AutoFilt RF3 Automatic Self-Cleaning Filter PDFs/Hydac Filters/Hydac Autofilt RF3.pdfAutoFilt® RF3...

Transcript of AutoFilt RF3 Automatic Self-Cleaning Filter PDFs/Hydac Filters/Hydac Autofilt RF3.pdfAutoFilt® RF3...

AutoFilt ® RF3 AutomaticSelf-Cleaning Filter

Cou

rtes

y of

CM

A/F

lody

ne/H

ydra

dyne

▪ M

otio

n Con

trol

▪ H

ydra

ulic

▪ P

neum

atic

▪ E

lect

rica

l ▪ M

echa

nica

l ▪ (

800)

426

-548

0 ▪

ww

w.c

maf

h.co

m

2

DESIGN

The AutoFilt® RF3 is an automaticself-cleaning filtration systemdesigned for continuousmaintenance-free filtration for allmajor manufacturing andprocessing industries. It removessolid contamination from lowviscosity fluids such as water andmachine tool coolants. Its ruggedconstruction and self-cleaningfeature provide companies withincreased machinery reliabilityresulting in reduced operating, laborand maintenance costs.

Superior removal of contaminationparticles from water is accomplishedwith Slotted Tube / Wedge WireFilter Elements ranging from 50 to3,000 microns and SuperMeshTM

Filter Elements with 25 and 40microns.

The automatic self-cleaning processbegins, as soon as, the filter elementsbecome contaminated. Due to theunique single element cleaningprocess, the total filtered flow is notreduced during the cleaning process.

Flow rates range can range from20-31,000 GPM and housings areavailable with ANSI mounting portflanges from 2” to 36”.

HYDAC can supply numerouscombinations of housing materials,as well as, system operatingequipment to reach the optimuminstallation for every industryapplication.

COST EFFECTIVENESS

Particle contamination in wateraccelerates the rate of wear onsystem components such asspray nozzles, water valves, andpipelines. This could result inpremature component failure.

The use of automatic self-cleaningfilters lead to a significant decreasein service and maintenance intervalsresulting in time and labor savings.As well, costs for replacementequipment and waste disposalcan be minimized.

Process water is typicallycontaminated with solids andwater companies apply surchargesto handle the contaminant discharge.The HYDAC AutoFilt® RF3 isideally suited for removing thesecontaminants prior to dischargethus reducing or eliminating anyfinancial surcharge.

TECHNICAL DATA

Flow Rates• 20 - 31,000 gpm

ANSI Flange Sizes• 2” - 36”

Filtration Micron Ratings• 25 - 3000 µm

Maximum Operating Pressure• 90 to 150 psi*

Power Source• Electric, Pneumatic, or

Electro-pneumatic

Power Requirements• 480 3-phase VAC*• 80 psi air pressure

Filter Housing Material• Carbon Steel• Stainless Steel 316Ti

Internal Parts• Stainless Steel 304

Self-Cleaning Valve• Stainless Steel akin 316

Filter Elements• Stainless Steel 316L

Corrosion Protection for CarbonSteel Vessel• Polyurethane• Rubber coating

Special Coatings and Steels areAvailable for Severe FluidApplications

Filter Vessel Certification• ASME Code available

*Other Models Available, Consult Factory

Cou

rtes

y of

CM

A/F

lody

ne/H

ydra

dyne

▪ M

otio

n Con

trol

▪ H

ydra

ulic

▪ P

neum

atic

▪ E

lect

rica

l ▪ M

echa

nica

l ▪ (

800)

426

-548

0 ▪

ww

w.c

maf

h.co

m

3

Model Code: Filter AssemblyRF3 5 EPT NG N 1 3 0 / KS1000 5 12345678 .

Filter TypeRF3 = AutoFilt®

Filter SizeFlow Range (GPM) ANSI Flange

C = 20 - 120 2”0 = 110 - 500 4”1 = 400 - 1120 6”2 = 880 - 1980 8”2.5 = 1760 - 2600 10”3 = 2420 - 3780 12”4 = 3550 - 7480 16”5 = 6600 - 10,780 20”6 = 8800 - 15,850 24”7 = 13,200 - 22,000 28”8 = 19,800 - 31,000 36”

Drive Control / Connecting VoltageEPT = Electric / Pneumatic cycle control, ∆p dependentEU = Electric control, ∆p dependentPT = Pneumatic cycle control, ∆p dependent, size C-4PTZ = Pneumatic cycle timed control, size C-47 = 3X415V/N/PE 60Hz8 = 3X460V/X/PE 60Hz

Housing Material / Corrosion ProtectionN = Standard steel 1.0038, outside primedNM = Standard steel 1.0038, outside primed, inside metallogal® painted (Polyurethane)NG = Standard steel 1.0038, outside primed, inside rubber coated (Butyl Coated)E = Stainless steel 1.4571A = with ANSI-flanged, additional A at the end

Shut-Off Valve MaterialN = Standard steelE = Stainless steel

Differential Pressure Gauge1 = Pressure chamber, Aluminum 3.2583022 = Pressure chamber, Stainless steel 1.43053 = with pressure mediators stainless steel 315 TI

Flange Position Inlet & Outlet1 = outlet opposite inlet (standard)2 = outlet turned 90° clockwise direction compared to standard3 = outlet turned 180° clockwise direction compared to standard4 = outlet turned 270° clockwise direction compared to standard

Modification Number

Element SetKD25 = Conical SuperMeshTM

KD40 = Conical SuperMeshTM

KS50 = Conical slotted tubes (wire wedge)KS100 = Conical slotted tubes (wire wedge)KS200 = Conical slotted tubes (wire wedge)KS300 = Conical slotted tubes (wire wedge)KS400 = Conical slotted tubes (wire wedge)KS500 = Conical slotted tubes (wire wedge)KS1000 = Conical slotted tubes (wire wedge)KS1500 = Conical slotted tubes (wire wedge)KS2000 = Conical slotted tubes (wire wedge)KS2500 = Conical slotted tubes (wire wedge)KS3000 = Conical slotted tubes (wire wedge)

Size of Element SetUse same code selected in filter size

Drawing Number(omit) = standard versionFor special versions a number will be provided after technical clarification at head office

Vessel Certification(omit) = standard versionASME = ASME version

1 2 3 4

Cou

rtes

y of

CM

A/F

lody

ne/H

ydra

dyne

▪ M

otio

n Con

trol

▪ H

ydra

ulic

▪ P

neum

atic

▪ E

lect

rica

l ▪ M

echa

nica

l ▪ (

800)

426

-548

0 ▪

ww

w.c

maf

h.co

m

4

OPERATION

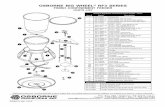

The design of the AutoFilt® RF3 Self-Cleaning Filter is simple yet highlyeffective. The basic construction consistsof the main housing, inlet and outletports with flanged connections, filterelements, outlet valve and actuatorand electronic operating controls. Allof these combined together provide acompletely automated self-cleaningfiltration system.

The process begins with fluid passingthrough the inlet flange reaching thefilter elements by flowing from insidethe element to outside. Solidcontamination is then trapped on theinside of the Wedge-Wire filter element.As contamination increases, thedifferential pressure between thecontaminated and clean side increases.When the set differential pressure isreached, 7 psid typical, self-cleaningprocess is triggered.

Note: This self-cleaning activation hasan adjustable differential pressure ortime setting. (see Starting the AutomaticSelf-Cleaning Process on page 6.)

The self-cleaning process is onecomplete cycle which cleans oneelement at a time in succession. Thegeared motor turns the contaminationdischarge arm under the filter elementto be cleaned. The contaminationdischarge valve is then opened by anactuator. This results in a highpressure drop within the filter elementbeing cleaned, which forces theparticles into the discharge line.During this operation, only a smallamount of clean fluid is used tocomplete the cleaning process.

A typical self-cleaning cycle takes lessthan 30 seconds. The cleaning cycletakes place with no interruption in flowor pressure drop.

The unique conical element designand internal mounting configurationallows for smooth flow transition,resulting in a minimal pressure lossduring the cleaning process.

Advantage to the customer: Fewerself-cleaning cycles and a minimumloss of flushing fluid.

Cutaway: RF3Cou

rtes

y of

CM

A/F

lody

ne/H

ydra

dyne

▪ M

otio

n Con

trol

▪ H

ydra

ulic

▪ P

neum

atic

▪ E

lect

rica

l ▪ M

echa

nica

l ▪ (

800)

426

-548

0 ▪

ww

w.c

maf

h.co

m

5

Element Filtering:Inside to Outside

Element Back-Flushing:Outside to Inside

Vessel Filtration:Inside to Outside

Vessel Self-Cleaning:Outside to Inside

Cou

rtes

y of

CM

A/F

lody

ne/H

ydra

dyne

▪ M

otio

n Con

trol

▪ H

ydra

ulic

▪ P

neum

atic

▪ E

lect

rica

l ▪ M

echa

nica

l ▪ (

800)

426

-548

0 ▪

ww

w.c

maf

h.co

m

5.14.43.62.92.21.50.70 5.8

4,400

440

40

44,000

1,750

175

17,500

Pounds Per Square Inch

Gal

lons

Per

Min

ute

RF3-7RF3-8

RF3-6

RF3-5

RF3-4

RF3-3

RF3-2.5RF3-2

RF3-1

RF3-0

RF3-C

AE

AF

6

Starting The AutomaticSelf-Cleaning Process• Pressing the Test Button on the

Control Panel

• Electrically activated Test Button

• Differential Pressure set point isexceeded, e.g., 7 psid

• Adjustable Timer, e.g., 12 hours

• Combination Differential Pressureand Adjustable Timer

Flow Curves

Element Opening QuotientEFQx determines consistent flow without reverse flow through the filterelement during the filtering and self-cleaning process. The EFQx value isthe ratio of the opening filtration surface of an element to the cross sectionof the opening of the element inlet.

EFQx = AF

AE

X = Filtration rating in µm

Example: EFQ100 < 3 forelements with filtrationrating of 100 µm

Note: The curves are for filter rating from 100 µm - 3000 µm. For 50 µm the pressure dropincreases by 30%. This is true for sizes RF3 0 - 8. For RF3 C there is no increase inpressure drop. For 25, 40, and 50 µm the pressure drop increases by 30%.

Ready To OperateThe filter control unit anddifferential pressure measuringlines are already connected. Oncethe inlet, outlet, and discharge lineshave been attached, only thepower and/or air supply need to beconnected.

Variable Filter GeometryThe outlet flange can be oriented in any 90˚ increment in comparison to theinlet. The discharge line incorporates a slip flange which enables positioningat any angle in which the housing legs do not interfere. The AutoFilt RF3 canbe easily integrated into any plant due to these flexible mounting options.

Cou

rtes

y of

CM

A/F

lody

ne/H

ydra

dyne

▪ M

otio

n Con

trol

▪ H

ydra

ulic

▪ P

neum

atic

▪ E

lect

rica

l ▪ M

echa

nica

l ▪ (

800)

426

-548

0 ▪

ww

w.c

maf

h.co

m

Advantages ...and the Benefits to You!of the AutoFilt® RF3

Extensive standard features Excellent price to performance ratiofor numerous applications

Reliable and safeAutomatic operation Set it & Forget it

Low operating costs

Continuous fluid flow No interruption of unit operationduring self-cleaning Minimum fluid loss

Flow rate up to 31,000 gpm High process performance

Service friendly Low maintenance & replacement part costs

Isokinetic filtration and cleaning Maximum utilization of filter surface areaFull filtration performance after cleaning process

Conical filter elements Minimal Dp curveOptimum EFQx

Slotted-tube filter elements Long service lifeOptimum filtration and cleaning properties

Pulse-aided cleaning Additional dynamic element cleaningwith low loss of cleaning fluid

Adjustable controls Customer-specific for numerous applications

Flow-optimized filtration High flow characteristics in compact dimensions

Static sealing between Guaranteed high filtration qualitycontaminated and clean sides

Variable housing isometry Reduced costs due to space saving and simple installation

Numerous equipment options Customer specific for numerous applications

Ready to operate unit Simple installation and commissioning

ISO 9001 certification High quality & performance standards

7

Filter ElementsTypes and Micron Ratings

• Slotted tube (Wedge-Wire) 50 - 3000 µm

• SuperMeshTM 25 and 40 µm

Cou

rtes

y of

CM

A/F

lody

ne/H

ydra

dyne

▪ M

otio

n Con

trol

▪ H

ydra

ulic

▪ P

neum

atic

▪ E

lect

rica

l ▪ M

echa

nica

l ▪ (

800)

426

-548

0 ▪

ww

w.c

maf

h.co

m

© C

opyr

ight

200

3 H

YD

AC

TE

CH

NO

LOG

YC

OR

PO

RA

TIO

N -

Bro

chur

e -

Aut

o-Fi

lt R

F3 A

utom

atic

Sel

f-C

lean

ing

Filte

r#0

2080

115

/ 12

.03

HYDAC PROCESS FILTRATION2260 City Line Road • Bethlehem, PA 18017Phone (610) 266-0100 • Fax (610) 264-3540www.hydacusa.com • [email protected]

APPLICATIONS

WATER PLANTS:AutoFilt® RF3 installed as a 1st stagefilter for the removal of sand anddebris from underground water.Extended life is provided to thecartridge elements protecting reverseosmosis systems.

PROCESS WATER:AutoFilt® RF3 is used to remove solidcontamination from incoming riverand lake process water. Protection isprovided to critical plant operatingcomponents. As well, the AutoFilt®

RF3 can be used to filter dischargewater, thus reducing and/or eliminatingexcessive water company surcharges.

POWER PLANTS:AutoFilt® RF3 is used to remove scalefrom water protecting cooling generators.Filtration of the power plant sealingwater will increase the service life ofturbine shaft sliding-ring seals.

COOLING TOWERS:AutoFilt® RF3 is used to filter waterused in cooling towers to prevent theclogging of the condensers.

STEEL INDUSTRY:AutoFilt® RF3 is used to protectnozzles and pumps during the highpressure descaling process. Inaddition, protection is provided duringthe cooling process for blast furnacesand rolling mills.

PAPER INDUSTRY:AutoFilt® RF3 is used to protectnozzles from becoming clogged onpaper machines.

MACHINE TOOLS:AutoFilt® RF3 is used to filter coolinglubricants used on machine tools.

STEAM SUPPLY:AutoFilt® RF3 is used to remove pipingscale protecting the heat exchangers.

FOOD INDUSTRY:AutoFilt® RF3 is used to filter suppliedmunicipal water used in food processing.

CHEMICAL PLANTS:AutoFilt® RF3 is used to filter processwater used by chemical plants forcooling and production.

Cou

rtes

y of

CM

A/F

lody

ne/H

ydra

dyne

▪ M

otio

n Con

trol

▪ H

ydra

ulic

▪ P

neum

atic

▪ E

lect

rica

l ▪ M

echa

nica

l ▪ (

800)

426

-548

0 ▪

ww

w.c

maf

h.co

m