ASSEMBLY INSTRUCTION MANUAL - Yale Hoist and Manuals/Yale Crane... · SINGLE GIRDER CRANE BRIDGES...

Transcript of ASSEMBLY INSTRUCTION MANUAL - Yale Hoist and Manuals/Yale Crane... · SINGLE GIRDER CRANE BRIDGES...

1

ASSEMBLYINSTRUCTION

MANUAL

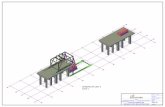

SINGLE GIRDER TOP RUNNING BRIDGESWITH

INDIVIDUAL MOTOR DRIVEN ANDHAND GEARED TRUCKS

Rated Loads;1 thru 15 tons / 2000 thru 30000 lbs.1 thru 15 tonnes / 1000 thru 15000 kg.

Follow all instructions and warnings in building this bridge.

The building of any bridge presents some risk of personal injury or property damage. That risk is greatly increased if properinstructions and warnings are not followed. Before starting construction the builder should become thoroughly familiar withall warnings, instructions and recommendations in this manual.

Retain this manual for future reference and use.

October, 2004 COPYRIGHT 2004, COLUMBUS MCKINNON CORPORATION PART NO. 113533-81

2

WheelWheelBase

ASCE Runway Rail

25# 30# 40#60# &70#

80# &85#

6"6"6"

4’ - 6"6’ - 0"7’ - 6"

8994#89948038

9560# 9560 8038

11,242#10,0768038

– –– –– –

– –– –– –

8"8"8"

4' - 6"6' - 0"7' - 6"

– –– –– –

12,74712,74712,747

14,99014,99013,802

20,986#17,30813,802

22,485#17,30813,802

10"10"10"

4' - 6"6' - 0"7' - 6"

– –– –– –

– –– –– –

– –– –– –

26,23222,28317,754

28,10622,28317,754

TO BUILD TOP RUNNINGSINGLE GIRDER CRANE BRIDGES

THE INFORMATION CONTAINED IN THIS MANUAL IS FORINFORMATIONAL PURPOSES ONLY AND THEMANUFACTURER DOES NOT WARRANT OR OTHERWISEGUARANTEE (IMPLIEDLY OR EXPRESSLY) ANYTHINGOTHER THAN THE COMPONENTS MANUFACTURED ANDASSUMES NO LEGAL RESPONSIBILITY (INCLUDING, BUTNOT LIMITED TO CONSEQUENTIAL DAMAGES) FORINFORMATION CONTAINED IN THIS MANUAL.

GENERAL

The assembly and manufacturing instructions in this manual arefor use in conjunction with the manufacturers componentsidentified by Catalog numbers listed under the two types ofdrives covered by this manual on pages 15 and 16.

Although the supplied components are designed to conformwith the requirements of CMAA 74, Specification for Top Running& Under Running Single Girder Electric Overhead TravelingCranes Utilizing Under Running Trolley Hoist and ANSI B30.17,Safety Standard for Overhead and Gantry Cranes, it is theinstaller's responsibility to assure that the furnished craneassembly complies in total with all applicable local, state andnational codes and standards including those mentioned herein.On a hand powered crane with an electric hoist, a fused safetydisconnect switch should be provided and mounted on thebridge near the main collectors. Crane wiring should be done bya licenced electrician and be in accordance with the NationalElectric Code (ANSI/NFPA 70).

The crane bridges described in this manual are intended fornormal indoor service. Bridges to be used for outdoor or unusualservice require special consideration.

This manual illustrates specific configurations for the range ofcoverage shown, specifically from 10 foot thru 60 foot spans andup to and including 15 tonne capacity. Minor deviations to theconfigurations shown (such as shaft bearing spacing, shaftlengths, etc.) may be made providing that any changes and/oralterations to those shown, be performed only by a properlyqualified person. The manufacturer accepts no responsibility forany altered bridge configurations.

Material listed by catalog numbers on pages 15 and 16 areapplicable only to crane configurations outlined in this manual,specifically limited to a maximum rated load of 15 tonnes and amaximum span of 60 feet.

Cataloged end trucks listed on page 15 will accommodate railsizes shown on this page. Maximum wheel loads are shown foreach wheel size.

Maximum Wheel Load with Crane Centered on the Wheelbase.

The above chart contains allowable Equivalent Durabiity WheelLoads in accordance with CMAA Specification #74, revised2004.

RUNWAYS: Runway beams on which these cranes will operatemust be amply strong to support crane bridge, hoisting equipment,and rated load. Runway rails must be level and parallel within±1/8”. Rail joints must be smooth and held firmly in alignmenteither by bolted splice bars or welding. Rails should be securelyfastened to runway beam.

MATERIAL TO BE PURCHASED LOCALLY TO COMPLETE A CRANE BRIDGE

STRUCTURAL STEEL: All structural steel should be firstquality, free from rust and excessive mill scale, and conform toASTM A 36, Standard Specification for Structural Steel.

For the drawing identifying all dimensions, material sizes, locationof cross shafting, brackets, etc.; refer to the following chart:

NON-FACTORY AUTHORIZATIONS OR MODIFICATIONOF EQUIPMENT AND USE OF NON-FACTORY REPAIRPARTS CAN LEAD TO DANGEROUS OPERATION ANDINJURY.

TO AVOID INJURY:• Do not alter or modify equipment without factory

authorization.• Do use only factory provided replacement parts.

WARNING

Bridge Assembly Page

Individual Drive 9Hand Powered 10

3

BRIDGE BEAMS: For each rated load, span and type of bridgeselect bridge beam from the tables shown on pages 17 thru 24.

The beam which is selected to be used for the bridge girder mustbe straight with flanges parallel to each other and flanges 90degrees to the web. See Figure 1 below.

Figure 1.

NOTICE

A. All of the tables used in selection of structural steel beamshave been produced by our engineering department using wellestablished design guides for this type of crane bridge. IT ISIMPORTANT THAT ALL INSTRUCTIONS BE FOLLOWED ANDTHAT RECOMMENDED COMPONENT APPLICATION LIMITSNOT BE EXCEEDED.

B. Assembly of beam and channel requires welding. IT ISEXTREMELY IMPORTANT TO THE SAFETY OF THIS BRIDGETHAT THIS WELDING BE DONE BY A COMPETENT WELLTRAINED WELDER. It is our strong recommendation that thewelder used in this construction be qualified as prescribed bythe American Welding Society (AWS) Specification for WeldingIndustrial and Mill Cranes D14.1 - latest issue.

FABRICATION OF GIRDER FOR BRIDGEBEAM WITH CAPPING CHANNEL

Refer to Figure 2. Place channel on supports as shown in StepI. The beam is sighted for camber and placed with camber indirection shown in Step II. Weld one end of the channel to thebeam. Clamp, with “C” clamps, the channel to the beam flange.Provide sufficient “C” clamps so as to hold the channel in contactwith the beam.

Figure 2.

12725C

SHOWING CORRECT BEAM SELECTION 11953

4

METHOD OF SETTING END TRUCK TO GIRDERLINE A-A MUST BE PARALLEL TO LINE B-B

Weld in accordance with the weld information given, starting atone end, staggering the weld from side to side, proceeding tothe opposite end of the channel without interruption. It isimportant to stagger the weld from side to side in order to retainbeam straightness. After welding, draw a taut string from end toend of beam as shown. Beam should either be parallel to stringor have some camber. Camber should not exceed 1/888 ofspan.

CROSS SHAFTS: For hand geared cranes, cross shafts arerequired. The cross shafts are to be of AISI 1018 cold drawnsteel, with standard mill tolerance of +.000”, -.002”. For shaftdiameter and lengths, refer to Figure 9, Hand Geared BridgeAssembly. The builder must check that the cross shaft couplingsclear cross shaft bearings.

ASSEMBLING BRIDGE GIRDERTO END TRUCKS

1. Refer to Figure 5-Bridge "Whale's Tail" Bolted End Connec-tion, Figure 5B-Bridge Bolted Plate End Connection and Figure6-Bridge Welded End Connection. Figure 5 shows a girder endconnection that may be optionally purchased as a kit. Figure 5Bshows another optional bolted plate girder connection that maybe purchased. Figure 6 is an end connection that may befabricated by the crane builder. Make the notch to the dimen-sions shown with a ½" radius at the intersection of the cuts witha cutting torch and smooth the burned area by grinding. If thegirder extends below the truck a second notch may be required

2. Locate end trucks in the notch of the girder, one at each endof the girder. Make certain trucks are level with each other andare level with the bottom flange of the beam as shown inFigure 3. The girder web is centered on the truck wheelbase.

It is quite possible that the top flange of the girder is not leveleven though the bottom flange is level. DO NOT LEVEL FROMROUGH TRUCK STRUCTURE. Correct operation of the hoist-trolley requires that the bottom flange is level.

3. To check the distance between the trucks, push all truckwheels toward the center of the span. The distance from theoutside of the wheel on one side of the span to the inside of thewheel on the other side of the span should equal the span lengthfor the 8” and 10” diameter wheels. For the 6” diameter wheelsthis dimension should be the span length minus 23/64”. SeeFigure 4. The tolerance on these distances is +1/32”.

Figure 3.

12847C2

Figure 4.

12983

Trolley stops (clip angles) must be installed on bothends of the bridge beam to prevent hoist trolley fromrunning off the end of the beam, which could result ininjury to the operator and others and damage to theload and other property.

WARNING

to clear the runway or main conductors. Support beam abouttwo feet from each end on a pair of horses, or other suitablesupport (adjustable, with clamping ability is preferred). Placebeam on supports so that camber side is at top. In case of beamswith capping channels the channel side is up. When setting upthe beam on supports, make certain that the bottom flange islevel.

5 Figure 5. Bridge "Whale's Tail" Bolted End Connection.

12979B2

6

Figure 5B. Bridge Bolted Plate End Connection

5B12979

7 Figure 6. Bridge Welded End Connection.

12981B

8

4. There are measuring dimples available on the inside faces ofthe truck above the axles. To check the squareness, use a springscale on the end of a steel tape and measure diagonally acrossthe crane. Then measure across the opposite diagonal with thesame force on the scale. These dimensions should be within 1/16” of each other.

Any other method of squaring the trucks that gives comparableresults may be used.

After squaring the trucks double check the span at both ends ofthe trucks.

5. After assuring that the trucks are accurately positioned andsquared, complete girder connections as shown in Figures 5, 5Band 6.

6. For the bolted end connection, first clamp the horizontalgusset plate (Ref. No. 3) to the top of the truck so that the centerof the holes is in line with the center of the trucks. If truck tube iswarped use shims to level the connection. Do not twist truck tube.

Do not use excessive heat or weld that might cause distortion.Alternate welds as much as possible. Weld the angles (Ref. No.5), long leg horizontal, to the web of the girder and to the gussetplate. Next, place the rings (Ref No. 1) in the holes on the gussetplates and weld to the top of the truck. Place the cap (Ref. No. 2)on the inner ring and hold in place with a couple of bolts. Bolt theconnection (Ref. Nos. 2, 7 and 8).

7. Position the angle (Ref. No. 4), short leg, against the side of thetruck and weld in place. Using the angle as a template drill three½" diameter holes in the web of the girder and bolt up (Ref Nos.6, 8 and 9).

8. For the welded end connection weld the angles (Ref. No. 3),long leg horizontal, to the truck and to the girder web. Position theangle (Ref. No. 2), short leg, against the side of the truck and weldin place to the truck and to the girder web. Weld the brace (Ref.No. 1) in place. All welded connections must have this brace.

Note

9

See Figure 10 For Section A-A and Detail A.

Figure 8. Motor Driven Bridge Assembly.

12977B2

10

See Figure 10 For Sections A-A Thru D-D And Detail A.

Figure 9. Hand Geared Bridge Assembly.

12978B2

11

For Cross Shaft Diameter, Dimension D and Dimension E, See Figure 9.

Figure 10. Bridge Details.

12984-2

12

INSTRUCTIONS FOR ASSEMBLINGINDIVIDUAL DRIVE CRANE BRIDGES

1. Refer to Figure 8, Motor Driven Bridge Assembly.

2. Prepare bridge girder with capping channel, if required (SeePage 3). Notch girder as shown in Figures 5 and 6.

3. Follow instructions for assembling bridge girder to end trucksas outlined on Page 4.

4. The gear case (with wheel pinion), motor and brake areshipped as an assembly. Bolt this assembly to the side of thetruck with four socket head cap screws with lockwashers. Installvent plug in place of pipe plug at top of the gear case.

5. The electrical enclosure and fused disconnect switch is to bemounted where required by the crane builder. Assure allclearances.

6. Locate and weld trolley stop angles at the ends of the girderas shown on Figure 8.

INSTRUCTIONS FOR ASSEMBLINGA HAND GEARED CRANE BRIDGE

1. Refer to Figure 9, Hand Geared Bridge Assembly.

2. Prepare bridge girder with capping channel, if required (SeePage 3). Notch girder as shown in Figures 5 and 6.

3. Follow instructions for assembling bridge girder to end trucksas outlined on Page 4.

4. Mount and bolt the hand geared drive adapter for the crossshaft to the side of the truck with four socket head cap screwswith lockwashers.

5. Locate and clamp cross shaft support angles to the girder.Recheck that angles are level and square and finish weldingaccording to Figure 9.

6. Form pillow block supports by mounting the angle and platetogether as shown in Section C-C of Figure 10. Mount thecompleted assembly to the pillow blocks by bolting.

7. Place the proper number of pillow blocks (with supportangles) and couplings on each shaft section. Check to insurethat the vertical angle is in the correct relationship with the crossshaft support angle (back of angle to back of angle). Notice thatthe separate bearing locking collar has a counterbore on oneside. This counterbore fits over the protruding inner race of thepillow block bearing. Place locking collar on the shaft properly.

8. Place the hand chain wheel and guide on the appropriateshaft section (near the center of the crane) within 12” of abearing support. For cranes 10 tonnes and more, a keyway5/16” x 5/32” needs to be cut into the cross shaft location at thehand chain wheel. Put key in place.

9. Set shafting in place, align pillow blocks to cross shaft supportangles and clamp in place.

10. Check horizontal and vertical alignment of the cross shaft byusing a taut line. Weld pillow block support angles to the crossshaft support angles when alignment is assured.

11. Set space between cross shafts to 1/8”. Position couplingsand drill 3/8” diameter holes through the shaft and couplingusing the holes in the coupling as a guide. The coupling has apredrilled hole through one side only. The shaft and coupling arethen secured by hex head bolts with lockwashers and nuts.

12. Slide bearing locking collars into place next to pillow blocks.Make sure that the counterbore in the collar is fitted over theextended race of the bearing. Fasten to shaft with set screw inlocking collar.

13. Locate and weld trolley stop angles at the ends of the girderas shown on Figure 9.

PAINTING

After all welding is completed and prior to installing the crossconductors, wire brush all steel and remove all scale, weldsplatter, flux and any other foreign matter. Grease spots are tobe cleaned using commercially available solvent. Wash withclear water an area six inches either side of all welds to removeflux residue.

The electrical panel must be closed, and areas such as theswitch handle, Off-On identification, wheel gear and pinion, andnameplate, etc., must be masked prior to painting.

Any national brand zinc-rich, chromate primer may be used andapplied according to the manufacturer’s directions. Final coat isrecommended to be high gloss enamel, especially suited forsteel surfaces and as recommended by any national brand paintmanufacturer. Application must be in accordance withmanufacturer’s recommendations.

MARKINGS

Codes require that the capacity of the bridge be shown on bothsides of the crane, legible from the floor. Normal practice formarking is to use capacity in tons. For example: 1 TON, 2 TON,etc. Stencil forms are readily available that may be used withbrush on or spray-can paint. Commercially available blockletters and numerals with adhesive backing could also be used.Selection of size should be such that the sign can be easily readfrom the operating floor.

The builder’s name shall also be placed on the crane in aprominent location along with a serial number or other means ofcrane identification.

NOTICE

The crane builder and user are responsible for markingthe crane and also to check for compliance with alllocal, state and national codes.

13

PUSH BUTTON SYSTEM

The preferred way of operating the controllers on the crane fromthe floor is a festooned system sold as a kit. This is to be installedas shown in the literature supplied with this system.

CROSS CONDUCTOR SYSTEM

A cross conductor system is a means of providing electriccurrent from the main conductors to the moving hoist-trolley.

The preferred cross conductor system is a festooned systemsold as a kit and it is to be installed as shown in the literaturesupplied with this system.

MAIN COLLECTOR ASSEMBLY

Refer to Figure 11, Main Collector Assembly.

The collectors listed (Catalog Numbers 931077, 931078, 931080and 931099) are compatible with and will operate only onconductor bars listed as Catalog Numbers for Crane Runwayson page 14. The builder must check to ensure that the properspacing and location of the conductors will clear all obstructionsin the building.

INSTALLATION OF THE CRANE BRIDGE

Installation of the crane on the runway shall be performed onlyby a qualified crane installer. For information regarding attachingand lifting or moving the loads during installation, refer to ANSIB30.17 - latest edition, Chapter 17-3 and other applicablecodes.

Figure 11. Main Collector Assembly.

12980

Ordinarily the crane is grounded to the runway beamthrough the contact with the crane wheels. Certainenvironments may prevent proper grounding by thismeans. In those cases, a 4th runway conductor andcollector should be provided to assure adequategrounding.

This also applies to the cross conductors and theelectrical contact between the trolley wheels and thebridge girder.

WARNING

Before installing the crane on the runway, lock therunway conductor disconnect switch in the open (off)position.

WARNING

14

Prior to the start of any crane erection the building should bemeasured for spans of rails and clearances. These measure-ments should be checked against the corresponding cranemeasurements to insure correctness of “fit”. After assurancesthat the crane fits the building, determine orientation of thecrane position with respect to the runway.

These types of cranes are usually lifted into position on therunway rails in one piece.

Immediately after the crane is placed on the runway rails checkwheel flange clearances to the rail. Clearance between side ofrail head and inside flange of wheel will vary from 3/4” to 1-1/8”depending on the wheel and rail combination and whether or notthe truck is centered on the rail. Total wheel float will not be lessthan the 3/4" recommended by CMAA Specification #74.

NOTE: It is suggested that the trolley and hoist beinstalled on the crane bridge at this time so that allwiring connections can be completed.

FUSE AND MAINLINE DISCONNECT PANELS

Mainline disconnect panels and fuse bridge control panels areprovided as options to assist users in complying with OSHAcodes. When ordering with crane, they will be completelyinstalled inside of electrical enclosures.

Electrical service is to be connected to the crane equipped withfuse panels and mainline disconnect panels as shown in theproper wiring diagram. Wiring diagrams are in Part No. 113533-83, Wiring Diagrams for Bridge Control Panels.

LUBRICATION

1. Wheel bearings are permanently lubricated and require noadditional lubricant.

2. Drive wheel gears are to be lubricated with an open type geargrease which is heavy, plastic, extreme pressure and tacky;such as MOBILTAC 375 NC or equal.

3. The gear case lubricant should be changed every year or2000 hours of service for moderate usage. The lubricant shouldbe changed more frequently if the service is more severe. Use17 oz. of AGMA lubricant number 5, compounded, (Mobilgear630) if the ambient temperature is 15° to 60°F or AGMA lubricantnumber 7, compounded, (Mobilgear 634) if the ambient tem-perature is 50° to 125°F.

4. It is recommended that the areas of the cross shaft coveredby bearing and couplings be coated with FEL-PRO C5-A, orequal, anti-seize lubricant.

Before crane operation the vent plug must be in the properlocation in the gear case. The vent plug replaces the pipe plugin the highest location on the end of the gear case. See Part No.113533-82, Operating Instructions and Parts List, Drive GearCase, included with drive.

BRAKE

A separate piece of literature in the literature package coversparts and adjustment of the brake.

OPERATION

Prior to placing the crane into service, OSHA requires that theuser perform and record certain tests including proof loading thecrane. Refer to ANSI B30.17-latest edition for information con-cerning these requirements.

SPECIFICATIONS

Specifications may be purchased from:

Specification Address

AGMA American Gear ManufacturersAssociation1500 King Street, Suite 201Alexandria, VA 22314-2730

ANSI American National StandardsInstitute11 W. 42nd Street, 13th FloorNew York, NY 10036

ASCE American Society of Civil Engineers1801 Alexander Bell DriveReston, VA 20191-4400

ASTM American Society for Testing andMaterials100 Barr Harbor DriveWest Conshohocken, PA 19428-2959

AWS American Welding Society550 N. W. LeJune RoadMiami, FL 33126

CMAA Material Handling Industry8720 Red Oak Blvd., Suite 201Charlotte, NC 28217-3992(CMAA is Crane ManufacturersAssociation of America, Inc.)

NFPA National Fire Protection Association11 Tracy DriveAvon, MA 02322-9908

OSHA Superintendent of DocumentsU.S. Government Printing OfficeWashington, DC 20402(OSHA is Title 29 CFR Parts 1901.1 to1910.999)

Power supply must be same voltage, frequency andphase as specified on crane motor nameplate.

CAUTION

15

End Truck Assembly(One Right and One Left Hand Truck)

RatedLoad

Range(tonnes)

ForSpansThru(ft) Catalog Number

WheelBase

WheelDia.(in)

Min.Rail

(#/yd.)

1 thru 5364860

TRFA0604.5AR2TRFA0606.0AR2TRFA0607.5AR2

4’ - 6"6’ - 0"7’ - 6"

666

252525

5 thru 10364860

TRFA0804.5AR3TRFA0806.0AR3TRFA0807.5AR3

4’ - 6"6’ - 0"7’ - 6"

888

303030

5 thru 10364860

TRFA0804.5BR3TRFA0806.0BR3TRFA0807.5BR3

4’ - 6"6’ - 0"7’ - 6"

888

606060

10 thru 15

36486060

TRFA1004.5BR3TRFA1006.0BR3TRFA1007.5BR3*TRFA1007.5BR4

4’ - 6"6’ - 0"7’ - 6"7’ - 6"

10101010

60606060

RatedLoad

Range(tonnes)

ForSpansThru(ft)

Cross ShaftBearing Assembly

Cross ShaftCoupling

HandChainWheel

and Guide- 1 Ass’y.

Req’d.

HandChainwith

OpenLink(36

Feet)NumberReq’d.

CatalogNumber

NumberReq’d

CatalogNumber

1 thru 10

12222836425260

1234567

904625

2233444

8280 913115 8282

10 thru 15

12222836425260

1234567

904625

2233444

8280 332189-3 8282

THESE TRUCKS ARE COMMON TO ALL BRIDGES HAND GEARED BRIDGE COMPONENTS

MATERIAL LISTED BELOW IS REQUIRED TO BUILD THESE BRIDGE CRANES

*Bumpers are larger than standard (3.2" diameter).

Bumpers and rail sweeps are standard.

The wheelbase of the end truck shall be 1/8 of the span orgreater - per CMAA 74.

1 End Truck Assembly - See Truck Chart.1 Hand Geared Drive Adapter Assemblies Per Truck

(2 Req'd. per Crane): Catalog Number 232342-6

CATALOG NUMBERS REQUIRED FOR OPTIONAL EQUIPMENT

*12 Conductor - Flat Cable (#14-4C & #16-8C)#14 Power Cable Good for 10 HP @ 460V or 5 HP @ 230V (20 Amps).

Festoon Systems Main Collectors

DescriptionCatalogNumber

Collector Pole & Bracket 901590

30A Main Collectors Short Arm Long Arm

931077931078

100A Main Collectors Short Arm Long Arm

931099931080

Catalog Number for Bolted Bridge End Connection: 444697-10

90A Insulated Figure 8 Runway Conductors.

Description

Catalog Numbers for Span of

50’ 60’ 70’ 80’ 90’ 100’ 150’ 200’

Crane Runway Kit 931119 931120 931121 931122 931123 931124 931125 931126

Description

Catalog Numbers for Span of

50’ 60’ 70’ 80’ 90’ 100’ 150’ 200’

Crane Runway Kit 931119 931120 931121 931122 931123 931124 931125 931126

16

Total HP 200V 230V 460V 575V Total HP 200V 230V 460V 575V

1 Speed Control - without Soft Start 1 Speed Control - with Soft Start

1235

7.510

444231-11444231-12444231-13444231-15444231-17444231-19

444231-21444231-22444231-23444231-25444231-27444231-29

444231-41444231-42444231-43444231-45444231-47444231-49

444231-51444231-52444231-53444231-55444231-57444231-59

1235

7.510

444711-11444711-12444711-13444711-15

NANA

444711-21444711-22444711-23444711-25

NANA

444711-41444711-42444711-43444711-45444711-47444711-49

444711-51444711-52444711-53444711-55444711-57444711-59

2 Speed Control - without Soft Start 2 Speed Control - with Soft Start

1235

7.510

444232-11444232-12444232-13444232-15444232-17444232-19

444232-21444232-22444232-23444232-25444232-27444232-29

444232-41444232-42444232-43444232-45444232-47444232-49

444232-51444232-52444232-53444232-55444232-57444232-59

1235

7.510

444712-11444712-12444712-13444712-15

NANA

444712-21444712-22444712-23444712-25

NANA

444712-41444712-42444712-43444712-45444712-47444712-49

444712-51444712-52444712-53444712-55444712-57444712-59

TotalHP

200V 230V 460V 575V

Control D.B.R. Control D.B.R. Control D.B.R. Control D.B.R.

Variable Frequency Control

1235

7.510

448550-11448550-12448550-13448550-15448550-17448550-19

448491-31448491-32448491-33448491-34444946-64444946-65

448550-21448550-22448550-23448550-25448550-27448550-29

448491-31448491-32448491-33448491-34444946-64444946-65

448550-42448550-42448550-43448550-45448550-47448550-49

448491-62448491-62448491-63448491-64444946-79444946-80

445351-52445351-52445351-53445351-55445351-57445351-59

444946-E1444946-E1444946-E2444946-E3444946-E4444946-E5

MotorHP

MotorRPM

200V, 3Ph, 60Hz 230V, 3Ph, 60Hz 460V, 3Ph, 60Hz 575V, 3Ph, 60Hz

MotorCat No.

BrakeCat No.

MotorCat No.

BrakeCat No.

MotorCat No.

BrakeCat No.

MotorCat No.

BrakeCat No.

.5/.25.75/.38

1/.5

1200/6001200/6001200/600

331982-56331982-76331982-41

108461-F1913314913314

331982-57331982-77331982-42

108461-F1913314913314

331982-58331982-78331982-43

108461-F1913314913314

331982-59331982-79331982-44

108461-F2913315913315

.5/.17.75/.25

1/.331.5/.52/.67

3/1

1800/6001800/6001800/6001800/6001800/6001800/600

331982-51331982-71331982-01330031-11330031-21330031-31

108461-F1108461-F1108461-F1

913314913316913316

331982-52331982-72331982-02330031-12330031-22330031-32

108461-F1108461-F1108461-F1

913314913316913316

331982-53331982-73331982-03330031-13330031-23330031-33

108461-F1108461-F1108461-F1

913314913316913316

331982-54331982-74331982-04330031-14330031-24330031-34

108461-F2108461-F2108461-F2

913315913317913317

TraverseGear Case

Cat. No.GearRatio

BridgeFPM with1200 RPM

Motor

BridgeFPM with1800 RPM

Motor

444689-1444689-2444689-3444689-4

13.048.966.976.08

50Not UsedNot UsedNot Used

75100125150

MotorHP

MotorRPM

200V, 3Ph, 60Hz 230/460V, 3Ph, 60Hz 575V, 3Ph, 60Hz

MotorCat. No.

BrakeCat. No.

MotorCat. No.

BrakeCat. No.

MotorCat. No.

BrakeCat. No.

1/23/41

120012001200

331981-57331981-77331981-42

108461-F1913314913314

331981-58331981-78331981-43

108461-F1913314913314

331981-59331981-79331981-44

108461-F2913315913315

1/23/41

1-1/223

180018001800180018001800

331981-52331981-72331981-02329925-11329925-21329925-31

108461-F1108461-F1108461-F1

913314913316913316

331981-53331981-73331981-03329925-11329925-21329925-31

108461-F1108461-F1108461-F1

913314913316913316

331981-54331981-74331981-04329925-12329925-22329925-32

108461-F2108461-F2108461-F2

913315913317913317

MATERIAL LISTED BELOW IS REQUIRED TO BUILD THESE BRIDGE CRANES

INDIVIDUAL DRIVE - MOTOR DRIVEN BRIDGE COMPONENTS

Controls (All 3Ph, 60Hz) (NA = Not Available or Not Applicable)

1 Speed - VFC Motors Traverse Gear Cases

2 Speed Motors

17

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

2 Ton Rated Load

101214161820

10X 25.412X 31.812X 31.812X 35.012X 40.812X 40.8

10X 25.410X 25.410X 25.410X 25.412X 31.812X 31.8

7X 9.87X 9.87X 9.8

8X 11.58X 11.58X 11.5

10X 2610X 2610X 3010X 3010X 3012X 35

12X 2212X 2212X 2212X 2210X 2616X 36

7X 9.87X 9.87X 9.87X 9.8

9X 13.410X 15.3

2224262830

12X 50.0— —— —— —— —

12X 31.812X 31.812X 31.812X 40.812X 40.8

8X 11.58X 11.59X 13.4

7X 9.87X 9.8

14X 3810X 3912X 4012X 4514X 48

16X 3616X 3616X 3616X 3616X 36

10X 15.310X 15.310X 15.310X 15.312X 20.7

3234363840

— —— —— —— —— —

12X 40.815X 42.915X 42.915X 42.915X 42.9

9X 13.48X 11.59X 13.49X 13.4

10X 15.3

12X 5012X 5314X 6114X 6116X 67

12X 4012X 4014X 4314X 4318X 50

12X 20.712X 20.712X 20.712X 20.710X 15.3

4244464850

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

18X 76— —— —— —— —

18X 5018X 5016X 5018X 5018X 50

10X 15.310X 15.312X 20.712X 20.712X 20.7

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

21X 6221X 6221X 6821X 6221X 62

12X 20.712X 20.712X 20.715X 33.915X 33.9

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

3 TON RATED LOAD

101214161820

12X 40.812X 40.812X 40.818X 54.718X 54.720X 66.0

12X 31.812X 40.812X 40.812X 40.812X 40.812X 40.8

8X 11.57X 9.87X 9.87X 9.87X 9.87X 9.8

12X 3512X 3516X 4014X 4314X 4814X 48

10X 3910X 3910X 3910X 3912X 4014X 43

12X 20.712X 20.712X 20.712X 20.712X 20.712X 20.7

2224262830

20X 66.024X 80.024X 80.020X 86.020X 96.0

12X 40.812X 40.818X 54.718X 54.718X 54.7

9X 13.412X 20.79X 13.49X 13.49X 13.4

14X 4812X 5014X 5312X 5812X 58

14X 4318X 5018X 5018X 5018X 50

12X 20.710X 15.310X 15.310X 15.310X 15.3

3234363840

— —— —— —— —— —

18X 54.718X 54.718X 54.718X 54.720X 66.0

9X 13.49X 13.4

12X 20.712X 20.712X 20.7

14X 6116X 6714X 6814X 7416X 89

18X 5016X 5016X 5016X 5016X 57

10X 15.312X 20.712X 20.712X 20.712X 20.7

4244464850

— —— —— —— —— —

20X 66.020X 66.020X 66.020X 66.020X 66.0

12X 20.712X 20.712X 20.715X 33.915X 33.9

16X 89— —— —— —— —

16X 5718X 6018X 6021X 6221X 68

12X 20.712X 20.712X 20.712X 20.712X 20.7

5254565860

— —— —— —— —— —

20X 66.024X 80.024X 80.024X 80.024X 80.0

15X 33.915X 33.915X 33.915X 33.915X 33.9

— —— —— —— —— —

21X 6221X 6821X 6821X 7324X 76

15X 33.915X 33.915X 33.915X 33.915X 33.9

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

1 TON RATED LOAD

101214161820

7X 15.38X 18.48X 18.4

10X 25.410X 25.412X 31.8

7X 15.37X 15.37X 15.37X 15.38X 18.48X 18.4

6X 8.26X 8.26X 8.26X 8.27X 9.87X 9.8

8X 188X 188X 218X 218X 218X 24

8X 158X 158X 158X 188X 18

12X 22

7X 9.87X 9.87X 9.8

8X 11.58X 11.57X 9.8

2224262830

12X 40.812X 40.812X 40.8

— —— —

8X 18.410X 25.410X 25.410X 25.412X 31.8

10X 15.37X 9.87X 9.87X 9.8

8X 11.5

8X 2810X 3010X 3310X 3310X 39

12X 2212X 2212X 2212X 2212X 22

7X 9.87X 9.87X 9.87X 9.87X 9.8

3234363840

— —— —— —— —— —

12X 31.812X 31.812X 31.812X 40.815X 42.9

8X 11.58X 11.58X 11.5

7X 9.88X 11.5

12X 4012X 4512X 4512X 5014X 53

12X 2212X 2612X 2614X 3014X 30

7X 9.810X 15.310X 15.39X 13.49X 13.4

4244464850

— —— —— —— —— —

15X 42.915X 42.915X 42.915X 42.9

— —

8X 11.5 9X 13.4 9X 13.412X 20.7

— —

— —— —— —— —— —

14X 3016X 3616X 3616X 3618X 50

12X 20.710X 15.310X 15.310X 15.310X 15.3

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

18X 5018X 5018X 5018X 5021X 62

10X 15.310X 15.312X 20.712X 20.712X 20.7

BEAM SIZE SELECTION FOR VARIOUS SPANS

ENGLISH MEASURE (TONS) - MOTOR DRIVEN BRIDGE

1. Section designation is in accordance with AISC.

2. Beam sizes listed are American standard (S) beams, wideflange (W) and channel (C) sections.

3. Use ASTM A 36 grade steel, first quality, free of rust andexcessive mill scale.

4. The bridge is designed in accordance with CMAASpecification 74, revised 1994 and is based on thefollowing assumptions:

Hoist + * AllowableRated Trolley Wheel Allowable FlangeLoad Dead Load Diameter Flange Width Thickness1 Ton 500# 4" 9-1/8" 11/16"

2 500 4 11-1/4 11/163 800 4 11 15/165 1100 6-1/2 11 1-5/32

7-1/2 1200 6-1/2 11 1-5/3210 2500 8 13-3/4 1-1/215 3200 8 13-3/4 1-1/2

*LTI four wheel trolleys (one per hoist) with the wheelsequally loaded.Tons are short tons.DLFB, DLFT and HLF are assumed to be 1.1, 1.1 and .15respectively.IFD is assumed to be .1.Assumed additional dead load (for cross conductors) is6 #/'.The bridge is assumed to be an indoor bridge.

5. If any of the above assumptions are exceeded contact thefactory for beam selection.

6. No additional loading such as footwalks, platforms, cabs,machinery, etc., is allowed.

7. Beam substitution is allowed by going to an increasedspan, but not by going to an increased load.

18

ENGLISH MEASURE (TONS) - MOTOR DRIVEN BRIDGE

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

5 TON RATED LOAD

101214161820

18X 54.718X 54.720X 66.020X 66.020X 66.024X 80.0

12X 40.812X 40.812X 40.818X 54.718X 54.718X 54.7

7X 9.88X 11.5

12X 20.79X 13.49X 13.4

10X 15.3

16X 5016X 5014X 5316X 5716X 5718X 65

18X 5018X 5012X 5016X 5016X 5024X 62

10X 15.310X 15.312X 20.712X 20.712X 20.710X 15.3

2224262830

20X 86.020X 86.024X106.024X106.024X106.0

18X 54.720X 66.020X 66.020X 66.020X 66.0

12X 20.79X 13.49X 13.49X 13.49X 13.4

18X 6518X 7114X 7416X 7714X 82

16X 5716X 5716X 5718X 6018X 65

12X 20.712X 20.712X 20.712X 20.712X 20.7

3234363840

— —— —— —— —— —

20X 66.020X 66.020X 66.020X 66.024X 80.0

10X 15.312X 20.715X 33.915X 33.912X 20.7

14X 8216X 8916X 89

16X 10016X 100

18X 6518X 7118X 7118X 7121X 83

12X 20.712X 20.712X 20.712X 20.712X 20.7

4244464850

— —— —— —— —— —

24X 80.024X 80.024X 80.024X 80.024X 80.0

15X 33.915X 33.915X 33.915X 33.915X 33.9

— —— —— —— —— —

21X 8321X 8321X 9321X 8321X 83

12X 20.712X 20.712X 20.715X 33.915X 33.9

5254565860

— —— —— —— —— —

24X 80.024X 90.024X106.024X106.024X106.0

15X 33.915X 40.015X 33.915X 33.915X 40.0

— —— —— —— —— —

21X 8324X 8424X 9424X 9424X 94

18X 42.718X 42.715X 33.915X 33.918X 42.7

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

10 TON RATED LOAD

101214161820

24X 80.020X 86.0

24X 106.024X 106.024X 106.024X 106.0

20X 66.020X 66.024X 80.024X 80.024X 80.024X 90.0

9X 13.410X 15.310X 15.310X 15.312X 20.712X 20.7

21X 8316X 8921X 93

16X 10016X 10018X 119

18X 7121X 8321X 8321X 9321X 9321X 93

12X 20.712X 20.712X 20.712X 20.712X 20.712X 20.7

2224262830

24X 121.0— —— —— —— —

24X 80.024X 90.0

24X 106.024X 106.024X 106.0

15X 33.915X 33.912X 20.712X 20.712X 20.7

18X 11918X 11924X 13121X 13233X 141

21X 9321X 9321X 93

27X 11427X 114

15X 33.915X 33.918X 51.915X 33.915X 33.9

3234363840

— —— —— —— —— —

24X 106.024X 106.024X 106.024X 106.024X 121.0

12X 20.715X 33.915X 33.915X 40.015X 40.0

24X 14624X 14624X 14624X 14624X 162

27X 11427X 11430X 13230X 13230X 132

18X 42.718X 42.715X 33.915X 33.915X 33.9

4244464850

— —— —— —— —— —

24X 121.0— —— —— —— —

18X 42.7— —— —— —— —

24X 162— —— —— —— —

30X 13230X 13224X 14624X 14624X 162

18X 42.718X 42.718X 42.718X 51.918X 42.7

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

24X 16224X 16224X 16236X 17036X 170

18X 42.718X 42.718X 42.718X 42.718X 51.9

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

7½ TON RATED LOAD

101214161820

20X 75.024X 80.024X 80.020X 86.0

24X 106.024X 106.0

20X 66.020X 66.020X 66.020X 66.020X 66.024X 80.0

9X 13.49X 13.49X 13.4

10X 15.312X 20.710X 15.3

18X 6518X 7118X 7114X 8214X 8210X 88

16X 5716X 5718X 6518X 6518X 7118X 71

12X 20.712X 20.712X 20.712X 20.712X 20.712X 20.7

2224262830

24X 106.024X 106.024X 121.0

— —— —

24X 80.024X 80.024X 80.024X 80.024X 80.0

10X 15.312X 20.712X 20.715X 33.915X 33.9

16X 8921X 93

16X 10016X 10027X 114

21X 8321X 8321X 8321X 9321X 93

12X 20.712X 20.712X 20.712X 20.712X 20.7

3234363840

— —— —— —— —— —

24X 90.024X 106.024X 106.024X 106.024X 106.0

15X 33.912X 20.712X 20.712X 20.712X 20.7

30X 132— —— —— —— —

21X 9321X 9321X 9321X 9321X 93

12X 20.712X 20.715X 33.915X 33.918X 42.7

4244464850

— —— —— —— —— —

24X 106.024X 106.024X 106.024X 106.024X 106.0

15X 33.915X 33.915X 33.915X 33.915X 40.0

— —— —— —— —— —

27X 10227X 11427X 11427X 11427X 114

18X 42.715X 33.915X 33.915X 33.915X 33.9

5254565860

— —— —— —— —— —

24X 121.024X 121.024X 121.0

— —— —

15X 40.018X 42.718X 58.0

— —— —

— —— —— —— —— —

27X 11430X 12430X 13230X 12430X 132

18X 42.715X 33.915X 33.918X 42.718X 42.7

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

15 TON RATED LOAD

101214161820

24X 106.0— —— —— —— —— —

24X106.024X106.024X106.024X106.024X106.024X106.0

12X 20.712X 20.712X 20.712X 20.715X 33.915X 33.9

18X 11921X 13224X 14624X 14624X 14624X 162

18X 11918X 11918X 11930X 13230X 13224X 146

15X 33.915X 33.915X 33.915X 33.918X 42.718X 42.7

2224262830

— —— —— —— —— —

24X121.0— —— —— —— —

18X 42.7— —— —— —— —

24X 16224X 16224X 16236X 18236X 194

24X 14624X 14624X 16224X 16224X 162

18X 42.718X 58.018X 42.718X 42.718X 42.7

3234363840

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

36X 19436X 21036X 210

— —— —

24X 16224X 16236X 18236X 18236X 182

18X 42.718X 58.018X 42.718X 42.718X 42.7

4244464850

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

36X 18236X 19436X 19436X 19436X 194

18X 51.918X 42.718X 42.718X 42.718X 58.0

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

36X 21036X 21036X 21036X 210

— —

18X 42.718X 42.718X 42.718X 58.0

— —

19

BEAM SIZE SELECTION FOR VARIOUS SPANS

ENGLISH MEASURE (TONS) - HAND GEARED BRIDGE

1. Section designation is in accordance with AISC.

2. Beam sizes listed are American standard (S) beams, wideflange (W) and channel (C) sections.

3. Use ASTM A 36 grade steel, first quality, free of rust andexcessive mill scale.

4. The bridge is designed in accordance with CMAASpecification 74, revised 1994 and is based on thefollowing assumptions:

Hoist + * AllowableRated Trolley Wheel Allowable FlangeLoad Dead Load Diameter Flange Width Thickness1 Ton 500# 4" 9-1/8" 11/16"

2 500 4 11-1/4 11/163 800 4 11 15/165 1100 6-1/2 11 1-5/32

7-1/2 1200 6-1/2 11 1-5/3210 2500 8 13-3/4 1-1/215 3200 8 13-3/4 1-1/2

*LTI four wheel trolleys (one per hoist) with the wheelsequally loaded.Tons are short tons.DLFB, DLFT and HLF are assumed to be 1.1, 1.1 and .15respectively.IFD is assumed to be 0.Assumed additional dead load (for cross conductors andcross shaft) is 13 #/'.The bridge is assumed to be an indoor bridge.

5. If any of the above assumptions are exceeded contact thefactory for beam selection.

6. No additional loading such as footwalks, platforms, cabs,machinery, etc., is allowed.

7. Beam substitution is allowed by going to an increasedspan, but not by going to an increased load.

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

1 TON RATED LOAD

101214161820

7X 15.37X 15.37X 15.38X 18.48X 23.0

10X 25.4

7X 15.37X 15.37X 15.37X 15.38X 18.48X 18.4

6X 8.26X 8.26X 8.26X 8.27X 9.87X 9.8

8X 158X 158X 158X 188X 188X 21

8X 158X 158X 158X 158X 18

12X 22

7X 9.87X 9.87X 9.87X 9.8

8X 11.57X 9.8

2224262830

10X 25.412X 31.812X 31.812X 35.012X 40.8

10X 25.410X 25.410X 25.410X 25.412X 31.8

7X 9.87X 9.87X 9.87X 9.8

8X 11.5

10X 2610X 2610X 3010X 3014X 34

12X 2212X 2212X 2212X 2212X 22

7X 9.87X 9.87X 9.87X 9.87X 9.8

3234363840

12X 40.8 15X 42.9

— —— —— —

12X 31.812X 31.812X 31.812X 40.815X 42.9

8X 11.58X 11.59X 13.49X 13.48X 11.5

12X 3514X 3812X 4014X 4314X 48

12X 2212X 2614X 3014X 3014X 30

7X 9.89X 13.49X 13.49X 13.49X 13.4

4244464850

— —— —— —— —— —

15X 42.9 15X 42.9 15X 42.9

— —— —

8X 11.5 8X 11.5 8X 11.5

— —— —

14X 4814X 5321X 6221X 6824X 76

16X 3616X 3616X 3616X 3618X 50

10X 15.310X 15.310X 15.312X 20.710X 15.3

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

24X 76— —— —— —— —

18X 5018X 5018X 5024X 6224X 62

10X 15.310X 15.310X 15.310X 15.310X 15.3

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

2 TON RATED LOAD

101214161820

10X 25.410X 25.410X 25.410X 25.412X 31.812X 31.8

10X 25.410X 25.410X 25.410X 25.410X 25.412X 31.8

7X 9.87X 9.87X 9.87X 9.87X 9.8

8X 11.5

10X 1912X 2212X 2210X 2610X 2610X 30

12X 2212X 2212X 2212X 2212X 2210X 26

7X 9.87X 9.87X 9.87X 9.87X 9.8

9X 13.4

2224262830

12X 35.0 12X 40.8 12X 40.8 12X 50.0

— —

12X 31.812X 31.812X 31.812X 31.812X 40.8

8X 11.58X 11.58X 11.58X 11.57X 9.8

10X 3014X 3412X 3512X 4012X 40

16X 3616X 3616X 3616X 3616X 36

10X 15.310X 15.310X 15.310X 15.310X 15.3

3234363840

— —— —— —— —— —

15X 42.915X 42.915X 42.915X 42.915X 50.0

8X 11.58X 11.58X 11.58X 11.59X 13.4

14X 4314X 4814X 5314X 6114X 61

16X 3612X 4014X 4314X 4318X 50

10X 15.312X 20.712X 20.712X 20.710X 15.3

4244464850

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

16X 6716X 6716X 6718X 7618X 76

18X 5018X 5018X 5018X 5018X 50

10X 15.310X 15.310X 15.310X 15.312X 20.7

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

24X 6224X 6221X 6221X 6224X 62

10X 15.310X 15.312X 20.712X 20.712X 20.7

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

3 TON RATED LOAD

101214161820

12X 31.812X 35.012X 40.812X 40.812X 40.812X 40.8

12X 31.812X 31.812X 40.812X 40.812X 40.812X 40.8

8X 11.58X 11.5

7X 9.87X 9.87X 9.87X 9.8

10X 3010X 3012X 3512X 3512X 3514X 38

10X 3910X 3910X 3910X 3912X 4014X 43

12X 20.712X 20.712X 20.712X 20.712X 20.712X 20.7

2224262830

12X 40.812X 50.018X 54.720X 66.020X 66.0

12X 40.812X 40.815X 42.915X 50.018X 54.7

7X 9.87X 9.8

8X 11.58X 11.59X 13.4

16X 4014X 4312X 4514X 4814X 48

14X 4314X 4318X 5018X 5018X 50

12X 20.712X 20.710X 15.310X 15.310X 15.3

3234363840

20X 66.024X 80.024X 80.024X 80.020X 86.0

18X 54.718X 54.718X 54.718X 54.718X 54.7

9X 13.49X 13.49X 13.49X 13.49X 13.4

14X 5314X 6118X 6516X 6716X 67

18X 5018X 5018X 5018X 5018X 50

10X 15.310X 15.310X 15.310X 15.310X 15.3

4244464850

— —— —— —— —— —

18X 54.718X 54.720X 66.020X 66.020X 66.0

9X 13.412X 20.7

9X 13.49X 13.4

10X 15.3

16X 7716X 8916X 89

27X 10227X 114

24X 6224X 6224X 6224X 6221X 62

10X 15.310X 15.310X 15.310X 15.312X 20.7

5254565860

— —— —— —— —— —

24X 80.024X 80.024X 80.024X 80.024X 80.0

10X 15.310X 15.310X 15.312X 20.712X 20.7

27X 114 27X 114 30X 124

— —— —

21X 6224X 6224X 6824X 6824X 68

12X 20.712X 20.712X 20.712X 20.712X 20.7

20

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

5 TON RATED LOAD

101214161820

12X 40.812X 40.815X 42.918X 54.718X 54.718X 54.7

12X 40.812X 40.812X 40.812X 50.018X 54.718X 54.7

7X 9.87X 9.87X 9.8

8X 11.59X 13.49X 13.4

10X 4516X 4518X 4618X 4618X 4616X 50

18X 5018X 5018X 5018X 5016X 5016X 50

10X 15.310X 15.310X 15.310X 15.312X 20.712X 20.7

2224262830

18X 54.720X 66.020X 66.024X 80.024X 80.0

18X 54.718X 54.718X 54.720X 66.020X 66.0

9X 13.49X 13.49X 13.49X 13.49X 13.4

18X 5516X 5716X 5718X 6514X 68

24X 6224X 6224X 6216X 5716X 57

10X 15.310X 15.310X 15.312X 20.712X 20.7

3234363840

24X 80.020X 96.0

24X 106.024X 106.024X 106.0

20X 66.020X 66.020X 66.020X 66.020X 66.0

9X 13.49X 13.49X 13.49X 13.49X 13.4

24X 7616X 7716X 7716X 8924X 94

18X 6018X 6518X 6518X 6518X 71

12X 20.712X 20.712X 20.712X 20.712X 20.7

4244464850

24X 106.0— —— —— —— —

20X 66.024X 80.024X 80.024X 80.024X 80.0

10X 15.310X 15.310X 15.310X 15.312X 20.7

27X 10227X 11427X 11430X 12430X 132

18X 7121X 7321X 7321X 8321X 83

12X 20.712X 20.712X 20.712X 20.712X 20.7

5254565860

— —— —— —— —— —

24X 80.024X 90.024X 80.0

24X 106.024X 106.0

12X 20.712X 20.715X 33.912X 20.712X 20.7

— —— —— —— —— —

24X 8424X 8424X 8424X 9424X 94

12X 20.712X 20.712X 20.712X 20.715X 33.9

ENGLISH MEASURE (TONS) - HAND GEARED BRIDGE

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

10 TON RATED LOAD

101214161820

20X 66.020X 66.020X 66.020X 75.024X 80.024X 80.0

20X 66.020X 66.020X 66.020X 66.024X 80.024X 80.0

9X 13.49X 13.49X 13.49X 13.4

10X 15.310X 15.3

18X 7118X 7121X 8321X 8321X 9321X 93

18X 7118X 7121X 8321X 8321X 8321X 93

12X 20.712X 20.712X 20.712X 20.712X 20.712X 20.7

2224262830

24X 80.020X 86.0

24X 106.024X 106.024X 106.0

24X 80.024X 80.024X 80.0

24X 100.024X 106.0

10X 15.310X 15.312X 20.710X 15.312X 20.7

21X 9321X 9321X 93

27X 11427X 114

21X 9321X 9321X 9321X 93

27X 114

12X 20.712X 20.712X 20.712X 20.715X 33.9

3234363840

24X 121.0— —— —— —— —

24X 106.024X 106.024X 106.024X 106.024X 106.0

12X 20.712X 20.712X 20.712X 20.712X 20.7

27X 11427X 11418X 11924X 13124X 131

27X 11427X 11427X 11427X 11427X 114

15X 33.915X 33.915X 33.915X 33.918X 42.7

4244464850

— —— —— —— —— —

24X 106.024X 106.024X 121.024X 121.0

— —

12X 20.712X 20.712X 20.715X 40.0

— —

21X 13224X 14624X 14624X 14624X 162

30X 12430X 12430X 13230X 13230X 132

15X 33.915X 33.915X 33.915X 33.915X 33.9

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

24X 16236X 21036X 210

— —— —

30X 13230X 13233X 14136X 15036X 170

15X 33.915X 33.915X 33.918X 42.718X 42.7

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

7½ TON RATED LOAD

101214161820

20X 66.020X 66.020X 66.020X 66.020X 66.020X 66.0

20X 66.020X 66.020X 66.020X 66.020X 66.020X 66.0

9X 13.49X 13.49X 13.49X 13.49X 13.49X 13.4

16X 5716X 5718X 6518X 6518X 6518X 71

16X 5716X 5716X 5718X 6518X 6518X 65

12X 20.712X 20.712X 20.712X 20.712X 20.712X 20.7

2224262830

24X 80.024X 80.024X 80.020X 86.0

24X 106.0

20X 66.024X 80.024X 80.024X 80.024X 80.0

9X 13.410X 15.310X 15.310X 15.310X 15.3

18X 7118X 7121X 8321X 8321X 83

18X 7118X 7118X 7121X 8321X 83

12X 20.712X 20.712X 20.712X 20.712X 20.7

3234363840

24X 106.024X 106.024X 106.0

— —— —

24X 80.024X 80.024X 90.0

24X 106.024X 106.0

10X 15.310X 15.310X 15.312X 20.712X 20.7

21X 9324X 94

27X 10227X 11427X 114

21X 8321X 8321X 9321X 9321X 93

12X 20.712X 20.712X 20.712X 20.712X 20.7

4244464850

— —— —— —— —— —

24X 106.024X 106.024X 106.024X 106.024X 106.0

12X 20.712X 20.712X 20.712X 20.712X 20.7

30X 13230X 132

— —— —— —

21X 9321X 9324X 94

27X 10227X 114

12X 20.712X 20.712X 20.715X 33.915X 33.9

5254565860

— —— —— —— —— —

24X 106.024X 106.024X 106.024X 121.0

— —

12X 20.715X 33.915X 50.018X 58.0

— —

— —— —— —— —— —

27X 11427X 11427X 11427X 11427X 114

15X 33.915X 33.915X 33.915X 33.915X 33.9

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

15 TON RATED LOAD

101214161820

20X 96.024X 106.024X 106.024X 106.024X 106.024X 106.0

24X 106.024X 106.024X 106.024X 106.024X 106.024X 106.0

12X 20.712X 20.712X 20.712X 20.712X 20.712X 20.7

18X 11918X 11918X 11918X 11921X 13230X 132

16X 10027X 11418X 11918X 11930X 13230X 132

15X 33.915X 33.915X 33.915X 33.915X 33.915X 33.9

2224262830

24X 106.0— —— —— —— —

24X 106.024X 106.024X 121.0

— —— —

12X 20.712X 20.715X 33.9

— —— —

30X 13224X 14624X 14621X 14736X 160

30X 13224X 14624X 14624X 14624X 162

15X 33.918X 42.718X 42.718X 42.718X 42.7

3234363840

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

24X 16224X 16224X 16224X 16236X 170

24X 16224X 16224X 16224X 16224X 162

18X 42.718X 42.718X 42.718X 42.718X 42.7

4244464850

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

36X 18236X 19436X 19436X 210

— —

36X 17036X 17036X 18236X 18236X 182

18X 42.718X 42.718X 42.718X 42.718X 42.7

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

36X 18236X 18236X 18236X 19436X 194

18X 42.718X 42.718X 51.918X 42.718X 42.7

21

BEAM SIZE SELECTION FOR VARIOUS SPANS

METRIC MEASURE (TONNES) - MOTOR DRIVEN BRIDGE

1. Section designation is in accordance with AISC.

2. Beam sizes listed are American standard (S) beams, wideflange (W) and channel (C) sections.

3. Use ASTM A 36 grade steel, first quality, free of rust andexcessive mill scale.

4. The bridge is designed in accordance with CMAASpecification 74, revised 1994 and is based on thefollowing assumptions:

Hoist + * AllowableRated Trolley Wheel Allowable FlangeLoad Dead Load Diameter Flange Width Thickness1 Tonne 227kg 4" 9-1/8" 11/16"

2 227 4 11-1/4 11/163 363 4 11 15/165 499 6-1/2 11 1-5/32

7-1/2 544 6-1/2 11 1-5/3210 1134 8 13-3/4 1-1/215 1451 8 13-3/4 1-1/2

*LTI four wheel trolleys (one per hoist) with the wheelsequally loaded.DLFB, DLFT and HLF are assumed to be 1.1, 1.1 and .15respectively.IFD is assumed to be .1.Assumed additional dead load (for cross conductors) is2.72 kg/'.The bridge is assumed to be an indoor bridge.

5. If any of the above assumptions are exceeded contact thefactory for beam selection.

6. No additional loading such as footwalks, platforms, cabs,machinery, etc., is allowed.

7. Beam substitution is allowed by going to an increasedspan, but not by going to an increased load.

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

1 TONNE RATED LOAD

101214161820

8X 18.48X 18.48X 23.0

10X 25.412X 31.812X 31.8

7X 15.37X 15.37X 15.38X 18.48X 18.48X 18.4

6X 8.26X 8.26X 8.27X 9.87X 9.87X 9.8

8X 218X 218X 218X 218X 248X 24

8X 158X 158X 188X 18

12X 2212X 22

7X 9.87X 9.8

8X 11.58X 11.5

7X 9.87X 9.8

2224262830

12X 40.812X 40.812X 50.0

— —— —

10X 25.410X 25.410X 25.410X 25.412X 31.8

7X 9.87X 9.87X 9.87X 9.8

8X 11.5

8X 2810X 3310X 3310X 3310X 39

12X 2212X 2212X 2212X 2212X 22

7X 9.87X 9.87X 9.87X 9.87X 9.8

3234363840

— —— —— —— —— —

12X 31.812X 31.812X 31.815X 42.915X 42.9

8X 11.58X 11.5

10X 15.38X 11.58X 11.5

12X 4012X 4514X 4812X 5024X 76

12X 2212X 2614X 3014X 3014X 30

8X 11.510X 15.3

9X 13.49X 13.49X 13.4

4244464850

— —— —— —— —— —

15X 42.915X 42.915X 42.9

— —— —

8X 11.5 9X 13.410X 15.3

— —— —

— —— —— —— —— —

16X 3616X 3616X 3616X 3618X 50

10X 15.310X 15.310X 15.312X 20.710X 15.3

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

18X 5018X 5018X 5021X 6221X 62

10X 15.312X 20.712X 20.712X 20.712X 20.7

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

2 TONNE RATED LOAD

101214161820

12X 31.812X 31.812X 35.012X 40.812X 40.812X 40.8

10X 25.410X 25.410X 25.412X 31.812X 31.812X 31.8

7X 9.87X 9.8

9X 13.48X 11.58X 11.58X 11.5

10X 2610X 3010X 3010X 3012X 3512X 35

12X 2212X 2212X 2210X 2616X 3616X 36

7X 9.87X 9.87X 9.8

12X 20.710X 15.310X 15.3

2224262830

— —— —— —— —— —

12X 31.812X 40.812X 40.812X 40.812X 40.8

9X 13.47X 9.87X 9.87X 9.87X 9.8

10X 3912X 4014X 4312X 4512X 50

16X 3616X 3610X 3910X 3912X 40

10X 15.310X 15.312X 20.712X 20.712X 20.7

3234363840

— —— —— —— —— —

15X 42.915X 42.915X 42.915X 42.915X 50.0

8X 11.58X 11.59X 13.4

10X 15.312X 20.7

12X 5312X 5814X 6114X 6118X 76

12X 4014X 4314X 4314X 4318X 50

12X 20.712X 20.712X 20.712X 20.710X 15.3

4244464850

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

18X 76— —— —— —— —

18X 5018X 5018X 5018X 5021X 62

10X 15.310X 15.312X 20.712X 20.712X 20.7

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

21X 6221X 6821X 6221X 6221X 62

12X 20.712X 20.715X 33.915X 33.915X 33.9

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

3 TONNE RATED LOAD

101214161820

12X 40.812X 40.818X 54.718X 54.718X 54.720X 66.0

12X 40.812X 40.812X 40.812X 40.812X 40.812X 40.8

7X 9.87X 9.87X 9.87X 9.8

8X 11.510X 15.3

12X 3518X 4010X 4510X 4514X 4814X 48

10X 3910X 3912X 4014X 4314X 4318X 50

12X 20.712X 20.712X 20.712X 20.712X 20.710X 15.3

2224262830

20X 75.024X 80.020X 86.020X 86.0

— —

18X 54.718X 54.718X 54.718X 54.718X 54.7

9X 13.49X 13.49X 13.49X 13.4

10X 15.3

12X 5014X 5314X 5314X 6114X 61

18X 5018X 5018X 5018X 5016X 50

10X 15.310X 15.310X 15.310X 15.312X 20.7

3234363840

— —— —— —— —— —

18X 54.718X 54.720X 66.020X 66.020X 66.0

12X 20.712X 20.79X 13.4

10X 15.312X 20.7

16X 6714X 6814X 7414X 8216X 89

16X 5016X 5016X 5716X 5716X 57

12X 20.712X 20.712X 20.712X 20.712X 20.7

4244464850

— —— —— —— —— —

20X 66.020X 66.020X 66.020X 66.020X 66.0

12X 20.712X 20.715X 33.915X 33.915X 33.9

16X 89— —— —— —— —

18X 6018X 6018X 6521X 6821X 68

12X 20.712X 20.712X 20.712X 20.715X 33.9

5254565860

— —— —— —— —— —

24X 80.024X 80.024X 80.024X 80.024X 80.0

15X 33.915X 33.915X 33.915X 33.915X 33.9

— —— —— —— —— —

21X 6821X 6821X 7324X 7624X 76

15X 33.915X 33.915X 33.915X 33.915X 33.9

22

METRIC MEASURE (TONNES) - MOTOR DRIVEN BRIDGE

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

5 TONNE RATED LOAD

101214161820

18X 54.720X 66.020X 66.020X 66.024X 80.024X 80.0

12X 40.818X 54.718X 54.718X 54.718X 54.720X 66.0

8X 11.59X 13.49X 13.49X 13.4

12X 20.79X 13.4

16X 5016X 5716X 5718X 6018X 6518X 65

12X 5012X 5016X 5016X 5716X 5716X 57

12X 20.712X 20.712X 20.712X 20.712X 20.712X 20.7

2224262830

20X 86.020X 96.0

24X 106.024X 106.024X 121.0

20X 66.020X 66.020X 66.020X 66.020X 66.0

9X 13.49X 13.49X 13.4

10X 15.312X20.7

18X 7114X 7414X 8214X 8216X 89

16X 5718X 6018X 6518X 6518X 71

12X 20.712X 20.712X 20.712X 20.712X 20.7

3234363840

— —— —— —— —— —

24X 80.024X 80.024X 80.024X 80.024X 80.0

10X 15.310X 15.312X 20.712X 20.715X 33.9

16X 89 16X 89 16X 100 16X 100

— —

18X 7118X 7121X 8321X 8321X 83

12X 20.712X 20.712X 20.712X 20.712X 20.7

4244464850

— —— —— —— —— —

24X 80.024X 80.024X 80.024X 80.024X 90.0

15X 33.915X 33.915X 33.915X 40.015X 40.0

— —— —— —— —— —

21X 8321X 9321X 9321X 8321X 93

12X 20.712X 20.712X 20.718X 42.715X 33.9

5254565860

— —— —— —— —— —

24X 106.024X 106.024X 106.024X 106.024X 106.0

15X 33.915X 33.915X 33.915X 40.015X 40.0

— —— —— —— —— —

21X 9324X 9424X 9424X 94

27X 102

15X 33.915X 33.915X 33.918X 42.718X 42.7

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

7½ TONNE RATED LOAD

101214161820

24X 80.024X 80.020X 86.0

24X 106.024X 106.024X 106.0

20X 66.020X 66.020X 66.024X 80.024X 80.024X 80.0

9X 13.49X 13.4

12X 20.710X 15.310X 15.312X 20.7

18X 7118X 7114X 8221X 8316X 8921X 93

18X 6518X 6518X 7118X 7121X 8321X 83

12X 20.712X 20.712X 20.712X 20.712X 20.712X 20.7

2224262830

24X 106.024X 106.0

— —— —— —

24X 80.024X 80.024X 80.0

24X 106.024X 106.0

12X 20.715X 33.915X 33.912X 20.712X 20.7

21X 9316X 10016X 10027X 11430X 132

21X 8321X 9321X 9321X 9321X 93

12X 20.712X 20.712X 20.712X 20.712X 20.7

3234363840

— —— —— —— —— —

24X 106.024X 106.024X 106.024X 106.024X 106.0

12X 20.712X 20.712X 20.712X 20.715X 33.9

— —— —— —— —— —

21X 9321X 9321X 93

27X 11427X 114

15X 33.915X 33.918X 42.715X 33.915X 33.9

4244464850

— —— —— —— —— —

24X 106.024X 106.024X 121.024X 121.024X 121.0

15X 33.915X 33.915X 33.918X 42.718X 51.9

— —— —— —— —— —

27X 11427X 11427X 11430X 12430X 132

15X 33.915X 33.918x 42.715X 33.915X 33.9

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

30X 13230X 13230X 13230X 13230X 132

15X 33.915X 33.918x 42.718x 42.718x 58.0

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

10 TONNE RATED LOAD

101214161820

20X 86.024X 106.024X 106.024X 106.024X 106.0

— —

20X 66.024X 80.024X 80.024X 80.024X 80.0

24X 106.0

12X 20.710X 15.310X 15.312X 20.715X 33.912X 20.7

21X 9321X 93

18X 11918X 11918X 11918X 119

21X 8321X 9321X 9321X 9321X 9321X 93

12X 20.712X 20.712X 20.712X 20.715X 33.915X 33.9

2224262830

— —— —— —— —— —

24X 106.024X 106.024X 106.024X 106.024X 106.0

12X 20.712X 20.712X 20.712X 20.715X 33.9

18X 11921X 13224X 14624X 14624X 146

21X 9327X 11427X 11427X 11430X 132

18X 51.915X 33.915X 33.918X 42.715X 33.9

3234363840

— —— —— —— —— —

24X 106.024X 106.024X 121.024X 121.0

— —

15X 33.915X 40.018X 42.718X 45.8

— —

24X 14624X 16224X 16224X 16224X 162

30X 13230X 13230X 13230X 13224X 146

15X 33.915X 33.915X 33.918X 42.718X 42.7

4244464850

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

24X 162— —— —— —— —

24X 14624X 16224X 16224X 16224X 162

18X 51.918X 42.718X 42.718X 42.718X 42.7

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

36X 17036X 17036X 17036X 17036X 182

18X 42.718X 42.718X 42.718X 51.918X 51.9

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

15 TONNE RATED LOAD

101214161820

— —— —— —— —— —— —

24X 106.024X 106.024X 106.024X 106.024X 121.0

— —

12X 20.712X 20.712X 20.715X 33.918X 42.7

— —

12X 13612X 13624X 14621X 14724X 16224X 162

18X 11918X 11924X 14624X 14624X 14624X 162

15X 33.918X 42.718X 42.718X 42.718X 42.718X 42.7

2224262830

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

24X 16236X 18236X 19436X 19436X 194

24X 16224X 16224X 16224X 16236X 182

18X 42.718X 42.718X 42.718X 42.718X 42.7

3234363840

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

36X 21036X 210

— —— —— —

36X 18236X 18236X 18236X 19436X 194

18X 42.718X 42.718X 51.918X 42.718X 42.7

4244464850

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

36X 19436X 19436X 21036X 21036X 210

18X 42.718X 58.018X 42.718X 42.718X 42.7

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

23

BEAM SIZE SELECTION FOR VARIOUS SPANS

METRIC MEASURE (TONNES) - HAND GEARED BRIDGE

1. Section designation is in accordance with AISC.

2. Beam sizes listed are American standard (S) beams, wideflange (W) and channel (C) sections.

3. Use ASTM A 36 grade steel, first quality, free of rust andexcessive mill scale.

4. The bridge is designed in accordance with CMAASpecification 74, revised 1994 and is based on thefollowing assumptions:

Hoist + * AllowableRated Trolley Wheel Allowable FlangeLoad Dead Load Diameter Flange Width Thickness1 Tonne 227kg 4" 9-1/8" 11/16"

2 227 4 11-1/4 11/163 363 4 11 15/165 499 6-1/2 11 1-5/32

7-1/2 544 6-1/2 11 1-5/3210 1134 8 13-3/4 1-1/215 1451 8 13-3/4 1-1/2

*LTI four wheel trolleys (one per hoist) with the wheelsequally loaded.DLFB, DLFT and HLF are assumed to be 1.1, 1.1 and .15respectively.IFD is assumed to be 0.Assumed additional dead load (for cross conductors andcross shaft) is 5.90 kg/'.The bridge is assumed to be an indoor bridge.

5. If any of the above assumptions are exceeded contact thefactory for beam selection.

6. No additional loading such as footwalks, platforms, cabs,machinery, etc., is allowed.

7. Beam substitution is allowed by going to an increasedspan, but not by going to an increased load.

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

2 TONNE RATED LOAD

101214161820

10X 25.410X 25.410X 25.412X 31.812X 31.812X 31.8

10X 25.410X 25.410X 25.412X 31.812X 31.812X 31.8

7X 9.87X 9.87X 9.8

8X 11.58X 11.58X 11.5

12X 2212X 2212X 2210X 2610X 3010X 30

12X 2212X 2212X 2212X 2216X 3616X 36

7X 9.87X 9.87X 9.87X 9.8

10X 15.310X 15.3

2224262830

12X 40.8 12X 40.8 12X 40.8

— —— —

12X 31.812X 31.812X 40.812X 40.812X 40.8

8X 11.58X 11.57X 9.87X 9.87X 9.8

10X 3012X 3514X 3812X 4014X 43

16X 3616X 3616X 3616X 3612X 40

10X 15.310X 15.310X 15.310X 15.312X 20.7

3234363840

— —— —— —— —— —

15X 42.915X 42.915X 42.915X 42.915X 50.0

8X 11.58X 11.58X 11.58X 11.5

12X 20.7

14X 4814X 4814X 5314X 6116X 67

12X 4014X 4314X 4318X 5018X 50

12X 20.712X 20.712X 20.710X 15.310X 15.3

4244464850

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

16X 67 16X 67 16X 67 18X 76

— —

18X 5018X 5018X 5018X 5024X 62

10X 15.310X 15.310X 15.310X 15.310X 15.3

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

24X 6224X 6221X 6221X 6224X 62

10X 15.310X 15.312X 20.712X 20.712X 20.7

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

1 TONNE RATED LOAD

101214161820

7X 15.37X 15.37X 15.38X 18.48X 23.0

10X 25.4

7X 15.37X 15.37X 15.37X 15.38X 18.48X 18.4

6X 8.26X 8.26X 8.27X 9.87X 9.87X 9.8

8X 158X 15

10X 178X 188X 21

10X 22

8X 158X 158X 158X 18

12X 2212X 22

7X 9.87X 9.87X 9.8

8X 11.57X 9.87X 9.8

2224262830

10X 25.412X 31.812X 31.812X 40.812X 40.8

10X 25.410X 25.410X 25.410X 25.412X 31.8

7X 9.87X 9.87X 9.8

8X 11.58X 11.5

10X 2610X 2610X 3010X 3014X 34

12X 2212X 2212X 2212X 2212X 22

7X 9.87X 9.87X 9.87X 9.87X 9.8

3234363840

12X 40.8 12X 50.0

— —— —— —

12X 31.812X 31.812X 40.815X 42.915X 42.9

8X 11.58X 11.57X 9.8

8X 11.58X 11.5

12X 3512X 4014X 4314X 4314X 48

12X 2212X 2614X 3014X 3014X 30

8X 11.59X 13.49X 13.49X 13.49X 13.4

4244464850

— —— —— —— —— —

15X 42.9 15X 42.9 15X 50.0

— —— —

8X 11.5 8X 11.5 9X 13.4

— —— —

14X 4821X 6221X 6821X 6824X 76

16X 3616X 3616X 3618X 5018X 50

10X 15.310X 15.310X 15.310X 15.310X 15.3

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

18X 5018X 5018X 5024X 6224X 62

10X 15.310X 15.312X 20.710X 15.310X 15.3

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

3 TONNE RATED LOAD

101214161820

12X 40.812X 40.812X 40.812X 40.812X 40.812X 40.8

12X 40.812X 40.812X 40.812X 40.812X 40.812X 40.8

7X 9.87X 9.87X 9.87X 9.87X 9.87X 9.8

10X 3012X 3512X 3514X 3816X 4018X 40

10X 3910X 3910X 3914X 4314X 4314X 43

12X 20.712X 20.712X 20.712X 20.712X 20.712X 20.7

2224262830

12X 50.018X 54.718X 54.720X 66.020X 66.0

12X 40.812X 50.018X 54.718X 54.718X 54.7

7X 9.88X 11.59X 13.49X 13.49X 13.4

10X 4516X 4514X 4814X 4814X 53

18X 5018X 5018X 5018X 5018X 50

10X 15.310X 15.310X 15.310X 15.310X 15.3

3234363840

20X 75.024X 80.024X 80.020X 86.020X 96.0

18X 54.718X 54.718X 54.718X 54.720X 66.0

9X 13.49X 13.49X 13.49X 13.49X 13.4

18X 6018X 6516X 6716X 6716X 77

18X 5018X 5016X 5016X 5024X 62

10X 15.310X 15.312X 20.712X 20.710X 15.3

4244464850

— —— —— —— —— —

20X 66.020X 66.020X 66.020X 66.020X 80.0

9X 13.49X 13.49X 13.49X 13.4

10X 15.3

16X 7716X 8924X 94

27X 10227X 114

24X 6224X 6224X 6221X 6221X 62

10X 15.310X 15.310X 15.312X 20.712X 20.7

5254565860

— —— —— —— —— —

24X 80.024X 80.024X 80.024X 80.024X 80.0

10X 15.310X 15.312X 20.712X 20.712X 20.7

27X 114 30X 124

— —— —— —

24X 6221X 6824X 7624X 7624X 76

12X 20.712X 20.712X 20.712X 20.712X 20.7

24

METRIC MEASURE (TONNES) - HAND GEARED BRIDGE

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

5 TONNE RATED LOAD

101214161820

12X 40.812X 50.018X 54.718X 54.718X 54.718X 54.7

12X 40.812X 40.818X 54.718X 54.718X 54.718X 54.7

7X 9.87X 9.8

9X 13.49X 13.49X 13.49X 13.4

18X 4618X 4618X 4616X 5018X 5516X 57

18X 5012X 5016X 5016X 5014X 5324X 62

10X 15.312X 20.712X 20.712X 20.712X 20.710X 15.3

2224262830

20X 66.020X 66.020X 75.024X 80.024X 80.0

18X 54.720X 66.020X 66.020X 66.020X 66.0

9X 13.49X 13.49X 13.49X 13.49X 13.4

16X 5716X 5718X 6018X 6518X 71

16X 5716X 5716X 5718X 6018X 65

12X 20.712X 20.712X 20.712X 20.712X 20.7

3234363840

20X 86.024X 106.024X 106.024X 106.024X 106.0

20X 66.020X 66.020X 66.024X 80.024X 80.0

9X 13.49X 13.49X 13.4

10X 15.310X 15.3

16X 7716X 7716X 8924X 94

16X 100

18X 6518X 6518X 7118X 7118X 71

12X 20.712X 20.712X 20.712X 20.712X 20.7

4244464850

24X 121.0— —— —— —— —

24X 80.024X 80.024X 80.024X 80.024X 80.0

10X 15.310X 15.310X 15.312X 20.712X 20.7

27X 114 27X 114 30X 124 30X 132

— —

21X 8321X 8321X 8321X 8324X 84

12X 20.712X 20.712X 20.712X 20.712X 20.7

5254565860

— —— —— —— —— —

24X 80.024X 80.0

24X 106.024X 106.024X 106.0

12X 20.715X 33.912X 20.712X 20.715X 33.9

— —— —— —— —— —

24X 8424X 9424X 9424X 94

27X 102

12X 20.712X 20.712X 20.715X 33.915X 33.9

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

10 TONNE RATED LOAD

101214161820

20X 66.020X 66.024X 80.024X 80.024X 80.024X 80.0

20X 66.020X 66.024X 80.024X 80.024X 80.024X 80.0

9X 13.49X 13.4

10X 15.310X 15.310X 15.310X 15.3

21X 8321X 8321X 9321X 9321X 9321X 93

21X 8321X 8321X 8321X 9321X 9321X 93

12X 20.712X 20.712X 20.712X 20.712X 20.712X 20.7

2224262830

24X 106.024X 106.024X 106.024X 106.024X 106.0

24X 90.024X 106.024X 106.024X 106.024X 106.0

10X 15.312X 20.712X 20.712X 20.712X 20.7

21X 9327X 11427X 11427X 11427X 114

21X 9321X 93

27X 11427X 11427X 114

12X 20.718X 42.715X 33.915X 33.915X 33.9

3234363840

— —— —— —— —— —

24X 106.024X 106.024X 106.024X 106.024X 106.0

12X 20.712X 20.712X 20.712X 20.715X 33.9

30X 12430X 12421X 13233X 14124X 146

27X 11430X 12430X 12430X 12430X 132

15X 33.915X 33.915X 33.915X 33.915X 33.9

4244464850

— —— —— —— —— —

24X 121.0— —— —— —— —

15X 33.9— —— —— —— —

24X 14624X 14624X 14624X 16224X 162

30X 13230X 13230X 13233X 14124X 146

15X 33.915X 33.915X 33.915X 33.918X 42.7

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

36X 19436X 210

— —— —— —

24X 16224X 16224X 16236X 17036X 170

18X 42.718X 42.718X 42.718X 42.718X 42.7

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

7½ TONNE RATED LOAD

101214161820

20X 66.020X 66.020X 66.020X 66.024X 80.024X 80.0

20X 66.020X 66.020X 66.020X 66.020X 66.024X 80.0

9X 13.49X 13.49X 13.49X 13.49X 13.4

10X 15.3

16X 5718X 6518X 6518X 7118X 7118X 71

16X 5718X 6518X 6518X 7118X 7118X 71

12X 20.712X 20.712X 20.712X 20.712X 20.712X 20.7

2224262830

24X 80.024X 80.024X 80.020X 96.0

24X 106.0

24X 80.024X 80.024X 80.024X 80.024X 90.0

10X 15.310X 15.310X 15.310X 15.310X 15.3

21X 8321X 8321X 8321X 8321X 93

21X 8321X 8321X 8321X 8321X 93

12X 20.712X 20.712X 20.712X 20.712X 20.7

3234363840

24X 106.024X 106.024X 121.0

— —— —

24X 106.024X 106.024X 106.024X 106.024X 106.0

12X 20.712X 20.712X 20.712X 20.712X 20.7

21X 9316X 10027X 11427X 11430X 124

21X 9321X 9321X 9321X 9324X 94

12X 20.712X 20.712X 20.712X 20.712X 20.7

4244464850

— —— —— —— —— —

24X 106.024X 106.024X 106.024X 106.024X 106.0

12X 20.712X 20.712X 20.712X 20.712X 20.7

30X 132— —— —— —— —

27X 11427X 11427X 11427X 11427X 114

15X 33.915X 33.915X 33.915X 33.915X 33.9

5254565860

— —— —— —— —— —

24X 106.024X 121.024X 121.0

— —— —

15X 33.915X 33.915X 50.0

— —— —

— —— —— —— —— —

27X 11427X 11430X 12430X 12430X 124

15X 33.915X 33.915X 33.915X 33.915X 33.9

SpanThru(ft) S

Sw/C

W

Ww/C

S C W C

15 TONNE RATED LOAD

101214161820

24X 106.024X 106.024X 106.024X 106.024X 106.0

— —

24X 106.024X 106.024X 106.024X 106.024X 106.024X 106.0

12X 20.712X 20.712X 20.712X 20.712X 20.712X 20.7

18X 11918X 11930X 13212X 13624X 14624X 146

18X 11918X 11930X 13230X 13224X 14624X 146

15X 33.915X 33.915X 33.915X 33.918X 42.718X 42.7

2224262830

— —— —— —— —— —

24X 121.0— —— —— —— —

15X 50.0— —— —— —— —

21X 14724X 16224X 16224X 16224X 162

24X 14624X 16224X 16224X 16224X 162

18X 42.718X 42.718X 42.718X 42.718X 42.7

3234363840

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

24X 16236X 17036X 18236X 18236X 182

24X 16224X 16236X 17036X 18236X 182

18X 42.718X 42.718X 42.718X 42.718X 42.7

4244464850

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

36X 18236X 19436X 210

— —— —

36X 18236X 18236X 18236X 19436X 194

18X 42.718X 42.718X 42.718X 42.718X 42.7

5254565860

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

— —— —— —— —— —

36X 19436X 19436X 19436X 21036X 210

18X 42.718X 42.718X 42.718X 42.718X 42.7

Notes

Notes

Notes

A. Seller warrants that its products and parts, when shipped, and itswork (including installation, construction and start-up), when performed,will meet applicable specifications, will be of good quality and will befree from defects in material and workmanship. All claims fordefective products or parts under this warranty must be made inwriting immediately upon discovery and, in any event, within one (1)year from shipment of the applicable item unless Seller specificallyassumes installation, construction or start-up responsibility. Allclaims for defective products or parts when Seller specifically assumesinstallation, construction or start-up responsibility, and all claims fordefective work must be made in writing immediately upon discoveryand, in any event, within one (1) year from completion of theapplicable work by Seller, provided, however, all claims for defectiveproducts and parts made in writing no later than eighteen (18) monthsafter shipment. Defective items must be held for Seller’s inspectionand returned to the original f.o.b. point upon request. THEFOREGOING IS EXPRESSLY IN LIEU OF ALL OTHERWARRANTIES WHATSOEVER, EXPRESS, IMPLIED ANDSTATUTORY, INCLUDING, WITHOUT LIMITATION, THE IMPLIEDWARRANTIES OF MERCHANTABILITY AND FITNESS.

WARRANTYWARRANTY AND LIMITATION OF REMEDY AND LIABILITY

B. Upon Buyer’s submission of a claim as provided above and itssubstantiation, Seller shall at its option either (i) repair or replace itsproduct, part or work at either the original f.o.b. point of delivery or atSeller’s authorized service station nearest Buyer or (ii) refund anequitable portion of the purchase price.

C. This warranty is contingent upon Buyer’s proper maintenance andcare of Seller’s products, and does not extend to normal wear andtear. Seller reserves the right to void warranty in event of Buyer’s useof inappropriate materials in the course of repair or maintenance, orif Seller’s products have been dismantled prior to submission to Sellerfor warranty inspection.

D. The foregoing is Seller’s only obligation and Buyer’s exclusiveremedy for breach of warranty, and is Buyer’s exclusive remedyhereunder by way of breach of contract, tort, strict liability or otherwise.In no event shall Buyer be entitled to or Seller liable for incidental orconsequential damages. Any action for breach of this agreementmust be commenced within one (1) year after the cause of action hasaccrued.

414 West Broadway AvenueP.O. Box 769

Muskegon, Michigan 49443-0769

(800) 742-9269 Phone(800) 742-9270 Fax