AYLESBURY 'KB' TYPE FLOAT VALVES - Heat Tracing...Installation of valves should be in accordance...

Transcript of AYLESBURY 'KB' TYPE FLOAT VALVES - Heat Tracing...Installation of valves should be in accordance...

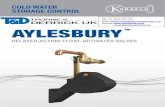

AYLESBURY™ 'KB' TYPE FLOAT VALVES

SIZES (DN): 2"(50)HF, 2½”(65)SF & 3”(80)RB

PLEASE PLACE LABEL ON TANK LID ABOVE VALVE FOR FUTURE REFERENCE.

PRE-INSTALLATION CHECKS AYLESBURY Valves are unlike any other float operated valve, ballcock or ball valve. Please read these instructions and refer to attached drawings before installation. Installation of valves should be in accordance with The Water Supply (Water Fittings) Regulations 1999 and BS6700:1997 Para. 2.2.4 Keraflo Valves contain a pair of maintenance free ceramic discs. Do NOT attempt to dismantle the Valve - even if you are curious! Should the Valve ever become blocked with debris, ask Keraflo for a Service Manual. EVIDENCE OF DISASSEMBLY OR SIGNS OF MISUSE MAY INVALIDATE WARRANTY.

OPERATING SPACE: Check for sufficient clearance - see dimension sheet Ki025* and Ki026* for working dimensions.

CHAIN LENGTH: Do not cut or shorten the Stainless Steel Chain - its weight is critical. Likewise do not add weight by lengthening.

OVERFLOW/ WARNING PIPE:

Check the position of the Overflow and Warning Pipe (where fitted). See sheet Ki026* for closing water level (TWL) range.

TURBULENT WATER: Exceptionally turbulent waters, eg: cooling towers, should be avoided directly beneath the float. Calming measures such as baffle plates, still ponds etc. should be implemented.

FLANGED TANKS: The design of Aylesbury 'KB' Type Valves, sizes 2”(50)HF, 2½”(65)SF and 3”(80)RB, allows a minimum clearance of 25mm between the Counter Weights and the tank wall. The Valve should be fitted at least 220mm above an internal flange.

ROUND TANKS: Minimum tank diameters required

Valve 2”HF 2½”SF 3”RB Min tank diameter (m) 1.80m 1.80m 1.80m

SLOPING TANK WALL: The wall to which the Aylesbury Valve is to be attached must be vertical. If the wall around the fixing hole is sloped, tapered washers must be used. These are generally available from the tank supplier.

PIPEWORK SUPPORT: Aylesbury Valves create virtually no tank wall stress. Additional pipework support is therefore unnecessary; provided the Code of Practice for the support of pipework in general is met.

SERVICING VALVES: A servicing valve must be fitted as near as is reasonably practicable to the float operated valve. A servicing valve incorporating a particle strainer is highly recommended.

AYLESBURY™ 'KB' TYPE FLOAT VALVES

SIZES (DN): 2"(50)HF, 2½”(65)SF & 3”(80)RB

P/KBTFINSTALL/04-08 Page 2 of 5 KBTFInstall

INSTALLATION INSTRUCTIONS

Installation of valves should be in accordance with The Water Supply (Water Fittings) Regulations 1999 and BS6700:1997 Para. 2.2.4

WARNING! THE BUILT-IN SPIRIT LEVELS MUST BE USED TO ALIGN THIS VALVE. FAILURE TO FOLLOW THE PROCEDURE LISTED BELOW WILL PREVENT THE VALVE OPERATING CORRECTLY.

REFER TO DRAWINGS DURING INSTALLATION To avoid damage fit the Actuator Tubes after installing the Valve in the tank.

1 Before fitting the Valve, flush the supply pipes to clear all debris. Tanks and pipes should be disinfected using the procedures in BS 6700:1997 Para 3.1.10

2 Remove and retain the Double R Clips and Actuator Levers from the Valve Body.

3. Remove and discard the protective cap from the Tail. Remove and retain one Backnut. Insert the Valve

Tail through the hole in the tank wall, replace the Backnut with the flanged side against the tank wall.

4. Connect the supply pipe via a servicing valve, then hand thighten Backnuts to suit. To prevent the Valve Assembly turning when tightening the pipe fitting, use either a wrench or a spanner on the Valve Tail where indicated in drawing Ki026*. DO NOT USE A WRENCH ON ANY OTHER PART OF THE VALVE. The Valve Assembly must be positioned absolutely horizontal.

5. Fit the Actuator Tubes over their respective Spigots with the Hangers furthest from the tank wall. (The

Tube with the red dot should be fitted to the Valve with the red dot and the cap screw heads on the brackets should face away from the Valve Assembly).

6. Fit the Actuator Levers over the Spigots and push their Pins through their respective Brackets and into the

hole in each Wheel behind. Place a finger or thumb through the loop in one of the Double R Clips, then push the Clip into the groove in one of the Spigots until it clicks into place, repeat on remaining Spigot.

7. The Actuator Tubes will be tilting down towards the tank wall (brass end lowest). NOTE: neither the Link

Tube Assemlby nor the chain is connected at this stage. The Spirit Levels should indicate level (bubble exactly between black lines). If a Spirit Level does not indicate level, its individual Valve needs to be rotated at its screwed connection into the Tee where indicated in Ki025*. This joint is sealed by an O ring so can be moved without fear of a leak. Loosen the Backnut by the Tee and rotate the Valve until the bubble in the Spirit Level is precisely between the black lines. Tighten Backnut then check alignment again. The bubble must be precisely between the black lines.

8. Remove and discard the protective caps from the Discharge Assemblies.

9. One end of the Link Tube Assembly is already fitted to the Stud of one Actuator Tube. Locate the other end

of the Link Tube Assembly over the other Actuator Tube Stud before inserting and deforming the Split Cotter Pin. NOTE: to avoid straining the Link Tube Assembly during installation, push the end of the Actuator Tube down.

10. Hang the chain on the Hanger. The length of this chain determines the opening water level - see

"ADJUSTING OPENING WATER LEVEL (LWL)" below.

11. Position the Closing Float Assembly along the chain to the required closing water level. Hook the Float Adjusting Peg THROUGH the required loop in the chain - see "ADJUSTING CLOSING WATER LEVEL (TWL)" below.

AYLESBURY™ 'KB' TYPE FLOAT VALVES

SIZES (DN): ¾”(20), 1”(25), 1¼”(32), 1½”(40)SF, ,1½”(40)HF, 2”(50)SF

ADJUSTING OPENING WATER LEVEL (LWL) Refer to drawing Ki026* The Valve will open once the water level has dropped far enough to expose most of the Opening Buoy. When the Actuator Tubes are held horizontal, the groove in the Opening Buoy indicates the exact opening water level. Adjust the length of the chain with the Hanger. Loop the excess chain into the Hanger as shown in drawing Ki025*.

DO NOT CUT OR REMOVE ANY CHAIN, ITS WEIGHT IS CRITICAL. The standard length of chain enables a lowest open level of 2000mm. A longer chain (factory fit option only) is available upon request

ADJUSTING CLOSING WATER LEVEL (TWL) When the Actuator Tubes are held horizontal, the closing water level is located at the mid point of the Closing Float. Drawing Ki026* also shows the closing water level in relation to the Closing Float when the valve is in the closed position. The highest achievable closing water level is 210mm from the centreline of the Valve. This can be achieved by having no spare chain links between the Hanger and the Float Adjusting Peg. The lowest closing water level (1610mm from the centreline of the Valve) can be achieved by having the float touching the top of the Opening Buoy whilst using all of the available chain (last link on Hanger). Position the Float Assembly along the chain to the required closing water level. Hook the Float Adjusting Peg THROUGH the required loop in the Chain. Applications where the Top Water Level (TWL) can rise after the Valve has closed will cause the Chain to become slack. A cable tie/ratchet strap should be fitted over the Float Adjusting Peg in such a way as to prevent the chain from slipping off. Ensure the Chain cannot become entangled with tank tie bars etc.

DELAYED ACTION (LEVEL DIFFERENTIAL) The delayed action (level differential) is the difference between opening and closing water levels. This is adjustable between 390mm (Float touching top of Opening Buoy) and 1815mm (Float Adjusting Peg almost touching Hanger whilst using all of the available chain) on drawing Ki026*.

TESTING Before leaving the installation, test the Valve operation a number of times ensuring the Valve moves freely from the open to the closed position and from the closed to the open position. Where a Valve has not been in operation for a period of time it is also recommended that the above procedure is carried out.

ATTACHED DRAWINGS Ki025* Aylesbury KB Type Dimensions – Front View Ki026* Aylesbury KB Type Dimensions – Side View

KERAFLO RESERVE THE RIGHT TO CHANGE SPECIFICATIONS, DESIGN AND MATERIALS WITHOUT PRIOR NOTICE.

P/KBINSTALL/04-08 Page 4 of 5 KBInstall

P/KBINSTALL/04-08 Page 5 of 5 KBInstall

![The Aylesbury™ Float Valve Range4].pdf · The Aylesbury™ Float Valve Range Aylesbury valves are designed to provide an accurate and efficient ... any water storage tank remains](https://static.fdocuments.net/doc/165x107/5a824d037f8b9a571e8e169e/the-aylesbury-float-valve-4pdfthe-aylesbury-float-valve-range-aylesbury.jpg)