ASME SEC VIII D3 PART KF-10.pdf

Click here to load reader

-

Upload

nguyengiadinh1980 -

Category

Documents

-

view

226 -

download

2

Transcript of ASME SEC VIII D3 PART KF-10.pdf

ARTICLE KF-10SPECIAL REQUIREMENTS FOR HELICALLY WOUND

INTERLOCKING STRIP VESSELS

KF-1000 SCOPE

The requirements of this Article apply specificallyto pressure vessels consisting of an inner cylindricalshell (or a number of concentric shells) and a sur-rounding winding that carries a part of the end load.The vessel is fabricated by helically winding a profiled,interlocking strip over the total length of the vessel(see Fig. KF-1000). Tightness of the winding, to ensureeven distribution of the stresses, is achieved by heatingthe strip during winding or by winding under tension.

KF-1001 General Fabrication Requirements

The rules of this Article shall be used as a supplementto or in lieu of applicable requirements given in ArticlesKF-1 through KF-6. When requirements of this Articlediffer from those of Articles KF-1 through KF-6, theyare specifically delineated.

KF-1010 INNER CYLINDER ANDEXTENSIONS

The outside diameter of the inner cylinder shall beprofiled with helical grooves corresponding to thetongues of the interlocking strip. The inner cylindershall be fitted with extensions; see Fig. KF-1010, sketch(a). The start and finish of each layer of winding shallbe on these extensions. When the required number oflayers has been applied, the ends of the outer layershall be fixed and the extensions removed; see Fig.KF-1010, sketch (b). Shrink rings shall be placed overthe wrappings at each end; see Fig. KF-1010, sketches(c) and (d).

KF-1020 WINDING METHOD

The winding method specified in KF-1021 or KF-1022 shall be used. The winding tightness achievedby the following methods produces a close fit between

146

the layers. Each layer overlaps the layer underneathand the layers interlock with each other. The widthand thickness of the strip material shall be measuredto determine the thickness of the radial gap at anysection in the strip. The profile section of the stripshall be such as to limit the radial gap between adjacentlayers of the strip to 0.010 in. (0.25 mm) maximumat any location. The strip profile shall be measured atthe start of the winding and at the end of the winding.The gap between adjacent strips shall be measured oneach layer of the vessel and shall not exceed 0.030in. (0.76 mm).

KF-1021 Hot Winding

The material shall be heated to a temperature in therange from 1,560°F to 1,780°F (849°C to 971°C),followed by rapid cooling using a stream of compressedair. The heating shall be performed as part of thefabrication operation, with the heating being performedsubsequent to uncoiling the bar from a mandrel. Thecooling shall be performed as the bar is formed intoa layer of the vessel.

KF-1022 Winding Under Tension

The winding shall be performed, under tension, atatmospheric temperature to produce the required tight-ness in the layers.

KF-1030 MECHANICAL PROPERTIES OFTHE WINDING STRIP

KF-1031 Hot Wound Strip

When applying the winding in accordance with KF-1021, the material shall be tested for conformancewith the mechanical property requirements by testingspecimens obtained after heat treatment from prolonga-tions of the vessel wall. One test shall be made for

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

KF-1031 PART KF — FABRICATION REQUIREMENTS KF-1060

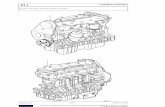

FIG. KF-1000 HELICALLY WOUND INTERLOCKING STRIP DETAILS

each vessel from each lot. A lot shall consist of notmore than 10,000 lb of material from the same heat.

KF-1032 Strip Wound Under Tension

When the winding is applied in accordance with KF-1022, the mechanical properties are not affected bythe procedure and, therefore, the samples may be takenbefore or after winding.

KF-1033 Frequency of Tests

Mechanical property tests specified in KF-1032 shallbe performed on each heat of winding strip and shallmeet the requirements of the applicable materials speci-fication.

KF-1040 BUTT WELDING OFINTERLOCKING STRIPS

When necessary to permit winding of a layer withan uninterrupted length of interlocking strip, butt welded

147

joints shall be used to join strip lengths. The weldedjoints shall be ground to reestablish the original profile.All butt welds in the outer layer and 10% of the buttwelds in inner layers shall be examined by the ultrasonicmethod in accordance with Article KE-3. All butt weldsshall be examined 100% of their length by the magneticparticle method in accordance with KE-334.

KF-1050 PROFILE OF THE WINDINGSTRIP

The winding strip shall be formed with grooves andcorresponding tongues on both sides in order to producean interlocking cylindrical wall capable of sustainingthe imposed loads. A typical pattern is illustrated inFig. KF-1000.

KF-1060 HYDROSTATIC TEST

For helically wound interlocking strip vessels, twohydrostatic tests shall be performed. The requirements

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

Fig. KF-1010 2001 SECTION VIII — DIVISION 3

FIG. KF-1010 INNER CYLINDER AND EXTENSIONS

148

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

KF-1060 PART KF — FABRICATION REQUIREMENTS KF-1063

for determining the maximum permissible elongationare as follows.

(a) During the first test, the longitudinal expansionshall be measured at design pressure, at test pressure,and again after the test pressure is reduced to designpressure. The difference in the measured lengths atdesign pressure shall not exceed 0.1% of the originallength.

(b) During the second test, the length of the vesselshall be measured at the test pressure and after thepressure has been completely released. The longitudinalcontractioneL shall not exceed the tangential contractioneT of a solid wall vessel of the same dimensions,where:

eL pL1 − L

L

eT p1.7Pt

E(Y2 − 1)

149

whereEp modulus of elasticity, psiLp final length of vessel at atmospheric pressure

after the second test, in.L1p measured length of vessel at second test pres-

sure, in.Ptp test pressure, psiYp diameter ratio (DO/DI)

eLp longitudinal contraction, in./in.eTp tangential contraction, in./in.

KF-1061 Vent Holes

Vent holes are not required in helically wound inter-locking strip construction.

KF-1062 Nozzles and Connections

Nozzles and connections are not permitted in helicallywound interlocking strip shells.

KF-1063 Supports

Supports shall only be attached to ends of theouter shell.

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services