ASME SEC VIII D3 PART KD-7.pdf

-

Upload

nguyengiadinh1980 -

Category

Documents

-

view

227 -

download

3

Transcript of ASME SEC VIII D3 PART KD-7.pdf

ARTICLE KD-7DESIGN REQUIREMENTS FOR ATTACHMENTS,

SUPPORTS, AND EXTERNAL HEATING ANDCOOLING JACKETS

KD-700 GENERAL REQUIREMENTS

The requirements of this Article are in addition tothe requirements given in Articles KD-2, KD-3, andKD-4.

(a) Supports, lugs, brackets, stiffeners, and otherattachments may be welded or bolted to the vesselwall. A detailed fatigue and fracture mechanics analysisin accordance with the requirements of Article KD-3or KD-4, as applicable, of the effect of all attachmentson the pressure boundary is required.

(b) Attachments shall approximately conform to thecurvature of the shell to which they are to be attached.

(c) Attachments may be welded to a pressure vesselonly as permitted by the rules of this Division.

(1) Resistance welded studs, clips, etc., shall notbe used.

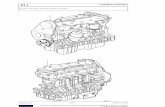

(2) Some acceptable types of welds are shown inFig. KD-700.

(3) All welds joining nonpressure parts to pressureparts shall be continuous full-penetration welds; seeKF-220(c).

(d) Attachments may be welded directly to welddeposit cladding, in which case the following require-ments shall apply.

(1) For clad construction, attachments may bemade directly to the cladding only if loadings producingprimary stresses in the attachment weld do not exceed10% of the design stress intensity value of the attach-ment or the cladding material, whichever is less. Forhigher loadings, there shall be sufficient attachmentwelding either directly to the base metal or to weldoverlay cladding to develop the strength for the primarystress loadings (portions of weld not required forstrength, e.g., for weld continuity or sealing, may bewelded directly to the cladding).

(2) For linings, attachments should be made di-rectly to the base metal or to weld overlay cladding.

71

Analysis and tests shall be made to establish theadequacy and reliability of attachment before makingany attachments directly to the lining (successful experi-ence with similar linings in comparable service mayprovide a basis for judgment).

KD-710 MATERIALS FOR ATTACHMENTS

KD-711 Attachments to Pressure Parts

Those attachments welded directly to pressure partsshall be of a material listed in Part KM. The materialand the weld metal shall be compatible with that ofthe pressure part. The designer is cautioned to considerthe effects of differences in coefficients of expansionmodulus of elasticity and yield strength between materi-als at the design temperature.

KD-712 Minor Attachments

Minor attachments are defined as parts of small size[not over 3⁄8 in. (10 mm) thick or 5 cu in. (0.82 dm3)volume] carrying no load or insignificant load requiringno load calculation in the Designer’s judgment, suchas nameplates, insulation supports, and locating lugs.

Except as limited by Parts KF or KM, where nowelding is permitted, minor attachments may be ofmaterial not listed in Section II, Part D and may bewelded directly to the pressure part provided:

(a) the material is identified as complying with anASTM specification and is suitable for welding;

(b) the material of the attachment and the pressurepart are compatible insofar as welding is concerned;

(c) the welds are postweld heat treated when requiredin Part KF.

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

Fig. KD-700 2001 SECTION VIII — DIVISION 3

FIG. KD-700 SOME ILLUSTRATIVE WELD ATTACHMENT DETAILS

72

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

KD-720 PART KD — DESIGN REQUIREMENTS KD-750

KD-720 WELDS ATTACHINGNONPRESSURE PARTS TOPRESSURE PARTS

KD-721 Location Restrictions

Welds attaching nonpressure parts to pressure partsshall be no closer than (Rmts)

0.5 to a gross structuraldiscontinuity, where

Rmp mean radius of curvature of shell at thediscontinuity

tsp shell thickness

KD-722 Types of Attachment Welds

Attachment of nonpressure parts to pressure partsshall be one of the following types:

(a) full-penetration weld1 [see Fig. KD-700, sketch(c)];

(b) full-penetration weld plus fillet weld on one orboth sides, in accordance with Fig. KD-700, sketches(a) and (b).

KD-723 Stress Values for Weld Materials

Attachment weld strength shall be based on theminimum weld area and the design stress intensityvalue in Section II, Part D and stress criteria in ArticleKD-2 for the weaker of the two materials joined.

KD-724 Attachment Welds — FatigueAnalysis

The fatigue analysis evaluations of Article KD-3 orKD-4, as applicable, shall apply.

1 The prior deposition of weld metal to provide a boss for the buttweld is permissible provided it is examined for soundness by suitablenondestructive examination. The Manufacturer shall also give consid-eration to heat treatment of the buildup.

73

KD-730 DESIGN OF ATTACHMENTS

The effects of attachments, including external andinternal piping connections, shall be taken into accountin checking for compliance with the other requirementsof this Division.

KD-740 DESIGN OF SUPPORTS

(a) Vessel supports shall accommodate the maximumimposed loadings. The imposed loadings include thosedue to pressure, weight of the vessel and its contents,machinery and piping loads, wind, earthquake, etc. (seeArticle KD-2). Wind and earthquake loads need notbe assumed to occur simultaneously.

(b) The membrane stress intensity in that part of thesupport within the jurisdiction of this Division shallnot exceed the limits established in Fig. KD-230.

(c) Supports of vertical vessels provided with remov-able bottom closures shall be designed so as to allowthe bottom closure to be periodically removed forservice and inspection.

KD-750 JACKETED VESSELS

When a vessel constructed to this Division is to befitted with a jacket for heating or cooling purposes,the jacket shall meet the following rules.

(a) The portion of a jacket welded directly to aDivision 3 vessel shall meet the rules of Division 3for the direct attachment weldment (actual attachmentweld and attachment material) as covered by Parts KFand KM. The remainder of the jacket shall meet thedesign rules of this Division, Division 2, or Division1, in accordance with the User’s Design Specification.

(b) A jacket attached by means other than directwelding to the vessel shall meet the design rules ofthis Division, Division 2, or Division 1. Spacer bars andjacket closures shall meet the materials and fabricationrequirements of the same Division.

COPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling ServicesCOPYRIGHT American Society of Mechanical EngineersLicensed by Information Handling Services

![KD-A645 / KD-R640 / KD-R540 / KD-R440 - Car Audio ...santafeautosound.com/uploads/product-manuals/JVC KD-R540.pdfKD-A645 / KD-R640 / KD-R540 / KD-R440 GET0829-001A [J/JW] ENGLISH ESPAÑOL](https://static.fdocuments.net/doc/165x107/5aaf5da87f8b9a25088d67c4/kd-a645-kd-r640-kd-r540-kd-r440-car-audio-kd-r540pdfkd-a645-kd-r640.jpg)