b Tap Report

-

Upload

prateekbaldwa -

Category

Documents

-

view

218 -

download

0

Transcript of b Tap Report

-

8/13/2019 b Tap Report

1/131

Advanced Batteries for Electric Vehicles:An Assessment of Performance, Cost, and Availability

DRAFT

June 22, 2000

Prepared fortate of California Air !esources Board

acramento, California

By

"he #ear 2000 Battery "echnolo$y Advisory Panel

%enahem Anderman

-

8/13/2019 b Tap Report

2/131

&rit' !( )alhammer*onald %acArthur

*+CA+%E!

The findings and conclusions in this report are those of the authors and notnecessarily those of the State of California Air Resources Board. The mention ofcommercial products in connection with the material presented herein is not to beconstrued as actual or implied endorsement of such products.

ii

-

8/13/2019 b Tap Report

3/131

E-EC."+VE .%%A!#

When the California Air Resources Board began to consider battery-powered Es

as a potentially ma!or strategy to reduce "ehicle emissions and impro"e air #uality$ it did

so with the "iew that the broadest mar%et would be ser"ed by electric "ehicles with

ad"anced batteries$ and it structured its &E credit mechanisms to encourage the

de"elopment and deployment of Es with such batteries. Consistent with this "iew$ the

Air Resources Board defined the scope of wor% for the first Battery Technical Ad"isory

'anel study to focus on ad"anced batteries.

(i"e years after the modification of the )**) &ero Emission ehicle regulation$and after a period of intensi"e effort to de"elop$ deploy and e"aluate ad"anced electric

"ehicles$ one %ey remaining #uestion is whether batteries can be a"ailable in +,, that

would ma%e electric "ehicles acceptable to a large number of owners and operators of

automobiles. The answer to this #uestion is an important input to the California Air

Resources Boards year +,,, Biennial &E regulation re"iew. The authors of this report

were as%ed to assist ARB in de"eloping an answer$ wor%ing together as a new Battery

Technical Ad"isory 'anel /BTA' +,,,0.

The 'anel concentrated its in"estigation on candidate E-battery technologies

that promise ma!or performance gains o"er lead-acid batteries$ appear to ha"e some

prospects for meeting E-battery cost targets$ and are now a"ailable from low-"olume

production lines or$ at least$ laboratory pilot facilities. 1n the "iew of the 'anel$ other

types of ad"anced batteries not meeting these criteria are highly unli%ely to be introduced

commercially within the ne2t 3-4 years. While the focus of BTA' +,,, li%e the first

battery panel was to be on ad"anced batteries because of their basic promise for superiorperformance and range$ ARB as%ed the 'anel to also briefly re"iew the lead-acid battery

technologies used in some of the Es deployed in California. This re#uest recogni5ed

that Es with lead-acid batteries were introduced in the )**,s by se"eral ma!or

automobile manufacturers beginning with 6eneral 7otors8 E)$ and that Es e#uipped

iii

-

8/13/2019 b Tap Report

4/131

with recently de"eloped lead-acid batteries were performing significantly better than

earlier Es.

The 'anel8s approach was similar to that of the )**3 BTA'9 "isits to the leading

de"elopers of ad"anced batteries and to ma!or automobile manufacturers engaged in

electric-"ehicle de"elopment$ E deployment$ and in the e"aluation of E batteries:

follow-on discussions of the 'anel8s obser"ations with these organi5ations: 'anel-internal

critical re"iew of information and de"elopment of conclusions: and preparation of this

report. To assist the 'anel members with the de"elopment of !udgment and perspecti"e$

they were gi"en business-confidential technical and strategic information by nearly all ofthe 'anel8s information sources. This report$ howe"er$ contains unrestricted material

only. The 'anel8s findings and conclusions are as follows.

The impro"ed lead-acid E batteries used in some of the Es operating in

California today gi"e these "ehicles better performance than pre"ious generations of lead

acid batteries. ;owe"er$ e"en these batteries remain handicapped by the low specific

energy that is characteristic of all lead-acid batteries. 1f E truc%s or representati"e

-

8/13/2019 b Tap Report

5/131

charging efficiency and cycle life at ele"ated temperature indicate that i7; batteries

ha"e realistic potential to last the life of an E$ or at least ten years and ),,$,,, "ehicle

miles. Se"eral battery companies now ha"e limited production capabilities for i7; E

batteries$ and plant commitments in +,,, could result in establishment of manufacturing

capacities sufficient to produce the #uantities of batteries re#uired under the current &E

regulation for +,,. Current i7; E-battery modules ha"e specific energies of 3 to

4,Wh?%g$ comparable to the technologies of se"eral years agoreported in the BTA'

)**3 report /)0and ma!or increases are unli%ely. 1f i7; battery weight is limited to

anacceptable fraction of E total weight$ the range of a typical

-

8/13/2019 b Tap Report

6/131

testing of prototype i 1on batteries meeting all critical re#uirements for E application

are li%ely to re#uire at least three to four years. Another two years will be re#uired to

establish a production plant$ "erify the product$ and scale up to commercial production.

Based on se"eral /albeit not all0 of the cost estimates pro"ided by de"elopers and on the

'anel8s own estimates$ these batteries will be significantly more e2pensi"e than i7;

batteries at a production "olume of around ),$,,, pac%s per year. E"en in much larger

production "olumes$ i 1on E batteries will cost less than i7; only if substantially

less e2pensi"e materials become a"ailable$ and after manufacturing technologies

combining high le"els of automation$ precision and speed ha"e been de"eloped.

ithium-metal polymer E batteries are being de"eloped in two programs aimed

at technologies that might cost >+,,?%Wh or less in "olume production. ;owe"er$ thesetechnologies ha"e not yet reached %ey technical targets$ including most notably cycle life$

and they are in the pre-prototype cell stage of de"elopment. 1t is unli%ely that the steps

re#uired to achie"e commercial a"ailability of i 'olymer batteries meeting the

performance and life re#uirements$ as well as the cost goals for E propulsion$ can be

completed in less than 4 to F years.

Battery de"elopers$ GSABC$ and the si2 ma!or automobile manufacturers ser"ing

the California mar%et ha"e in"ested e2tensi"e financial and talent resources in de"elopinga di"ersity of E batteries and e"aluating them in electric "ehicles. Battery performance

and reliability has been e2cellent in many$ and generally ade#uate in nearly all$ of the

more than )

-

8/13/2019 b Tap Report

7/131

costs substantially below current pro!ections: the 'anel considered this unli%ely for the

ne2t -F years. 1n addition$ the practical range pro"ided by the batteries of current Es is

limited. (or applications where increased range is desired$ the resulting larger-capacity

batteries would aggra"ate the ad"anced-battery cost problem in proportion$ and they

would raise increasingly serious "olume and weight issues.

All ma!or carma%ers are now acti"ely pursuing other ad"anced-technology

"ehiclessuch as hybrid and mini Esto achie"e emission reductions. i%e

con"entional Es$ ;Es and mini-Es depend on impro"ed batteries for their technical

and cost feasibility. ;owe"er$ they re#uire only a fraction of an E8s battery capacity

between 3= and 3,=$ depending on ;E technology and application. Battery cost is

thus substantially reduced$ and thereby one of the largest barriers to the commercial"iability of these new automoti"e products. The 'anel was made aware of the impressi"e

battery technology progress achie"ed in this area by se"eral of the E-battery de"elopers.

There is little doubt that the de"elopment of i7; and i 1on battery technologies for

;E and mini-E applications has benefited directly and substantially from E-battery

de"elopment. Con"ersely$ the successful commerciali5ation of ;Es$ and possibly mini-

Es$ in the coming years can be e2pected to result in continued impro"ements of

ad"anced battery technologies. @"er the longer term$ these ad"ancestogether with

li%ely ad"ances in electric dri"e technologies and reductions in "ehicle weightmight

well increase performance and range$ and reduce costs$ to the point$ where electric

"ehicles could become a widely accepted product.

"ii

-

8/13/2019 b Tap Report

8/131

"ABE /& C/"E"

E-EC."+VE .%%A!#(((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((+++

"ABE /& C/"E"((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((V+++

+" /& "ABE((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((+-

+" /& &+1.!E(((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((-

AC)/E*1E%E"(((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((-+

EC"+/ +( +"!/*.C"+/(((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((((3

1.). 'GR'@SE AD SC@'E.....................................................................................................................1.+. STGDH A''R@AC;..........................................................................................................................,$,,, to more than >F,$,,, per pac%$ re#uiring hea"y

subsidies by the E manufacturers to attract "ehicle lessees. A ma!or focus of the 'anel

thus was to in"estigate li%ely costs of "olume-produced ad"anced batteries and to assess

their acceptability against E-battery target costs.

7ost E and E-battery de"elopers as well as other sta%eholders in the

commerciali5ation of Es ha"e de"eloped E-battery cost targets?re#uirements to guide

their de"elopment strategies and policies. Among these$ the GSABC cost targets$ shown

in Table II.1$ are by far the best %nown and ha"e been widely used in past assessments. 1t

is the 'anel8s understanding that the GSABC battery long-term cost target was deri"ed

from the assumption that the life-cycle /total ownership0 costs for Es need to be

comparable to those for the corresponding con"entional "ehicles. ;owe"er$ no details of

that deri"ation and the underlying assumptions ha"e been published. 1n addition$ the

GSABC cost targets for E batteries are nearly a decade old$ e2cept for the recently

adopted commerciali5ation cost target of >)3,?%Wh. 1n "iew of the considerable

uncertainty that surrounds this important sub!ect$ a current loo% at what might constitute

appropriate cost targets for E batteries appears !ustified.

Cost "ar$ets>!e@uirements( 'ostulating cost e#ui"alence of Es with their

counterpart 1CE "ehicles is a rational starting point for establishing battery cost targets.To con"ert this general postulate into specific cost target/s0 re#uires se"eral assumptions

and a cost-estimating methodology. @ne %ey assumption is that the total ownership cost

of a "ehicle o"er its life /life cycle cost0 is the most appropriate measure of cost$ another

is that the cost of the E minus battery in mass production will be comparable to the cost

of the 1CE "ehicle. Although there is no uni"ersal agreement on the latter assumption$

)+

-

8/13/2019 b Tap Report

24/131

se"eral carma%ers mentioned it as a possibility if Es were e"entually produced in

numbers comparable to those for popular 1CE models.

Based on these assumptions$ the 'anel used a simple methodology to de"elop an

independent perspecti"e on target battery costs. 1n this approach$ the battery is amorti5edo"er the life of the E$ and the amorti5ation cost is lumped with electricity cost into the

E8s cost of Pelectric energyQ. Together with the assumption abo"e about basic "ehicle

costs$ the assumption of life-cycle cost-e#ui"alence between an electric and a

con"entional "ehicle then reduces to the e#ui"alence of lifetime costs of the electric

energy and the motor fuel consumed by these "ehicles$ respecti"ely.

1nAppendix E$ target battery costs are calculated with this methodology as the net

present "alue of the E8s energy cost sa"ings o"er its assumed ),-year life for a range of

"alues of the %ey parameters. The PTypical Current 'arametersQ segment of Table E.1

presents target battery costs calculated for energy efficiencies and costs typical for

today8s 1CE and electric "ehicles: the E efficiencies are ta%en from Appendi2 C /see

Table (.2 line 50).

The calculations indicate target battery costs of appro2imately >$3,, to >

-

8/13/2019 b Tap Report

25/131

E)$ see Appendix ( Table (.20 does not ha"e a higher target battery cost if the

anticipated higher motor-fuel efficiency of a broadly corresponding 1CE "ehicle is ta%en

into account. As e2pected$ motor-fuel cost is the single most important factor. (or

e2ample$ increasing fuel cost by +3= from >).?gal to >).4?gal increases target battery

cost for the commercial "ehicle by 4=. @n the other hand$ the data of Table E.1show

that target battery costs are substantially reduced at higher electricity costs /e.g.

),X?%Wh0.

This general picture does not change greatly with increased annual mileage and

for impro"ed electric and 1CE "ehicle efficiencies$ as shown in Table E.1 under the

Yearer-Term Scenarios (a"orable to EsY. The impact of E efficiency impro"ements

is predictably small

)

at low electricity costs$ and e"en further increases in motor-fuel costraise target battery costs for

-

8/13/2019 b Tap Report

26/131

1t is important to note that >3$,,, is the upper end of the target battery cost range

in the nearer term$ "alid only if essentially all assumptionsparticularly basic "ehicle

cost e#ui"alence$ and battery lifeare fa"orable to Es. The specific costs target for

ad"anced batteries would be substantially higher only if motor-fuel costs increaseddrastically abo"e >+?gal$ or if the needed E-battery capacities were to decrease

substantially below +F%Wh because of much-reduced range re#uirements and?or greatly

increased E efficiencies. one of these possibilities seems li%ely in the foreseeable

future$ at least in the Gnited States$ although some of them might materiali5e o"er the

long term.

++(2( CA*+*A"E BA""E!+E

The primary focus of the 'anel8s in"estigation was to assess the de"elopment

status and li%ely future costs of the ad"anced batteries that appeared to ha"e reasonable

prospects for meeting performance re#uirements and cost goals for electric "ehicle

propulsion$ and for becoming commercially a"ailable by +,, or soon thereafter.

1n the "iew of the 'anel$ this assessment could be limited to battery technologies

that$ at the outset of the study$ appeared to meet a number of screening criteria9

performance that met or at least approached the near-term targets in Table

II.1$ abo"e$ with some prospects for impro"ements beyond these targets:

prospecti"e mass-production costs that$ on the basis of the battery

materials and fabrication techni#ues in"ol"ed$ might fall into the acceptable range

discussed abo"e: and

de"elopment status and plans that held out realistic prospects for battery

commercial a"ailability within the ne2t -3 years$ according to the generic

timetable illustrated in

-

8/13/2019 b Tap Report

27/131

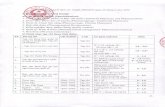

&i$ure ++(3( Battery and Electric Vehicle +nteractive *evelopment "imeline

Year: 0 1 2 3 4 5 6 7 8 9 10BATTERY DEVELOPMENT

R&D

Cell Design & testing

Module Design; ilot ro!ess de"elo#ent

$ilot $rodu!tion; #odule testing; $a!% design

$a!% ield 'rial ( #anu)a!turing de"elo#ent

a!tor* +nstallation & ,tartu

-olu#e $rodu!tion

Year )ro# -e.i!le /aun!.: 10 9 8 7 6 5 4 3 2 1 0VEHICLE DEVELOPMENT

De"elo !on!et

'est $rotot*e atteries De"elo ,e!i)i!ation

'est -e.i!les internall* it. $rotot*e atteries

leet ield 'est it. $ilot atteries

Design & uild -e.i!le $rodu!tion $lant

$rodu!tion

Basic cell desi$nestablished

Commit to Pilot

PlantCommit toProductionPlant

Commit to &leet"est

Commit toVehicleProduction

)

-

8/13/2019 b Tap Report

28/131

Application of these criteria eliminated a number of candidate battery systems

from the 'anel study. 1n this regard$ lead-acid and nic%el-cadmium batteries represent a

special case. either of these batteries passes the screening test abo"e since they are

fundamentally incapable of meeting the %ey performance targets for specific energy and

energy density$ see Table II.1. @n the other hand$ both battery types are used in electric

"ehicles currently on public roads$ including Es deployed under the California8s 7oA

as well as thousands of nic%el-cadmium-powered Es in (rance. ;owe"er$ with the

e2ception of the lightweight E) carrying

-

8/13/2019 b Tap Report

29/131

for more than fi"e years by a number of companies in Napan and Europe. The system8s

promise of high specific energy was a ma!or attraction$ and its specific power and cycle

life also offered reasonable prospects of meeting E-battery re#uirements. While Sony

and ARTA$ two of the technology leaders$ terminated i 1on E-battery de"elopment

in recent years$ se"eral other e2perienced de"elopers of con"entional and ad"anced

batteries ha"e continued their programs. E#ually important$ ma!or funding continues to

be pro"ided by GSABC for %ey aspects of i 1on battery de"elopment$ including

achie"ement of ade#uate durability and safety$ and reduction of battery costs. 1n "iew of

the promising prospects and ongoing de"elopment efforts$ and because a number of

ATRA Es /See Table (.10 powered by pre-prototype i 1on batteries operate

successfully in California under issan8s 7oA$ lithium-ion batteries were selected by the

'anel as the second candidate E-battery technology to be in"estigated in some detail.

1n addition$ the 'anel selected lithium-metal polymer batteries for an e"aluation

of their prospects of becoming commercially a"ailable by +,, or soon thereafter. 1n

part$ this selection was made because of the basic potential of the i polymer system for

higher specific energy and lower cost than those of other ad"anced batteries. The 'anel

was also aware of the significant technical progress achie"ed o"er the last se"eral years in

two important programs that appear committed to de"elopment of commercially "iable i

polymer E batteries in the relati"ely near future.

(inally$ the 'anel e2amined a specific lithium-ion polymer technology for which

claims of high specific energy and energy density are being made: its findings are

summari5ed inAppendix =.1n the main$ howe"er$ the 'anel8s in"estigation focused on

the status and prospects of nic%el-metal hydride$ lithium-ion$ and lithium-metal polymer

batteries as the systems with the best prospects of meeting the performance and cost

re#uirements for E applications. The 'anel8s findings are summari5ed in Section 111.

)F

-

8/13/2019 b Tap Report

30/131

++(;( EVBA""E!# C/" &AC"/!

(rom the outset of this study$ it was clear that battery costs were not only

important issues with the ad"anced systems currently used in Es$ but were recogni5ed

as a ma!or economic barrier to the widespread mar%et introduction of electric "ehicles.

Ac#uisition and analysis of battery-cost information$ therefore$ became important aspects

of the 'anel8s wor%.

This section re"iews the ma!or factors that contribute to battery cost. 1t is intended

to support the discussion of system-specific costs in subse#uent sections and to gi"e the

reader of this report /as it did earlier for the 'anel0 a framewor% for assessing the battery-

cost information ac#uired in this study.

The basic unit of a battery is the cell$ which has a low unit "oltagetypically )-)$,,,?%Wh. 67@8s pro!ection for fully burdened

costs of the 6eneration-+ product is >,,?%Wh at the pac% le"el$ for a production "olume

of +,$,,, pac%s per year. 67@ is now e"aluating additional mar%ets for the technology$

such as hybrid "ehicles and scooters$ to increase production "olume beyond the E

mar%et demand and thus achie"e incrementally lower costs. With encouragement from

678s AT and from GSABC$ 67@ is also e2ploring the possibility of reali5ing residual

"alue for i7; batteries at the end of their useful life in E ser"ice. This effort is

focusing on secondary usage of such batteries in less demanding applications such as

rural$ '-based electrification in de"eloping countries.

The operating life and ele"ated-temperature performance of 67@8s i7;

technology still need to be fully pro"en. ;owe"er$ the main obstacle in the de"elopmentof 67@8s E-battery businessthe problem common to all de"elopers of ad"anced E

batteriesis the high product costcompared to the costs that are considered acceptable if

Es are to be mar%etable. With few orders and a high rate of operating and capital

e2penditure$ continued support from 67 is not assured. A specific barrier mentioned by

67@ is battery warranty. 67@ surmises that the warranty re#uirements of "ehicle

manufacturersmight include as much as years with ),,= replacement$ followed by a

prorated warranty for up to ), years. 1n 67@8s own words$ Pa business using reasonable

ris% analysis would not be able to pro"ide such a warranty by the year +,,Q.

PAA/+C EV EE!1#

Company /vervieD( 'anasonic E Energy /'EE0$ owned ,= by 7atsushita

and

-

8/13/2019 b Tap Report

42/131

EVBattery *esi$n and Performance( A *3Ah prismatic cell in a thermoplastic

case is the basic element of 'EE8s i7; battery for full-si5e Es. Ten such cells in

series are strapped together in a molded plastic enclosure to ma%e up a )+ and ).)%Wh

module /designation9 E-*30. The energy ratings of the E-*3 module are Wh?%g and

)3, Wh?liter$ and specific power is rated +,, W?%g at F,= DoD. The module design and

performance characteristics are included in Table III.1below.

(eatures of the cell include the following9

AB3 alloy-based negati"e pasted on nic%el-plated steel current collector:

Spherical nic%el hydro2ide-based positi"e with cobalt$ 5inc$ and yttrium-

compound additi"es$ spray-impregnated into a nic%el-foam current collector:

Sulfonated-polypropylene separator and J@;-based electrolyte withi@; additi"e.

Charge acceptance and cycle life at ele"ated temperatures of 'EE8s i7;

technology$ concerns until the recent past$ are now ade#uate for temperatures up to at

least

-

8/13/2019 b Tap Report

43/131

/,,W?%g0 but somewhat lower specific energy /3FWh?%g0. 1n the same plant$ 'EE is

assembling .3Ah$ 4.+ modules consisting of cylindrical D-si5e$ ultra-high-rate

'anasonic cells. These modules are used in the batteries of the Toyota 'R1GS$ and the

;onda 1S16;T hybrid electric "ehicles. 7ost recently$ 'EE has de"eloped a .3Ah

module comprising prismatic cells with yet higher specific power for the new "ersion

of the 'R1GS$ and a production line for it is currently being completed.

Production Capability, Cost and Business Plannin$( 'EEs production

facility has a capacity of +,, E-pac%s per month$ each comprising +< ),-cell /*3Ah or

+FAh0$ )+ modules. The manufacturing process is semi-automatic$ with considerable

hand labor still used in module assembly and in the formation step. 'EE has been the

main supplier of i7; batteries for the Es produced by ;onda$ Toyota$ and (ord undertheir California 7@As. 'roduction pea%ed in )**F when 'EE supplied o"er *,, pac%s

to these companies. The production of E modules has decreased since then$ and 'EE

does not anticipate substantial new orders in the near future. The production "olume of

the +F Ah module$ designed for Toyota8s Pe-comQ city E and ;ondas PCity 'alQ$ is

increasing$ but it is still at a "ery low le"el. 'EE8s production capacity for full-si5e E

batteries could be scaled up to se"eral thousand pac%s per year in )+ to )F months$ but

there are currently no plans to e2pand capacity.

'EE8s module cost /sale price to @E7s0 is appro2imately >)$),,?%Wh at the

current production "olume of around , pac%s?month. This price is pro!ected to decrease

to appro2imately >3,,?%Wh at a production "olume of 3,, pac%s?month. At the latter

le"el$ materials account for appro2imately 3= of total manufacturing cost$ direct labor

for about ),=$ and o"erhead e2penses for about +3=. At a production "olume of +$,,,

to 3$,,, pac%s?month$ the module cost is pro!ected to decrease to appro2imately

>,,?%Wh. (inally$ at production rates e2ceeding ,$,,, pac%s?month 'EE sees a

possibility for further price reductions to appro2imately >+3,?%Wh.

'EE8s business focus is now clearly on ;Es. The company has two steady

customers in Napan9 ;onda$ which uses cylindrical modules in the 1S16;T$ and Toyota$

+

-

8/13/2019 b Tap Report

44/131

which will now be supplied with the new$ higher-power prismatic modules for the

'R1GS. Currently$ ;E pac%s are being produced at a rate of about +$,,, per month.

'EE has great confidence in the performance of its i7; technology for E

and ;E applications. The operating temperature limit for efficient charge and long life

has reached at least ,,?%Wh in "olumes re#uired for &E

compliance$ nor below >+3,?%Wh in true mass production. As a result$ 'EE does note2pect a large mar%et to de"elop for the technology$ and the company sees no business

!ustification for increasing in"estments in E-*3 production.

'EEs assessment of the mar%et potential of i7; hybrid-E batteries is #uite

different. With two ma!or car companies already in ;E production$ and with the

e2pectation of performance impro"ements and cost reductions for ;E batteries$

scenarios for a profitable business do e2ist. The company$ originally founded to

commerciali5e i7; technology for E applications$ has now become a leading

producer of i7; batteries for ;Es$ and it is mo"ing forward to e2ploit the

opportunity.

A&"

Company /vervieD( SA(T$ a wholly owned di"ision of the (rench Alcatel

group$ is a ma!or producer of industrial$ military and consumer batteries$ with a dominant

international position in industrial and aircraft nic%el-cadmium batteries. 1ts

manufacturing facilities are located in (rance$ Sweden$ and the Gnited States. SA(T is an

established manufacturer of E batteries$ producing appro2imately )$3,, pac%s?year of

)+ %Wh "ented i-Cd batteries for E con"ersions of 'eugeot and Renault small cars

-

8/13/2019 b Tap Report

45/131

and "ans /seeAppendix

-

8/13/2019 b Tap Report

46/131

more than ,, cycles at

-

8/13/2019 b Tap Report

47/131

targets /see Table II.1abo"e0 shows that these batteries appear to meet most of the %ey

E re#uirements$ with the e2ception of specific energy and cost.

The i7; module8s presently demonstrated specific energy of to 4, Wh?%g$

corresponding to appro2imately 33-,Wh?%g at the pac% le"el$ falls well short of the

GSABC goals /Table II.10 and will limit the range of a

-

8/13/2019 b Tap Report

48/131

"able +++(3( Characteristics of i%4 EV modules

.nit 1%/ PEVE A&"Desi*n Characteristics

ominal Capacity Ah *, *3 *Anode Chemistry - AB+ AB3 AB3

ominal %odule Volta$e ).+ )+ )+ or +; Wh ? liter )4, )3, )

-

8/13/2019 b Tap Report

49/131

-

8/13/2019 b Tap Report

50/131

&i$ure +++(2( Char$e Acceptance vs( "emperature of +mproved i%4 Batteries

Se"eral pac% designs depend on li#uid cooling while others utili5e air cooling.The trade-off between battery performance$ efficiency$ life and cost for the two cooling

approaches is a comple2 optimi5ation problem that will depend on the ambient

temperatures in which Es are operated$ and will change with further technical

impro"ements in battery-temperature characteristics. Both battery de"elopers and E

manufacturers need to be in"ol"ed in the e"aluation of the preferred cooling approach.

i7; E batteries ha"e ade#uate specific power at temperatures ranging from

^),C to 3,C. While i7; batteries e2hibit somewhat higher self-discharge rates and

lower charge efficiencies than other candidate E-battery systems$ these effects are

sufficiently small as to be only minor disad"antages. (inally$ car companies and battery

de"elopers are confident that the i7; battery does not create ha5ards in any of the

specified abuse tests and meets the safety re#uirements of the E application.

0

20

40

60

80

100

120

25 30 35 40 45 50 55 60

'e#erature @C

Caa!i

t*Ao)Bo#inal

Improved Conventional

*

-

8/13/2019 b Tap Report

51/131

Commercial. The three de"elopers of i7; E-battery pac%s "isited by the

'anel ha"e reached an ad"anced pilot-le"el?early-production stage. All three will re#uire

)F to +)$,,,?%Wh is pro!ected to fall to about >3,?%Wh at the production

"olumes necessary to meet the California +,, &E mandatean implied re#uirement

for ),$,,, to ,$,,, pac%s per year. At higher "olumes$ the lowest pro!ected module

price is abo"e >++3?%Wh$ which translates to more than >+3,?%Wh at the pac% le"el.

The 'anel re"iewed ipmans1data on ad"anced E-battery costs and compared

them to the data presented in)< to >)34?%Wh appears optimistic+. Gsing ipmans material cost estimate

ne"ertheless$ and assuming /again somewhat optimistically0 that materials represent 44=

_Te 9ip+an 'tdy 67 wa' condcted in early 1>>> wen te 9ME 69ondon Metal Excange7 price o&

nic#el?a +a@or &actor in te co't o& :iM; batterie'?wa' !) to ! per #g lower tan it ad been in o/er

10 year'. In te &ir't arter o& 2000 te 9ME price o& nic#el ad ri'en to between !>.)0 and !10 per #g.+In addition to 'ing a lower nic#el price 9ip+an +ade no allowance &or engineering yield

+an&actring 'crap and prodct de*rating de to +an&actring /ariation'. Togeter te'e latter &actor'

can add ) to 20% to +aterial 'age per #$ and t' to te !"#$ e'ti+ate' o& battery co't.

-

8/13/2019 b Tap Report

52/131

&i$ure +++(;( Cost Estimates for i>%4 EV %odules

of the Cost of 6oods /C@60$ and that the gross margin is +3=$ we obtain a C@6 in therange of >)4< to >+,

-

8/13/2019 b Tap Report

53/131

&i$ure +++( year H1eneration;I material pricin$

0

50

100

150

200

250

Materials Module Cost o) oods C Module Cost $ri!e to M

(%?.

;!ti"e

#aterials

7le!trol*te

,earatorCurrent !olle!tion

Matri:

Cell and #odule

a!%aging

alan!e

Materials

6t.er

Manu)a!turing

Costs

C6

Margin

-

8/13/2019 b Tap Report

54/131

+++(2( +"4+.%+/

III.2.1. Intro%uction

;istorically difficult issues with cycling and safety of metallic lithium ha"e led to

the de"elopment of carbon host materials for lithium as negati"e electrodes in organic-

electrolyte batteries. This de"elopment was %ey to the successful commerciali5ation for

consumer applications of small i 1on batteries that use lithiated /i.e.$ lithium-containing0

metal-o2ide-positi"e and lithiated-carbon-negati"e electrodes.

The host material of i 1on negati"e electrodes is made from special grades ofgraphitic or co%e carbons$ or from combinations of such carbons. The generic

composition of the positi"e electrode is i7@+$ with cobalt o2ide /7[Co0 commonly

used in small commercial cells. ;owe"er$ due to its high cost$ iCo@ +is precluded from

consideration for E batteries that would need substantial amounts of that material.

De"elopers of large i 1on cells currently employ a manganese compound$ i7n+@

-

8/13/2019 b Tap Report

55/131

i 1on technology was first commerciali5ed by Sony in )**) /0. @"er the last F

years$ small cylindrical and prismatic cells ha"e become the first choice as portable

power sources for laptop computers$ cellular phones and similar de"ices. About F,

million small cells with an estimated "alue of more than >+ billion were sold worldwide

in )***. The top se"en producers are all Napanese companies: between them$ they

account for more than *F= of the )*** world production /30.

A %ey attraction of the i 1on system is its high cell "oltage. ot only does this

translate to high specific energy$ but it also ma%es it possible to use a smaller number of

cells per battery$ for reduced cost and increased reliability. Specific energies as high as

)3, Wh?%g ha"e been achie"ed at the cell le"el. Among the other attracti"e attributes of

the i 1on battery are high power$ high energy efficiency /including essentially ),,=coulombic efficiency0$ low self-discharge$ and potential for good cycle life regardless of

the depth of discharge /40.

Due to its attracti"e energy and power characteristics$ i 1on technology has

become an important candidate for E and other applications re#uiring large cells. The

de"elopment of E "ersions of the battery began at Sony Corporation around )**.

;owe"er$ Sony and se"eral other ma!or battery companies discontinued i 1on E-

battery de"elopment in recent years$ mostly because they percei"ed future E-battery

mar%ets to be highly uncertain. The three currently leading de"elopers of E batteries

using i 1on technology are Napan Storage Battery /NSB0$ Shin-Jobe$ a company of

Napans ;itachi group$ and SA(T$ a di"ision of the (rench Alcatel group.

The de"elopment of i 1on technology for E applications presents significant

challenges beyond those of consumer batteries. The top three of these are the

achie"ement of acceptable le"els of cost$ safety and operating life.

-

8/13/2019 b Tap Report

56/131

Cost( At least four factors ma%e ma!or contributions to the cost of i 1on

batteries9

Acti"e materials$

Electrolyte and separator$

7anufacturing$ dri"en by the high cost of the precision e#uipment

re#uired to achie"e high yields of a reliable and safe product$ in the face of the

"ery tight process margins for thin-film cell technology$

Thermal and electrical module and battery management$ made necessary

by the great sensiti"ity of the i 1on chemistry to o"ercharge and o"erheating.

afety > Abuse !esistance( @rganic-electrolyte batteries permit the use of high-specific-energy electrochemical couples but generally are more sensiti"e to abuse. The i

1on battery employs two "ery energetic electrodes separated by a thin organic separator

soa%ed in an organic electrolyte. @"ercharge can create conditions that are e"en more

energetic$ with i metal deposited on the negati"e electrode$ and with the positi"e

electrode becoming chemically unstable at ele"ated temperatures /+,,C0. (urther$ the

energy released by combustion of the battery materials is substantially higher than the

energy stored electrochemically in the battery. (inally$ the electrolyte sol"ents normally

used can create ha5ardous conditions since they ha"e significant "apor pressure at

moderately ele"ated temperatures and are flammable.

Despite these potential safety problems$ consumer i 1on batteries are en!oying

rapid growth$ with "ery few$ relati"ely minor safety incidents reported. The industry has

been able to pro"ide ade#uately safe products by combining appropriate cell designs with

electronic protection of modules and pac%s against o"ercharge$ e2cessi"e current drain$

and o"erdischarge.

The de"elopment of a safe E i 1on battery presents greater challenges$ due to

the much higher energy content of cells$ modules$ and pac%s$ and because of the

difficulty of dissipating heat from a larger mass with a lower surface-to-"olume ratio.

Standards for the safety #ualification of consumer cells ha"e been determined by

-

8/13/2019 b Tap Report

57/131

Gnderwriters aboratory and other groups$ and these are accepted as sufficient. ;owe"er$

the abuse-tolerance standards for E batteries ha"e only been formulated recently /SAE N

+

-

8/13/2019 b Tap Report

58/131

-

8/13/2019 b Tap Report

59/131

negati"e electrode$ electrolyte$ and separatorare typical for i 1on technology. (or

longer life and greater safety$ the cell charging "oltage is limited to

-

8/13/2019 b Tap Report

60/131

particularly since 7itsubishi is not one of the si2 large car companies affected by the

+,, mandate. NSB8s cost goal for E-battery modules in large production "olumes is

around >+4,?%Wh or less..

NSB is e2pending significant resources in large i 1on cell de"elopment and is

establishing a technology base in the field. As an important industrial battery company

and a ma!or participant in the "olume production of portable i 1on batteries$ NSB is in a

good position to de"elop a competiti"e i 1on E-battery product. ;owe"er$ due to the

large mar%et ris% and a series of unresol"ed technical challenges$ the company is

de"eloping its i 1on E-battery technology "ery cautiously and without a definite

commerciali5ation plan. NSB sees the i 1on mar%et for large cells as de"eloping first for

specialty ? military applications$ then for ;Es and$ possibly$ e"entually for Es.

A&"

Company /vervieD. An o"er"iew of SA(T was presented abo"e /see Section

111.)0. As noted there$ early pilot-cell and module-fabrication facilities for i 1on batteries

are in operation at SA(T8s Bordeau2 plant. SA(T is also de"eloping i 1on cells for the

space$ military$ telecom and ;E mar%ets. Especially in the space and military large-cell

mar%ets$ SA(T already holds a position through the sale of its other battery products.

EVBattery *esi$n and Performance. SA(Ts i 1on E cell is cylindrical and

spirally wound$ with a nominal capacity of

-

8/13/2019 b Tap Report

61/131

The performance characteristics of the *,Ah$ ),.3 module are gi"en in Table

III.below. They include energy performances of )F Wh?%g and +), Wh?liter$ and

specific power of 4* W?%g for , seconds at F,= depth of discharge. The operating

temperature range is appro2imately -3VC to 3,VC: below about -3VC$ the battery re#uires

e2ternal heating. Demonstrated cycle life is currently 33, cycles$ but cycling tests are still

running. Cycle life is charge-rate dependent$ with faster charge resulting in diminished

cycle life due to the increased ris% that metallic i is deposited on the graphite negati"e

electrode surface. Therefore$ a minimum charge time of 3 hours is specified. Calendar

life is under study$ with a best current estimate of more than 3 years based on

e2trapolation of data from ongoing tests. 1n the current configuration$ SA(T8s module

has not yet passed some of the o"ercharge and crushing ? nail penetration tests.

SA(T is also de"eloping cells with capacities of +3 to , Ah and modules

composed of these cells for small Es and ;Es as well as Ah cells and modules for

power assist-type ;Es. @"er the last three years$ SA(T has installed )3 i 1on battery

pac%s in e2perimental "ehicles.

'roduction Capability$ Cost and Business 'lanning. Earlier this year$ SA(T

established a pilot-le"el facility for manufacturing

-

8/13/2019 b Tap Report

62/131

"able +++(2( A&"s proFected i +on module cost

olume /pac%s?year0 Hear 7odule Cost />?%Wh0),, +,,,-+,,) +,,,

+3,?%Wh in the

foreseeable future. These issues appear to put ma!or near-term in"estments in production

facilities at high ris%. Current uncertainties notwithstanding$ SA(T is positioning itself to

supply i 1on pac%s to the E mar%et if and when such a mar%et does de"elop.

4+)/BE EEC"!+C %AC4+E!# C/(, "*

3)

-

8/13/2019 b Tap Report

63/131

Company /vervieD. Shin-Jobe is a ;itachi group company with ma!or business

units in batteries$ electrical e#uipment including rectifiers$ G'S$ golf carts$ and plastics.

Shin-Jobe8s products include lead-acid batteries for automobile S1$ industrial /traction

and stationary0 and portable applications$ as well as portable i-Cd batteries.

Shin-Jobe discontinued production of portable i 1on batteries in )**F due to

pressures from se"ere price competition in that mar%et. ;owe"er$ a i 1on cell and

module-de"elopment program for utility load-le"eling and E?;E applications is

maintained at the company8s Saitama facility$ and the program has a small pilot plant for

producing i 1on E cells and modules. These efforts recei"e technical support form the

;itachi Corporate Research aboratory.

EVBattery *esi$n and Performance( Shin-Jobe8s i 1on E cell is cylindrical

and spirally wound$ with a nominal capacity of *,Ah. A typical E module has eight

cells in series to yield a ,-"olt$ +.4 %Wh module. Shin-Jobe8s cell chemistry features a

hard-carbon /co%e0 negati"e electrode$ and a i7n+@

-

8/13/2019 b Tap Report

64/131

ele"ated temperatures battery capacity fades relati"ely rapidly e"en when the battery is

idle$ acommon wea%ness of i 1on technologies using lithium-manganese spinel-based

positi"e electrodes. The 'anel suspects that operating life under these conditions is li%ely

to be rather short$ possibly only one year. The primary failure mode at room temperature

is a rise in cell impedance$ mostly caused by growth of the passi"ating film at the

negati"e electrode-electrolyte interface. At

-

8/13/2019 b Tap Report

65/131

per year is >,, to >4,, per %Wh$ or >)F$,,, to >+)$,,, per E pac%. At ),,$,,, pac%s

per year$ the pro!ected battery specific cost falls to >+3,-3,?%Wh$ with materials

accounting for as much as 43= of the total. According to Shin Jobe$ the cost pro!ections

for high production "olumes contain a large element of uncertainty$ in part because their

materials suppliers are not pursuing cost reduction "ery aggressi"ely due to a general lac%

of con"iction that a substantial E mar%et will materiali5e.

Shin-Jobe and issan$ its main customer for i 1on E batteries$ see the high

cost of these batteries as a ma!or barrier to the commerciali5ation of Es. Thus$ there

appears to be no business case for Shin-Jobe to establish an E-battery production

capability. Conse#uently$ Shin-Jobe is now focusing on i 1on ;E batteries in the

belief that a "iable mar%et for ;Es and their batteries will de"elop and that thecompany can produce a battery capable of meeting the needs of that mar%et. Because

Shin-Jobe is not planning to in"est in the E-battery business$ the company is not a

realistic candidate for the production of E pac%s in the +,,-+,, time frame and

probably beyond.

3

-

8/13/2019 b Tap Report

66/131

III.2.. !ummary

"echnical( The design and performance characteristics of the E modules of the

three leading i 1on E-battery de"elopers are summari5ed in Table III.. The NSB and

Shin-Jobe technologies utili5e i7n+@

-

8/13/2019 b Tap Report

67/131

"able +++(;( Characteristics of i +on Batteries

.nit JB hin)obe A&"

*esi$n Characteristics

ominal Cell Capacity Ah FF *, *,

Cell *esi$n - 'rismatic Cylindrical Cylindrical

Positive Electrode Chemistry - i7n+,< i7n+,< ii77Y@+/`0

ominal %odule Volta$e )3 , ),.3

umber of Cells in %odule ] < F

ominal %odule Ener$y JWh ).+ +.4 )

Performance Characteristics

pecific Ener$y C>; Wh ? %g *4 * )F

Ener$y *ensity C>; Wh ? liter )F ))< /)0`` +),

pecific PoDer cell level3,= DoD$

+, sec.

3,= DoD$

), sec

F,= DoD$

, sec.

at +,VC or +3VC W ? %g F), 43, /+3VC0

-

8/13/2019 b Tap Report

68/131

-

8/13/2019 b Tap Report

69/131

&i$ure +++(6( Cost Estimates for i +on EV %odules

1n an attempt to shed light on these discrepancies$ the 'anel de"eloped a

simplified material cost estimate for the future production of ),,$,,, E-battery pac%s

per year$ based on the first-hand e2perience of i 1on technology by one of its members.

The 'anel8s estimates are illustrated in)3?%Wh). Assuming /as in the 'anel8s analysis of i7;-module

costs0 that materials represent 44= of the Cost of 6oods /a high percentage that translates

into the lowest realistic cost0$ and with a low gross margin of +3=$ a module cost of

>+4,?%Wh was calculated$ in good /if perhaps somewhat fortuitous0 agreement with the

estimates of Shin-Jobe and NSB.

)Te Panel obtained co't pro@ection' &ro+ e'tabli'ed 'pplier' &or te ) large't co't dri/er' o& te 9i Ion

cell at a &tre 6a''+ed to be 2007 prodction /ol+e ei/alent to 100000 0*#$ E pac#' per year.

Te Panel ten a''+ed a 0% redction in te co't o& te po'iti/e and negati/e acti/e +aterial' toanticipate 17 &rter co't lowering in 9i:iM3M-O2pre'ently +ade in relati/ely '+all antitie' and 27 te

'e o& lower*co't natral*grapite negati/e'. Oter a''+ption' inclded !20"#$ &or cell and +odle

ca'ing and ter+inal' !10"#$ &or +odle electronic' and !5"#$ &or +i'cellaneo' +aterial'.

100

200

300

400

500

600

700

0 20000 40000 60000 80000 100000 120000

$a!%s er Year

(%?.

$eveloper % $eveloper B $eveloper C

3F

-

8/13/2019 b Tap Report

70/131

&i$ure +++(5( Cost A$$re$ation for i +on %odulesloDend estimates 300,000 pac=s > year

The 'anel notes that the E business will not be large enough to dri"e i 1onmaterial costs$ e"en at production "olumes of ),,$,,, pac%s?year). While RMD in this

area remains "ery acti"e$ due to the rapid e2pansion of the technology in the consumer

products sector and its growth potential in other mar%ets$ ma!or inno"ations that could

lead to materials costs significantly below those estimated by the 'anel appear unli%ely in

the near term. Thus$ the 'anel tends to agree with the Napanese de"elopers that i 1on E

module prices much below >,,?%Wh cannot be e2pected in the foreseeable future.

1f i 1on E batteries are to become commercially "iable$ operating life and abuse

tolerance issues will need to be resol"ed first$ and then the cost of the technology will

ha"e to be reduced$ at least to the le"els pro!ected for i7; batteries. When considering)Ba'ed on an e'ti+ated 1>>> prodction o& 2 +illion #$ o& '+all 9i Ion batterie' 6400 +illion cell' at ana/erage o& ) $7 and a pro@ected annal growt rate o& at lea't 20% 6)7 te prodction o& '+all batterie'

in 200 'old exceed te ei/alent o& 5 +illion #$. Prodction o& 100000 0*#$ E pac#' in tat

year ei/alent to +illion #$ wold be le'' tan )0% o& con'+er 'age.

0

50

100

150

200

250

300

Materials Module Cost o) oods C6 Module Cost $ri!e to 67M

(%?.

Margin

C6

Materials

t.er

Manu)a!turing

Costs

Ele#troni#s & 't(er

)erminals &

pa#*a+in+

;!ti"e

#aterials

7le!trol*te

,earator &

oils

3*

-

8/13/2019 b Tap Report

71/131

the prospects for achie"ing these ob!ecti"es$ it must be %ept in mind that any less

e2pensi"e$ new materialsespecially acti"e materials and electrolytesthat might be

introduced$ will ha"e to comply with the life and abuse tolerance re#uirements of the E-

battery.

+++(;( +"4+.%%E"A P/#%E!

III..1. Intro%uction

(orty years of research to de"elop rechargeable batteries with lithium-metal

negati"e electrodes has established that achie"ing a practical cycle life for lithiumelectrodes in li#uid electrolytes is e2tremely difficult. With continued cycling$ the lithium

deposited during charging becomes finely di"ided and$ therefore$ highly reacti"e as well

as increasingly una"ailable to the cell reaction. This process creates substantial safety

ha5ards and se"erely limits cycle life. About +, years ago$ the disco"ery that polar

polymers of the polyethylene-o2ide /'E@0 family can dissol"e lithium salts prompted

systematic in"estigation of the use of such polymers as film electrolytes in rechargeable

lithium batteries /F0. 1t was found that lithium electrodes cycled while in contact with

'E@-based solid electrolytes appears to maintain a smoother surface$ ma%ing longer

cycle life possible. Also$ polymer electrolytes are more stable in contact with lithium than

are organic sol"ents$ and they ha"e "ery low "apor pressures. All these characteristics

contribute to the chemical stability and safety of the i polymer systems compared to

lithium-metal-based cells and batteries with organic-li#uid electrolytes.

Due to the "ery low lithium salts solubility and ion mobility in 'E@-based solid

electrolytes$ lithium-metal polymer batteries must operate abo"e room temperature$typically between ,C and *,C. This constraint tends to limit these batteries to

applications for which thermal insulation and management can be pro"ided within the

applications8 physical and cost constraints. This e2cludes the portable battery mar%et but

is not considered a ma!or issue for E batteries that$ in any case$ re#uire thermal

,

-

8/13/2019 b Tap Report

72/131

management for reasons of battery life and safety. Accordingly$ for more than two

decades$ se"eral organi5ations ha"e been attempting to de"elop i polymer batteries for

electric "ehicles. Two programs are still acti"e today9 those of Argo-Tech?;ydro-Iubec

near 7ontreal$ Canada$ and Bollor?ED( in Iuimper$ (rance. The 'anel "isited both

organi5ations to discuss their de"elopment status and plans.

Argo-Tech8s and Bollor8s i polymer batteries use thin lithium-foil negati"e

electrodes$ and positi"e electrodes that contain "anadium o2ide / +@/3-20$with 2U)0 as the

acti"e material. The electrolyte /which also ser"es as the separator0 is a 'E@ polymer

with other polymeric additi"es into which a fluorinated lithium salt /typically lithium-

trifluoromethanesulfonimide0 is dissol"ed. When in contact with a source of lithium ions$

the +,3compound can re"ersibly intercalate and release up to ,.* i ions per "anadiumatom. The specific capacity /for ).F i ion per +,30 is +

-

8/13/2019 b Tap Report

73/131

The i polymer system8s theoretical specific energy of

-

8/13/2019 b Tap Report

74/131

III..2. Li Polymer Com)anies

A!1/"EC4

Company /vervieD( The 1nstitut de Recherche d8;ydro-Iubec /1REI0$ the

research organi5ation of the large Canadian electric utility$ has been engaged in i

'olymer Battery research since )*4*. 1n )**

-

8/13/2019 b Tap Report

75/131

Without the benefit of complete data$ the 'anel8s best estimates of the current

performance of Argo-Tech8s battery module are as follows9

pecific ener$y: )), to ), Wh?%g

Ener$y density: ), to )3, Wh?liter

Cycle life, 90 *o*, *": +3, to ,, cycles

pecific poDer: Z,, W?%g /F,= DoD$ , seconds0

Calendar life: Gn%nown$ but probably more than years

*evelopment and Commercial tatus, Business Plannin$ and Prospects(

Argo-Tech8s E element$ cell$ and module production processes are in the pre-pilot

stage. A full-si5e E pac% has been assembled$ and Argo-Tech plans to install it in a"ehicle later this year. As the design and the manufacturing processes are still e"ol"ing$

the organi5ation8s capability for pilot production is difficult to assess.

The cost of Argo-Tech8s E-battery de"elopment is being shared by GSABC.

The GSABC contract for the now completed 'hase + program had been awarded to a

!oint "enture between 7 /7innesota 7ining and 7anufacturing Co.0 and Argo-Tech$ in

which 7 was responsible for the de"elopment and fabrication of the positi"e electrode-

electrolyte PlaminateQ structure. While the !oint "enture was discontinued in )***$ 7 is

still continuing to manufacture and supply the half-cell laminate. ;owe"er$ Argo-Tech is

now see%ing alternati"e supplier/s0 with a longer-term commercial commitment.

Argo-Tech8s current module production cost is estimated to be se"eral thousand

dollars per %Wh. The company pro!ects a reduction to >,,?%Wh at a production "olume

of about ,$,,, E pac%s per year. To bring the cost down to less than >+

-

8/13/2019 b Tap Report

76/131

-

8/13/2019 b Tap Report

77/131

B//!K, EEC"!+C+"K *E &!ACE E*&, C4E+*E! EEC"!+C

Company Bac=$rounds. ED( is the largest electric utility company in the world

and the dominant utility company in (rance$ with large corporate RMD facilities and

substantial e2pertise in the field of battery management and testing. ED( has had aninterest in E technology for o"er +, years$ and it owns and operates se"eral thousand

electric "ehicles. 1ts commitment to Es led ED( to start the lithium-polymer battery

pro!ect in the early )**,s.

Bollor is a (rench industrial conglomerate with sales e2ceeding >.3 billion in

se"eral industrial fields. Bollor8s battery de"elopment is carried out by the company8s

plastic films and specialty papers group in Iuimper$ (rance. The group has e2tensi"ee2perience and e2pertise in the precise e2trusion and metali5ation of plastic films for

capacitors and holds about

-

8/13/2019 b Tap Report

78/131

outside "endors. The electrolyte includes 'E@ as well as a second polymer that is added

to facilitate film processing and impro"e mechanical properties.

According to Bollor$ at the current stage their 'B system is achie"ing a specific

energy of )

-

8/13/2019 b Tap Report

79/131

larger potential for safety than other lithium systems. While Bollor e2pressed confidence

in its ability to scale up the manufacturing process$ the 'anel considers it unli%ely that$

gi"en the current state of de"elopment and the issues remaining to be resol"ed$ the

present effort can result in a technically pro"en$ high-performance and cost-competiti"e

lithium-metal polymer battery for the E mar%et$ that will !ustify in"estment in a "olume

production plant in less than 3 to years.

III... !ummary

The 'B technology has the highest theoretical specific energy of the three

systems re"iewed in this report. ;owe"er$ the actual specific energy and energy densitydemonstrated to date at the module le"el are not better than those of the best i 1on E

batteries.

1f 'B battery-le"el specific energy and energy density can achie"e parity with

those of i 1on batteries$ the technology8s ad"antages o"er the i 1on technology are

e2pected to be greater safety and lower cost. Regarding safety$ the absence of high-

"apor-pressure organic sol"ents should gi"e the 'B battery greater tolerance to abuse.

While this is a reasonable e2pectation$ it is too early to be #uantified$ as is the potentially

ha5ardous presence of metallic lithium in the 'B system.

The 'B technology offers the lowest potential cost of unprocessed acti"e

materials among the ad"anced batteries presently under de"elopment for E applications.

;owe"er$ this ad"antage might well be offset by the cost impact of the stringent

manufacturing re#uirements and the difficulties inherent in assembling a large thin-layer

battery. When considering the steps still ahead$ 'B de"elopment does not ha"e thebenefit of the %nowledge and e2perience ac#uired in the mass manufacturing of small i

1on and i7; cells. 7aterial specifications$ cell and module design$ and process

parameters are still e"ol"ing for the 'B technology$ and until a more mature design and

pro"en manufacturing processes emerge$ cost estimates for high "olume production of

'B E batteries remain uncertain.

F

-

8/13/2019 b Tap Report

80/131

A limited ability to cycle has always been a wea%ness of rechargeable lithium-

metal batteries. While both 'B de"elopers are showing significant impro"ements in this

area compared to their status of only )-+ years ago$ the best cycle-life performance

demonstrated so far at the module le"el is about

-

8/13/2019 b Tap Report

81/131

&i$ure +++(8( Battery and Electric Vehicle +nteractive *evelopment "imelineand the tatus of the Advanced Batteries of this tudy

Year: 0 1 2 3 4 5 6 7 8 9 10BATTERY DEVELOPMENT

R&D

Cell Design & testing

Module Design; ilot ro!ess de"elo#ent

$ilot $rodu!tion; #odule testing; $a!% design

$a!% ield 'rial ( #anu)a!turing de"elo#ent

a!tor* +nstallation & ,tartu

-olu#e $rodu!tion

Year )ro# -e.i!le /aun!.: 10 9 8 7 6 5 4 3 2 1 0VEHICLE DEVELOPMENT

De"elo !on!et

'est $rotot*e atteries De"elo ,e!i)i!ation'est -e.i!les internall* it. $rotot*e atteries

leet ield 'est it. $ilot atteries

Design & uild -e.i!le $rodu!tion $lant

$rodu!tion

Basic cell desi$nestablished

Commit to PilotPlant

Commit toProductionPlant

Commit to &leet"est

Commit toVehicleProduction

Lithium

PolymerLithium

Ion &i'(

4,

-

8/13/2019 b Tap Report

82/131

+++(

-

8/13/2019 b Tap Report

83/131

III.".1. DaimlerChrysler

7ore than a decade ago$ Chrysler selected the mini"an as the corporation8s

primary electric "ehicle platform. The 3 electric TE ans sold by Chrysler in )**-)**3

were e#uipped with nic%el-iron or nic%el-cadmium batteries$ both of which pro"edunsuitable. The E'1C electric "an was introduced in )**4 with an ad"anced-design lead-

acid battery. The E'1C "an remained the main E platform of the newly formed

DaimlerChrysler corporation$ but the limitations of lead-acid batteries led the corporation

to e"aluate i7; E batteries. @n the basis of its e"aluations$ DaimlerChrysler turned

to SA(T8s *3Ah i7; battery technology /de"eloped with co-funding from GSABC0

for the ma!ority of the E'1C electric "ans produced and deployed under the corporation8s

7oA with the California ARB. Jey characteristics of these "ans are summari5ed in

Table (.1: details on the SA(T i7; battery technology were presented in Section 111.)

abo"e.

(ield e2perience with the more than *,E'1C "ans e#uipped with i7; batteries

indicates that the E'1C electric "an can pro"ide satisfactory function and utility for

selected fleet operators. (or e2ample$ the E'1C pro"ed "ery suitable in handling the

payload and relati"ely mild duty cycle /+,-

-

8/13/2019 b Tap Report

84/131

battery pac%s in sufficient numbers to meet DaimlerChrysler8s needs at a fi2ed battery

price that is consistent with the module cost le"els in

-

8/13/2019 b Tap Report

85/131

III.".2. For%

(ord has been engaged in E de"elopment for se"eral decades$ with a historically

strong focus on ad"anced electric power train technology de"elopment. Gnder its 7oA

with the California ARB$ (ord de"eloped and deployed a battery-powered "ersion of itsRanger truc% with the characteristics included in Table (.1.

Appro2imately 3,, Ranger Es were supplied originally with Delphi lead-acid

E batteries$ a product that had significant reliability and durability problems. A number

failed in less than two years$ and replacement after only ),$,,, miles of ser"ice was

re#uired for many of them because of substantially degraded performance. Delphi has

since discontinued promotion and the Ranger is now supplied with a battery from East

'enn 7anufacturing Co.$ whose characteristics are shown inAppendix

-

8/13/2019 b Tap Report

86/131

1n (ord8s "iew$ the primary issue with i7; batteries is their high cost. @ne

leading manufacturer #uoted prices of nearly >3,,?%Wh and about >,?%Wh$ for

guaranteed production "olumes of 3$,,, and +,$,,, pac%s?year$ respecti"ely. E"en true

mass production /e.g. ),,$,,, pac%s?year0 would lower this number only to >++3-

+3,?%Wh. The energy density of about)3,Wh?liter is another serious concern because it

limits the Ranger E-battery capacity to less than ,%Wh and the "ehicle range to about

F+ miles /under the SAE N )< test cycle0$ less than 43 miles at freeway speeds$ and 3,-

43 miles in real-world dri"ing /seeAppendix ( Table (.20.

(ord technical staff belie"es that lithium-ion E batteries are se"eral years behind

i7; and that they are unli%ely to offer significant energy density increases or costreductions compared to i7;$ e"en if current technical issues with calendar life and

abuse tolerance are resol"ed. These problems are considered fundamental and$

accordingly$ thought to re#uire ma!or ad"ances or brea%throughs$ primarily in the acti"e-

materials area. As a conse#uence$ (ord is not currently wor%ing on the integration and

e"aluation of i ion batteries in its Es. The company is satisfied with its participation in

the GSABC program that is supporting i ion E-battery technology de"elopment and

ad"anced materials RMD.

Similarly$ (ord is not directly in"ol"ed in lithium-metal polymer E-battery

technology but relies on its participation in the GSABC program. GSABC has been

supporting ;ydro Iuebec?Argo-Tech who are engaged in the world8s largest program to

de"elop lithium-metal polymer E batteries /see also Argo-Tech and GSABC

subsections under Sections 111. and 111.

-

8/13/2019 b Tap Report

87/131

the aggregate demand for Es in California will fall short of meeting ARB8s &E

re#uirements. Conse#uently$ e"en small Es would need subsidies to attract sufficient

buyers or lessees. This would result in mar%et distortions that could hurt the longer-term

prospects of such "ehicles. 1n (ord8s "iew$ a free-mar%et approach is needed for the

introduction of &E and partial-&E "ehicles.

III.".. +eneral 'otors

67 has remained a world leader in electric "ehicle technology o"er the last

se"eral decades$ and the de"elopment and introduction of the E) was originally

concei"ed as a demonstration of that leadership. Together with the S-), electric truc%$ the

E) is now ser"ing as 678s E offering under its 7oA with the California ARB. 67

published a complete set of performance$ efficiency and mileage cost data for the E)

and S-), operated with two types of lead-acid and a nic%el-metal hydride battery: some

of these data are included in Table' (.1 and (.2(

1n %eeping with 678s strategy to de"elop and introduce E and other ad"anced-

"ehicle technologies in a series of steps to limit cost and ris%$ the second-generation E)

is now being introduced. 1t has a number of technology impro"ements including more

compact power electronic controls that represent a 43= cost reduction from first-

generation control technology. The E) and S-), Es were originally deli"ered with

Delphi lead-acid E batteries. The e2perience with these batteries was disappointing

inasmuch as they did not deli"er their rated capacity in typical dri"ing. As a result$ E)

range was limited to 43-F, miles in "arious city and highway test cycles$ 3,-43 miles in

Preal worldQ dri"ing. The corresponding ranges for the S-), electric truc% were lower

than for the E) by a factor that e2ceeded the ).4 ratio of the two "ehicles8 gross

"ehicle weights. The substitution of the 'anasonic E-)+, lead-acid battery in late )***

increased the range of both "ehicles by ,-

-

8/13/2019 b Tap Report

88/131

Since fall )***$ both "ehicles are also a"ailable with a 67@ 44Ah$ )3,?%Wh0. 67 AT management noted that no

de"eloper of ad"anced batteries has shown a credible path to achie"ing this goal. Het$ an

ad"anced battery is needed to achie"e the ),, mile real-life range that$ according to

678s mar%et research in con!unction with the E)$ is important to users. E"en

increments of range in the ),, mile domain are considered "aluable by operators of the

E). The mar%et importance of factors beyond cost is attested to by 678s finding that

dropping the E) lease rate substantially did not generate many more leases.

67 concludes that$ in addition to see%ing continued battery-cost reductions$

alternati"e strategies are needed to achie"e cost feasibility of battery-powered Es.

44

-

8/13/2019 b Tap Report

89/131

'ossible strategies include obtaining re"enue from sale of used i7; E batteries$ and

introduction of city cars. 67 belie"es that mandating the introduction of Es is not a

constructi"e step towards their commerciali5ation and that Pcon"entionalQ Es are not a

solution to the os Angeles air-#uality problem. The city car could become part of the

solution$ but only with a system-le"el change of transportation in the os Angeles air

basin.

III.".". ,!ABC

The Gnited States Ad"anced Battery Consortium was formed in )**) as a

collaborati"e program of the G.S. (ederal 6o"ernment /represented by D@E0$ the three

ma!or G.S. automobile manufacturers /represented by GSCAR0$ and the country8selectric utilities /represented by E'R10. The mission of GSABC is to support and guide

RMD programs to de"elop electric "ehicle batteries with the performance$ operating and

cost characteristics re#uired for commercially "iable electric "ehicles. The GSABC

programs are carried out and cost-shared by industrial organi5ations capable of

commerciali5ing successfully de"eloped E-battery technologies.

Since the program8s initiation$ GSABC has funded the de"elopment of nic%el-

metal hydride$ lithium-ion and lithium-metal polymer E batteries with about >++,

million$ supplemented by >F, million worth of in-%ind contributions from the battery

de"elopers. GSABC continues to be a ma!or factor in ad"anced E-battery de"elopment

because the organi5ation represents the financial commitments of ma!or G.S.

sta%eholders in Es and E batteries$ and it benefits from the "iews and guidance of the

sta%eholders8 battery e2perts.

The 'anel met with GSABC management for a discussion of the program8s

current focus and of the management8s future perspecti"e on ad"anced E batteries.

GSABC program support played a ma!or role in the e"olution of two of the three i7;

technologies used in the Es introduced under the California 7oAs. GSABC recently

concluded its sponsorship of i7; E-battery cost-reduction programs with indications

that i7; materials costs could be reduced to le"els close to >)

-

8/13/2019 b Tap Report

90/131

analysis$ this materials cost translates to appro2imately >+)3,?%Wh and

long-term target of >),,?%Wh /see Table II.10.

GSABC program emphasis and support has shifted to the de"elopment of thelithium-ion and lithium-metal polymer battery technologies at SA(T and Argo-Tech$

respecti"ely. The current performance status$ cost pro!ections and outloo% for commercial

a"ailability of these systems are re"iewed in Sections 111.+ and 111. abo"e. (or i 1on$

the %ey remaining issues are calendar and cycle-life$ abuse tolerance?safety$ and cost

/especially materials cost0. (or i polymer$ they are cycle-life and cost$ especially

manufacturing cost. These issues need to be resol"ed without compromising the

achie"ement of performance targets.

Although funding from D@E has been eroding$ the collaborati"e industry?federal

go"ernment program of the GSABC remains committed to pursuing the de"elopment of

i 1on and i polymer batteries with the performance and costs re#uired to ma%e Es

attracti"e to customers. 1f successful o"er the coming -< years$ one or both of these

programs should result in pilot-plant #uantities of pre-prototype batteries that more

closely approach the GSABC performance and life targets. 1f achie"ement of cost goals

can be pro!ected with confidence at that time$ )43?%Wh.

III.".$. (on%a

With the E 'GS$ ;onda introduced the world8s first modern$ purpose-designedfour-passenger electric "ehicle with an ad"anced battery. The characteristics of the E

'GS are included in Table (.1: appro2imately +F, of these "ehicles are currently in

ser"ice in California. ;onda maintains that the E 'GS has a highly efficient power

train$ with motor-controller efficiency a"eraging abo"e *,= in city dri"ing. ;owe"er$ as

with other state-of-the-art Es$ the "ehicle8s range is substantially less in real-life dri"ing

4*

-

8/13/2019 b Tap Report

91/131

than in typical test cycles due to se"eral factors$ the most important being dri"ing

conditions on public roads "ersus dynamometer tests$ dri"er beha"ior$ and the e2tent of

air conditioning and?or heating used /seeAppendix ( Table (.20.

All E 'GS "ehicles ha"e the 'anasonic E Energy E-*3 i7; battery$ with

the characteristics presented in Table III.1.The latter all fall within the en"elope of the

battery performance cur"es specified by ;onda for the "ehicle. 1n the ;onda E 'GS$

the battery is li#uid-cooled$ and the coolant loop is integrated with motor cooling.

Control of coolant flow is managed to allow for different thermal conditions$ including

the relati"e temperatures of components and coolant. The battery has a number of

important safety features including charge termination triggered by a hydrogen-detection

system$ waterproof electric wiring$ and automatic high-"oltage cut-off in case of acollision. Battery bo2$ water-cooling and other pac% components add more than ),= to

battery weight when modules are assembled into the battery installed in the "ehicle.

Battery #uality control and reliability ha"e been encouraging for such a radically

new automoti"e component$ with a defect rate of about )= for a production run of

appro2imately ,, E-'GS batteries. Battery capacity remained abo"e F,= for

customers8 "ehicles used up to + months$ but a first replacement was re#uired for one

"ery-high-mileage "ehicle after less than two years of operation. A small number of

battery pac%s re#uired a special reconditioning procedure to restore capacity. Battery

charge management has since been modified to incorporate a reconditioning cycle under

operating conditions that can cause a temporary loss of battery capacity. ;onda8s

e"aluation of li#uid-cooled *3Ah i7; batteries is continuing. 1t is also carrying out

testing of impro"ed *3Ah 'EE i7; technology$ and e"aluating an air-cooled 3,Ah$

)3%Wh i7; battery ha"ing both significantly impro"ed charging efficiency at ele"ated

temperatures and a higher operating temperature limit.

;onda has a long history of monitoring candidate E-battery systems that

included lead-acid$ nic%el-cadmium$ sodium-sulfur$ nic%el-metal hydride$ lithium-ion and

sodium-nic%el chloride /&EBRA0. @f the latter four systems with potential to deli"er

good specific energy$ the &EBRA and sodium-sulfur high-temperature /,,-3,\C0

F,

-

8/13/2019 b Tap Report

92/131

batteries ha"e been eliminated$ since in ;onda8s "iew they do not offer significant

ad"antages o"er the other ad"anced technologies.

;onda has wor%ed with se"eral i 1on battery de"elopers for almost a decade and

e"aluated three different positi"e electrode chemistries. @n that basis$ ;onda does not

ha"e an optimistic e"aluation of i 1on batteries and belie"es that ma!or impro"ements

are needed to ma%e the technology a serious candidate for E propulsion. 1n particular$

;onda is concerned about capacity degradation with cycling and o"er time$ and it sees

issues with safety$ including lea%age of flammable electrolyte during o"ercharge. 1n

addition$ ;ondas in-house analysis suggests that the costs of i 1on batteries would be

substantially higher than i7; costs for comparable production "olumes. ithium-metal

polymer batteries might be e"aluated in the future$ although ;onda has #uestionsregarding the ade#uacy of i polymer battery power density.

(rom its e2perience with the E 'GS introduction and the interaction with

owners and users of the "ehicles$ ;onda has concluded that cost$ range and battery

recharge time are the most important battery-related factorsin the acceptance of Es in

the mar%et place. The difficulty of the cost challenge is illustrated below$ where ;onda8s

estimates of future i7; battery module costs /deri"ed from detailed pro!ections of

materials costs by %ey materials suppliers$ and from manufacturing-cost estimates

pro"ided by battery de"elopers0 are compared with ;onda8s battery cost-goals9

200; proFection: >+,% ? +F%Wh$ or >4+, ? %Wh )$,,, pac%s ? year

200; proFection: >),% ? +F%Wh$ or >, ? %Wh ),$,,, pac%s ? year

Cost $oal: >+% ? +F%Wh$ or Z >4, ? %Wh

;onda8s mar%et research indicates that$ despite a number of attracti"echaracteristics$ Es with the current high-cost and performance limitations appeal only to

a "ery limited number of customers. To o"ercome this mar%et limitation$ ma!or ad"ances

or brea%throughs are re#uired in E costs /primarily battery but also "ehicle costs0$ E

range /higher battery specific energy and energy density0$ and charging time /higher

F)

-

8/13/2019 b Tap Report

93/131

-

8/13/2019 b Tap Report

94/131

summari5ed in Table III.. Reliability of the battery has been e2cellent to date$ with no

failures obser"ed among the thousands of *,Ah cells used in issan8s ATRA and

;yper-7ini Es. issan belie"es that the %ey challenges in the introduction of lithium-

ion battery-powered Es are cost reduction$ e2tension of dri"ing range$ and

demonstration of satisfactory durability$ especially of the battery.

1n the nearer term and at low production "olumes /e.g. a few thousand units?year0$

ATRA costs will e2ceed those of comparable 1CE "ehicles se"eralfold$ with the battery

contributing materially to the high cost. This can be inferred from )$+,, for the cost ofthe electrical and thermal management systems$ a +%Wh-battery would cost about

>,$,,,clearly far too much for cost feasibility. 1n mass production$ issan belie"es

that the costs of Es /e2cluding batteries0 could e"entually approach the cost of higher-

end 1CE "ehicles. Ta%ing a >+4,?%Wh battery module cost for a production "olume of

),,$,,, pac%?year from,, for battery

management systems in mass production$ a +%Wh i 1on battery would cost about

>*$,,. This approaches i7; battery mass production costs but remains significantly

abo"e thehighestcost targets discussed in Section 11.+.3 abo"e.

issan considers that the mar%et for Es with limited performance and pro!ected

high costs is nowhere near the

-

8/13/2019 b Tap Report

95/131

III.".. Toyota

i%e other leading automobile manufacturers worldwide$ Toyota has maintained

acti"e electric "ehicle de"elopment programs for decades. 1n the )**,s$ Toyota

substantially increased its efforts to de"elop the RA

-

8/13/2019 b Tap Report

96/131

and poor charge acceptance of the nic%el o2ide positi"e at ele"ated temperatures.

;owe"er$ an additi"e to the positi"e is now permitting satisfactory charge acceptance of

impro"ed i7; batteries tested in the laboratory at temperatures as high as 33-,VC.

Because of the limited number of RA< E "ehicles in the field and the e2cellentdurability of their batteries$ good battery failure statistics are not yet a"ailable. The bench

test data in

-

8/13/2019 b Tap Report

97/131

-

8/13/2019 b Tap Report

98/131

the 'anel noted that for e"ery "ehicle the Preal-lifeQ range was reported to be

significantly less than the range achie"ed in simulated test cycles /see also Appendix (

Table (.20. This fact has the important conse#uence that the battery capacity re#uired for

a desired E range capabilityand thus battery weight as well as costtend to be