ASME PV Equations & Heads.pptx

-

Upload

umer-iftikhar-ahmed -

Category

Documents

-

view

215 -

download

0

Transcript of ASME PV Equations & Heads.pptx

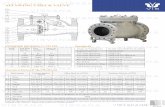

ASME Equations for Calculating Shell Thicknesses(Sec VIII, Div 1, UG- 27)

1) Cylindrical shells (Internal pressure & longitudinal seams, Circumferential stress):

When P <= 0.385SE

2) Cylindrical Shells (Internal pressure & circumferential seams, Longitudinal stress):

When P <= 1.25SE

3) Spherical Shells:

When P <= 0.665SE)

E = Joint efficiencyP = Internal design pressureR = Inside radius of the shell (spherical or cylindrical)S = Allowable stresst = Minimum thickness

These equations are also valid for pipes and tubes subjected to internal pressure (Sec VIII, Div 1, UG- 31 )

Head Connections(Sec VIII, Div 1, UG-32)

1) Hemispherical Heads:

2) 2:1 Ellipsoidal Heads:

When P <= 0.665SE LL = Inside crown radius

Most ideal shape for the head L = R (the inside radius of cylindrical shell)

More economical compared to hemispherical heads

![C100 Cryomodule End Can Pipeline Design per ASME B31tnweb.jlab.org/tn/2009/09-002.doc · Web viewRules in ASME B&PV code [2] Section VIII “Rules for Construction of Pressure Vessels”](https://static.fdocuments.net/doc/165x107/5ac0817e7f8b9aca388bfb16/c100-cryomodule-end-can-pipeline-design-per-asme-viewrules-in-asme-bpv-code-2.jpg)