Assignment 1 SOP (1)

-

Upload

john-schnettler -

Category

Documents

-

view

125 -

download

4

Transcript of Assignment 1 SOP (1)

Fermenter & Bright Tank Clean-In-Place and Sanitize-In-Place Standard Operating Procedure

March 23, 2016

New Belgium Pilot Brewery

John Schnettler

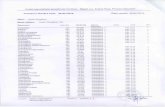

Table of Contents

Table of Contents

Process Flow of Procedures: Pg. 3

Fermenter/Bright Tank Clean In Place:

Purpose/Safety/Materials: Pg. 4

Step 1: Pg. 4

Step 2-5: Pg. 5

Step 6-10: Pg. 6

Step 11-15: Pg. 7

Fermenter/Bright Tank Sanitize In Place:

Purpose/Safety/Materials: Pg. 8

Step 1: Pg. 8

Step 2-4: Pg. 9

Step 5-7: Pg. 10

Quality Assurance/Quality Control: Pg. 11

References: Pg. 12

Process Flow of Procedures

Fermenter/Bright Tank Clean In Place Procedure: 1. Verify glycol has been closed before rinsing respective tank. 2. Depressurize tank. 3. Attach upward elbow pipe with tri-clamp and gasket to sample cock. 4. Attach long hose to butterfly valve near heat exchanger and house water source. Attach other

end of long hose to spray ball inlet/blowoff arm.

5. Attach short hose to fermenter bottom drain valve (or bright tank central drain valve) and open butterfly.

6. Open house water source second to rinse tank with spray ball. Rinse tank through spray ball for several minutes, draining out of both the drain valve and the standing valve.

7. Close the drain valve and standing valve and fill the tank for 60 seconds if 10 hL tank, 90-120 seconds for 20 hL tank. Close house water supply valve when finished.

8. Depressurize and disconnect the long hose from the butterfly valve and reconnect to the centrifugal pump outlet, leaving the other end still connected to the spray ball inlet/blowoff arm. Connect the short hose to the inlet of the centrifugal pump.

9. Open the fermenter/bright tank drain valve allowing water to flow into the pump. Turn the pump on to verify that the pump is cycling water through the spray ball.

10. Turn the pump off after verifying the pump and spray ball are working correctly. Add the proper

amount of Ultra Niter and X Puma to the tank via the upward elbow pipe. Turn the pump on

and allow the first CIP cycle to run for at least 30 minutes. Drain the tank and rinse thoroughly.

11. Refill the tank and reconnect the short hose to the pump inlet, the long hose to the pump outlet, and prime the pump for the second cycle. Add the proper amount of BRU-R-EZ Caustic and allow the second cleaning cycle to run for at least 15 minutes.

12. After the second CIP cycle, drain the tank again and rinse thoroughly. 13. Return the pump, hoses, and chemicals to their proper storage areas and perform any other

necessary clean up.

Fermenter/Bright Tank Sanitize In Place Procedure:

1. Fill the kettle approximately halfway and use bottom steam jacket to heat water to at least 83 degrees Celsius.

2. Attach a sample cock to its proper opening on the tank with a gasket and tri-clamp. For bright tanks, also put the long carbonation stone with gasket and tri-clamp into its proper opening, but don’t fully attach the carbonation stone.

3. Next, attach long hose to butterfly valve near heat exchanger and house water source. Attach other end of long hose to spray ball inlet/blowoff arm.

4. Attach short hose to fermenter bottom drain valve (or bright tank central drain valve) and open butterfly.

5. Press wort pump button at the brewhouse control panel to send hot water from the kettle to the tank. Once the tank’s thermostat reads at least 80 degrees Celsius, the tank is sufficiently sanitized.

6. For fermenters, simply pressurize the tank to 10 psi. For bright tanks, fully attach the carbonation stone. Also, attach a CO2 regulator to the spray ball inlet/Blowoff arm and open the valve. Purge the tank of oxygen for at least 30 minutes, close all openings, and pressurize the tank to 10 psi.

7. Return the hoses to their proper storage areas and perform any other necessary clean up.

Fermenter/Bright Tank Clean In Place (CIP)

Purpose: The following processes are conducted in order to ultimately remove the majority of soils

from the interior surfaces of pilot brewery fermenters and bright tanks. An initial acid/surfactant cycle

helps to remove beerstone (calcium oxalate), encourage passivation of stainless steel, and loosen

protein soils which are further broken down and removed by a secondary caustic cycle. Longer than

average cycle times and heavier than average chemical additions may be employed for dirtier tanks.

Safety: There are a number of safety concerns to consider when executing the following processes.

Working in a production facility, proper attire should be worn including steel, close-toed shoes and

safety glasses and protective gloves when handling chemicals. Caution must be exercised when working

with chemicals and eyes or skin should be washed at appropriate emergency station within the pilot

brewery if chemical contact is made. In addition, caution must also be exercised with the use of hot

water and hot stainless steel vessels in the brew house due to the fact that serious burns can be

sustained. Never open valves or hoses on rinsing or cleaning loops. Again, proper following of

procedure and use of gloves is imperative. Furthermore, working with carbon dioxide gas and

pressurized tanks requires caution and proper following of procedure. If carbon dioxide alarms sound in

the brewhouse, exit the building immediately.

Materials: (All can be found within pilot brewery)

Long Hose (House Water Source/Spray Ball Inlet (Blowoff arm)/Centrifugal Pump Outlet)

Short Hose (Drain Hose/Centrifugal Pump Inlet)

Centrifugal Pump

Ultra-Niter (General Purpose Acid: 1 quart per 10 hL, 2 quarts per 20 hL)

X Puma (General Purpose Cleaner: 0.25 quarts per 10hL, 0.5 quarts per 20hL)

BRU-R-EZ Caustic (General Purpose Cleaner: 1 scoop per 10 hL, 2 scoops per 20hL)

Elbow Pipe with tri-clamp and gasket Procedure:

Step 1: VERIFY GLYCOL HAS BEEN CLOSED BEFORE RINSING TO AVOID HEAT-STRESSING TANK!!! To do so, turn the handle of the glycol outlet perpendicular to the glycol line.

Step 2: Fully depressurize tank by opening CO2 regulator before removing sample cock and CO2 regulator from spray ball inlet/blowoff arm to avoid burst of pressure. Next, remove attachments.

Step 3: Attach upward elbow pipe with tri-clamp and gasket to sample cock opening for easier chemical addition and pressure relief.

Step 5: Attach short hose to fermenter bottom drain valve (or bright tank central drain valve) and

open butterfly.

Step 4: Attach long hose to butterfly valve near heat exchanger and house water source. Attach

other end of long hose to spray ball inlet/blowoff arm.

Step 2 Step 3

(Note: Drain Valve is on the left facing

the tank, Standing Valve is on the right

facing the tank on all fermenters.)

Step 6: Open long hose butterfly first, then open house water source second to rinse tank with

spray ball. DO NOT open water source before opening Long Hose butterfly, this can put too much

pressure on the heat exchanger and potentially damage it.

Step 7: Rinse tank through spray ball for several minutes by opening the house water supply valve

until water runs clear, draining out of both the drain valve and the standing valve.

Step 8: After sufficient rinsing, close the drain valve and standing valve and fill the tank for 60

seconds if 10 hL tank, 90-120 seconds for 20 hL tank. Close house water supply valve when finished.

Water should be at 60 degrees Celsius, if too warm add cold water from brewhouse hose.

Step 9: Depressurize long hose by opening adjacent butterfly valve. Once depressurized, disconnect

the long hose from the butterfly valve and reconnect to the centrifugal pump outlet, leaving the

other end still connected to the spray ball inlet/blowoff arm. Connect the short hose to the inlet of

the centrifugal pump, located in the center of the pump.

(Note: Short drain hose is

connected to center of the

pump at the inlet, long

drain hose is connected to

the side arm of the pump

which is the outlet.)

Step 10: Open the fermenter/bright tank drain valve allowing water to flow into the pump. Turn the

pump on to verify that the pump is cycling water through the spray ball. If you cannot hear the

spray ball, the pump is pulling air and must be primed. To prime the pump, turn the pump on and

loosen the long hose slightly at the pump outlet allowing air bubbles to escape. After 10-15 seconds

or so, re-tighten the long hose and verify the spray ball is working.

Step 11: Turn the pump off after verifying the pump and spray ball are working correctly. Add the

proper amount of Ultra Niter (General Purpose Acid: 1 quart per 10 hL, 2 quarts per 20 hL) and X

Puma (General Purpose Cleaner: 0.25 quarts per 10hL, 0.5 quarts per 20hL) to the tank via the

upward elbow pipe. Turn the pump on and allow the first CIP cycle to run for at least 30 minutes.

Step 12: After the first CIP cycle, turn off the pump, disconnect the short hose from the pump inlet

and allow the tank to drain completely. Using a latter, open the manway of the fermenter and

inspect to see that most, if not all soils have been removed from the inside of the tank. If there is a

ring of soil in the fermenter, use a tank scrubber to remove the soil from the inside of the tank.

Rinse the tank using the long hose and house water for several minutes and allow the tank to drain.

Step 13: Once again, fill the tank for 60 seconds if 10 hL tank, 90-120 seconds for 20 hL tank.

Reconnect the short hose to the pump inlet, the long hose to the pump outlet, and prime the pump

for the second cycle. Add the proper amount of BRU-R-EZ Caustic (General Purpose Cleaner: 1 scoop

per 10 hL, 2 scoops per 20hL) via the open manway. Close the manway and turn on the pump

allowing the second cleaning cycle to run for at least 15 minutes.

Step 14: After the second CIP cycle, turn off the pump, disconnect the short hose from the pump

inlet and allow the fermenter to drain completely. Once again, disconnect the long hose from the

pump and reconnect to the house water manifold. Rinse the tank for several minutes until the

water runs clear and inspect the tank one final time to be sure it is clean.

Step 15: Return the pump, hoses, and chemicals to their proper storage areas and perform any

other necessary clean up. Rinse off tank if any chemical makes contact with the tank’s exterior.

Fermenter/Bright Tank Sanitize In Place (SIP)

Purpose: The following processes are conducted in order to ultimately remove any residual soils and

microbes from the interior surfaces of pilot brewery fermenters and bright tanks. Furthermore, purging

of bright tanks following SIP cycles creates an oxygen free environment inside the tank that promotes

shelf stability by eliminating sources of oxidation. For the purpose of the pilot brewery, high

temperature water is sufficient in killing off any microbial life within the tank that may be a source of

spoilage of the final product. Heating tanks above 80 degrees Celsius using hot water has repeatedly

been shown to provide the proper storage environment for fermented beer to mature and condition.

Safety: There are a number of safety concerns to consider when executing the following processes.

Working in a production facility, proper attire should be worn including steel, close-toed shoes and

protective gloves when handling hot water. Caution must be exercised with the use of hot water and

hot stainless steel vessels in the brew house due to the fact that serious burns can be sustained. Never

open valves or hoses on rinsing or cleaning loops. Furthermore, working with carbon dioxide gas and

pressurized tanks requires caution and proper following of procedure. If carbon dioxide alarms sound in

the brewhouse, exit the building immediately.

Materials: (All can be found within pilot brewery)

Long Hose (House Water Source/Spray Ball Inlet (Blowoff arm)

Short Hose (Drain Hose)

Elbow Pipe with tri-clamp and gasket Procedure:

Step 1: After rinsing, CIPing, and re-rinsing the fermenter/bright tank, the next step to prepare the tank for holding a new batch of wort/beer is to sanitize. UNLESS YOU INTEND TO FILL THE TANK WITHIN 72 HOURS OF SANITATION, WAIT TO SANITIZE THE TANK UNTIL YOU INTEND TO FILL IT WHETHOR IT BE ON A BREW OR TRANSFER DAY. First, fill the kettle roughly half-full (unless otherwise instructed) by opening the house water valve connected to the front of the kettle. As the water level rises above the first steam jacket, rotate the bottom jacket valve counter-clockwise to open steam flow to the kettle to heat the water. Heat the water to at least 83 degrees Celsius in order to bring the tank you intend to sanitize to at least 80 degrees Celsius.

Step 2: The tank should already have its glycol receiver valve closed, should be depressurized, and should have an opening for pressure to escape as you sanitize with hot water from the kettle. Attach a sample cock to its proper opening on the tank with a gasket and tri-clamp and put the long carbonation stone with gasket and tri-clamp into its proper opening when sanitizing a bright tank, but don’t fully attach the carbonation stone.

Step 3: Next, attach long hose to butterfly valve near heat exchanger and house water source. Attach other end of long hose to spray ball inlet/blowoff arm.

Step 4: Attach short hose to fermenter bottom drain valve (or bright tank central drain valve) and open butterfly.

Step 5: Once the water in the kettle has reached at least 83 degrees Celsius, make sure the whirlpool inlet on the kettle is shut, the whirlpool outlet on the kettle is open, both wort pump valves are open, and open the long hose valve connected to the heat exchanger manifold. Next, press the green wort pump button at the brewhouse control panel to activate the pump and send hot water from the kettle to the tank via the spray ball at 30-40% pump velocity. Monitor the tank’s thermostat as you send hot water to the kettle. Once the thermostat reads at least 80 degrees Celsius, the tank is sufficiently sanitized. Press the red wort pump button to inactivate the wort pump. Before disconnecting the long hose from the spray ball/Blowoff arm, relieve pressure in the line by opening the adjacent butterfly valve on the heat exchanger manifold.

Step 6: Immediately after sanitizing the tank and disconnecting the hoses used for the SIP cycle, fully attach the carbonation stone previously placed in its opening using a gasket and tri-clamp. Also, attach a CO2 regulator to the spray ball inlet/Blowoff arm and open the valve. Purge the tank of oxygen by attaching a CO2 line to the carbonation stone and allowing air to escape the bottom valve of the tank, the sample cock, and the CO2 regulator. Allow each opening to release air for several minutes, close all openings, and pressurize the tank to 10 psi.

Step 7: Now that the SIP cycle is complete and the fermenter/bright tank has been given a final rinse, return the hoses to their proper storage areas and perform any other necessary clean up.

Quality Assurance/Quality Control

By properly adhering to the procedures and troubleshooting of potential failures provided, quality can be both assured as well as controlled through prevention and detection of failure. The procedures outline a methodology that has been proven over decades of production experience to properly clean and sanitize beer fermentation and conditioning tanks, therefore avoiding detriments to the quality of the final product such as microbial contamination or oxidation and resulting lack of shelf stability. As previously mentioned, tanks are simply visually inspected for residual soils following cleaning cycles. The water volumes and temperatures, cleaning product amounts, and cycle durations have been shown over time and experience to typically remove all soils and destroy any microbial life. However, if a visual inspection indicates otherwise, such as a residual ring of soil where fermentation occurred, the cleaning cycle is to be continued for a longer duration until visual inspection indicates all soils have been removed. If further time is insufficient, higher chemical dosage rates may also be utilized. Similarly, if the Gehaltemeter (gas in liquid measurement device) indicates dissolved oxygen at levels higher than 100 ppb, than one corrective action would be to purge bright tanks longer and more vigorously in the future. In addition, if finished product fails sensory taste panel, then both cleaning and sanitizing of holding tanks must go under scrutiny to make sure tanks are properly prepared for a quality product. Overall, if strict adherence to procedures and troubleshooting is employed, the quality of the final product will not be negatively impacted due to a non-sterile or improperly purged holding tank.

References

Holzhauer, F., Johnson, D. (March/April 1996). Noncaustic Cleaning in the Brewery. Birkocorp: The New

Brewer.

![Accounts SOP[1]](https://static.fdocuments.net/doc/165x107/577d236c1a28ab4e1e99bf78/accounts-sop1.jpg)