August 1979 - Digital Library/67531/metadc283402/m2/1/high... · Pictorial Display ... Flowchart...

Transcript of August 1979 - Digital Library/67531/metadc283402/m2/1/high... · Pictorial Display ... Flowchart...

Distribution Category:LMFBR-Safety (UC-79p)

ANL-79-72

DISCLAIMER

t, ~* . ir r" ..i 1.ri r ., ,.,f1 Y t t r t .n l- y "!t U iI S r5 rv n IK t

'r. r ., ., ,.ia" ,y.+~~~, rr d ' xl.,.r rjfw frA n f h~ fM~r t '". rO- n

:,,' ' s~ f f~ur r d l .. ,. rt Ir; rrr'nfi^Sr'i~t r q tw It Lmtdr

1,,"rhr. ,r.i. 'f~,l A cii C'Iit Ar ,d'r'. ~r~rd ) )r j~j ,(1Iv Ur4 1,

ARGONNE NATIONAL LABORATORY9700 South Cass AvenueArgonne, Illinois 60439

ALICE: A HYBRID LAGRANGIAN-EULERIAN CODE FORCALCULATING FLUID-STRUCTURE INTERACTION TRANSIENTS

IN FAST-REACTOR CONTAINMENT

by

Han Y. Chu

Reactor Analysis and Safety Division

August 1979

3

TABLE OF CONTENTS

Page

ABSTRACT........................................ 7

I. INTRODUCTION................................... .7

II. METHODOLOGY ......................................... 9

A. Mathematical Formulations for Fluids . . . . . . . . . . . . . . . . 9

1. First Phase: Explicit Lagrangian Calculation . . . . . . . . . 11

2. Second Phase: Implicit Calculation . . . . . . . . . . . . . . . . 123. Second Phase: Pressure-work Calculation . . . . . . . . . . . 13

4. Third Phase: Rezone Calculation . . . . . . . . . . . . . . . . . 14

B. Mathematical Formulations for Solids and Shell Structures. . . 16

1. Quadrilateral Continuum Solid . . .. . . .. .. . ... . . . . .162. Shell Element . . . . . . . . .. . . .. . .. . . . . . . . . . .... 19

C. Equation of State of the Media . . . .. . . . . . . . . . . . . . . . . . 20

D. Fluid-Structure Interaction. . . . . . . . . . . . . . . . . . . . . . . . 21

E. Initial ant Boundary Conditions . . .. . . . . . . .. . . . . . . . . . 24

F. Stability............................................. 24

G. Marker Particles . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . 25

III. COMPUTER PROGRAM . . . . . . .. . . . . . . . . . .. . ... .. . .. 28

A. Input Information . . . . . . . . . . . . . . . . . ... . . . . . . . . . . . 28

B. Output Information . . . ... .. . . . . . .. . . . . ... . . ... .. 42

1. Standard Printout . . . . . ... . .. . . ... . . . ... . . .... 422. Optional Output... ...... . . .. .................. 423. Pictorial Display ...... ............................ 434. Calcomp Display . ..... .. . ... .... .. . . . . .. .. . .. 43

C. Limitation.............. ..................... 43

IV. SAMPLE PROBLEMS ........................... ....... 44

A. Shock-tube Test ................................... 44

B. The SNR-300 Test. . . . . . . .......... . . . . . . . . . . 46

C. The SRIlFlexible-vessel Test....................... 49

V. SUMMARYAND CONCLUSIONS .......... . .............. 55

4

TABLE OF CONTENTS

Page

ACKNOWLEDGMENTS ....................................... 56

REFERENCES...................................... .56

5

LIST OF FIGURES

No. Title Page

1. A Typical Cell and Suffix System . . . . .. . . . . . . . . . . .. . . .. . 10

2. Notation Used for Finite-difference Approximation.. .... .... . 11

3. Numbering Scheme for Calculating Internal Nodal Forces . . . . . . 17

4. Axisymmetric Shell Element . . . . . . .. . . . . . . . . . . . . . . . . . 19

5. Nodal Points at Fluid-Structure Interface . . . . . . . . . . . . . . . . . 21

6. Fluid-Structure Coupling Calculation. . . . . . . . . . . . . . . . . . .. 22

7. Fluid Flow at a Sharp Corner . . . . . . . . . . . . . . . . . . . . . . . . . 23

8. Relationship between Computational Cells in rz Plane and

9 Plane.. . . . .. . . . .. . . . . ..... . . . ................. 26

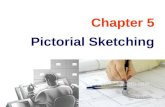

9. Flowchart for ALICE Code. . . . . . . . . . . . . . . . . . . . . . . . . . . 28

10. Component Numbers for Time-history Plot . . . . . . . . . . . . . . . 40

11. Schematic of Tube . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

12. Pressure Profile at 500 s, Lagrangian, No Artificial Viscosity. 45

13. Pressure Profile at 500 ps, Lagrangian, with ArtificialViscosities . . . . . . . . . . . . . . . . . . . . . . .. . . . . . . . . . . . . . 45

14. Pressure Profile at 500 ps, Eulerian, NoArtificial Viscosity . . . . 46

15. Vessel Configurations at Different Times . . . . . . . . . . . . . . . . . 47

16. Permanent Vessel Deformation. . . . . . . . . . . . . . . . . . . . . . . . 48

17. Test Model of SRI Flexible-vessel Experiment with Rigid CoreBarrel........................................- 49

18. Mathematical Model Used for ALICE Analysis..... ....... . . . . 50

19. Final Deformation Shape of Flexible Vessel in Test FV101 . . . . . 51

20. Final Deformation Shape of Flexible Vessel in Test FV102 .. . 51

21. Pressure Histories at Station 4 for Test FV102. .... .. .....- 51

22. Pressure Histories at Station 6 for Test FV102.......-....-... 52

23. Pressure Histories at Station 7 for Test FV102.......... 52

24. Pressure Histories at Station 8 for Test FV102...-...-..... . . 53

25. Pressure Histories at Station 9 for Test FV102. ....... .... 53

26. Impulse at Station 4 for Test FV102- . . . . . . . . . . . . . . . . . . . . 53

27. Impulse at Station 6 for Test FV10Z . . . . . . . . . . . . . . . . . . . 54

6

LIST OF FIGURES

No. Title Page

28. Impulse at Station 7 for Test FVl102........................ 54

29. Impulse at Station 8 for Test FVl102........................ 54

30. Impulse at Station 9 for Test FVI02........................ 54

31. Ves-el Configurations at Different Times for Test FV102 ......... 55

7

ALICE: A HYBRID LAGRANGIAN-EULERIAN CODE FORCALCULATING FLUID-STRUCTURE INTERACTION TRANSIENTS

IN FAST-REACTOR CONTAINMENT

by

Han Y. Chu

ABSTRACT

This report describes a reactor-containment code,

ALICE, which uses an arbitrary Lagrangian-Eulerian method

to describe the coolant motion, together with a Lagrangianmethod to analyze the response of the containment vessel andother solid media inside a reactor containment. The finite-difference formulation used to approximate the governing equa-tions for the motion of the coolant can be solved in either anexplicit or an implicit scheme; the finite-element formulation

used to approximate the governing equations for the containmentvessel and other solid media can be performed only in the ex-plicit scheme. Thus, the ALICE code can perform two types

of coupling calculations for the fluid and structure (implicit-explicit and explicit-explicit). The code is generalized so thatit can apply to problems either in a two-dimensional Cartesianor in a two-dimensional cylindrical-coordinate system. Thearbitrary Lagrangian-Eulerian method used for the fluid allowsthe vertices of the computing mesh to move with the coolant, asin the standard Lagrangian fashion; to remain stationary, as in

the standard Eulerian manner; or to move in a prescribed way,for example, to coincide with the movement of the adjacent struc-tures or to minimize excessive mesh distortions. Marker par-ticles are used to aid inflowvisualization and to define the freesurface or interfaces between two different materials. Severalexamples, comparing theoretical and experimental results, aregiven to illustrate the application of the code for reactor-containment analysis during a hypothetical core-disruptiveaccident.

I. INTRODUCTION

The advancement of digital computers made it possible to use numericalmethods for solving the fluid-structure interaction problems in a reactor con-tainment in a high nonlinear environment. Since the introduction ofithe REXCO codein 1969,' a number of containment codes have been developed and reported intheliterature. However, all these codes use either the Lag rangian2-s or the Eulerianmethod6- for describing the coolant motion and the Lagrangian method for analy.-ing the containment vessel and other solid media inside the containment.

8

In the Lagrangian approach, the mesh for computing fluid motionmoves with the fluid. Difficulties arise when the physical situation involves

a slip surface or severe distortions of the original mesh at later stages ofcalculations. In the Eulerian approach, on the other hand, the mesh for com-

puting fluid motion is fixed in space. Although such a mesh is ideal for treating

excessive fluid distortions, difficulties also arise when the physical situationinvolves material interfaces and moving boundaries. In a reactor containment,

the containment vessel, cover head, and internal structures are not rigidlyfixed in space. As they deform under the applied presure loads, their bound-

aries intersect the Eulerian grid lines to create irregular cells. Calculations

for these irregular cells are cumbersome. Furthermore, if the structures

move far away from their original positions, the calculations of these coupling

boundary conditions may become unrealistic.

This report describes a reactor containment code, ALICE (Arbitrary

Lagrangian-Eulerian Implicit-Explicit Containment Excursion code), whichuses the hybrid Lagrangian-Eulerian mesh for treatment of the coolant motionsto minimize the disadvantages for both the Lagrangian and the Eulerian

methods. The technique is based upon the ALE-ICE method developed by

Hirt et al. 9-" In the ALICE code, the grid for computing fluid motions is ahybrid of Lagrangian and Eulerian discretizations. Thus, the vertices of thecomputing grid can be moved with the fluid in a normal Lagrangian fashion,held fixed in space in a normal Eulerian manner, or moved in a prescribedway, for example, to correspond to the movement of the structure or to give

an optimum rezoning capability. Therefore, excessive mesh distortions can

be handled rather easily by using an optimum computing grid in the regionwhere the fluid is expected to move extensively. The computational proceduresat the fluid-structure interfaces can be greatly simplified by allowing the fluidcomputing mesh to move together with the structural boundary.

The hybrid Lagrangian-Eulerian method includes other advantages:(1) The mesh can be made in any arbitrary quadrilateral shape with differentaspect ratios to simulate narrow opening gaps or perforated-plate passageways,and (2) a better solution can be obtained as the pressure, density, and velocitycomponents in each computing cell are simultaneously adjusted during eachite ration.

The treatment for the containment vessel and other solid media insidethe containment uses a Lagrangian approach. Nonlinearities in materialproperties are approximated by multilinear segments to simulate the stress-strain relationships. A Von Mise criterion is used for the plastic calculations.Since the equations of motion for the structures are integrated explicitly intime, several time steps are usually needed to perform the structural analysisin order to match one time step for the fluid calculation for the implicit-explicitfluid-structure coupling problems.

The methodology used in the ALICE code is briefly described in Sec. II.Section IlI gives the flow chart and input and output information of the computer pro-gram. Section IV presents several examples illustrating the application of the code,together with comparisons of code predictions and existing experimental results.

9

II. METHODOLOGY

A. Mathematical Formulations for Fluids

The basic differential equations for solving fluid transient1 2 are

bop + bj(puj) = 0, (1)

bo(pui) + bj(puiuj -Pij) = pgi, (Z)

and

o(pE) + bj(pEuj -Pijui - p ajI) = pgjuj, (3)

in which bo and bj represent partial differentiation with respect to time and

coordinate, respectively, p the density, ui the velocity, gi the gravity accel-

eration, and p.the viscous coefficient. The specific total energy, E, is rep-

resented by E = {ujuj + I, where I is the specific internal energy. The heat-

conduction term is altered by the gradient of the specific internal energy with

a coefficient 0. The stress tensor Pij is expressed as

Pij = -p ij +tXekk6ij + .eij, (4)

where p is the scalar pressure prescribed by the density p and specific in-

ternal energy I, 6ij is the Kronecker delta, and

eij = ?jui + biuj. (5)

A" present, both viscosity coefficients, \ and p, have been chosen as constants

in the ALICE code.

Equations 1-3 are basic conservation equations of mass, momentum,

and energy. For the finite-difference approximations, it is convenient to in-

tegrate these equations over a volume element, V. Denoting the surface of Vby S and the outward normal of S by n, these equations become

fbop dV + p (uj - Uj)nj dS = 0, (6)V S

4 o(pui)dV' + [pui(uj - Uj) - Pij]nj dS' = gip dV', (7)5S,

and

I b0(pE)dV +f [pE(u1 - Uj) - Piju - pBbjI]nj dS =f pujgj dV, ()V S V

10

where Uj is the velocity of the bounding surface S. When Uj = uj, the equa-

tions are Lagrangian; when Uj = 0, the equations are Eulerian; and when

Uj / 0 and Uj $ uj, the equations are arbitrary Lagrangian-Eulerian.

To implement a finite-difference representation of the fluid flow, the

physical system is discretized into a number of quadrilateral cells. The ver-tices of these cells are designated by a pair of integers (i, j) with i counting

from left to right and j from bottom to top

(as shown in Fig. 1). Fluid variables p, p,

VERTEX VERTEX E, I, V, and M are assigned to the cell cen-

(1, 0 01',J \0ter (i + j + ); coordinates (x, y) and ve-"n''v locity components (u, v) are assigned at the

vertices. Finite -difference formulations arep, p, E.,I,V, M

(I/j/ outlined for both two-dimensional Cartesianand cylindrical-coordinate systems.

VERTEX VERTEX There are three phases of separated(I ) "+I'') calculations. In the first phase, an explicit

Lagrangian calculation is performed, in

which velocities are obtained from the pres-

Fig. 1. A Typical Cell and Suffix System sure gradients, body force, and viscouspressures. In the second phase, a Newton-

Raphson iteration method is used to obtain the advanced-time pressures im-

plicitly. Thus, the Courant stability criterion, which limits the pressure wave

to propagate over one cell size per time step, is eliminated. In the thirdphase, the mesh vertices are moved in a prescribed manner to coincide with

the structural movement, to avoid complex computational procedures for the

calculation of the irregular cells, or to maintain an optimum mesh, to elimi-nate excessive mesh distortions.

To improve the computational efficiency, several variables often used

in the computation are calculated and stored in the computer memory. Thesevariables include cell pressure, cell volume, cell total energy, and the masses

at the cell center and vertices. The finite-difference equations for computing

these variable- are

pi+(1/z),j+(1/) = f(Pi+(u/z),j+(i/z)' Ii+(1/z),j+(tz)), (9)

Vi+(1/2=),j+(1/) ) [(r1 + r2 + r3)A 1 + (r1 + r3 + r4)A 2], (10)

Ei+(1/z),j+(1/z) 'i+(1/z),j+(1/z) + (uf + ui + u + u4 + vf + vj + V3 + v4),

(11)

Mi+{(1),j+(1/Z) (p+(1/Z),j+(1/2)1+(2/)),j+(1/Z2),t12)

11

and

Mi, = 4Mi+(/z),j+(l/) + Mi+(j/z),j.(1/2) + Mi-C1/z),j- (1/2) + Mi-(/z),j+(1/z)

(13)

where r1 = xtfor cylindrical coordinates and rt = 1 for Cartesian coordinates,t = 1, 2, 3, or 4, and A1 and A2 are areas of the two triangles to form the

quadrilateral cell A (as shown in Fig. 2).

2S

3 A

A\4

c \

\ / /\ /

Fig. 2

Notation Used for Finite-difference A pproximation

1. First Phase: Explicit Lag:angian Calculation

In this phase, velocities and energy are calculated in severalsteps. The first itep counts the changes of those velocities and energy at thevertices caused by the gravational forces

ui,j = uI'J + gx 6 t,

vi,j = v + gybt,

(14)

(15)

dioj = [(gxun)ij + (gyvn)ij]8t, (16)

where the tildes over the quantities signify temporary new values, and the su-perscript n denotes the values at previous cycle.

The second step calculates the velocity changes due to pressuregradient and viscous stresses acting on the four surfaces of the momentumcontrol volume surrounding that vertex. As the calculation proceeds fromcell to cell, each vertex undergoes a sequence of adjustments caused by itsfour adjacent cells. For instance, in response to cell A, the expressions forthe velocity adjustment at vertex 4 (see Fig. 2) are

and

12

U4= i4 + WJjj(ri + r3)trxx(y3 - y:) + rXy(x1 - x3 )

+ r4 (y 1 - y3)p - krre[(xi - x3)(y2 - y4) + (x2 - x 4 )(y3 - y1)]} (17)

and

V4 = v 4 + jM-{z (ri + r3)[rry(y3 - y) + (nyy - p)(x1 - x3)]}, (18)

where pressure p and the components of the viscous stress tensor n ,nxy,ryy, and tre are evaluated in cell A. Details of these expressions are given

in Ref. 10.

The energy change at the vertex is calculated in the same fashion.Thus, the change of energy at the vertex 4 caused by the cell A is

Q4 = Q4 + Mt(r+ r3) {(ui + u3)[nxy(x1 - x3) - Trxr(yi - y3 )]

+ (v1 + v3)[n iy(y3 - y1 ) - nyy(x3 - xi)]}. (19)

Since the energy at each vertex is equally distributed to its fouradjacent cells, the change of energy in a cell is

Ti+(l/Z),j+(1/Z) = E(1/z), j+(1/) + (C3 + z + Q3 + Q4). (20)

The energy changes due to pressure works are calculated after implicit cal-

culation to permit the advanced-time pressures to be used in consistency withthe velocity changes.

2. Second Phase: Implicit Calculation

The basic task of the calculation in this phase is to eliminate the

Courant stability and to improve the application of the method to fluid flow

problems at all speed ranges. When an explicit solution is desired, this stepcan be omitted.

In summary, the procedures for calculating this phase are:

a. Calculate the discrepancy of th..nass equation for each cell,

S =A (PL - Pn) + PLT, (21)

where T. is the divergence of the velocity field,

13

T = iv(ra + rz)[(u& + ui)(yz - Y1) + (v + v4 )(xi - XZ)]

+ (rz + r3 )[(uF + uL)(Y3 - Yz) + (v2 + v3)(xZ - X3)]

+ (r3 + r4)1(u3L + u)(y4 - y3) + (v3 + v&)(x3 - x4j

+ (r4 + ri)[(ut + uL)(y1 - y4) + (vt + vfr)(x4 - xi)]}. (22)

Here, the superscript L identifies the quantities to be updated during each

iteration.

b. Calculate function F,

F = 1 1 (23)

t+ T +26t--+--

where c is the adiabatic sound speed of the fluid, and 6r and 8z are the aver-

age sizes of the computational cell in the radial and axial directions,

respectively,

6r = (x1 + x2 - x3 - x4 ) (24)

and

Sz = t(yz + y3 - Y4 - yi). (25)

Since the computational cells are in arbitrary quadrilateral shapes, the func-

tion F can be considered only as an approximation of bS/bp.

c. Calculate the pressure change,

6p = -wFS, (26)

where w is a relaxation factor. At present, a straight relaxation factor w = 1

is used in the ALICE analysis. The calculated pressure change is then addedto the pressure field. Velocities and densities are also adjusted according tuthe pressure changes.

Repeat steps a-c, until 8p in every cell satisfies 6p < eIPmaxl-At this stage, the iteration is considered to be sufficiently converged. Typi-cally, the value of e is 104.

3. Second Phase: Pressure-work Calculation

The pressure work is calculated by the pressures after iterationto coincide with the new velocities adjusted by the iterated pressures. The

14

energy change due to pressure work in a typical cell A (see Fig. 2) is

EA = EA + 4M Apiz(rl + rz)[(i1 + iz)(y 1 - yz) + (v 1 + iYz)(x2 - x1)]

+ p23(r2 + r,)[(i2 + i3)(yL - y3) + (2 + V3 )(x3 - x)]

+ p34 (r3 + r4)[( 3 +4)(y 3 - y4) + (V3 + i 4 )(x 4 - x3)I

+ p4 1(r4 + ri)[(i4 + i1)(y4 - y1) + (v4 + "1)(x 1 - x4)1} , (27)

where PiZ, P23. P34, and P41 are the boundary pressures weighted by the massesbetween two adjacent cells. For example, the boundary pressure betweencells A and B is

MBPA + MAPBP34 = MA+B (28)

= MA +MB

4. Third Phase: Rezone Calculation

If at this point of calculation, the mesh vertices are moved alongwith the fluid, then the results are Lagrangian. The Lagrangian solutions are

not accurate after severe zone distortions. To maintain an optimum computing

mesh, this pnase provides a continuous rezone calculation to permit vertices

of the mesh to move relative to the fluid. Convective fluxes due to these rela-tive motions are calculated to ensure the conservation of mass, momentum,and energy.

For the fluid-structure interaction problems, the best choice of

the mesh movement is to allow the vertices of the fluid cells adjacent to the

structures to move with the structures. Thus, moving boundary conditions canalways be accurately interpolated from the structures to the fluid zones.

To count those convective terms due to relative motions between

the computing mesh and fluid, the vertices are first moved to their newpositions,

x9t = xi9 + uP.t (29)

and

n+1 n GYi,j = Yi,j + vi,j t,(30)

where the superscript G on a velocity field denotes the prescribed mesh ve-

locity, and rnt' for each vertex is changed accordingly. The new volumes are1d 3

calculated based on these new vertices.

15

As shown in Fig. 2, for example, the relative motion of vertices 3and 4 to their right sweeps out of cell A and adds a small volume to cell B.

This small volume is

6t(r4 + r3)[G G L LV= 1( 4+ u3 - u4 - )(y4 - Y3)

+ (V4 + v? - v4 - v3)(x 3 - x4)]. (31)

Therefore, the mass subtracted from cell A and added to cell B is

6M = i(6V + +MA (6V - a l)MB, (32)VA VB

where a is a donor-cell weighting factor.

The change of energy is handled in the same way as

6(ME) = (6V + a1 VI) MAEA + {(6V - MBE VBI) B. (33)VA VB

Similar calculations are used on the other three sides of a cell. Changes of

mass and energy for a cell are accomplished after four sides of a cell are allcalculated.

The control volumes used for momentum calculation are differentfrom those for mass and energy calculations. The change of momentum for atypical vertex 4 is affected by its four surrounding surfaces. (See dashed

lines 31, 36, 68 and 81 in Fig. 2.) The movement of vertices 3 and 1 to the

right sweeps out the momentum volume of vertex 2 and adds a small volumeto the momentum volume of vertex 4. This small volume is expressed as

6t(r1 + r3)rG G L )L6V = 4 I(u1 + uG - u1 - u3 )(Y3 - Yi)

+ (vG vG - v[ - vF)(x, - x3)]. (34)

Thus, the momentum subtracted from the momentum volume of vertex 2 andadded to the momentum volume of vertex 4 is

SMA

6(Mu) =2 VA [(6V - Of 16V|)u4 + (6V + a 16V I)ul. (35)

The v momentum is computed in the same way, with v replacingu in the above equation.

16

After all the mass, energy, and momentum changes among all thecells and vertices have been calculated, the cell masses and energies are con-verted to densities and specific total energies, and vertex momenta are con-verted to velocities.

B. Mathematical Formulations for Solids and Sheli Structures

The Lagrangian approach is used in the analysis of the containmentvessel and of other solid media inside the reactor containment due to the

strong nature of the solid. The shell structure uses a finite-element method

as given in Refs. 13 and 14; the solid media use a finite-difference method as

given in Ref. 2. To facilitate the treatment of boundary conditions and the ar-bitrary combination of the solid media, the fluid, and the shell structures, theequations of motion used in the finite-difference calculation for the solid mediaare formulated through the use of intermediate noda! forces. Thus, the equa-

tions of motion for both solid and shell elements can be written as

M p = Fext .Fint, (36)

where M is the generalized mass matrix, u the generalized displacements,

Fext the generalized discretized external forces, and Fint the generalized dis-

cretized internal forces. The dots over a quantity denote time derivatives ofthat quantity. Nonlinearities in material properties are approximated by amultilinear stress-strain relationship. The equations of motion are integrated

explicitly in time using a central-difference approach. Thus, velocities and

displacements in the global coordinates are determined by the equations

C(t + At) = C(t) + lAt[(t) + i(t + At)] (37)

and

u(t + At) = u(t) + At(t) + }AtZL(t). (38)

At present, two types of elements (quadrilateral toroidal continuum

solid and conical shell element) are included in the ALICE analysis. They arebriefly described below.

1. Quadrilateral Continuum Solid

The continuum-solid material is represented by a quadrilateralelement with the same notations as used for the fluid cells. The mass of eachelement is assumed to be equally distributed to its four vertices. Therefore,the mass for a typical nodal point 4 (see Fig. 2) is

M4 = (MA + MB + MC + MD). (39)

17

The external forces are the fluid-pressure forces. The internal

forces at the vertices of a typical element (shown in Fig. 3) are

(fi)r = i[(Srr - p)(zz - z4) + Trz(r4 - rz)]ri - *(Srr - See)A, (40)

(fz)r = i[(Srr - p)(z3 - z1 ) + Trrz(ri - r3 )]rz - t(Srr - 56 9 )A, (41)

(f3)r = [(Srr - p)(z4 - zz) + T rz(rz - r4)]r3 - (Srr - S 6 6 )A, (42)

(f4)r = U[(Srr - p)(z 1 - z3 ) + Trz(r3 - r1 )]r4 -;(Srr - See)A, (43)

(fi ),= -i[(Szz - p)(rz - r4 ) + T rz(z4 - zz)]ri - : T rzA, (44)

(fz)z = -i[(Szz - p)fr3 - r1 ) + T rz(zi - z3 )]rz - 4t rzA, (45)

(f 3 )7 = - 1 [(Szz - p)(r4 - rz) + Trz(zz - z4)]r 3 - P rzA, (46)

and

(f4)z = -i[(Szz - p)(r1 - r3 ) + Trz(z3 - zl)]r 4 - tTrzA, (47)

where Srr, See, and Szz are the deviatoric components of the radial, circum-ferential, and axial stresses, respectively; Trz is the shearing stress; p isthe pressure; r and z are the coordi'iates in the radial and axial directions,

respectively; A is the area; and the subscripts r and z denote the internalnodal forces in the radial and axial directions, respectively.

3 2

CONTINUUM Fig. 3SOLID Numbering Scheme for Calcu-

MATERIAL lating Internal Nodal Forces

41

To calculate the stress for each element, the strain rates are

computed first. Strain rates are obtained by performing line integration alongthe counter 1 2 3 4 as shown in Fig. 3. They can be written as

err = - Zr4)(Z - z) - ( - (Z- Z4)], (48)

= -- [(ti - t4)(r3 - r) - (i 3 - i1)(r, - r4)], (49)dzz ZA

18

LV6 V (err f ezz),

(50)

and

a rid

erz 2A ilez- r4)(r 1 - r3 ) - (rt - rt)(rz - r4 ) 4 - )(zz - z4 )

- (rzz - /4)(z1 - z3)j. X51 )

The incremental strains, Aerr, Aezz,, Le, and Cerz, can be ob-

tained by the strain rates times the time increment. The deviatoric stressescalculated from the incremental strains are

Sn+1 n n+i/z) I LVr+(i')Srr= Srr + 2 A(Lerrf 3 Vn+qi/z>) (52)

sn+1 Sn + FLe j)n 4(1/2) 1 LVn+ (lIz)1(3[ lCVn +(/

Sn =z + 4 {(Aezz)n+(1/z) - - , (54)69 FAH 6d3 yn+(1/z>)

Tn+1 -n + (ter)n+(I/z)rz rz rz,

(55)

where tV is the incremental volume.

The invariant Jz,

2J1 = r(Sr) + z ) + kee ) + 2 jrz) ,(56)

is used for determining whether the stresses are in the elastic or plastic re-

gion. If ZJ 1 S z, the deviatoric stresses as calculated above are used

to compute the internal nodal forces; if 2J'> 4(anz, the deviatoric stresses1/2

computed above must be adjusted by a factor of (2/3)1/zSn/(Jo/ +) to calcu-

late the internal nodal forces, where an is a stress function obtained from theplastic stress-strain relationships.

The internal energy of the element is calculated from

In+1 = In .- j(pn + pn+)AVn+(1/) + Vn+(1/)(SrrAerr + SzzAezz

+ Segegee + TrzAerz). (57)

19

Since the mass in a Lagrangian element is constant, the density

is inversely proportional to the volume. After the advanced-time density and

internal energy have been obtained for an element, the pressure in this ele-

ment is given by the equation of state. De-

A tails of these calculations are in Ref. 2.

YB

2. Shell Element

The conical shell element (seeFig. 4) in the ALICE code uses a corotational

coordinate system. Rotation of the corota-

tional coordinate associated with an elementA

Y_ _ _ _is represented by the rotation of the line con-necting two nodal points of the element. The

corotational coordinate rotates, but does notFag. 4. AxisymmTnic shell element deform with the element. The masses at each

nodal point are determined in such a way that

the translational and rotational inertias are equivalent to the mass and mass

moment, respectively, of the segment between the nodal point and the midpoint

of the element.

The discretized external forces are those forces given by the

fluids or other adjacent elements. A shell element can be subjected to the

loadings on one side of the element or on both sides of the element, depending

upon the location of the element.

In the corotational coordinates (x and y) of an element, the strain-

displacement equations are

x m- y (58)Ox

and

1 adye = - dr - y cos a-,(59)

where S is the angle of inclination, dr and dy are the global displacements inthe radial and axial directions, respectively, and

5udefx

A ax

is the midplane strain. A cubic polynomial shape function in x is used for thetransverse displacement field. Therefore, the rotation in the corotationalcoordinate can be expressed as

4I) = 9 (tZ - 4CA + 3x1) z( 3 Z - 2 x),tz tC

in which Ci = i - a, the subscript i equals 1 or 2, and

rotation.

The stresses in the corotational coordinate

multilinear stress -strain relationships. The equationsforces are

1

'C-

V

(6x

(6c

- 4t)yl

a is the rigid-body

are obtained from thefor the internal nodal

- 2t)yl&x dV. (61)

The other internal nodalequilibrium equations

forces are obtained by invoking the self-

fy = -fxy = (m + my\ Z /

and

f 1 = -xfP

(62)

(63)

These nodal forces are then transformed to the global coordinatesfor calculating the generalized internal forces. Details of the derivation are

given in Ref. 13.

C. Equation of State of the Media

As described for the fluids and the elastic-plastic material, an equa-

tion of state that relates the pressure to the other variables is needed for thesolution of the conservation equations. At present, the ALICE code has thefollowing types of equation of state to simulate different material in a contain-ment system.

1. Murnaghan:

BO P Ba-B [ B ,(64)

Bb [po

where Bo and B6 are the bulk modulus and its derivative of the material.

20

(60)

21

2. Ideal gas:

p = ao(p - P o) + (fl - l)pI, (65)

where ao is the sonic speed at standard condition and T1 is the isentropicexponent.

3. Pressure as a function of the volume ratio V/Vo:

p = f -- . (66)

4. Pressure as a function of time:

p = f(t). (67)

D. Fluid-Structure Interaction

As mentioned earlier, the fluid uses an arbitrary Lagrangian-Eulerian

mesh with the options to choose explicit or implicit time integration; thestructure uses a Lagrangian mesh with only explicit time integration. Thus,the ALICE code can perform two types of coupling calculations, explicit-explicit and implicit-explicit, for the fluid and structural interactions. Thecoupling calculations are implemented in two separate steps. The fluid sup-plies the structure with a pressure loading, which causes the motion of thestructure. In return, the structure gives the fluid a moving boundary condi-tion at the fluid-structure interface. The best choice of the mesh movementfor a fluid-structure-interaction problem is that the vertices of the fluid cellsadjacent to the structures move with the structures. Thus, the movement of

the structures relative to the fixed space will not5' s create any additional irregular cells, and the com-

putational procedure is greatly simplified. Details-4' 4 of this type of calculation are described below.

FLUIDFI 3 3 STRUCTURE The node structure at a fluid-structure inter-

face is shown in Fig. 5. At each nodal point of a

2' 2 structural segment, there is a correspondirg fluidnodal point. Each node has a set of different veloc-

p. ities. In the structural calculations, the structuralvelocities at the n + 1 time cycle are computed from

Fig. 5. Nodal Points at Fluid- the fluid pressures at the end of n time cycles. Thestructure Interface computed structural velocities are then used as the

moving boundary conditions for the fluid at the fluid-structural interfaces. The boundary conditions require that the fluid at thefluid-structure interfaces can slide freely along the structural surfaces, butmust move together with the structure in the normal direction. Thus, to sat-isfy this boundary condition imposed by the structure, the fluid velocities

22

calculated after phase 1 and after each iteration cycle in phase 2 must be

modified. This adjustment of the fluid velocities is outlined below.

Figure 6 shows the structural segments with nodal points 1, 2, and 3

located on the right side of the fluid cells A and B with corresponding fluid

nodes 1', 2', and 3'. We assume that the direction normal at point 2 is deter-

mined by the line connecting points 1 and 3. Then the unit normal and unittangent at point 2 are

(68)n = i sin ) - j cos C)

and

t = i cos Q + j sin 0,

respectively, where

(69)

.. 1 x3 - x1

S =Cos~ r,

(X3r- xI) 2 + (y, - yx -)]

and i and j are the unit vectors in the xspectively. Thus, the structural velocitybecomes

vn = u2 sin ( - vz cos (,

(70)

(or r) and y (or z) directions, re-at point 2 in the normal direction

(71)

in which uz and vz are the velocity c nponents of the structure at point 2 inthe x (or r) and y (or z) direc' ons, respectively.

3t 3''31

8 T

2 2 . ,Y21

FLUID i

A STRUCTURE

i1.,1Y

Fig. 6

Fluid-Structure Cou-pling Calculation

To satisfy the moving boundary conditions, the fluid-velocity compo-nents (u2 ', vt') must be adjusted after each fluid-velocity calculation. Theconditions that require the fluid-velocity components to be changed from uzi

and vz' to uj' and vi' are

u4' sin e - vi cos 6 = u sin 8 - vt cos 6 (72)

23

and

ul cos 6 + vI' sin 6 = uz' cos a + v2 ' sin a.

Solving the above equations simultaneously, we have

up = u 2 sin2 6 - v2 sin e cos 0 u1 cos2 6 + v2 ' sin A cos 6

and

VI = -uz sin 6 cos e + vz cos? e + uz' sin 0 cos 0 + v2' s z 6.

(73)

(74)

(75)

Since the vertices of the fluid cell adjacent to the structure have been

moved with different velocities from the structural nodal points, a rezone cal-

culation is required in the third phase to count the convective terms due to

the relative motion between the fluid and the com-

puting mesh as the fluid vertices move back to co-incidewith the structural nodal points.

8

A

rCThe treatment of the fluid flow passing

around a sharp corner of a structure imposessome problems for the ALICE analysis. The rea-son for this is that, in the ALICE analysis, thevelocities are defined at the cell vertices. As can

be seen from Fig. 7, the fluid velocity at the cor-

ner of point 2 is discontinuous.Fig. 7. Fluid Flow at a

Sharp Corner To solve the fluid-flow problem at a sharp

corner, an assumption has been made in the ALICE

analysis for calculation of the fluid motion. For instance, to calculate thefluid velocity between cells A and B at the corner point, cell C is treated asif it were occupied by a structure; to calculate the fluid velocity betweencells B and C at the corner point, cell A is treated as if it were occupied bya structure. Thus, Eqs. 74 and 75 can be used for those velocity calculations,except that the angle along the structural surface 12 becomes

e = co-' I

s51 - - I

[ (xz - x1)2 + (yz - yi)2(76)

and the angle along the structural surface 23 becomes

ez = co-i[ - XZ

1 (x l- x212 + (Y3 . yz )Z

I

Xz - X1

(77)

24

These velocities are adjusted after the first-phase calculation and af-ter each iteration cycle in the second phase. In the third phase, the cell ver-tices for cells A, B, and C corresponding to the corner point are rezoned

back to the same corner point.

E. Initial and Boundary Conditions

Initial conditions are input by arrays of the p. ;cribed velocities,

densities, internal energies, and coordinates of the structural elements and

marker particles to represent the starting configuration of the fluid and therelative locations of the structural elements with respect to the fluid. Markerparticles are used to classify the computational cells as being in a fluid zone,a surface zone, or an empty zone.

Many kinds of boundary conditions are possible for the ALICE analy-sis. Most of the boundary conditions are achieved simply by adjusting the ve-

locities at the cell vertices. These adjustments must be done after the firstand third phases, and after each iteration cycle in the second-phase calcula-

tion. At a free surface, the requirement is that tangential and normal stressesmust vanish. Flip-slip boundary conditions passing a rigid obstacle are

treated the same as the fluid flow along a structure, except that the structuralvelocities are equal to zero. As a continuative outflow boundary, the outflowvelocities can be obtained in the same manner as the flow passing a sharp

corner.

F. Stability

As mentioned before, the ALICE code can perform both the implicit-

explicit and explicit-explicit fluid-structure coupling problems. For most

computational efficiency, the stability conditions are separately imposed onthe fluid and structural programs so that the fluid can use a larger time stepfor implicit-explicit coupling calculations. For the explicit-explicit coupling

calculations, the same time step for both fluid and structure calculations isusually used to avoid unstable computations.'15

For the fluid, there are two basic restrictions on the time-step size.One is related to the diffusion or diffusion-like terms; the other is related to

the convective-type terms.

If the viscosity terms are used in the first-phase calculation, the sta-

bility condition for the effusion terms is that the momentum cannot diffusemore than one cell width within each time step. This gives

(2 p )

8t (<2 + , (78)8r Z6z '

where 6r and 8z are approximated in the same manner as given in Eqs. 24and 25.

25

The stability condition for the convective terms is that the material

quantity is prohibited to be fluxed through more than one cell within one time

step. This gives

st < , (79)uR V- dS min

where V is the control volume for either the mass or momentum calculation,and uR is the relative velocity between the computing mesh and the fluid in thenormal direction of the surface dS.

For the continuum solid, the stability criterion is given by White, 16 that

is,

(1 + at)c At 6VW = x + 4az _ < 1, (80)

where at and aq are the linear and quadratic viscosity coefficients, respec-tively; c the speed of sound of the solid material; Ax the minimum distancebetween the mesh sides; AV the change of the specific volume; and V the spe-cific volume. Since the ALICE code uses the arbitrary quadrilateral cell, thevalue of Ax has been approximated by v/A, where A is the area of the cell. Ifboth at and aq vanish, this formulation has been automatically reduced to theCourant stability condition.

For the shell element, the time step is limited by the wave speeds and

the sizes of the elements

At < 1 and At < ,(81), 6 cb

where t is the distance between two nodes, and ct and cb are the longitudinaland flexural wave velocities, respectively, given by

S Ect = -

and (82)

z Ehzcb =12p

Here, E is the Young's modulus, p is the density, and h is the thickness ofthe shell.

G. Marker Particles

Marker particles in the ALICE code are used to define the free sur-faces and aid in visualization. They move with the local fluid velocities on

26

each time step. Since the ALICE code uses arbitrary quadrilateral cells, theusual linear-interpolation scheme cannot be directly applied. Thus, a coor-

dir, tte transformation from the rz plane to a unit-square it plane (see Fig. 8)must be executed to aid in determining the particle velocities.

2(r2 ,Z2 )

3(r3 ,Z 3) 3(0,1) 2(1,1)Fig. 8

I 1(r1 , Z 1) Relationship between Computationalz 4( r4 ,Z4) Cells in rz Plane and tg Plane

4(0,0) 1(1,0)

To transfer the coordinate system, the following auxiliary functionsare defined:

f( , T))= (1 - )rl + t9rz + (1 - )Tr3 + (1 - 5)(l - 9)r4 - r

and , (83)

h(g, V =(1 - TI)z1 + zz + (1 - ()pZ3 + (1 - g)(1 - lVZ4 - Zp

where r1 and z1 indicate the coordinates of vertex 1, and rp and zp denote the

coordinates of the marker particle p. If the correct values of p and 1p aresubstituted into Eqs. 83, the auxiliary functions f~p,'>p) and h(p, 'Typ) shouldvanish.

To find the values of tp and Tip in the {Ti plane, a Newton-type iterationscheme is used. Functions f(t, 11) and h(g, T) a-e first expanded into a Taylor'sseries at an estimated point (tp, 11p). Neglecting high-order terms, Eqs. 83become

f(tp, Sp) + 6t + 611 = 0

and (84)

h(Cps p) + 6-+ 61.j- = 0

Then the increments 6g and 61 which count the deviation from the estimated

point to the actual point can be obtained by

6t = D 1/D 1and (85)

81 = /DJ

27

where D is the Jacobian of the transformation b(f, h)/b(SA1), and D1 and D2

are

-f( p , op

D1cdh

-h( P) 11-6

and (86)

of Tp

D=

ah-h(Ep, T1P)

The previous-cycle values of p and Tp are usually used to start theiteration. At each iteration cycle, the increments 6 and 611 are added to (p

and 'p to form new estimated values of tp and rip. This process is repeated

until both 6E and 6T are smaller than e. Typically, c is 10- 4 . At that stage,

the iteration is considered to have converged. Experience shows that the con-

vergence occurs very rapidly, especially when the previous-cycle values ofp and tlp are used to start the iteration.

Having determined the tp and 1]p of the particle coordinates in the

g7 plane, we can obtain the local velocities of a marker particle as

up = 1(1 - ip);i + tplpuZ + (1 - tp)Tflpi3 + (1 - tp)(1 - Tp) 4. (87)

Thus, the new positions of the particle at time n + 1 are

rn+1 = rn + u 6t

and (88)

zn+1 = zn + vp 6t

The coordinate-transformation algorithm also offers a means for de-

termining the cell in which this particle is located. The converged values oftp and 'Tp must be in the range between 0 and 1. If, for example, p is greaterthan 1, this indicates that the particle has been moved to the cell on the rightside of line 12. Therefore, a correct cell number must be reassigned to re-

calculate the particle velocities.

28

III. COMPUTER PROGRAM

The computer program ALICE has been written in FORTRAN V language

and compiled on IBM 370-195 and IBM 3033 computers. Double precision isused for all the field variables of the fluid. In the structural program, singleprecision is used for all the field variables, except the one used for internalnodal forces. Dynamic allocation is applied on both the fluid and structuralprograms to save the core storage required for different applications. A

typical problem with 200 quadrilateral fluid cells, 1000 marker particles, and

20 structural elements requires approximately a 400 K core storage on theIBM 370-195 machine. The flowchart for the ALICE code is shown in Fig. 9.Input and output informations are described below.

START

REINPUT DATA

LAGRANGIAN? YES

NOC

REFL AG

FLUID CELLS

CALCULATE

CORE PRESSURE

ES CALCULATE

ST RUC TURE YS ST RUCTUR A LRESPONSE

COVR EAD YES...CALCULATEA

NO RESPONSE

EXPLICIT2LAGRANGIAN

CALCULATION

EXPLICIT ? YES

NO

IMPLICIT

CALCUL A TION

CALCUL ATE

PRESSURE WORK

LAGRANGI AN ? Y-

NO

REZONEC ALCUL A TION

CALCULATE

PARTICLES

CALCULATE

PRESSURE

NO+ . COMPLETE

YES

END

Fig. 9. Flowchart for ALICE Code

A. Input Information

The following types of cards are needed for the input of the program.They are listed in order.

29

Card FORTRANType Columns Format Name Description

1-80 (20A4) TITLE 80 characters of alphanumeric for problemidentification.

2 (1216)

1-6 IBAR Number of grid lines in the r (or x) direction.

7-12 JBAR Number of grid lines in the z (or y) direction.

13-18 KBAR Number of spaces reserved for marker

particles. KBAR 1.

3 (1216)

1-6 LOUT Parameter to determine restart capability andusage of auxiliary tapes.[OUT = 0: No auxiliary tape is needed.LOUT = 1: A binary tape 8 is required forwriting output data so that the problem may becontinued.

LOUT =2: Read input from a binary tape 9 forcontinuation of a previous problem.LOUT = 3: Program reads the input data froma binary tape 9 and writes the output data on abinary tape 8 for later continuation.

7-12 NCEND Stop cycle, the cycle number at which to termi-nate the run.

13-18 IPLOT Number of plot data to be written on a binarytape 1.

19-24 NPLOT Frequency of the cycle to write plot data on abinary tape 1.

25-30 IFILM Parameter to determine film plot.

IFILM = 0: No film plot.IFILM = 1: Film-plot data will be written on abinary tape 2.

31-36 NFILM Frequency of the cycle to write the film-plotdata on the binary tape 2.

37-42 NPRINT Frequency of the cycle to print out fluidvariables.

43-48 ICRDNT Parameter to determine coordinate system.ICRDNT = 0: 2-D cylindrical coordinatesystem.ICRDNT = 1: 2-D Cartesian coordinatesystem.

49-54 INDTIM Parameter to determine explicit or implicitintegration.

INDTIM = 0: ExplicitINDTIM = 1: Implicit.

55-60 IMESH Parameter to determine mesh movement.IMESH = 1: Lagrangian.IMESH = 2: Eulerian.IMESH a 3: Arbitrary Lagrangian-Eulerian.

61-66 IVISC Parameter to determine viscosity.IVISC = 0: Both viscosities A and uiareneglected in the calculation.IVISC s 1: A and u are entered intocalculation.

67-72 IVCTL Parameter to use restoring acceleration fromneighboring vertices.IVCTL = I: Using restoring acceleration.IVCTL a 0: No restoring acceleration.

CardType Columns

4

1-6

7-12

5

Format

(1216)

FORTRANName Description

NPRT1

NPRT2

(1216)

1-6

6 (16,E12.0)

1-6

7-18

Note: Use as many cards of Type 6 as

7 (121K)

1-6

7-12

13-18

NDE LT

NDTRn

DELTn

Parameter to print out iteration information insecond-phase calculation.NFRTI = 1: Print out iteration number forconvergence.NPRTI = 0: No printout.

Parameter to print out plot data.NPRT2= 1: Print out plot data.NPRT2 = 0: No printout.

Number of different integration time stepsused for the run.

Cycle number at which Ct will be changed.

Time-integration step, it, used for cycles

NDTRn- 1 o NDTRn.

required; total NDELT cards.

Specification of field variables to be written onplot tape 1, used only when IPLOT > 0.

IPLOTXn Cell or grid-line number in r (or x) directionfor IPLOTZn c 10; node number forIPLOTZn > 10

IPLOTYn Cell or grid-line number in y (or z) direction.

IPLOTZn Parameter to determine field variables for plot.IPLOTZn = 1: Pressure, in dynes/cm t .IPLOTZn = Z: Velocity in r (or x) direction,cm/s.

IPLOTZn = 3: Velocity in z (or y) direction,cm/s.IPLOTZn = 4: Density, in g/cm 3 .IPLOTZn = 5: Specific internal energy, indyne-cm.IPLOTZn = 6: Specific total energy, in dyne-cm.

IPLOTZn = 7: Mass, in grams.IPLOTZn = 8: Volume, in cm3 .IPLOTZn = 9: r (or x) coordinate, incentimeters.IPLOTZn = 10: z (or y) coordinate, incentimeters.

IPLOTZn = 11: Node velocity in r (or x)

direction, in cm/s.IPLOTZn = 12: Node velocity in a (or y)direction, cm/s.IPLOTZn = 13: Node displacement in r (or x)direction, in centimeters.IPLOTZn = 14: Node displacement in a (or y)direction, in centimeters.

Note: Use as many cards of Type 7 as required; total IPLOT cards.

8 (1216)

1-6 iSTURE

ICOVER7-12

Parameter to determine structure analysis.ISTURE = 0: No structural analysis.ISTURE = 1: Include structural analysis.

Parameter to determine cover-head analysis.ICOVER = 0: No cover-head analysis.ICOVER = 1: Include cover-head analysis.

30

31

Card FORTRANType Columns Format Name Description

8 (Contd.) (1216)

13-18 ISIDE Parameter to determine right-side boundary.ISIDE = 0: Rigid boundary.ISIDE = 1: Flexible boundary.

19-24 IBOTTM Parameter to determine bottom boundary.IBOTTM = 0: Rigid boundary.IBOTTM = 1: Flexible boundary.

25-30 ISOPEN Parameter to determine side opening at thehead-wall juncture.

ISOPEN 1: Side opening.ISOPEN = 0: No side opening.

31-36 ITOPEN Parameter to determine openings on coverhead.

ITOPEN = 1: Top openings on cover head.ITOPEN 0: No top opening.

37-42 - ICORE Parameter to determine core pressure.ICORE - I: Core pressure determined by

pvv_= C.ICORE = 2: Core pressure determined bypressure-volume table.ICORE 3: Core pressure determined bypressure-time table.

43-48 INDPS Parameter to determine negative pressure inthe equation of state.

INDPS = -1: Negative pressure is allowed inthe equation of state.

INDPS > 1: Negative pressure is not allowedin the equation of state (p > 0).

9 (1216)

1-6 NOBSTL Number of input sets to generate obstacles.

7-12 NMATL Number of different materials used for theanalysis.

13-18 NMAKR Number of input marker-particle sets to createmarker particles.

19-24 NCORE Number of gas cavities used for the analysis.There are usually two gas cavities in the con-tainment analysis. One is for the core region,and the other is for the inert-gas region.

25-30 NCOREA Number of particles used to define the volumeof the core region.

31-36 NCOREB Number of particles used to define the volumeof the inert-gas region.

37-42 NVFS Number of fluid-cell vertices not adjacent tostructure but moving with structural nodal points.

10 (1216)

1-6 NU Number of input sets to generate initial ve-locity in r (or x) direction.

7-12 NV Number of input sets to generate initial ve-locity in a (or y) direction.

13-18 N! Number of input sets to generate initial specificinternal energy.

19-24 NRHO Number of input sets to generate initial density.

25-30 NP Number of input sets to generate initialpressure.

32

Card FORTRANType Columns Format Name Description

10 (Contd.) (1216)

31-36 NM Number of input sets to identify material ineach cell.

11 (6E12.0)

1-12 ANC Alternative node-coupler coefficient.

13-24 OMEGA Iteration relaxation parameter.

25-36 ALPHAO First coefficient used in donor-cell form formass and energy calculation.

37-48 ALPHA1 First coefficient used in donor-cell form formomentum calculation.

49-60 BETAO Second coefficient used in donor-cell form formass and energy calculation.

61-72 BETA1 Second coefficient used in donor-cell form formomentum calculation.

12 (6E12.0)

1-12 GR Gravity component in r (or x) direction.

13-24 GZ Gravity component in z (or y) direction.

25-36 PINITA Initial pressure in the core region.

37-48 PINITB Initial pressure in the inert-nras region.

49-60 PVGAMA v for pv = c used in the core region.

61-72 PVGAMB v for pv = c used in the inert-gas region.

13 (6E12.0)

1-12 EPS Convergence criterion.

13-24 EPSC Small gap to count for slug impact calculation.

25-36 AQLG Quadratic artificial viscosity.

37-48 ALLG Linear artificial viscosity.

14 (I6,5E12.0)

1-6 MSn Parameter to determine the equation of stateto be used for the material.

MSn = 1: Murnaghan.

P= B(VB

Constants for this equation are supplied bycards of Type 15a.MSn = 2: Ideal gas.

p = a(o - po) + (1 - 1)pl

Constants for this equation are supplied by

cards of Type 15b.14 7-18 FLAMDAn 1, first viscosity coefficient, in dyne-s/cm'.

19-30 FMUn u, second viscosity coefficient, in dyne-s/cm.

31-42 RHOOn p 9, density at standard condition, in g/cm'.

15a (6E12.0) Constants for Murnaghan equation of state.

1-12 BMEn Bulk modulus of elasticity, in dynes/casn.

13-24 BMEPn Pressure derivative of bulk modulus ofelasticity.

Card FORTRANType Columns Format Name

15b (6E12.0)

1-12 AOn

13-24 GAMMAn

Note: There should be one set of cards of Type 14 andsets.

16 (1216)

1-6 NRIN

NZIN7-12

17

Description

Constants for idea' gas equation of state

Soni'. velocity, cm/s.

Isenrtropic exponent.

15a, or 14 and 15b, for each material; total NMATL

Number of sets of cards to generate uniformgrid in r (or x) direction.

Number of sets of cards to generate uniformgrid in z (or y) direction.

(216,2E12.0)

1-6

7-12

13-24

25-36

Note: Use as many cards of Type 17 as

18 (216,2E12.0)

1-6

7-12

13-24

25-36

Note: Use as many cards of Type 18 as

19 (1216)

1-6

13-18

19-24

25-30

Note: Use as many cards

20

1-6

7-12

of Type 19 as(416,E12.0)

13-18

NI Starting grid-line number for generating uni-form grids in r (or x) direction.

N2 Ending grid-line number for generating uni-form grids in r (or x) direction.

DRST r (or x) coordinate for the first uniform grid,in centimeters.

DRIN Space for generating uniform grids in r (or x)direction, in centimeters.

required; total NRIN cards.

Nl Starting grid-line number for generating uni-form grids in z (or y) direction.

N2 Ending grid-line number for generating uni-form grids in z (or y) direction.

DZST z (or y) coordinate for the first uniform grid,in centimeters.

DZIN Space for generating uniform grids in z (or y)direction, in centimeters.

required; total NZIN cards.

Identify material number in different zones.

11 Starting-cell number in r (or x) direction formaterial K.

12 Ending-cell number in r (or x) direction formaterial K.

J Starting-cell number in z (or y) direction formaterial K.

J2 Ending-cell number in z (or y) direction formaterial K.

K Material number.

required; total NM cards.

Initial velocity in r (or x) direction, u.

Ii Starting-grid number in r (or x) direction forinput u.

I2 Ending-grid number in r (or x) direction for'input u.

J1 Starting-grid number in a (or y) direction forinput u.

33

34

Card FORTRANType Columns Format Name Description

20 (Contd.) 19-24 J2 Ending-grid number in z (or y) direction forinput u.

25-36 URSV Velocity u, in cm/s.

Note: Use as many cards of Type 20 as required; total NU cards.

21 (416,E12.0) Initial velocity in z (or y) direction, v.

1-6 11 Starting-grid number in r (or x) direction forinput v.

7-12 12 Ending-grid number in r (or x) direction forinput v.

13-18 J1 Starting-grid number in z (or y) direction forinput v.

19-24 J2 Ending-grid number in z (or y) direction forinput v.

25-36 VRSV Velocity v, in cm/s.

Note: Use as many cards of Type 21 as required; total NV cards.

22 (416,E12.0) Initial specific material energy, 1.

1-6 11 Starting-cell number in r (or x) direction forinput I.

7-12 12 Ending-cell number in r (or x) direction forinput 1.

13-18 31 Starting-cell number in z (or y) direction forinput 1.

19-24 J2 Ending-cell number in a (or y) direction forinput I.

25-36 FIRSV Internal energy I, in dynercm/g

Note: Use as many cards of Type 22 as required; total NI cards.

23 (416,E12.0) Initial density, p.

1-6 11 Starting-cell number in r (or x) direction forinput P.

7-12 12 Ending-cell number in r (or x) direction forinput n.

13-18 JI Starting-cell number in z (or y) direction forinput r.

19-24 J2 Ending-cell number in z (or y) direction forinput o.

25-36 RHORSV Density r, in g/cm3.

Note: Use as many cards of Type 23 as required; total NRHO cards.

24 (416,E12.0) Initial pressure, p.

1-6 11 Starting-cell number in r (or x) direction forinput pressure p.

7-12 12 Ending-cell number in r (or x) direction forinput pressure p.

13-18 J1 Starting-cell number in a (or y) direction forinput pressure p.

19-24 J2 Ending-cell number in a (or y) direction forinput pressure p.

25-36 PRSV Pressure p, in dyne/cm'.

Note: Use as many cards of Type 24 as required; total NP cards.

35

Card FORTRANType Columns Format Name Description

25 (1216) Obstacles.

1-6 Il Starting-cell number in r (or x) direction forthe obstacle.

7-12 12 Ending-cell number in r (or x) direction forthe obstacle.

13-18 J Starting-cell number in z (or y) direction forthe obstacle

19-24 J2 Ending-cell number in z (or y) direction forthe obstacle.

Note: Use as many cards of Type 25 as required; total NOBSTL cards.

26 (216,4E12.0) Marker particles.

1-6 NX Number of columns of marker particles to becreated in r (or x) direction.

7-12 NY Number of rows of marker particles to be cre-

ated in z (or y) direction.

13-24 XO r (or x) coordinate of the first particle, incentimeters

25-36 YO z (or y) coordinate of the first particle, incentimeters.

37-48 DX Particle space in r (or x) direction, incentimeters.

49-50 DY Particle space in z (or y) direction, incentimeters.

Note: Use as many cards of Type 26 as required; total NMAKR cards.

27 (16,E12.0) Input for cover-head analysis.

1-6 NCRTBL Number of points on the force-displacementtable for the cover-head analysis.

7-18 CVRMAS Mass of the cover head, in grams.

28 (8E9.0)

1-9 CFn CFn and CDn are the forces and displacements,

9-18 CDn J respectively, for the table.etc.

Note: a. If ICOVER = 0, skip Type 27 and 28 cards completely.b. The displacements on Type 28 cards must be in increasing order.c. There are NCRTBL sets of forces and displacements input; each card consists of four sets.

29 (1216)

1-6 NOPEN Number of penetration openings on the coverhead.

30 (16,E12.0)

1-6 KOPENn Cell number in r (or x) direction for the topopening cell on the cover head.

7-18 FIPULSn Impulse to open the top penetration cellKOPENn.

Note: a. If ITOPEN = 0, skip Type 29 and 30 cards completely.b. Use as many cards of Type 30 as required; total NOPEN cards.

31 (16) Pressure-volume ratio table for core pressurecalculation.

1-6 NPVTBL Number of points on the pressure-volume ratiotable.

CardType

32

FORTRANColumns Format Name

(8E9.0)

1-9

10-18etc.

Description

CPR ESnC En CPRESn and CVOLRn are the pressure and vol-

CVOLRn ume ratio, respectively, for the table.

Note: a. If iCORE 4 1, skip Type 31 and 32 cards completely.b. The volume ratios on the pressure-volume ratio table must be in increasing order.c. There are NPVTBL sets of pressure- and volume-ratio input; each card consists of four sets.

33 (16) Pressure-time table for core pressurecalculation.

1-6 PPTTJIL Number of points on the pressure-time table.

34 (8E9.0)

1-9 PPTTB3Ln PF TTBLn and TPTTBLn are the pressure and

10-18 TPTTBLn time, respectively, for the table.etc.

Note: a. If ICORE / 2, skip Type 33 and 34 cards completely.b. The time on the pressure-time table must be in increasing order.

c. There are PPTTBL sets of pressure and time input; each card consists of four sets.

35 (616) Fluid- c ell vertic es not on fluid- structureinterface but moving with structural nodal points.

1-6 1 r (or x) index.

7-12 3 z (or y) index.

13-18 NF Corresponding structural nodal number.

Note: Use as many cards of Type 35 as required; total NVFS cards.

(20A4) TITL E

(515,5X,E10.6,15)

(1015)

NNODE

NELE

NUMMAT

NUMDIS

MXSTEP

DELT

NPRES

KONTRL(1)

80 characters of alphanumerics for identifica-tion of the structural analysis.

Parameter card

Number of nodes. For shell element, each nodeis assigned a "real" node number and a"dummy" node number NNODE counts both"real" and "dummy" nodes.

Number of elements (segments).

Number of material types.

Number of nodes at which one or more dis-

placement components are prescribed.

At cycle MXSTEP printer-plotter andCALCOMP output as specified on card Types 47and 48.

Time-increment parameter (only used withinWHAMS).DELT < 0.0: Program setsDELTmax = -DELT.DELT = 0.0: Program calculates DELTmaxwith no upper bound.DELT > 0.0: Program calculates DELTmax.If DELTmax> DELT, program sets DELTmax =DELT.

Number of load lines.

KONTRL(1) = 1: Axisymmetric problem.

36

36

37

1-80

1-5

6-10

11-15

16-20

21-25

31-40

41-45

38

I-S

Card FORTRANType Columns Format Name

38 (Contd.)

(1015)

MTYPE

NTYPE

NED

Note: There should be one set of cards ofand 41c for each material type.

40a (6E10.4)

1-10

11-20

21-30

31-40

41-50

(6E10.4)

Type 39, 40a,

E(1,MTYPE)

E(2,MT YPE)

E(3,MTYPE)

E(4,MTYPE)

E(5,MTYPE)

E(6,MTYPE)

E(7,MTYPE)

E(8,MTYPE)

(6E10.4)

(6E10.4)

(6E10.4)

ED(1)

ED(2)

ED(3)

ED(4)

ED(S)

ED(6)

ED(7)

ED(8)

ED(9)

ED(10)

ED(i 1)

ED(12)

ED(13)

ED(14)

ED(15)

ED(16)

39

1-5

6-10

37

Description

KONTRL(1) = 2: Plane-stress two-dimensional problem.KONTRL(1) = 3: Plane-strain two-dimensional problem.

Material cards.

Material type number.

NTYPE / 1: Use Type 40 material cards.NTYPE = 1: Use Type 41 material cards.

Number of line segments on the stress-straincurve for Type 41 material cards.

and 40b or one set of cards of Type 39, 41a, 41 ,

Material properties,

p: Density, in g/cm3.

E: Young's modulus, in dynes/cmZ.

ay: Initial yield stress, in dynes/cmt .Ep: Plastic modulus, in dynes/cm2.

Width of beam (only needed for plane-stressproblems; if not specified, it is assumed to beof unit width), in centimeters.

%lt: Ultimate stress, in dynes/cmZ.

Material properties.

V: Poisson's ratio.

Thickness of beam elements; only needed whennot specified in dummy node data, incentimeters.

Material properties.

p: Density, in g/Icm 3 .

al: Stress at point 1, in dynes/cm2.

cl: Strain at point 1.

a2: Stress at point 2, in dynes/cm.

Width of beam, in centimeters (only needed forplane-stress problem).

e¬: Strain at point 2.

Material properties.

v: Poisson's ratio.

t: Thickness of beam element, in centimeters.

Damping coefficient 1.

Damping coefficient 2.

Damping coefficient 3.

Damping coefficient 4.

Material properties.

as: Stress at point 3, in dynes/cm2.

es: Strain at point 3.

04: Stress at point 4, in dynes/cm'.

64: Strain at point 4.

40b

51-60

1-10

11-20

41a

41b

1-10

11-20

21-30

31-40

41-50

51-60

1-10

11-20

21-30

31-40

41-50

51-60

1-10

I1-20

21-30

31-40

41c

Card FORTRANType Columns Format Name

41c(Contd.) 41-50 ED(17)

51-60

42

ED(18)

(I5,5X,ZEI0.4)

1-5

11-20

21-30

Note: Nodal coordinates for nodes equispadata cards for intermediate nodes a:

43 (1115)

1-5

6-10

11-15

16-20

21-25

41-45

46-50

51-55

N

XC(N)

YC(N)

ced between

re skipped.

Description

a 5: Stress at point 5, in dynes/cm.

9,: Strain at point 5.

Node cards.

Node number.

X coordinate of real nodes. For "dummy"nodes (see NNODE description), thickness ofbeam may be specified through XC(N). In thatcase, all beam elements joined to node N willhave the same thickness at that point.

Y coordinate of real nodes.

two nodes will be automatically generated if the

Element cards.

M Element number.

NODE(I,M) Node NI of element.

NODE(2,M) Node N2 of element.

NODE(3,M) Node N3 of element (a "dummy" node for shellelement).

NODE(4,M) Node N4 of element (a "dummy" node for shellelement).

NODE(8,M) Node(8,M) = 1: Axisymmetric element.Node(8,M) = 2: Plane-stress, two-dimensional

element.Node(8,M) = 3: Plane-strain, two-dimensional

element.

NODE(9,M) Material type number.

NODE(10,M) Element type number.

Node(!0,M) = I: Thin shell element.

Node(10,M) = 2: Not used.

Node(10,M) = 3: Not used.

Node(10,M) = 4: Quadrilateral continuum solidelement.

Note: Node cards for elements that can be generated by adding one to all node numbers of the previouselement need not be included. The node data for these elements will be generated automatically.However, if this is done, the node numbers for the last element card must be included.

44 (110,E10.4) NODDIS Prescribed displacement cards. Use NUMDIScards.

N

I

1

The node at which one or more displacementcomponents are prescribed to be zero or somenonzero value given in subroutine FREEFD.

X component control; for dummy nodes, this isthe rotatory degree of freedom.

Y component control.I = 0: The component is unconstrained.I = l: The component is zero.I = 2: The component is a nonsero value,which is prescribed in FREEFD as a functionof time.

Not used.

38

1-7

8

9

10

39

Card FORTRANType Columns Format Name Description

44 (Contd.) 11-20 ANGLE Angle of inclination of local X axis relative toglobal x axis measured counterclockwise in

degrees. This local coordinate system enablesdisplacement components other than x and yto be prescribed.

Note: a. If NUMDIS = 0. skip this type of card.b. Use as many cards of Type 44 as required; total NUMDIS cards.

45 (4110) Output-control card.

1-10 NPFREQ Output frequency; time-history records of

specified nodal and cement information will beprinted for every NPFREQ time step.

11-20 NPRU Number of nodal time-history records; i.e.,displacements, velocities, or accelerations.

21-30 NPRS Number of element time-history records; i.e.,stresses, strains, etc.

31-40 NPIC Number of complete output pictures at specifiedtime steps; a complete picture consists of allnodal and element variables for a selection ofstresses, displacements, etc.

46 (8110) NPRU cards. Use as many cards as needed,

eight items per card, NPRU items total. IfNPRU = 0, no cards ot Type46 are used.

1-7 N Node number at which a specified displacement,velocity, or acceleration time history is to beoutput for each NPFREQ cycle.

8 L Component number:L = 1: x component (or rotatory componentfor dummy nodes).L = 2: y component.

9 K Nature of record:K = 0: Displacement record.K = 1: Velocity record.K = 2: Acceleration record.

10 M Plot control:M = 0: No plot.

M = 1: Nodal time history is plotted on printeronlyM = 2: Nodal time history is plotted on printerand Calcomp.M = 3: Nodal time history is plotted on printerand punched on cards.

11-17 N Node number.

18 L Component number.

19 K Nature of record.

20 M Plot control.

etc.

47 (8110) NPRS cards. Use as many cards as needed,eight items per cards NPRS items total. IfNPRS = 0, no cards of Typo 47 are used.

1-7 N Element for which 3 time history is to be

output.

8-9 L Component number.

10 K Plot control parameter (see card Type 46).

40

Card FORTRANType Columns Format Name Description

47 (Contd.) 11-17 N Element number.

18-19 L Component number.

20 K Plot control parameter.

etc.

Note: Component numbers used to specify the element records are shown in Fig. 10. Since the integrationfor the nodal forces uses two points along the length and five points through the depth of an element,50 records are available for each flexural element.

Ii

3 NODE I NODE 2 ®

Fig. 10

:omponent Numbers for

ime-history Plot

Ex 1 2 3 4 5 6 718 9 1011 il 12 13 14 15 16 17118 19 20

21 22 23 24 25 26 27128 29 30

Qg 31 32 33 34 35 36 37 38 39 40

YIELD fct 41 42 43 44 45 46 47 48 49 50

48 (2110) NPIC cards. Use a number of cards of Type 48equal to NPIC.

1-10 NPOUT Time step at which a complete output as spec-

ified by KONT is desired.

11-20 KONT KONT = 1: Output displacements at all nodes.KONT = 2: Output above plus coordinates of

deformed structure. (Output of dummy nodes

is meaningless for this card.)KONT = 3: Output above plus velocities and

accelerations at all nodes.KONT = 4: Output above plus all elementinformaton--stresses, strains, etc.

KONT = 5: Same printed output as KONT = 2;in addition, Calcomp plot of the deformedstructure.

KONT = 6: Same printed output as KONT = 3;in addition, Calcomp plot of the defo: medstructure.

KONT = 7: Same printed output as KONT = 4;in addition, Calcomp plot of the deformedstructure.

49 (615) Load-line card description.

1-5 IDUM Load-line number.

6-10 NDNOD Number of nodes or points on load line [usuallythe number of.(real) nodes on beam or shell].

11-15 IVOL(I) IVOL(I) = 1: Load line is part of an axisym-metric surface.

IVOL(I) = 2: Load line is part of a planesurface.

41

Card FORTRANType Columns Format Name Description

49 (Contd.) 16-20 INTl Not used.

21-25 INT2 Internal increment between nodes on load linefor automatic load-line node generation. IfINT2> 0, the load line is generated by addingINT2 to the previous node number, starting withthe first node specified on card Type 51.Set INT2 = 0 if automatic generation is notdesired. Usually INT2 = 1.

26-30 INT3 Internal increment between segments on loadline for automatic load-line segment genera-

tion. If INT3 > 0, the load-line segmentsgenerated by adding INT3 to the previous seg-ment number, starting with the first segmentspecified on card Type 52. Set INT3 = 0 ifautomatic generation is not desired. UsuallyINT3 = 1.

50 (1615)

1-5 KPRES(J) Not used.

51 (1615)

1-5 KNODE(J) Nodes on the load line; if all nodes can be6-10 KNODE(J+1) generated from KNODE(J) by increasing INT2,etc. J=1,NDNOD only KNODE(J) need be included. Total number

of nodes on all load lines is limited to 100.

52 (1615)

1-5 KSG(J) Segments on the load line; if all segments can6-10 KSG(J+1) be generated from KSG(J) by increasingetc. J=1,NDNOD-1 INT3, only KSG(J) need be included.

Total number of segments on all load lines islimited to 99.

53 (315) Segment/point connectivity cards.

1-5 LM Segment number.

6-10 IY(1,LM) First node number.

11-15 IY(2,LM) Second node number.

16-20 IY(3,LM) I, cell number in r (or x) direction for fluidcell (1,J) adjacent to segment LM.

21-25 IY(4,LM) J, cell number in z (or y) direction for fluidcell (1,J) adjacent to segment LM.

26-30 IY(5,LM) Parameter to identify loading condition ofsegment LM.IY(5,LM) = 0: One side of the segment sub-jected to fluid loading.IY(5,LM) = 1: Both sides of the segment sub-jected to fluid loading.

31-35 IY(6,LM) Orientation for segment LM; count from node 1to node 2.

IY(6,LM) = 1: From bottom to top.IY(6,LM) = 2: From left to right.IY(6,LM) = 3: From top to bottom.IY(6,LM) = 4: From right to left.

Note: Connectivity cards for segments that can be generated by adding one to all numbers of the previoussegment need not be included. The data for these segments will be automatically generated. How-ever, if this is done, the connectivity card for the last segment must be included.

Note: Cards of Types 49-53 are to be used in sets, one set for each load line. Total number of sets isNPRES; 0 < NPREb t 10.

42

B. Output Information

1. Standard Printout

In order for the user to easily understand and check his run, all

the input information and the information generated by the input cards are

printed at the beginning. These include:

a. Title of the run.

b. Integration time steps.

c. Coordinate- system option, mesh-movement option, implicit-

scheme option, structural- analysis option, etc.

d. Equations of state used for fluids.

e. All the initial conditions.

f. Structural nodal points and elements.

g. Multilinear stress-strain relationships used for structural

materials.

h. Structural loading lines and relationships with the fluid cells.

i. Marker particles.

Detail informations are also printed out at every NPRINT cycle.

These include:

a. Cycle number and corresponding time.

b. Vertex boundary conditions of the fluid cell. If this vertex is

connected to a structure, the corresponding node point is alsoprinted out.

c. r (or x) and z (or y) coordinates at each vertex.

d. Velocity components, u and v, at each vertex.

e. Density, mass, volume, and internal specific energy for eachcell.

f. Accelerations of the structural nodal points.

g. Velocities of the structural nodal points.

h. Displacements of the structural nodal points.

2. Optional Output

By the choice of the user, the following information can be op-tionally printed out. These include:

43

a. Cycle number, corresponding time, and number of iterationsto reach the convergence criterion (if NPRT1 / 0).

b. Plot information (if NPRT2 $ 0).

3. Pictorial Display

When pictorial display is desired (IFILM A 0), all the informationneeded for this display is written on a binary tape 2. Then this tape is usedto generate the display off-line by another program. Structural deformation,marker-particle movements, core expansions, and fluid-flow pattern can allbe seen on a series of these displays.

4. Calcomp Display

This display is also executed off-line by another small program.All the information on the binary tape 1 can also be printed out by options.

C. Limitation

As described earlier, a dynamic allocation is used for the ALICE code.There is no limitation on a particular parameter used for the program such

as number of grid lines in r (or x) direction or number of market particles.

Instead, a total space required for the problem is generated by these indi-vidual parameters. If the total space exceeds a certain value, the programwill stop and print out new dimensions for QD and LD. To run the problem,

the existing dimensions for QD and LD in the main program must be increased

according to these new values.

44

IV. SAMPLE PROBLEMS

As mentioned earlier, the ALICE code uses the hybrid Lagrangian-

Eulerian mesh to solve transient fluid-flow problems with solid interactions

in a containment system. To have confidence for the code performance, the

code predictions must be compared with the theoretical solutions and experi-

mental results. A variety of problems have been analyzed by the ALICE code;

three of them are described and illustrated below.

Rigid Tube Wall A. Shock-tube Test

Diaphragm Rigid The first example isRLid end Cap a shock-tube problem with anend Cap TlPPuP Tri r'Pr'ur initial pressure and density

d/2 discontinuity as given in Prob-

of Tube lem I of the APRICOT pro-

L/2 gram.' 7 The purpose of thisexample is to test the calcu-

L - - lation of the motion in the zx:0Kx L (or y) direction, check the

P = 100 bars Pr = 0.5.1P =002905 gm/cm 3 variables calculation in the

P = 0.0581 gm/cm 3 T1 = Tr = 600 K r (or x) direction, and evalu-

P = 0.5-"P :=50 bars Ug = Ur = 4303 X106 erg/gm ate the artificial viscosity usedfor the ALICE code. Figure 11

Fig. 11. Schematic of Tube. Conversion factor: shows the configuration of the

1 bar =r0.1 MPa: 1 erg 10-7 J. shock tube, which has a rigid

tube wall and two rigid end

caps and is divided into two gas regions by a diaphragm. The internal energies

and temperatures are the same on both sides; the density and pressure on the

left side (designated by the subscript 4) are twice the values on the right side(designated by the subscript r). At time t = 0, the diaphragm is removed.

A shock wave initiated at the interface is propagated toward the right side; a

rarefaction wave moves in the opposite direction.