF 184 kN.

STRENGTH 1870 MPa, RELAX 2, TO AS/NZS 4672.1 WITH MINIMUM BREAKING

STRANDS SHALL BE 7-WIRE, ORDINARY, DIAMETER 12.7mm, TENSILE

VIBRATING TABLE OR FORM VIBRATORS.

RIGID STEELFORMWORK MOULD WITH INTENSE COMPACTION USING A

THE REQUIRED COVER SPECIFIED IS BASED ON THE PLANK BEING CAST IN A

SURFACE SHALL BE 35mm UNLESS SPECIFIED OTHERWISE.

REQUIRED COVER TO REINFORCEMENT NEAREST TO THE CONCRETE

OF PRESTRESS SHALL BE 35 MPa.

MINIMUM COMPRESSIVE STRENGTH OF CONCRETE AT TRANSFER

MINIMUM 28 DAY COMPRESSIVE STRENGTH OF CONCRETE SHALL BE 50 MPa.

CONCRETE EXPOSURE CLASSIFICATION: ...

VIEW 1

-

300300

700

350

600

300

VOID

CEMENT FORMWORK SHEETING

PLACEMENT OF 18 THICK FIBRE

50 x 20 DEEP RECESS FOR

BROOM FINISHING TRANSVERSELY

THE MANUFACTURE OF THE PLANK BY

THIS SURFACE SHALL BE MADE ROUGH IN

ROUNDED TO R10

CHAMFERED 10 x 10 OR

BOTTOM EDGES SHALL BE

PLANK TYPE ...

ON OUTER EDGE OF

RECESS NOT REQUIRED

TYPE USED

SIZE OF RECESS TO SUIT BEARING

ELASTOMERIC BEARING.

5 DEEP RECESS FOR LAMINATED

50 50

20

500

SECTION 2

-

Q1

Q2

110

55

ALL STRANDS TO BE STRAIGHT

75

9 SPACES AT 50= 450

75

Q3

24/�12.7mm STRANDS OF 2 000mm AT EACH END

SHEATHED FOR DISTANCE

THESE STRANDS SHALL BE

50

50

50

55

� OF PLANK

110

STRANDS AND INTERNAL REINFORCEMENT NOT SHOWN

STRANDS NOT SHOWN

Q1 5-N12-X-50

17 950

1101-

Q1 5-N12-X-50

Q2

Q2 2-N12-L-250

Q1 1-N12-X-250,

58 BUNDLES OF

200

MIN

200

MIN

OF STRANDS AND REINFORCEMENT

BY THE DESIGNER TO SUIT ANCHORAGE

DENOTES DIMENSION TO BE DETERMINED

50 50

ELASTOMERIC BEARING (EACH END OF PLANK)

5 DEEP RECESS FOR LAMINATED

Ø300 VOID

Ø300 VOID

Q1 9-N12-X-150 Q1 9-N12-X-150

PLANK TYPE C - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT EITHER END OF PLANK

PLANK TYPE B - FIRST THREE PAIRS OF Q2 BARS ARE NOT REQUIRED AT ONE END OF PLANK

PLANK TYPE A - FIRST THREE PAIRS OF Q2 BARS ARE REQUIRED AT EACH END OF PLANKPLANK TYPE C - ... REQUIRED

PLANK TYPE B - ... REQUIRED

PLANK TYPE A - ... REQUIRED

1

-

1

-

2

-

2

-

LAPPED WITH Q1 BARS

Q2 11-N12-L-150

2 SETS OF

SPACED AS SHOWN IN SECTION

Q3 4-N20-S STAGGER IN PLAN

WITH Q1 BARS

Q2 11-N12-L-150 LAPPED

2 SETS OF

ELEVATION

PLAN250250 150150

1 000mm8006004002000

100200

1 000mm8006004002000

100200

PLAN

CONCRETE

PLAN

250150130 ( 70)

( 250)

600

50050

20

50

95

300300

95

REINFORCEMENT

100100 115

Q1

Q2

150160160

50

200 NOM

1

-

1

-

VIEW 1

-

SECTION 2

-

-

2

2

-

DENOTES BARS PLACED NORMAL TO PLANK � AT COMPOSITE ENDS

DENOTES DIMENSION FOR 7m TO 8m SPAN PSC PLANKS

THE NUMBER OF BUNDLES 'X' IS DEPENDANT ON THE PSC PLANK LENGTH

BAR MARK 'L' SHALL BE REPLACED WITH 'A' FOR 7m TO 8m SPAN PSC PLANK LENGTHS

LONGITUDINAL REINFORCEMENT AND PRESTRESSING STRANDS NOT SHOWN

BAR SPACING IS GIVEN ALONG � OF PLANK

Q1 2-N12-L-130 PARALLEL TO SKEW

Q2 1-N12-X-130 NORMAL TO PLANK �,

2 BUNDLES OF

NORMAL TO PLANK �

Q1 2-N12-L-250

Q2 1-N12-X-250,

'X' BUNDLES OF

REINFORCEMENT

TO SUIT GEOMETRY AND ANCHORAGE OF STRANDS AND

DENOTES DIMENSION TO BE DETERMINED BY THE DESIGNER� OF BEARING

� OF PLANK

TO SKEW

Q1 2-N12-L PARALLEL

Q3 1-N12-X SPLAYED,

1 BUNDLE OF

PARALLEL TO SKEW

Q5 1-N12-X, Q1 2-N12-L

1 BUNDLE OF

Q1 2-N12-L PARALLEL TO SKEW

Q4 1-N12-X SPLAYED,

1 BUNDLE OF

NORMAL TO PLANK �

Q1 2-N12-L-150 ( 250)

Q2 1-N12-X-150 ( 250),

5 BUNDLES OF

STRANDS

PRESTRESSING

LONGITUDINAL REINFORCEMENT

ACHIEVE NOMINAL COVER

TRIM FIRST 'X' BAR TO

AT COMPOSITE ENDS ONLY

Q1 3-N12-L-110 TIED TO Q2

AT COMPOSITE ENDS ONLY

Q1 3-N12-L-110 TIED TO Q2

PARALLEL TO SKEW

Q5 5-N12-X-55 ( 70)

OR ROUNDED TO R10

BE CHAMFERED 10 x 10

BOTTOM EDGES SHALL

TO SUIT BEARING TYPE USED

BEARING PAD. SIZE OF RECESS

5 DEEP RECESS FOR ELASTOMERIC

� OF PLANK

VOID

1° - 20°

RANGE

SKEW ANGLE

160160

PLANKS ONLY

9 - 18m SPAN

PLANKS ONLY

7m TO 8m SPAN

GENERAL NOTES

DESIGN LOADING: SM1600

DENOTES AS APPLICABLE TO RELEVANT SPAN LENGTHS.

IN CONJUNCTION WITH RELEVANT SPAN LENGTH PSC PLANK STANDARD DRAWINGS.

THESE DETAILS APPLY TO PSC PLANKS WITH SKEWED ENDS AND SHALL BE READ

SCALE STANDARD BAR SHAPES DIAGRAM

XSLA

H H

L

H

430

H

480

480

75150

0 150 300 450mm

WITH AS 5100.5.

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE

RIGHT ANGLE.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

ARE NORMAL TO THE PLANK �.

THE TRANSVERSE DIMENSIONS SHOWN FOR "X" BARS

AND ARE IN MILLIMETRES.

MEASURED FROM THE OUTSIDE FACES OF THE BARS

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE

COPYRIGHT ROADS AND MARITIME SERVICES 2018

SKEW 1-20

PSC PLANK GIRDER

B0315

STANDARD DRAWING No

EDMS No

DS2017/000900DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

PLAN

CONCRETE

100100100

PARALLEL TO SKEW

Q6 5-N12-X-60

AT COMPOSITE ENDS ONLY

Q1 3-N12-L-120 TIED TO Q2

55

AT COMPOSITE ENDS ONLY

Q1 3-N12-L-120 TIED TO Q2

LONGITUDINAL REINFORCEMENT

600 OR ROUNDED TO R10

BE CHAMFERED 10 x 10

BOTTOM EDGES SHALL

50050

20

50

300300

95

TO SUIT BEARING TYPE USED

BEARING PAD. SIZE OF RECESS

5 DEEP RECESS FOR ELASTOMERIC

Q1

Q2

95

130250

VOID

150

ACHIEVE NOMINAL COVER

TRIM FIRST 'X' BAR TO

PARALLEL TO SKEW

Q6 1-N12-X, Q1 2-N12-L

1 BUNDLE OF

TO SKEW

Q1 2-N12-L PARALLEL

Q4 1-N12-X SPLAYED,

1 BUNDLE OF

TO SKEW

Q1 2-N12-L PARALLEL

Q3 1-N12-X SPLAYED,

1 BUNDLE OF

Q1 2-N12-L PARALLEL TO SKEW

Q5 1-N12-X SPLAYED,

1 BUNDLE OF

Q1 2-N12-L-150 PARALLEL TO SKEW

Q2 1-N12-X-150 NORMAL TO PLANK ,

4 BUNDLES OF

PLAN

REINFORCEMENT

4 SPACES AT 160 = 640

200 NOM

REINFORCEMENT

TO SUIT GEOMETRY AND ANCHORAGE OF STRANDS AND

DENOTES DIMENSION TO BE DETERMINED BY THE DESIGNER

>20

SKEW ANGLE RANGE

STRANDS

PRESTRESSING

1

-

1

-

VIEW 1

-

SECTION 2

-

2

-

2

-

¶ OF PLANK

OF PLANK¶

¶ OF BEARING

¶NORMAL TO PLANK

Q1 2-N12-L-150

Q2 1-N12-X-150,

2 BUNDLES OF

¶NORMAL TO PLANK

Q1 2-N12-L-250

Q2 1-N12-X-250,

'X' BUNDLES OF

¶

¶

¶

DENOTES BARS PLACED NORMAL TO PLANK AT COMPOSITE ENDS

DENOTES DIMENSION FOR 7m TO 8m SPAN PSC PLANKS

THE NUMBER OF BUNDLES 'X' IS DEPENDANT ON THE PSC PLANK LENGTH

BAR MARK 'L' SHALL BE REPLACED WITH 'A' FOR 7m TO 8m SPAN PSC PLANK LENGTHS

LONGITUDINAL REINFORCEMENT AND PRESTRESSING STRANDS NOT SHOWN

BAR SPACING IS GIVEN ALONG OF PLANK

160160

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE WITH AS 5100.5.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A RIGHT ANGLE.

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

TO THE PLANK ¶.

THE TRANSVERSE DIMENSIONS SHOWN FOR "X" BARS ARE NORMAL

FROM THE OUTSIDE FACES OF THE BARS AND ARE IN MILLIMETRES.

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE MEASURED

PLANKS ONLY

7m TO 8m SPAN

PLANKS ONLY

9m TO 18m SPAN

GENERAL NOTES

DESIGN LOADING: SM1600.

DENOTES AS APPLICABLE TO RELEVANT SPAN LENGTHS.

DESIGN LOADING: SM1600.

IN CONJUNCTION WITH RELEVANT SPAN LENGTH PSC PLANK STANDARD DRAWINGS.

THESE DETAILS APPLY TO PSC PLANKS WITH SKEWED ENDS AND SHALL BE READ

SCALE 75150

0 150 300 450mm

STANDARD BAR SHAPES DIAGRAM

XSLA

H H

L

H

430

H

480

480

COPYRIGHT ROADS AND MARITIME SERVICES 2018

SKEW 21-30

PSC PLANK GIRDER

B0316

STANDARD DRAWING No

EDMS No

DS2017/000901DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

LONGITUDINAL REINFORCEMENT

600 OR ROUNDED TO R10

BE CHAMFERED 10 x 10

BOTTOM EDGES SHALL

50050

20

50

300300

95

TO SUIT BEARING TYPE USED

BEARING PAD. SIZE OF RECESS

5 DEEP RECESS FOR ELASTOMERIC

Q1

Q2

PLAN

OF PLANK

60

PARALLEL TO SKEW

Q8 5-N12-X-65 120

CONCRETE

VOID

NORMAL TO PLANK ¶

Q1 2-N12-L-250

Q2 1-N12-X-250,

'X' BUNDLES OF

6 SPACES AT 160 = 960

6 SPACES AT 100 = 600

PARALLEL TO SKEW

AT COMPOSITE ENDS ONLY

Q1 3-N12-L-130 TIED TO Q8

PARALLEL TO SKEW

AT COMPOSITE ENDS ONLY

Q1 3-N12-L-130 TIED TO Q8

Q1 2-N12-L PARALLEL TO SKEW

Q7 1-N12-X SPLAYED,

1 BUNDLE OFQ1 2-N12-L PARALLEL TO SKEW

Q6 1-N12-X SPLAYED,

1 BUNDLE OF

Q1 2-N12-L PARALLEL TO SKEW

Q5 1-N12-X SPLAYED,

1 BUNDLE OF

Q1 2-N12-L PARALLEL TO SKEW

Q4 1-N12-X SPLAYED,

1 BUNDLE OF

Q1 2-N12-L PARALLEL TO SKEW

Q3 1-N12-X SPLAYED,

1 BUNDLE OF

ACHIEVE NOMINAL COVER

TRIM FIRST 'X' BAR TO

250

150

PLAN

REINFORCEMENT

250 NOM

REINFORCEMENT

TO SUIT GEOMETRY AND ANCHORAGE OF STRANDS AND

DENOTES DIMENSION TO BE DETERMINED BY THE DESIGNER

PARALLEL TO SKEW

Q8 1-N12-X, Q1 2-N12-L

1 BUNDLE OF

>30

SKEW ANGLE RANGE

PRESTRESSING STRANDS

2

-

2

-

1

-

1

-

95

VIEW 1

-

SECTION 2

-

¶ OF PLANK

¶

OF BEARING¶

Q1 1-N12-L-150 PARALLEL TO SKEW

Q1 1-N12-L-150 NORMAL TO PLANK ,

Q2 1-N12-X-150 NORMAL TO PLANK ,

2 BUNDLES OF

¶

¶

NORMAL TO PLANK

Q1 2-N12-L-150

Q2 1-N12-X-150,

3 BUNDLES OF

¶

¶

DENOTES BARS PLACED NORMAL TO PLANK AT COMPOSITE ENDS

THE NUMBER OF BUNDLES 'X' IS DEPENDANT ON THE PSC PLANK LENGTH

BAR MARK 'L' SHALL BE REPLACED WITH 'A' FOR 7m TO 8m SPAN PSC PLANK LENGTHS

LONGITUDINAL REINFORCEMENT AND PRESTRESSING STRANDS NOT SHOWN

BAR SPACING IS GIVEN ALONG OF PLANK

¶

160160

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE WITH AS 5100.5.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A RIGHT ANGLE.

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

TO THE PLANK ¶.

THE TRANSVERSE DIMENSIONS SHOWN FOR "X" BARS ARE NORMAL

FROM THE OUTSIDE FACES OF THE BARS AND ARE IN MILLIMETRES.

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE MEASURED

PLANKS ONLY

7m TO 8m SPAN

PLANKS ONLY

9m TO 18m SPAN

GENERAL NOTES

DESIGN LOADING: SM1600

DENOTES AS APPLICABLE TO RELEVANT SPAN LENGTHS.

IN CONJUNCTION WITH RELEVANT SPAN LENGTH PSC PLANK STANDARD DRAWINGS.

THESE DETAILS APPLY TO PSC PLANKS WITH SKEWED ENDS AND SHALL BE READ

SCALE

STANDARD BAR SHAPES DIAGRAM

XSLA

H H

L430

H

480

480

H

75150

0 150 300 450mm

COPYRIGHT ROADS AND MARITIME SERVICES 2018

SKEW 31-40

PSC PLANK GIRDER

B0317

STANDARD DRAWING No

EDMS No

DS2017/000902DATE

APPROVED FOR USE STANDARD DRAWINGISSUE DATE

REVISION ISSUE

2

ISSUEDSTATUS

A1

DEC 2018

DRAWING TO:

SEND FEEDBACK ON THIS STANDARD DIRECTOR BRIDGES AND STRUCTURES

W.Ariyaratne

21.12.2018

LONGITUDINAL REINFORCEMENT

600 OR ROUNDED TO R10

BE CHAMFERED 10 x 10

BOTTOM EDGES SHALL

50050

20

50

300300

95

TO SUIT BEARING TYPE USED

BEARING PAD. SIZE OF RECESS

5 DEEP RECESS FOR ELASTOMERIC

Q1

Q2

PLAN

CONCRETE

OF PLANK

250

VOID

150

130

Q1 2-N12 PARALLEL TO SKEW

Q9 1-N12-X SPLAYED,

1 BUNDLE OF

60

7 SPACES AT 100 = 700

ACHIEVE NOMINAL COVER

TRIM FIRST 'X' BAR TO

7 SPACES AT 160 = 1 120

TO SKEW

Q1 2-N12 PARALLEL

Q6 1-N12-X SPLAYED,

1 BUNDLE OF

Q1 2-N12 PARALLEL TO SKEW

Q3 1-N12-X SPLAYED,

1 BUNDLE OF

TO SKEW

Q1 2-N12 PARALLEL

Q8 1-N12-X SPLAYED,

1 BUNDLE OFQ1 2-N12 PARALLEL TO SKEW

Q5 1-N12-X SPLAYED,

1 BUNDLE OF

Q1 2-N12 PARALLEL TO SKEW

Q4 1-N12-X SPLAYED,

1 BUNDLE OF

PARALLEL TO SKEW

AT COMPOSITE ENDS ONLY

Q1 3-N12-L-120 TIED TO Q10

PARALLEL TO SKEW

Q10 5-N12-X-60

PARALLEL TO SKEW

AT COMPOSITE ENDS ONLY

Q1 3-N12-L-120 TIED TO Q10

Q1 2-N12 PARALLEL TO SKEW

Q7 1-N12-X SPLAYED,

1 BUNDLE OF

PLAN

REINFORCEMENT

REINFORCEMENT PAST THE FRONT FACE OF THE BEARING

TO SUIT GEOMETRY AND ANCHORAGE OF STRANDS AND

DENOTES DIMENSION TO BE DETERMINED BY THE DESIGNER300 NOM

PARALLEL TO SKEW

Q10 1-N12-X, Q1 2-N12

1 BUNDLE OF

>40

SKEW ANGLE RANGE

PRESTRESSING STRANDS

2

-

2

-

1

-

1

-

95

VIEW 1

-

SECTION 2

-

¶ OF PLANK

OF BEARING¶

¶

NORMAL TO PLANK

Q1 2-N12-L-250

Q2 1-N12-X-250,

'X' BUNDLES OF

¶

NORMAL TO PLANK

Q1 2-N12-L-150

Q2 1-N12-X-150,

4 BUNDLES OF

¶

¶

DENOTES BARS PLACED NORMAL TO PLANK AT COMPOSITE ENDS

THE NUMBER OF BUNDLES 'X' IS DEPENDANT ON THE PSC PLANK LENGTH

BAR MARK 'L' SHALL BE REPLACED WITH 'A' FOR 7m TO 8m SPAN PSC PLANK LENGTHS

LONGITUDINAL REINFORCEMENT AND PRESTRESSING STRANDS NOT SHOWN

BAR SPACING IS GIVEN ALONG OF PLANK

¶160160

ALL BENDS SHALL BE FITMENT BENDS IN ACCORDANCE WITH AS 5100.5.

THE INCLUDED ANGLE OF ANY BEND SHALL BE A RIGHT ANGLE.

BARS SHALL BE GRADE D500N TO AS/NZS 4671.

BAR SIZE IS THE NOMINAL DIAMETER IN MILLIMETRES.

TO THE PLANK ¶.

THE TRANSVERSE DIMENSIONS SHOWN FOR "X" BARS ARE NORMAL

FROM THE OUTSIDE FACES OF THE BARS AND ARE IN MILLIMETRES.

DIMENSIONS SHOWN ON BAR SHAPES DIAGRAM ARE MEASURED

PLANKS ONLY

7m TO 8m SPAN

PLANKS ONLY

9m TO 18m SPAN

GENERAL NOTES

DESIGN LOADING: SM 1600.

DENOTES AS APPLICABLE TO RELVANT SPAN LENGTHS.

IN CONJUNCTION WITH RELEVANT SPAN LENGTH PSC PLANK STANDARD DRAWINGS.

THESE DETAILS APPLY TO PSC PLANKS WITH SKEWED ENDS AND SHALL BE READ

SCALE 75150

0 150 300 450mm

STANDARD BAR SHAPES DIAGRAM